Patents

Literature

64results about How to "Seek lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

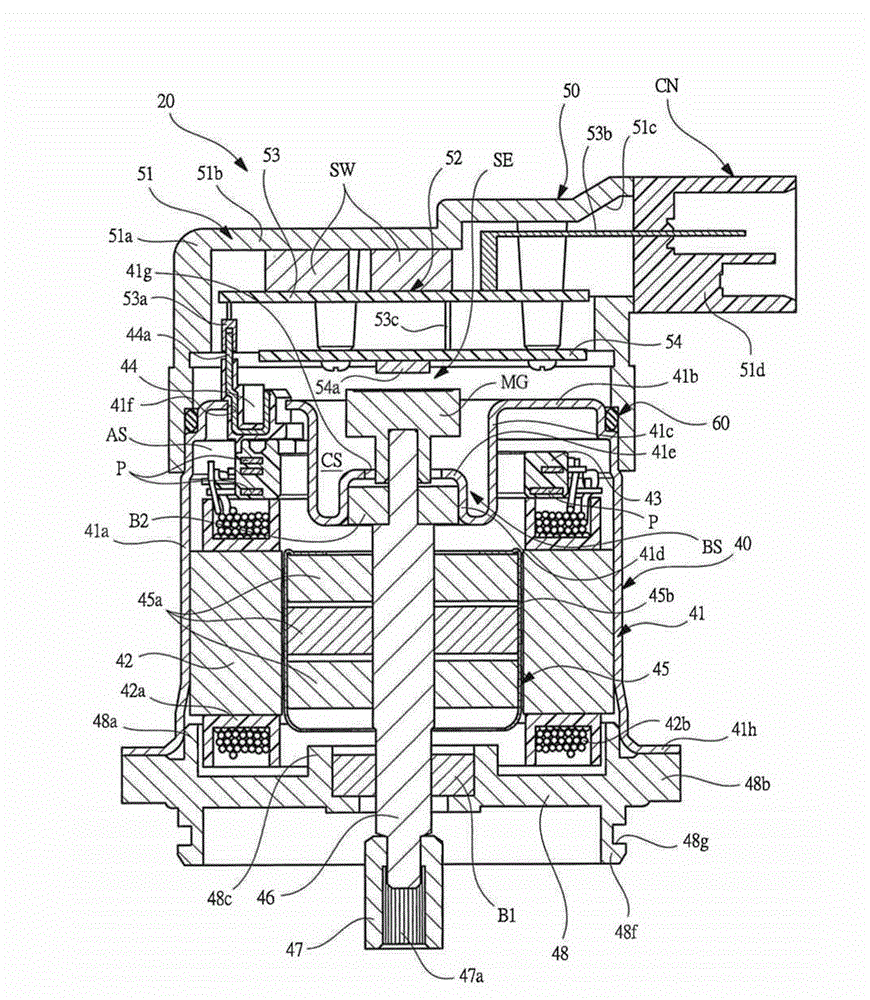

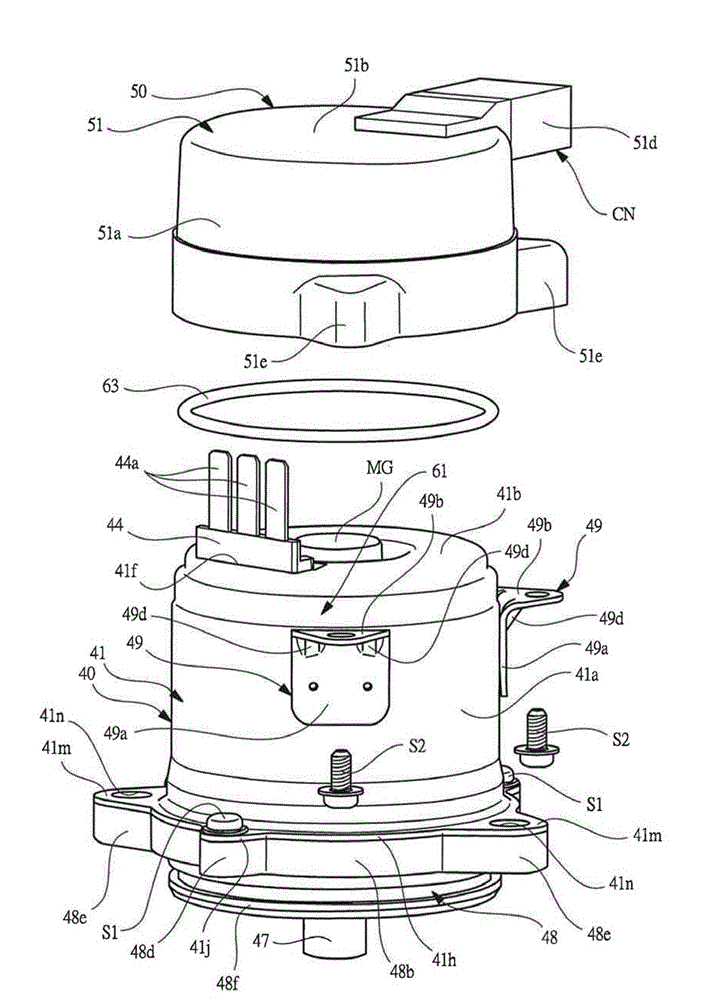

Brushless motor

InactiveCN103066787ASeek miniaturizationGuaranteed cooling effectAssociation with control/drive circuitsManufacturing dynamo-electric machinesBrushless motorsManufacturing cost reduction

The invention discloses a brushless motor which can ensure heat dissipation of a control device and meanwhile manufacturing process is simplified, manufacturing cost is reduced, and the brushless motor is minimized and has light weight. the brushless motor includes: a motor case 41 in which a cylindrical stator core 42 formed from steel plate by press molding is secured; a bracket 48 on one side in an axial direction of a motor case, a tip side of a rotary shaft 46 secured to a rotor 45 being rotatably supported by the bracket; and a housing member 51 on the other side in the axial direction of the motor case, a control device 52 for controlling the rotation of the rotor being accommodated in the housing member, the control device having a power-related circuit board 53 disposed on the side of a bottom 51b of the housing member and a control-related circuit board 54 disposed on the side of an opening of the housing member, semiconductor switching devices SW being disposed on the power-related circuit board in contact with the housing member.

