Open-end spinning device and spinning rotor for open-end spinning device

A technology of air spinning and rotor, which is applied in the direction of continuous winding spinning machines, spinning machines, textiles and papermaking, etc. It can solve the problems of high energy consumption and achieve the goals of reducing energy consumption, ensuring stability and saving materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

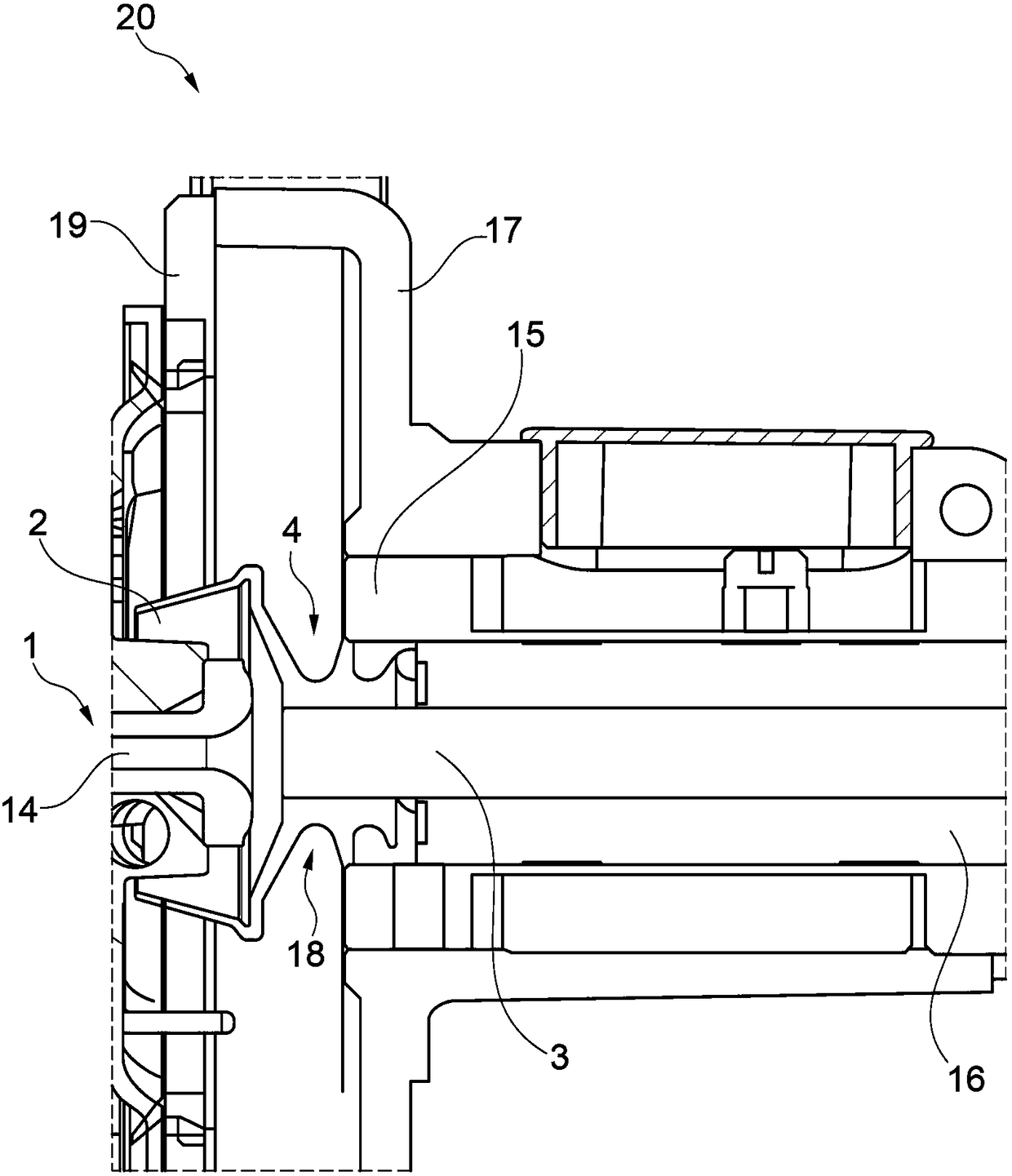

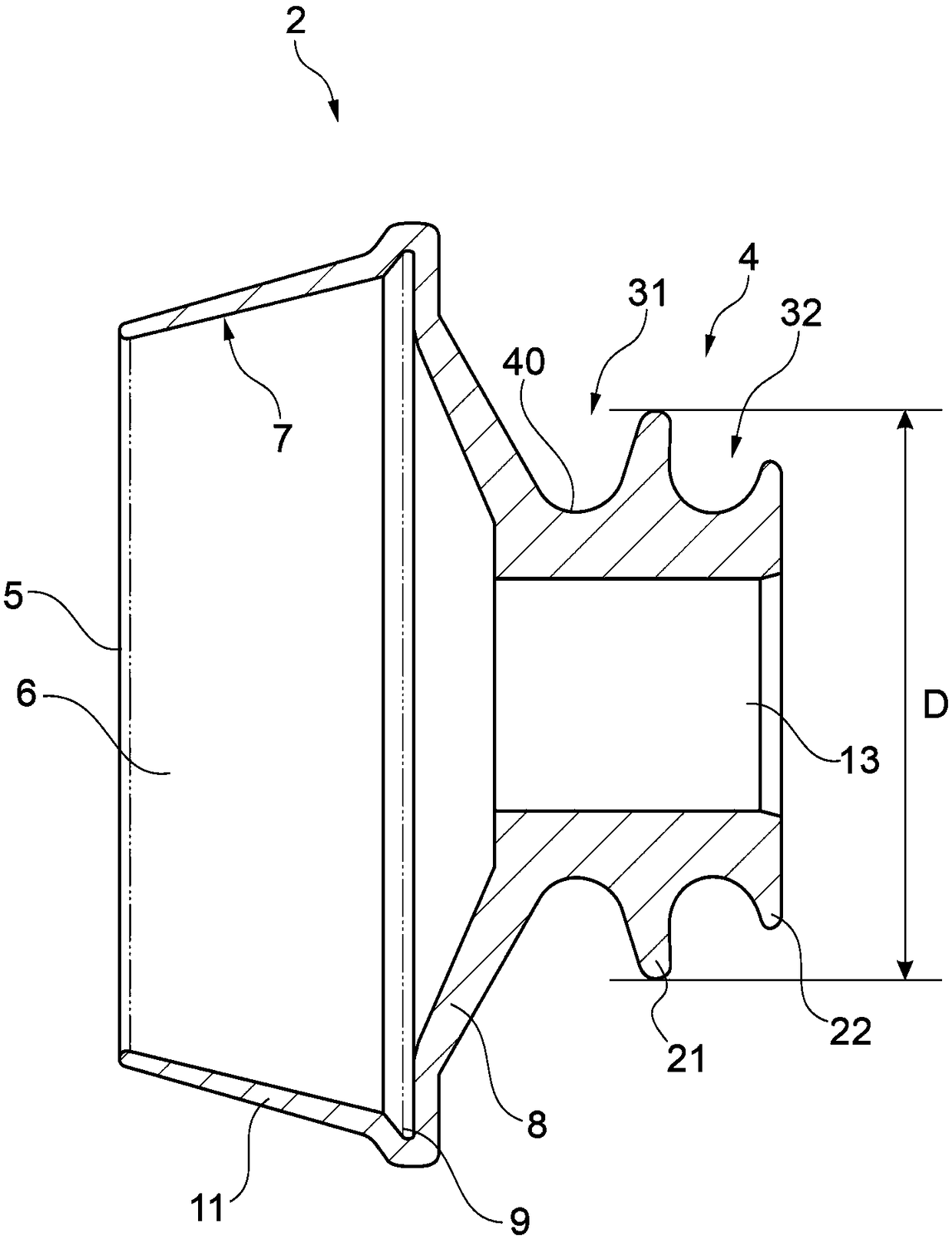

