Electric power detection method

A technology of electric power detection and detection box, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of affecting the service life of the detection equipment in the detection box, affecting the convenience of use, and difficulty in finding the detection line. , to achieve the effect of good use effect, convenient use and avoid chaotic arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

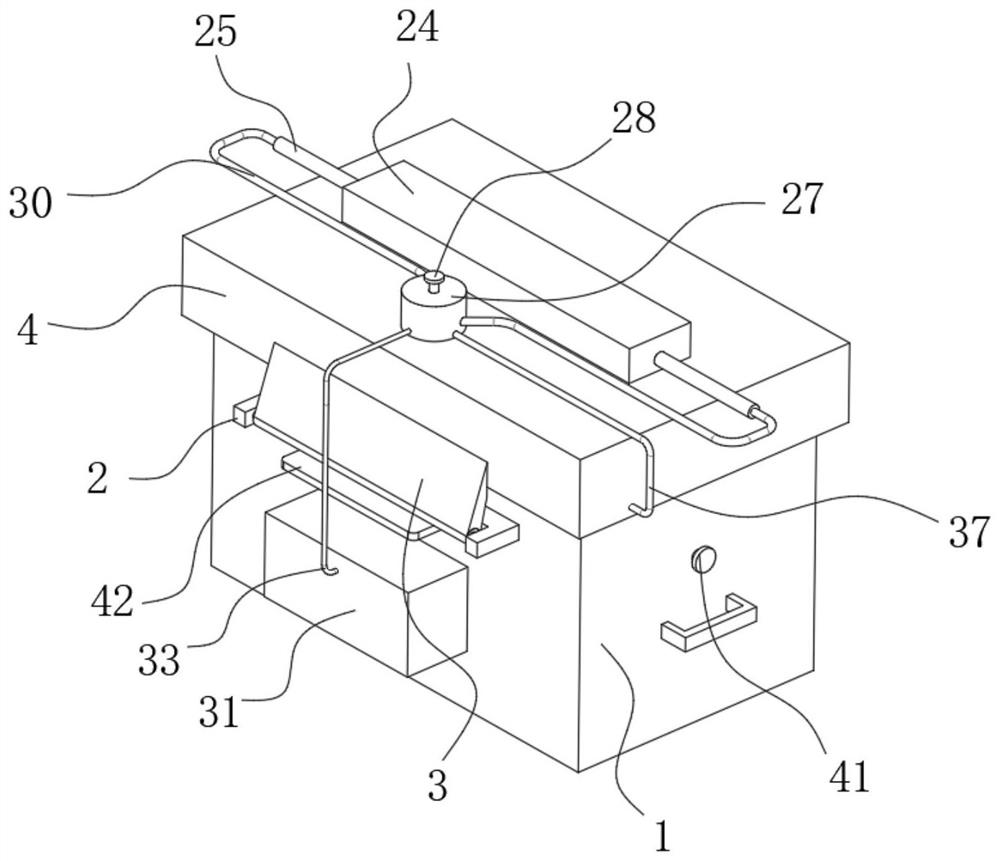

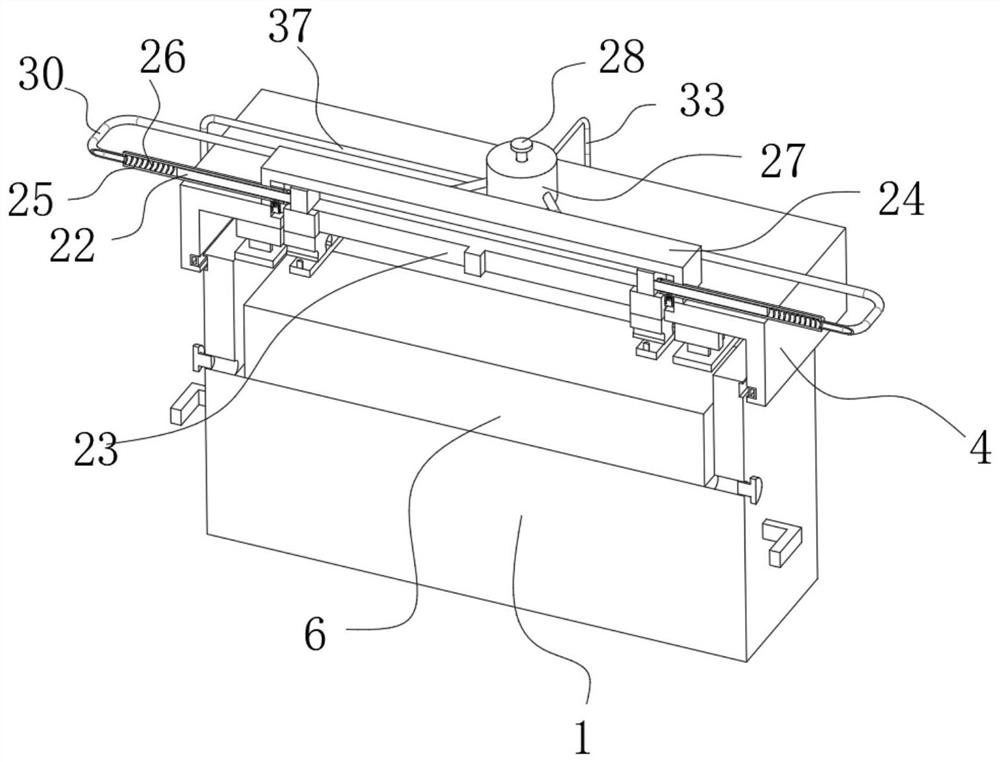

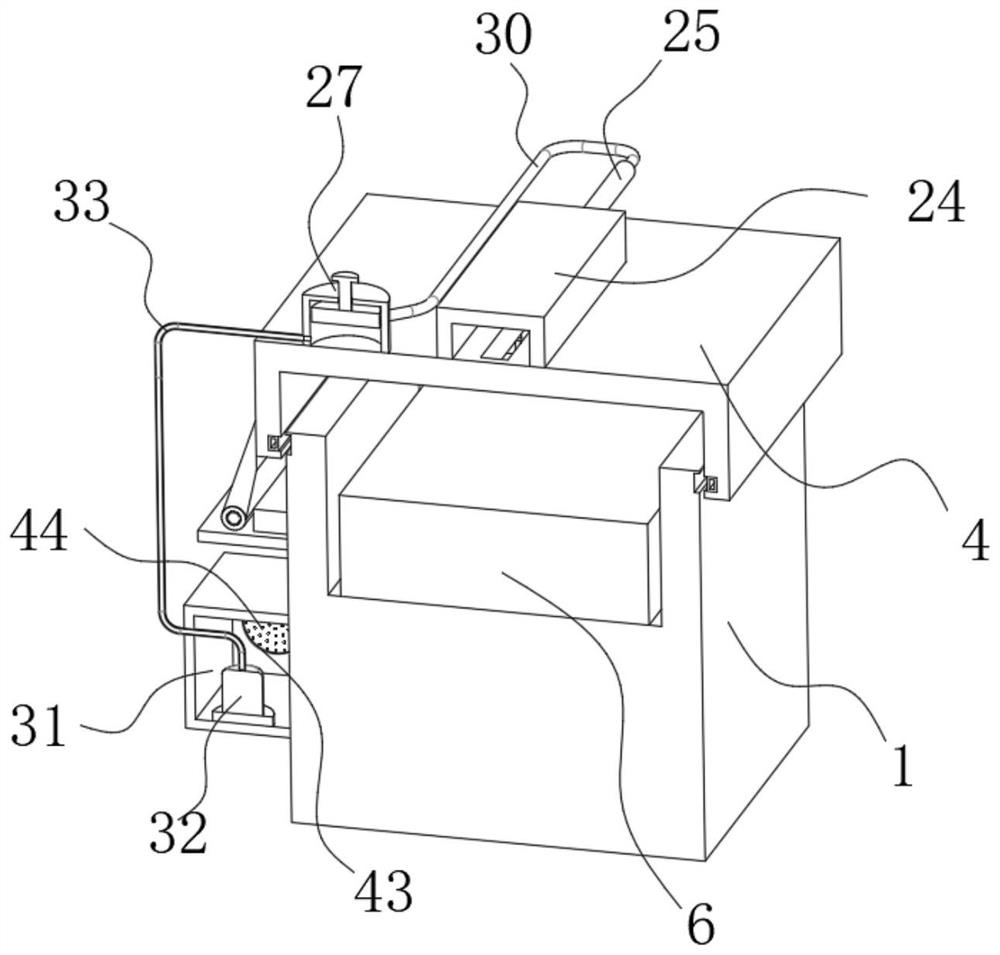

[0038] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, keep the sealing cover 4 open, and clamp the active end of the detection line into the slot 9, so that one side of the active end of the detection line is placed between the partition plates 7, and put the sleeve plate 12 on the top surface of the baffle 13. Sleeve into the No. 1 slot 10 of the partition plate 7, and then place the pressure plate 14 on the front of the movable seat 8, so that the mounting bolt 15 sleeved on the pressure plate 14 is threadedly sleeved with the threaded hole 19, and the clamping rod is 16. Clamp the detection wire end, cover the sealing cover 4 and start the air pump 32, so that the air pump 32 passes the gas into the control sleeve 27 through the No. 2 pipe 33, and makes the entering gas enter the fixed pipe 25 through the No. Inside, the gas entering the fixed pipe 25 pushes the sleeve rod 22 to move, wh...

no. 2 example

[0045] Second embodiment: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 12 As shown, after the detection equipment in the equipment seat 6 inside the detection box 1 completes the detection work, the used detection line is clamped in the clamping slot 9 of the