Owner:MITSUBA CORP

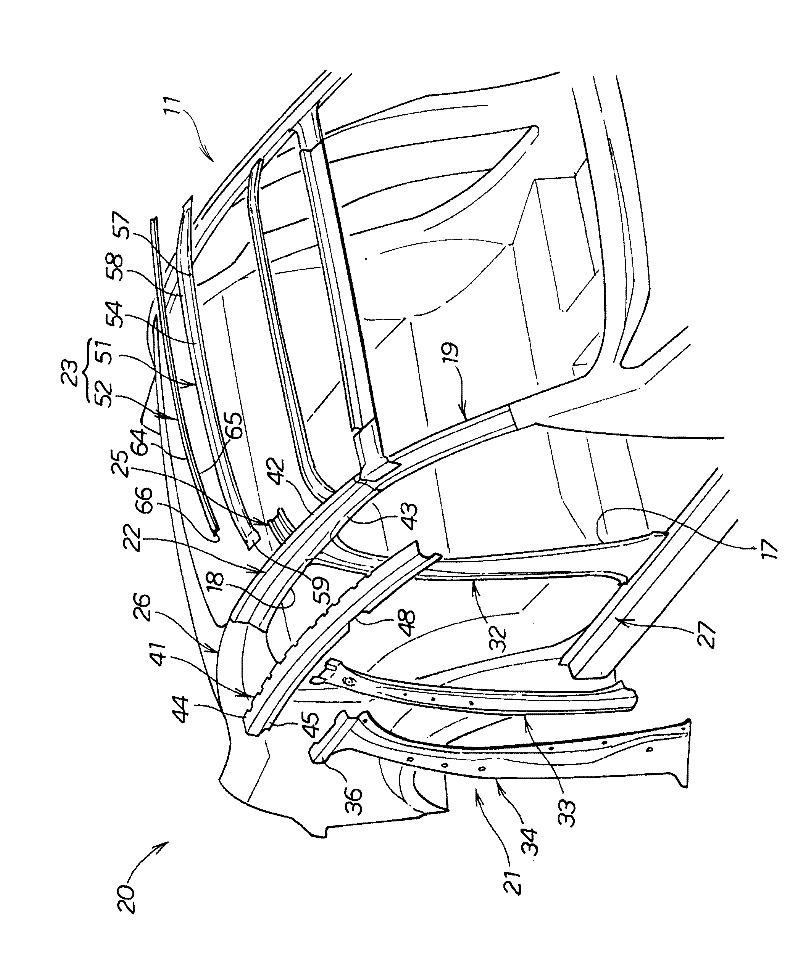

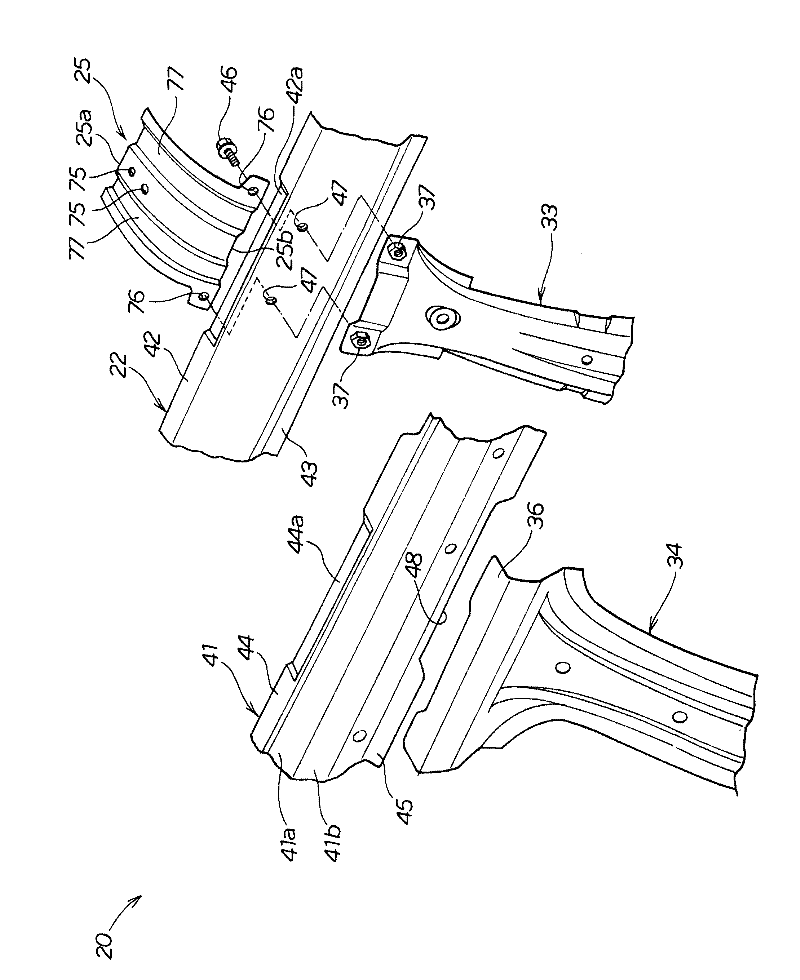

Upper vehicle body structure of automobile

ActiveCN102470899AIncrease interior spaceSuppress section crushingSuperstructure subunitsSuperstructure connectionsEngineering

Disclosed is an upper vehicle body structure (20) having a groove (31) between an outside panel (28) and a roof panel (24). The upper end of a center pillar stiffener (34) overlaps with a roof side stiffener (41). The roof side stiffener (41) is joined to a roof arch (23) at the groove (31). The upper end of a center pillar reinforcing member (33) inside the center pillar stiffener (34) is joined to an end (25b) of a corner gusset (25) at a position below the grooves (31), the other end (25a) of the corner gusset being connected to the roof arch (23). With this, concentration of impact load to the corner gusset (25) can be avoided.

