Single- or multi-tier press for manufacturing flake board

A multi-layer press and material board technology, which is applied in the direction of veneer presses, plywood presses, presses, etc., can solve the problems of high cost and affecting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

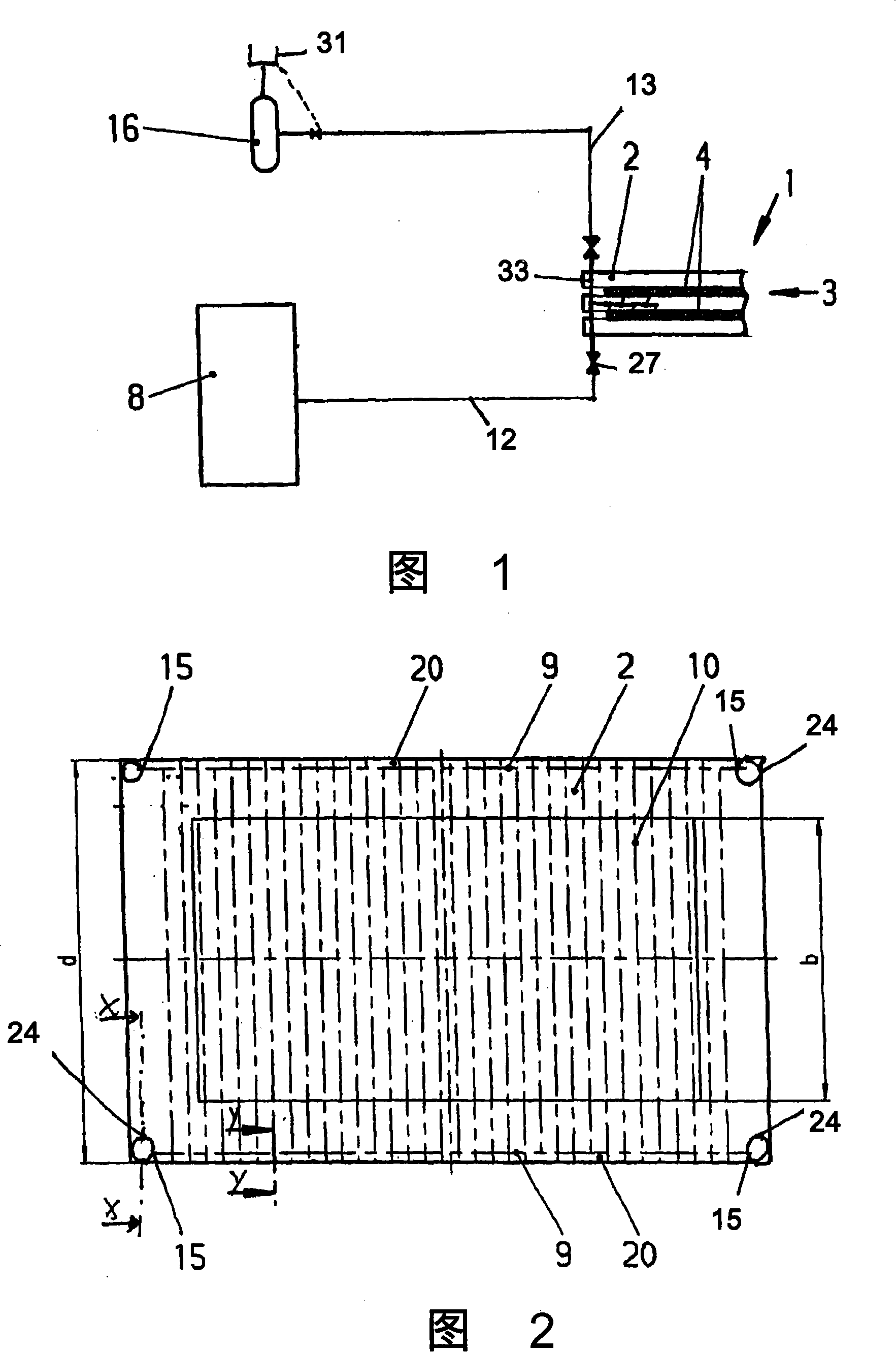

[0026] Figure 1 shows the schematic structure of a plant, which shows a partial view of a multilayer press 1 with three press plates 2, two plate layers 3 formed therethrough, one with steam storage The steam device of the tank 8, and the steam introduction pipe 12 drawn from the storage tank to the multi-layer press 1. The lead-in pipe is connected in the lower region of the multilayer press 1 to the first vertical through-hole of the press plate 2 and can be applied to the pressed product mat 4 via the supply channel 33 and the ducts present in the press plate 2 if required. steam. This is only shown schematically in the middle press platen 2 . On the press platen 2 of the upper deck 3 , vertical supply channels 33 are connected to the process gas discharge duct 13 and via the duct 13 to a vacuum device 16 or directly to a gas purifier 31 .

