A kind of fair-faced concrete composite exterior wall panel and its construction method

A technology of fair-faced concrete and composite exterior wall panels, which is applied in the treatment of walls, buildings, building materials, etc., can solve the problems of inability to integrate construction, the thermal insulation effect needs to be improved, and the efficiency of composite exterior wall panels is low, so as to meet the construction efficiency. Demand, reasonable structural design, and the effect of ensuring the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

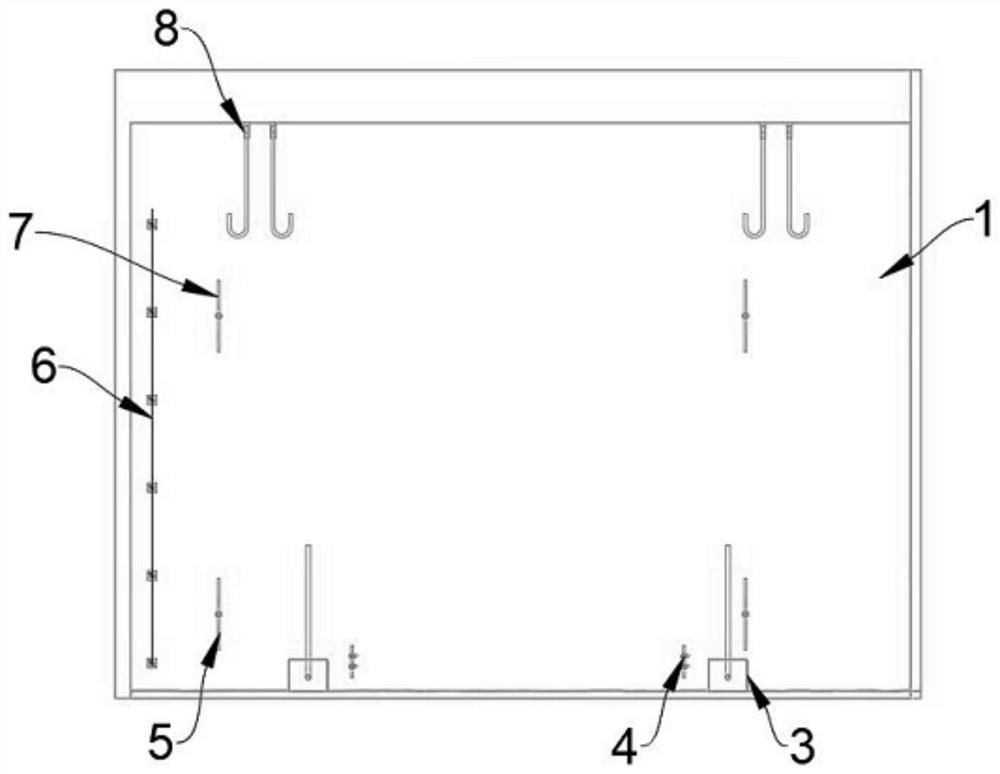

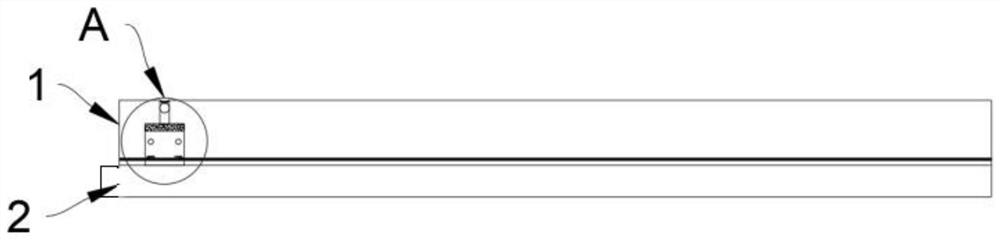

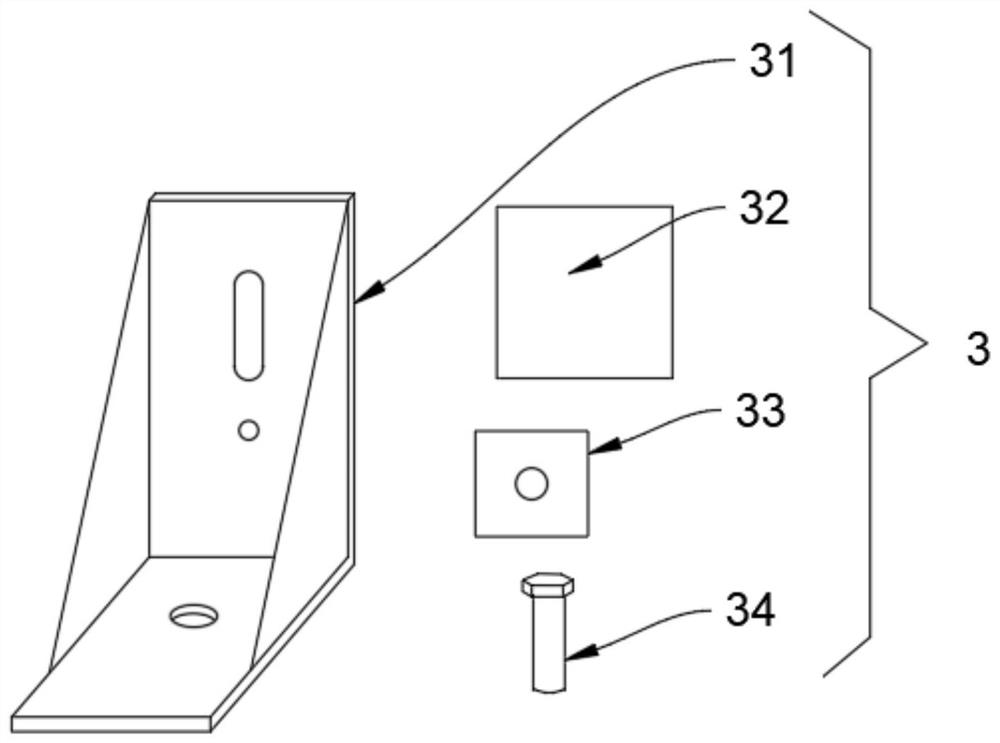

[0028] refer to Figure 1-5 , a composite exterior wall panel of clear-water concrete, comprising a clear-water concrete structural layer 1 and an insulating layer 2 arranged on the surface of the clear-water concrete structural layer 1, the clear-water concrete structural layer 1 is produced by an anti-beating process, and the thickness is 160mm, and the insulating layer 2 is made of clear water The concrete layer is sprayed after pouring, with a thickness of 0.5mm. The insulation layer 2 is made of recycled aggregate, dolomite powder, slag, talcum powder, vermiculite, expanded vitrified microbeads, magnesium oxide, Portland cement, anti-cracking agent and Made of perlite, the particle size of slag is 8mm, and the particle size of vermiculite is 9mm. The specific components are as follows: 100 parts of recycled aggregate, 40 parts of dolomite powder, 10 parts of slag, 30 parts of talcum powder, 10 parts of vermiculite, 0.1 parts of expanded vitrified microbeads, 7 parts of ma...

Embodiment 2

