Device and manufacturing method for packing piezoelectric ceramic

A piezoelectric ceramic and packaging device technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. The effect of improving the bearing capacity and preloading force, the method is simple, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

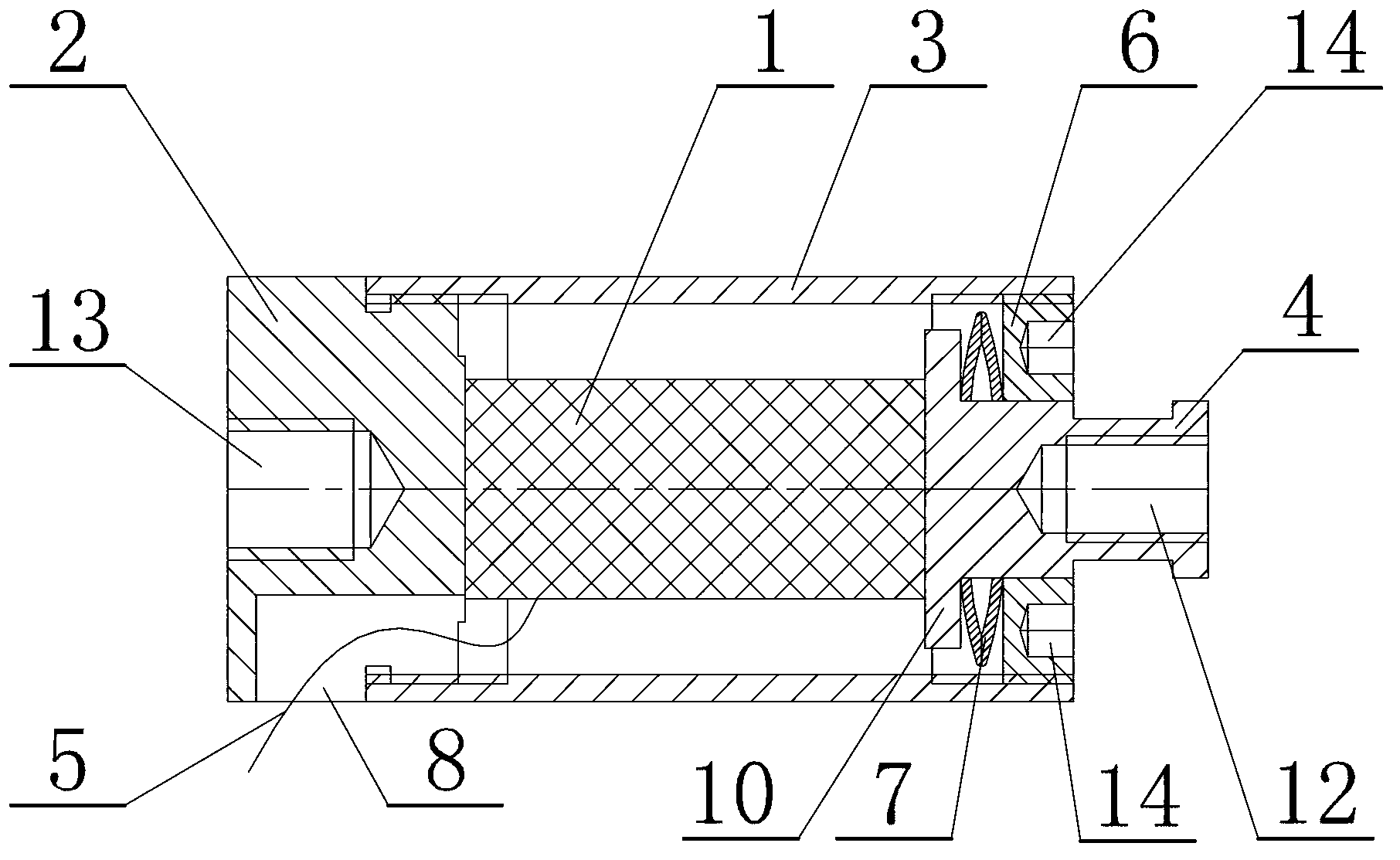

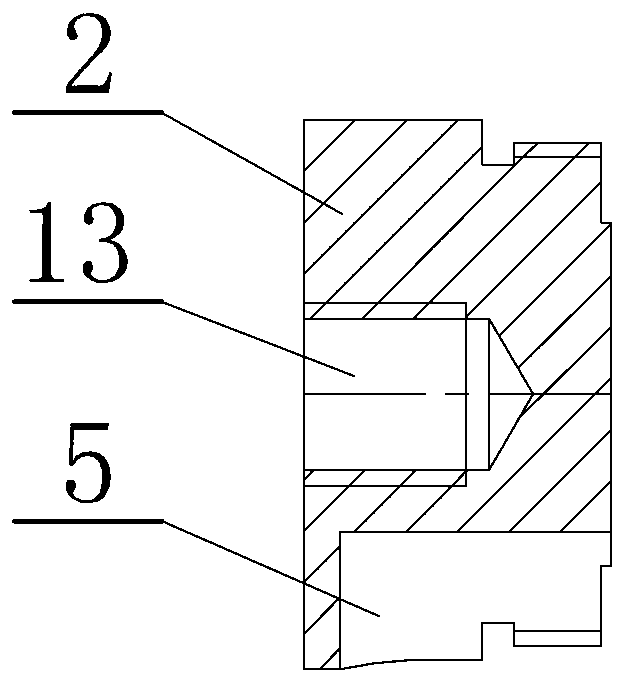

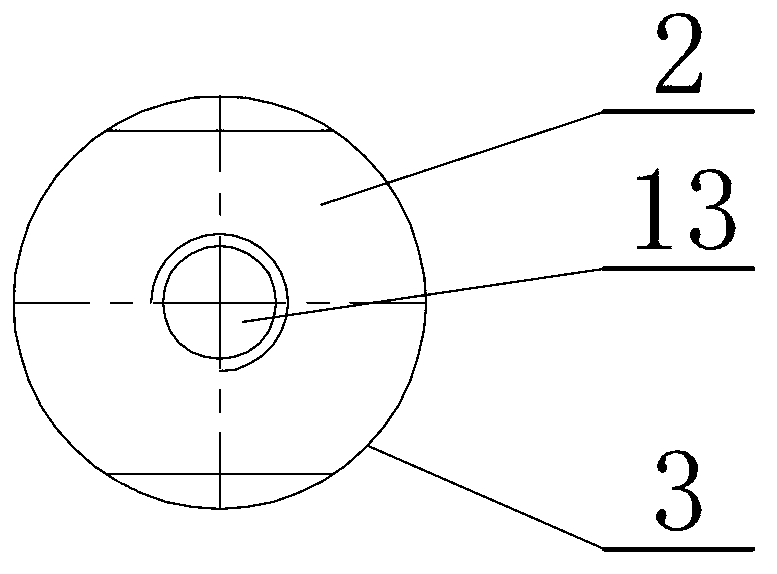

[0016] Specific implementation mode one: combine Figure 1 to Figure 16 Describe this embodiment, the piezoelectric ceramic packaging device described in this embodiment includes a piezoelectric ceramic 1, a base 2, an outer shell 3, a moving part 4, a power cord 5, a lock nut 6 and a disc 7, and the outer shell 3 It is a cylindrical shell, the piezoelectric ceramic 1 is installed inside the outer shell 3, the piezoelectric ceramic 1 is located between the base 2 and the moving part 4, the base 2 is screwed to one end of the outer shell 3, and the inner end surface of the base 2 is connected to the pressure One end of the electric ceramic 1 is fixedly connected, the base 2 is processed with a base slotted hole 8, the power cord 5 is connected to the piezoelectric ceramic 1 through the base slotted hole 8, and the lock nut 6 is screwed to the other end of the outer shell 3 , the locking nut 6 is processed with an axial through hole 9, the inner end of the moving part 4 is proce...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Note that the moving part 4 in this embodiment is a spherical push rod, a plane push rod, an external thread push rod or an internal thread push rod. When the present invention is applied in micro-nano motion work, different types of moving parts are selected according to different connection requirements. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , Figure 5 and Figure 6 Note that in this embodiment, when the moving part 4 is a spherical push rod, the end of the spherical push rod far away from the piezoelectric ceramic 1 is processed with a mounting hole 11 . The moving part 4 arranged in this way is more firmly connected with the outer casing 3. When the moving part 4 is a spherical push rod, the spherical push rod is also processed with a groove, and the ball push rod can be used only after the steel ball is installed in the groove. The steel ball is a conventional component in the industry, and the existing products are commercially available. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com