Inflatable electric power pipeline sealing device and production method

A technology for sealing equipment and production methods, which is applied in the installation of cables, electrical components, and cables in underground pipelines, and can solve problems such as shortening the service life, easily causing obstacles, and abrasion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

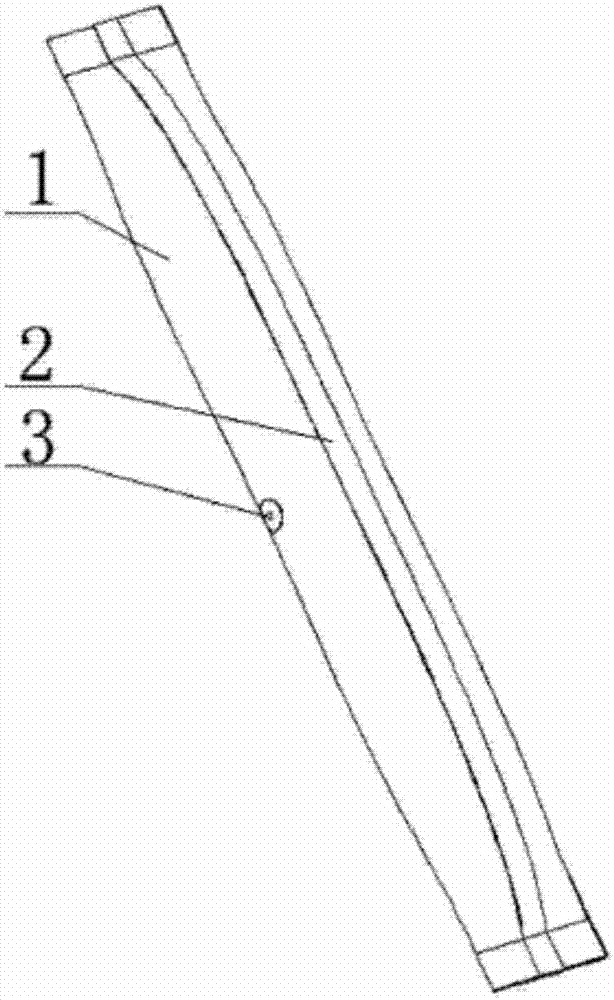

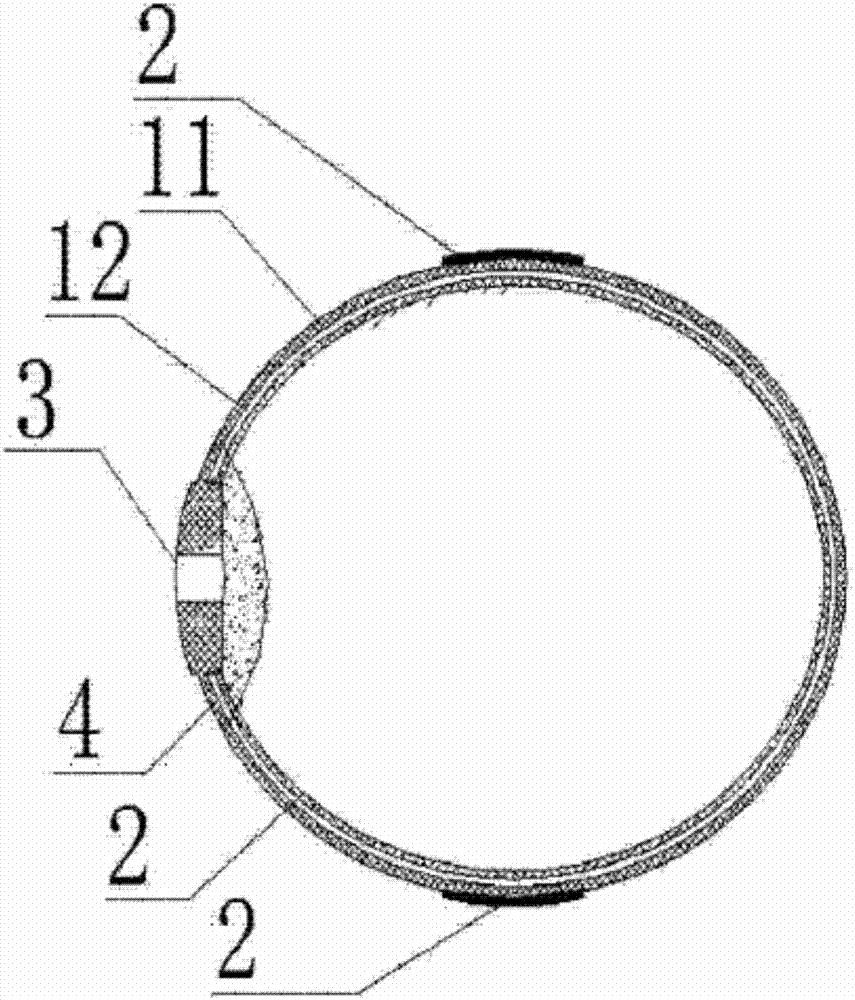

[0006] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but not as a limitation to the present invention. Such as figure 1 , figure 2 As shown, the inflatable power pipeline sealing equipment and production method described in this specific embodiment include an air-sealed bag body, and the air-sealed bag body includes a sealed bag body 1, and the sealed bag body 1 It is composed of a soft metal surface layer 11 and several polymer material layers 12. The sealed bag body 1 is a flat body with a cavity inside; A high-temperature-resistant waterproof film 2 that forms an integrated structure; one end of the sealed bag body 1 is provided with an air-filling port 3, and the air-filling port 3 contains a self-filling colloidal material 4; it adopts the following manufacturing steps: 1) plastic particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com