Pipe connecting device

A technology of pipe connection and union nut, which is applied in the direction of hose connection device, pipe connection arrangement, non-removable pipe connection, etc. The effect of reducing deformation or creep, maintaining sealing performance, and increasing the number of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

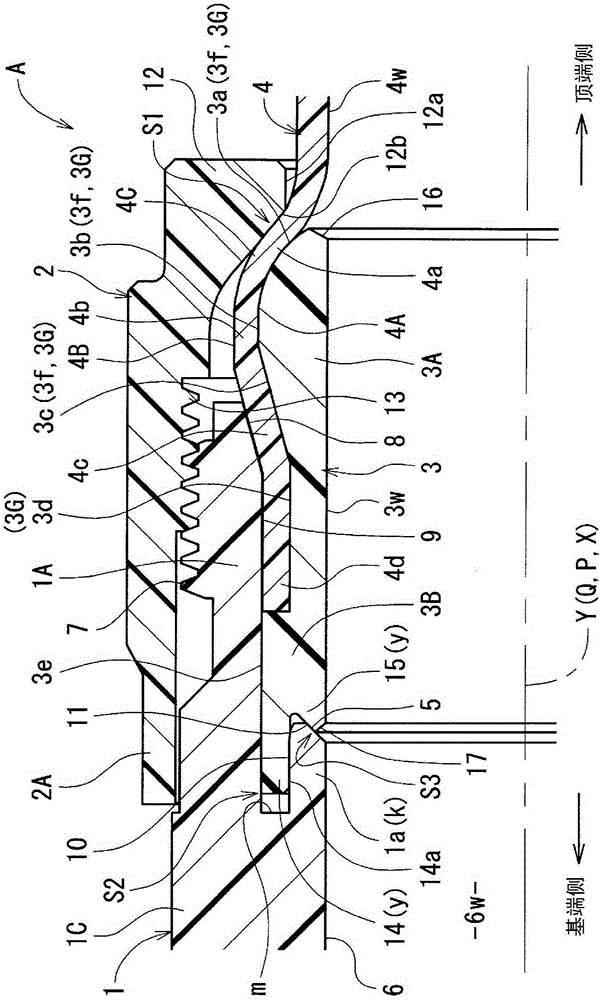

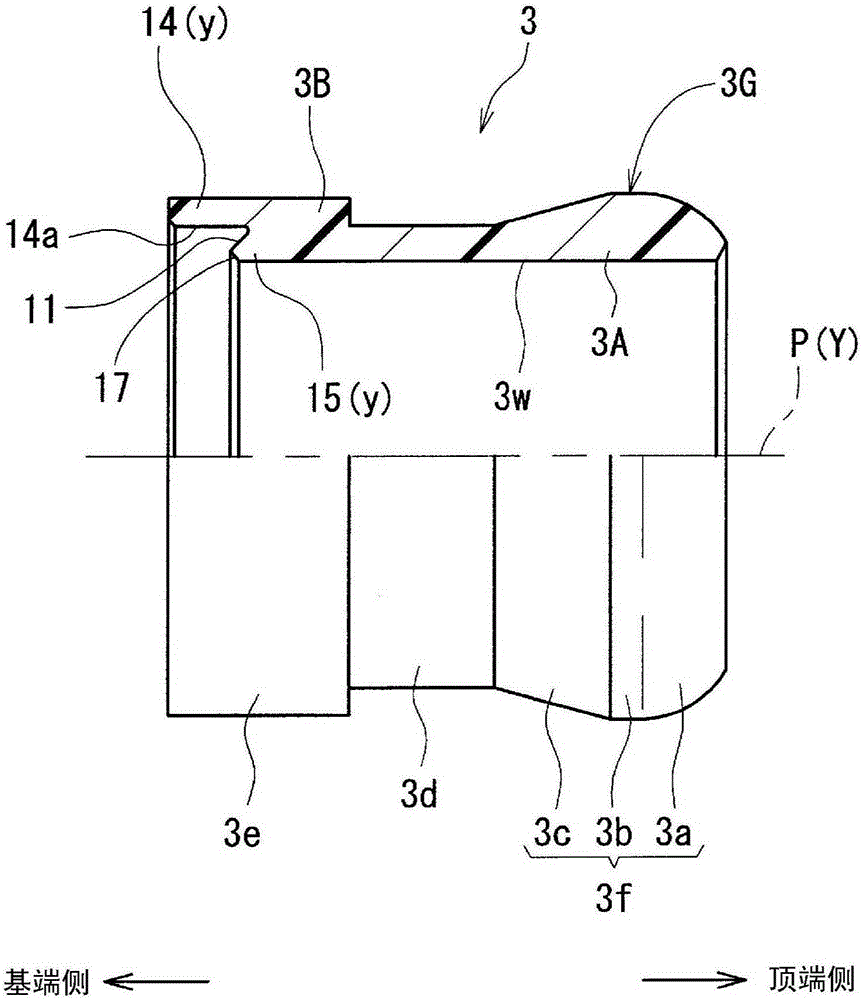

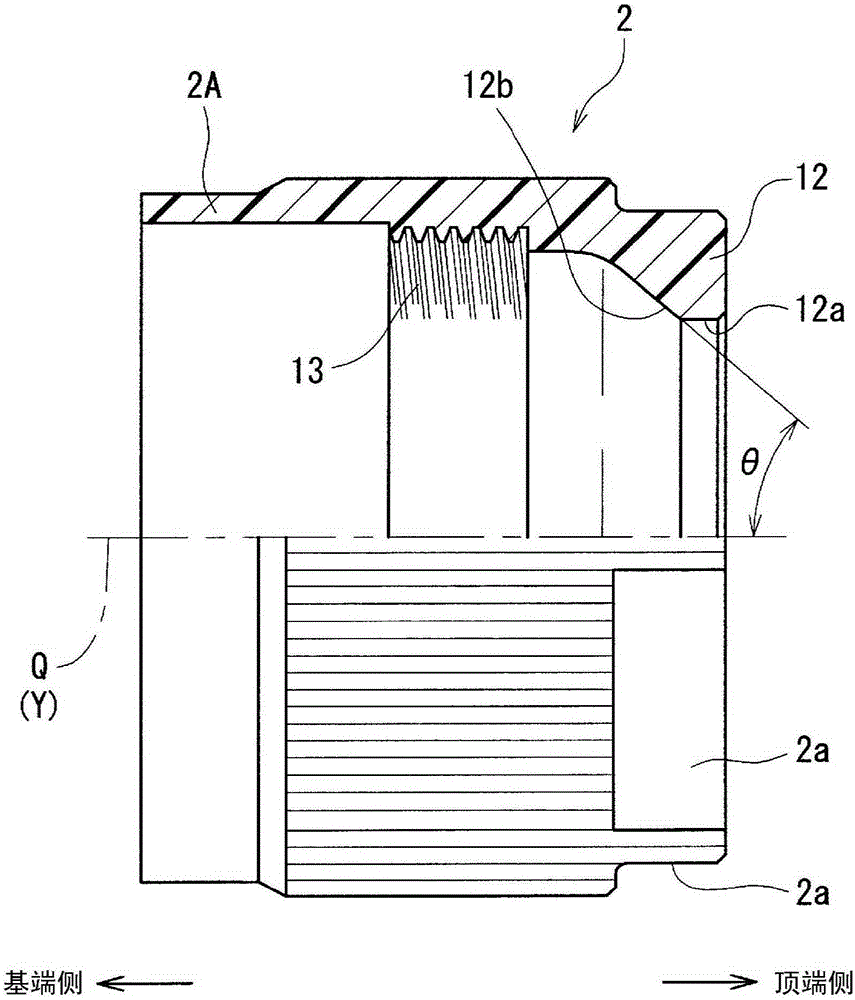

[0050] Such as figure 1 As shown, the pipe connecting device A is composed of pipe joints connecting pipes with each other, and has a pipe joint main body 1, a union nut 2, and an inner ring 3. The device starts to press into the end 4C of the tube 4 to connect the tube 4 in communication. The pipe joint main body 1, union nut 2, inner ring 3, and tube 4 are all made of resin such as fluororesin (eg, PTFE, PFA, ETFE, CTFE, ECTFE, etc.) excellent in heat resistance and chemical resistance. In addition, when the pipe joint main body 1, the inner ring 3, and the tube 4 are made of the above-mentioned fluororesin, the union nut 2 may be made of resin such as polyamide, polypropylene, or polyethylene. In addition, all of the pipe joint main body 1, the union nut 2, the inner ring 3, and the tube 4 can also be formed of resin such as polyamide, polypropylene, or polyethylene.

[0051] Such as figure 1 , Figure 4 As shown, the pipe joint main body 1 is a cylindrical structure, a...

Embodiment approach 2

[0100] Such as Figure 5 As shown, the pipe connection device A of the second embodiment differs from the pipe connection device A of the first embodiment only in the structure of the fitting cylindrical portion 3B.

[0101] That is, the fitting tube portion 3B of the inner ring 3 is formed with an outer peripheral surface 3e, an inner peripheral portion 3w, and a base-end enlarged inner peripheral surface 20 whose diameter becomes larger toward the proximal end side. On the other hand, in the pipe joint main body 1, an outer peripheral surface 18 having an inclined outer peripheral surface 18 is formed on the radially inner side of the base end side of the cylindrical screwing portion 1A so that the diameter becomes smaller as it approaches the distal end side. The small-diameter cylindrical portion 1a. Between the outer peripheral surface 18 of the narrowed small-diameter cylindrical portion 1a and the inner peripheral surface 9 of the cylindrical threaded portion 1A, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com