movable seat 8, the upper pressure plate 14 is installed, and the sealing cover 4 is covered, At the same time, the movable plug 41 is opened, and the air pump 32 is activated, so that the air pump 32 passes the gas into the control sleeve 27 through the No. 2 pipe 33. With the passage of the gas, the entering gas enters the fixed pipe 25 through the No. 1 pipe 30 and pushes the gas into the fixed pipe 25. The inner sleeve rod 22 moves, and after the sleeve rod 22 pushes the top plate 21 to move, the movable seat 8 moves and completes the automatic alignment, and at the same time, the front end of the sleeve rod 22 moves to the side of the air guide mechanism 39, and continues to introduce gas, The gas w...

no. 3 example

[0050] The third embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 and Figure 11 As shown, when the sealing cover 4 is closed and the air pump 32 is started, as the gas is passed into the control sleeve 27, part of the air enters the fixed pipe 25 through the No. 1 pipe 30, and part of the air enters the fixed pipe 25 through the No. 3 pipe 37. In the elastic airbag 36, as the elastic airbag 36 is continuously inflated and collided, the elastic airbag 36 after the collision is clamped in the No. 2 ring groove 35 on the outer surface of the detection box 1, and the sealing between the detection box 1 and the sealing cover 4 is completed. At the same time, the sealing cover 4 and the detection box 1 are successfully locked, and the sealing cover 4 cannot be turned over to open. After continuous ventilation completes the purging and cooling, the adjusting rod 28 is rotated downward, so that the sealing plug 29 moves down to seal the No. 1 pipe 30 and No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com