Zipper tape and packing bag with zipper tape

A buckle and bag body technology, applied in the directions of packaging, transportation, packaging, bags, etc., can solve the problems of hindering the cutting performance of the cutting part, the cutting part is difficult to be cut, and the cutting part cannot be subjected to stress, etc., and achieves sufficient sealing and good The effect of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0047] Hereinafter, a packaging bag with a zipper tape (hereinafter sometimes simply referred to as "packaging bag") according to a first embodiment of the present invention will be described with reference to the drawings.

[0048] In addition, the packaging bag of the present invention can be suitably used for filling liquid as the content to be stored, but it may also be filled with powder, solid, gel, or the like. In addition, although an example was shown in which the thick portion, the cut portion, and the seal base are provided on the female member, they may also be provided on the male member.

[0049] The structure of the bag with the buckle strap:

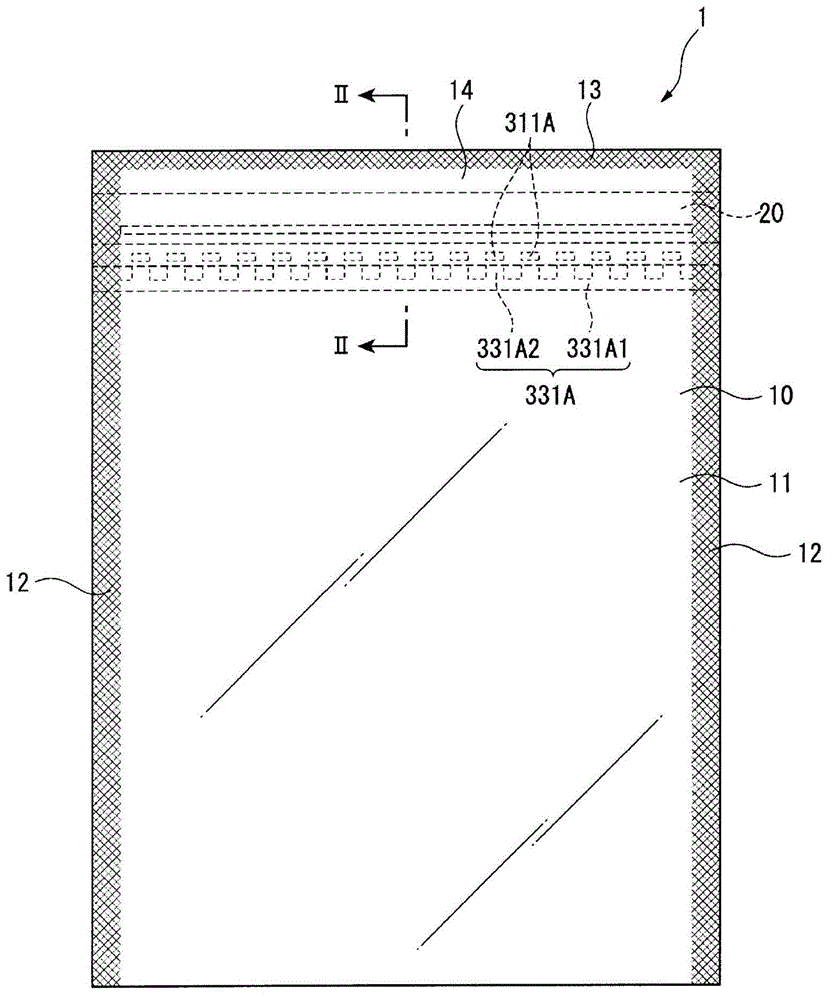

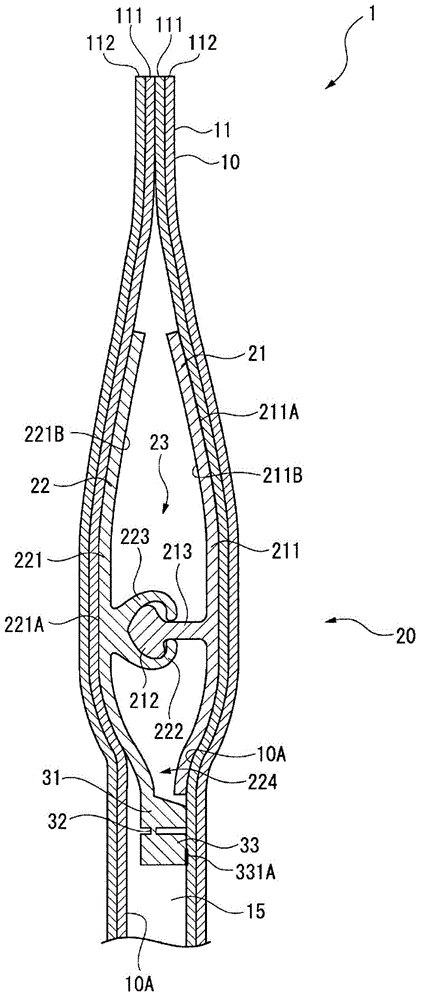

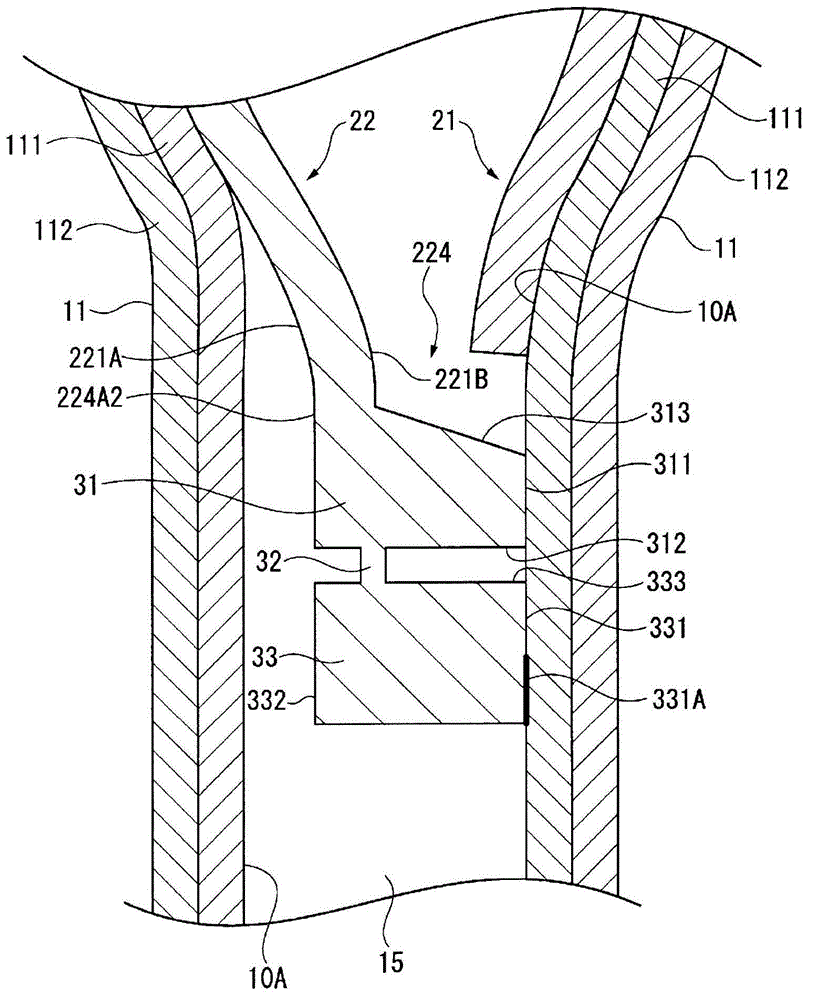

[0050] The packaging bag 1 of the present embodiment is as figure 1 and figure 2 As shown, there is a bag body 10 formed by laminating base film 11 as a packaging material and forming a side seal base 12 and an upper seal base 13 on the periphery thereof. On the inner surface 10A of the opening 14 of the bag body 10 ...

no. 2 approach

[0115] Next, a second embodiment of the present invention will be described with reference to the drawings.