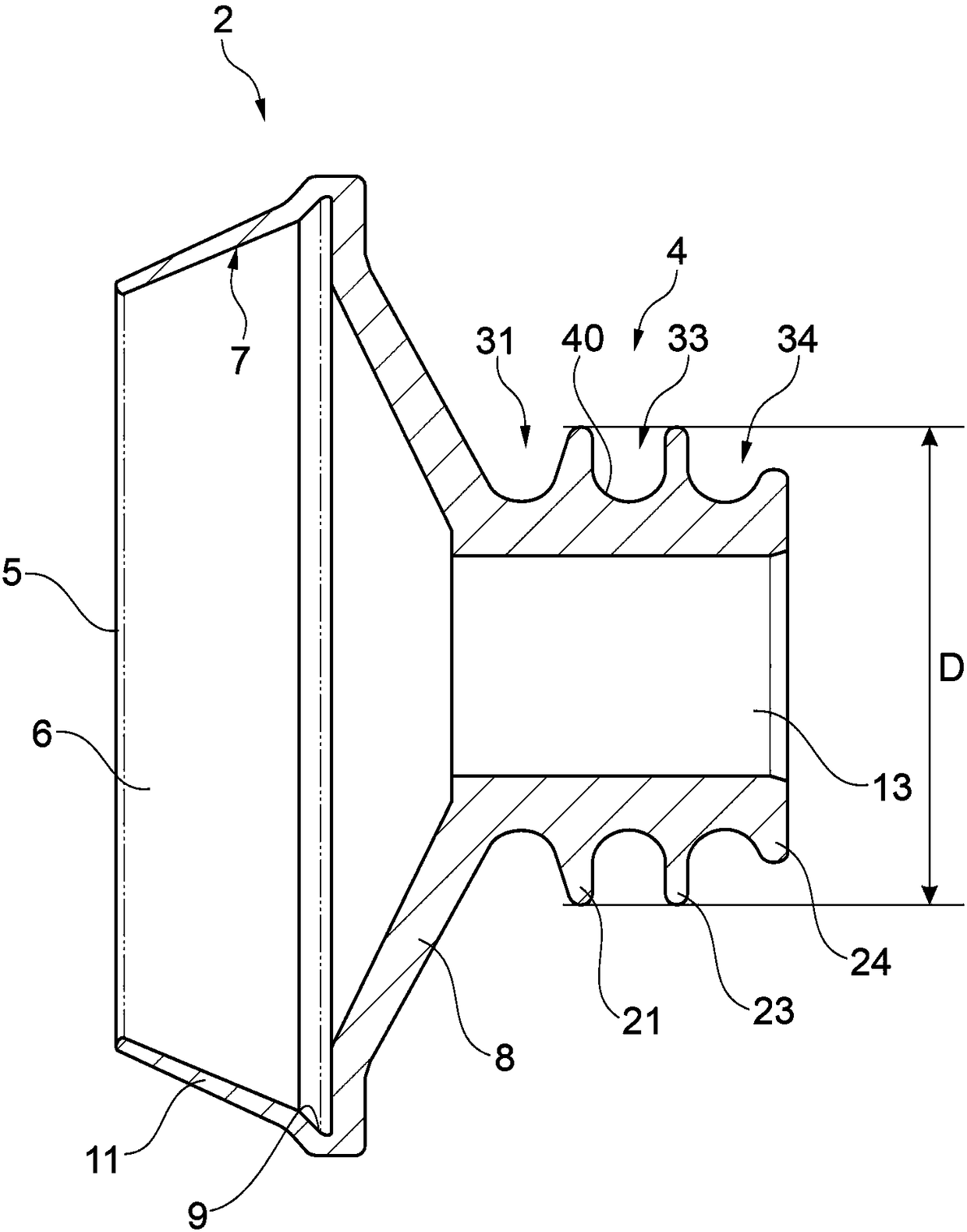

[0024] figure 1 Shown is an air spinning device 20 according to the invention. The spinning rotor 1 is rotatably installed in an air spinning device 20 . The spinning rotor 1 includes a rotor disk 2 and a rotor shaft 3 . Mounting of the rotor disk 2 on the rotor shaft 3 takes place by means of the flange 4 . The rotor disk 2 is arranged in a rotor housing 17 which can accept negative pressure. The rotor housing 17 is closed by a cover 19 which includes a channel plate connection. The channel plate connection projects into the interior 6 of the rotor disk 2 with the drawing channel 14 . Via the drawing channel 14 the yarn spun in the spinning rotor 1 is drawn off.

[0025] The rotor shaft 3 is mounted in bearings 16 outside the rotor housing 17 . The bearing 16 is held in a damping sleeve 15 protruding into the rotor housing 17 . One end of the damping sleeve 15 forms a through-opening 18 for the rotor housing 17 of the rotor shaft 3 for this purpose. Through hole 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com