[0034] refer to Figure 1-5 , a fair-faced concrete composite exterior wall panel, comprising a fair-faced concrete structural layer 1 and an insulating layer 2 arranged on the surface of the fair-faced concrete structural layer 1, the fair-faced concrete structural layer 1 is produced by an anti-beating process, and the thickness is 165 mm, and the insulating layer 2 is made of clear water The concrete layer is sprayed after pouring, with a thickness of 0.5mm. The insulation layer 2 is made of recycled aggregate, dolomite powder, slag, talcum powder, vermiculite, expanded vitrified microbeads, magnesium oxide, Portland cement, anti-cracking agent and Made of perlite, the particle size of slag is 8.5mm, and the particle size of vermiculite is 9.5mm. The specific components are as follows: 110 parts of recycled aggregate, 50 parts of dolomite powder, 15 parts of slag, 35 parts of talc powder, and 30 parts of vermiculite 5 parts, 5 parts of expanded vitrified microbeads, 10 part...

Embodiment 3

[0039] refer to Figure 1-5, a fair-faced concrete composite exterior wall panel, comprising a fair-faced concrete structural layer 1 and an insulating layer 2 arranged on the surface of the fair-faced concrete structural layer 1, the fair-faced concrete structural layer 1 is produced by an anti-beating process, and the thickness is 250 mm, and the insulating layer 2 is made of clear water The concrete layer is poured and then sprayed, with a thickness of 1 mm. A pre-embedded mechanism is installed on the fair-faced concrete structure layer 1, and the insulation layer 2 is made of recycled aggregate, dolomite powder, slag, talcum powder, vermiculite, expanded vitrified microbeads, and oxidized Made of magnesium, Portland cement, anti-cracking agent and perlite, the particle size of slag is 10mm, and the particle size of vermiculite is 11mm. The specific components are as follows: 120 parts of recycled aggregate, 60 parts of dolomite powder, and 20 parts of slag , 40 parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com