Modified polyvinyl chloride cable material resistant to water-soluble cutting fluid and bending deflection and preparation method thereof

A technology of polyvinyl chloride cable and polyvinyl chloride resin, which is used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of low expansion, high price, and cannot meet oil resistance at the same time, and achieve low expansion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

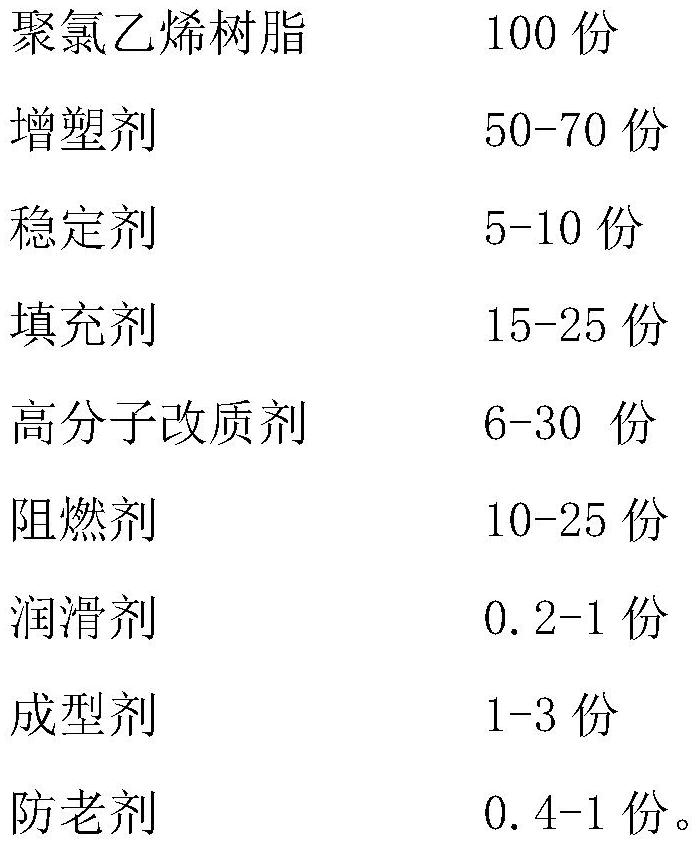

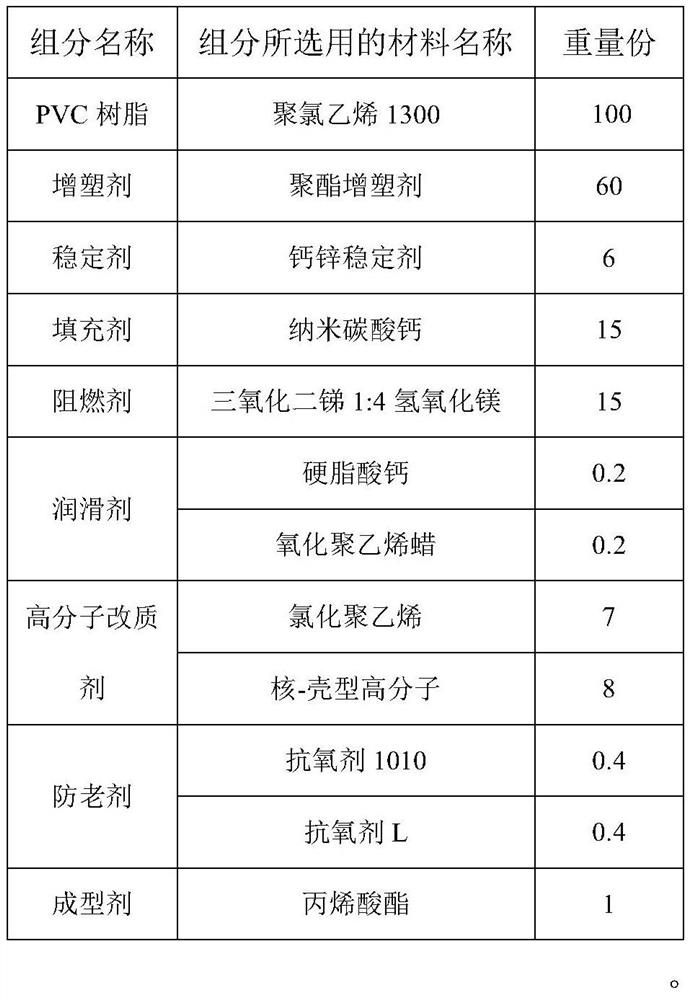

[0039] 1. Experimental materials

[0040] The composition and ratio of raw materials are shown in the table below.

[0041] The cable material formula table of embodiment 1~4

[0042]

[0043]

[0044] 2. Preparation method

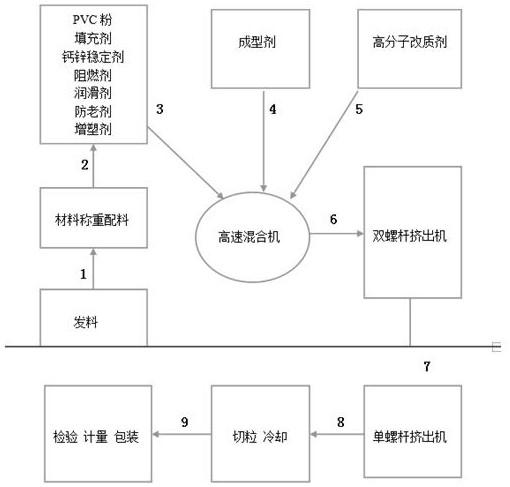

[0045] Embodiment 1-4 The preparation method of water-soluble cutting fluid-resistant bending-resistant modified polyvinyl chloride cable material includes the following steps:

[0046] 1) Add polyvinyl chloride resin powder, stabilizer, filler, flame retardant, lubricant, anti-aging agent and plasticizer to the high-speed mixer in sequence, start the machine to mix at high speed, and control the temperature at 150±5 degrees. Speed 1100rpm;

[0047] 2) Mix at high speed until the plasticizer is absorbed by the powder, add molding agent when the material temperature reaches 100°C, continue mixing until 145°C, add polymer modifier material, and discharge when the material temperature reaches the set temperature;

[0048] 3) Put the raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com