[0116] Figure 9 It is an enlarged perspective view showing the vicinity of the sealing base of the zipper tape in the packaging bag according to the second embodiment of the present invention. In addition, in the second embodiment, descriptions of the same or similar configurations as those of the first embodiment are omitted or simplified.

[0117] The thick portion 41 in the second embodiment is formed by forming the thick portion 31 in the first embodiment into a substantially rectangular cross section. The thick wall portion 41 has two ribs 411 along the longitudinal direction of the cutting portion 32 on the surface opposite to the inner surface 10A of the bag body 10 on which the male-side strip-shaped base portion 211 is mounted. 10A is bonded and has a triangular cross-section. The rib 411 is preferably formed to have a predetermined height dimension. Spec...

no. 3 approach

[0124] Next, a third embodiment of the present invention will be described with reference to the drawings.

[0125] Figure 10 It is a cross-sectional view showing a state where the male part and the female part of the zipper tape are engaged in the packaging bag according to the third embodiment of the present invention. Regarding the third embodiment, descriptions of the same or similar configurations as those of the above-described embodiments are omitted or simplified.

[0126] The cut portion 42 in the third embodiment is formed by forming the cut portion 32 in the second embodiment on a plane intersecting the inner surface 10A of the bag body 10 in the opposing direction of the thick portion 41 and the seal base portion 33 . In addition, in order to prevent pressure concentration when pressure is applied from the outside, it is preferable to provide a curved surface 421 formed by bending an acute-angled portion connected to the seal base 33 into an arcuate cross section....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com