Preparation process of uQ-MnZn soft-magnetic ferrite with ultralow value and high loss

A soft ferrite and preparation process technology, applied in the high-end field of soft ferrite materials, can solve the problems of energy consumption, energy saving and emission reduction, complicated processes, etc., and achieve uniform particle size, superior material performance, and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

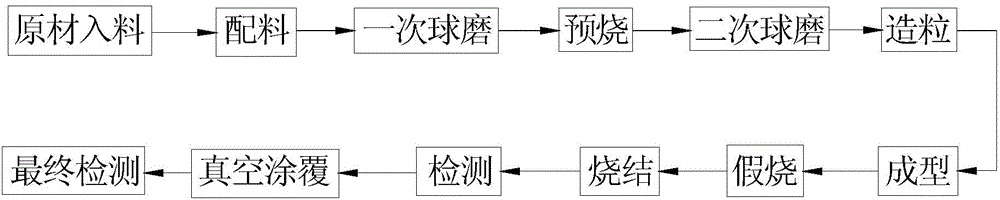

Image

Examples

Embodiment Construction

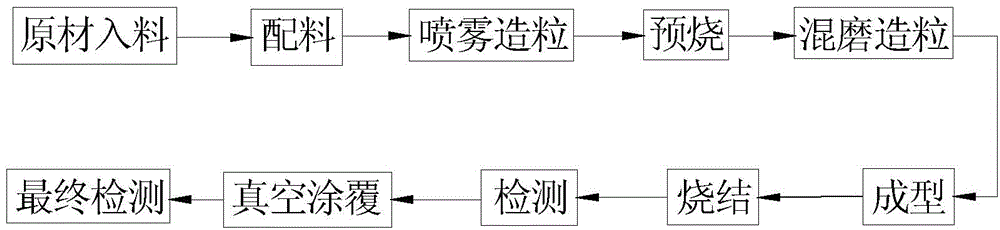

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

[0033] Such as figure 2 As shown, this embodiment adopts the following technical solutions: its production process is:

[0034] (1), powder:

[0035] (1.1) Powder formula: In addition to the detection and confirmation of the purity, particle size and particle shape of raw materials, a database of raw and auxiliary materials is established on the proportion formula of materials to determine the purity, particle size, specific surface area, uniformity, and po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com