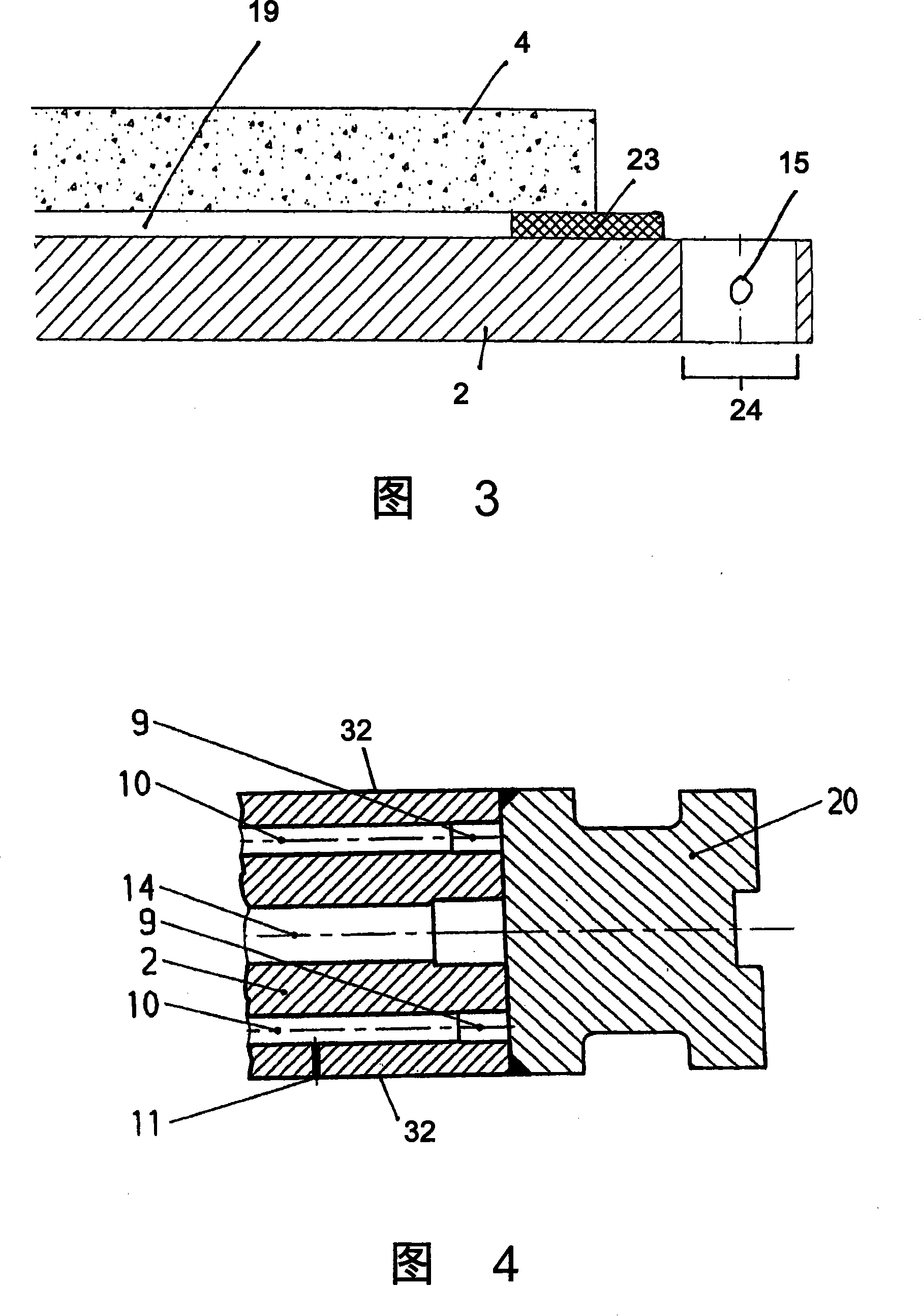

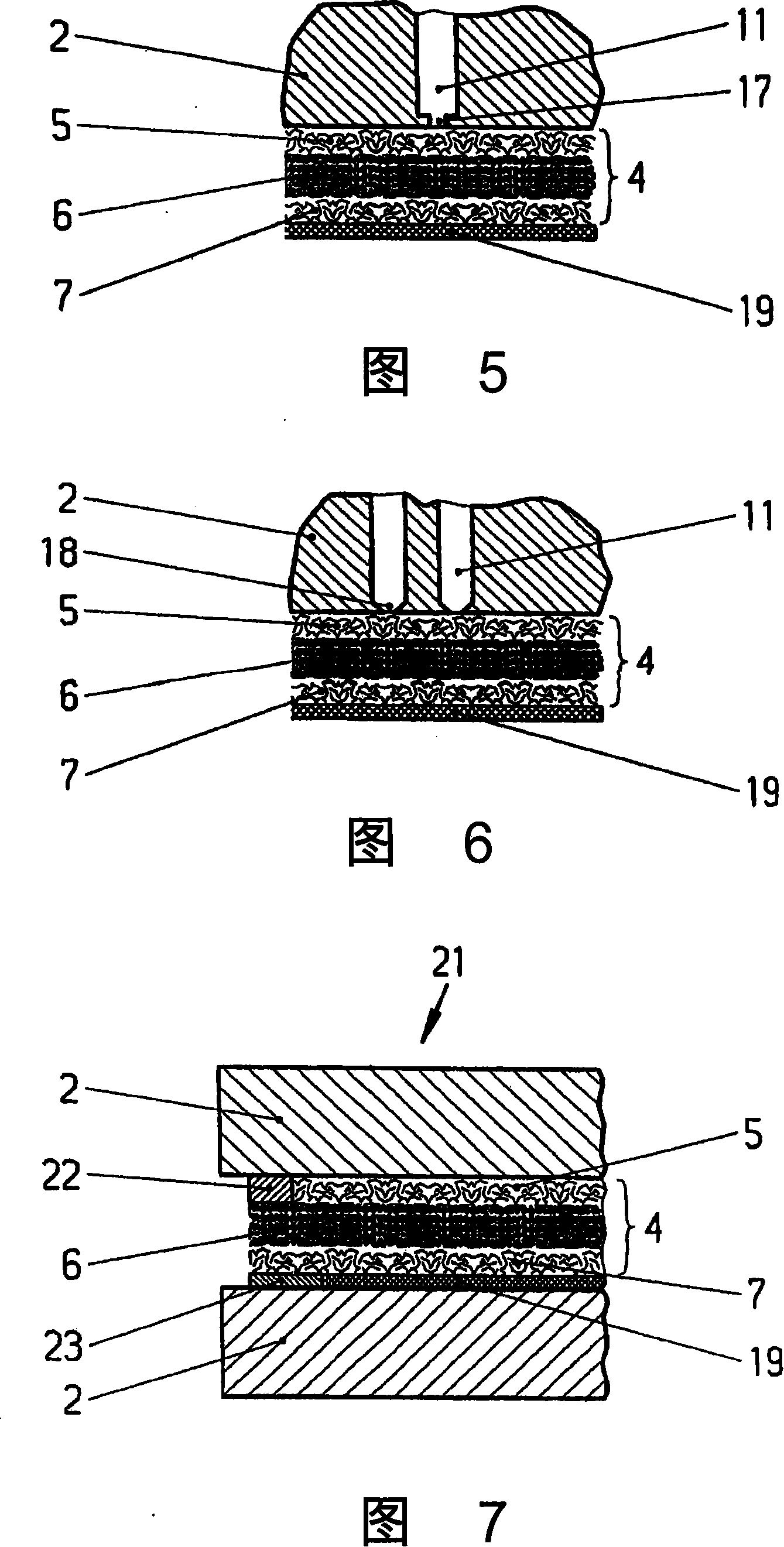

[0027] 2 to 4 show the construction of a press plate 2 with three perforated layers, which are arranged between an upper and a lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com