Owner:HONDA MOTOR CO LTD

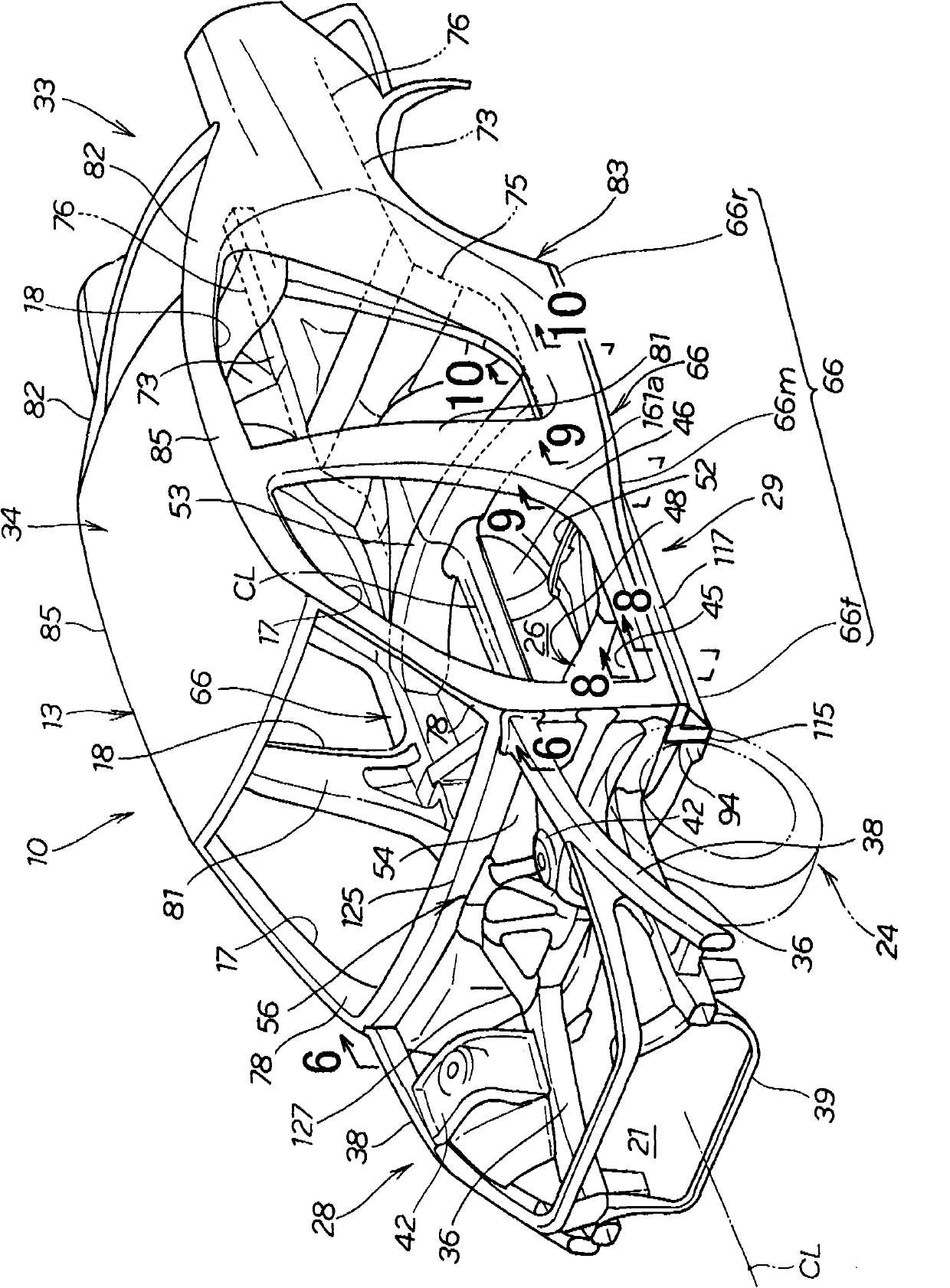

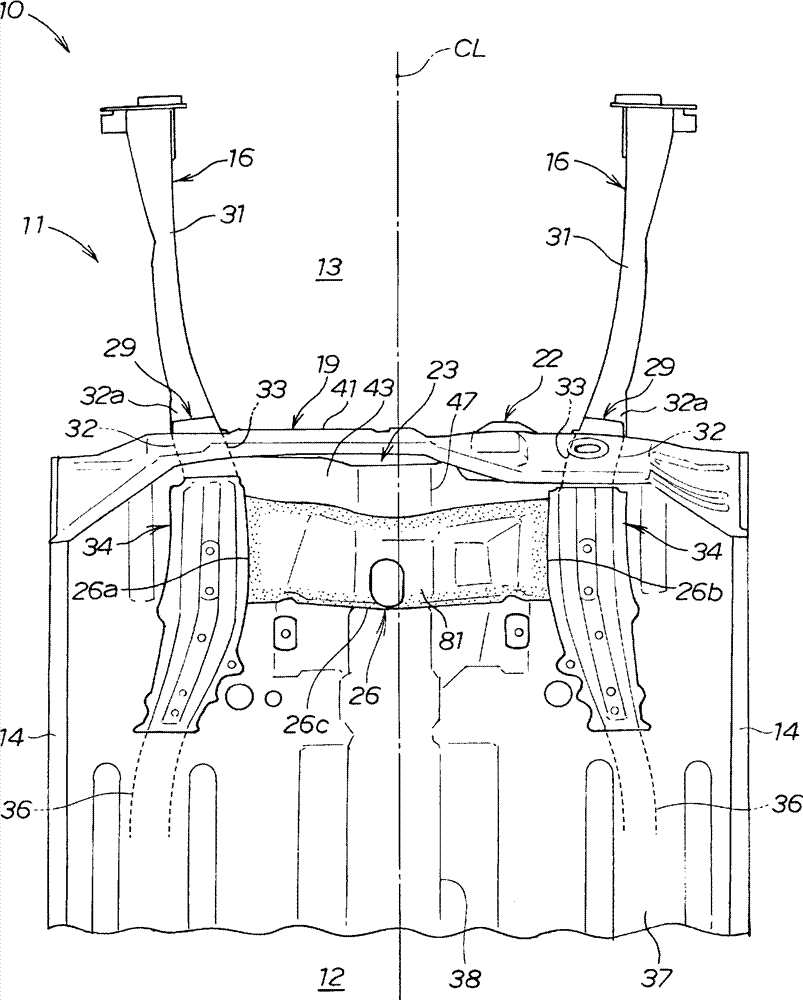

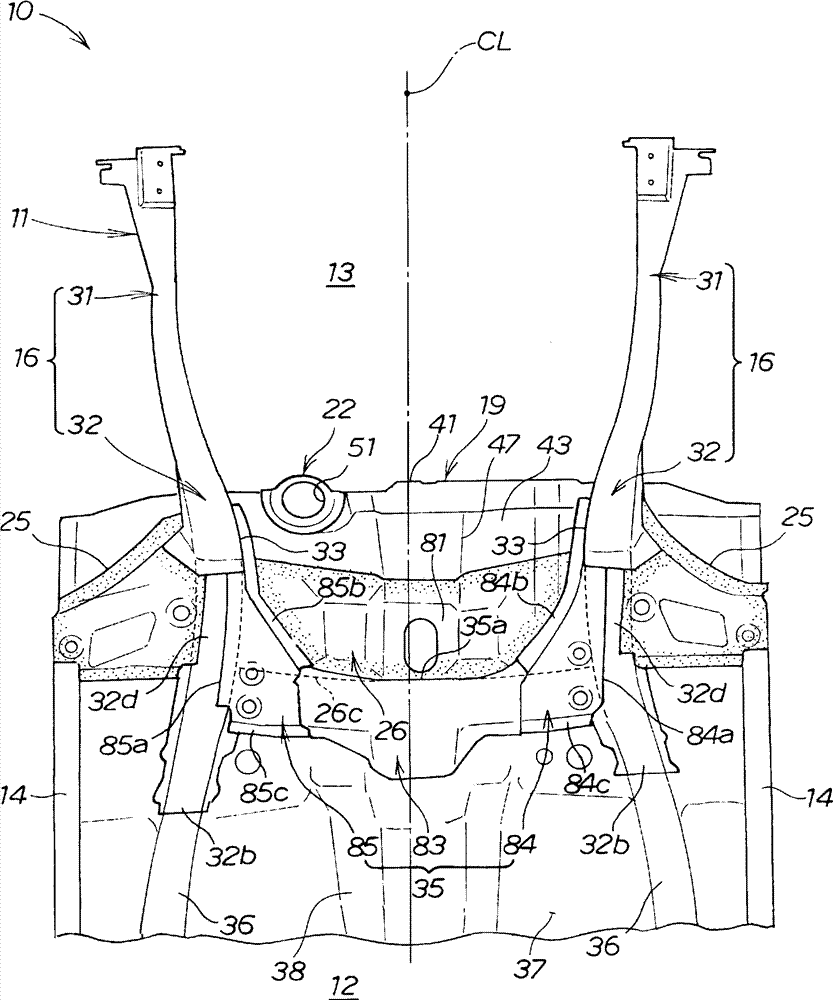

Vehicle body structure

InactiveCN102001362ARestraint torsionTwist to ensureUnderstructuresSuperstructure subunitsEngineeringSquare Shape

Owner:HONDA MOTOR CO LTD

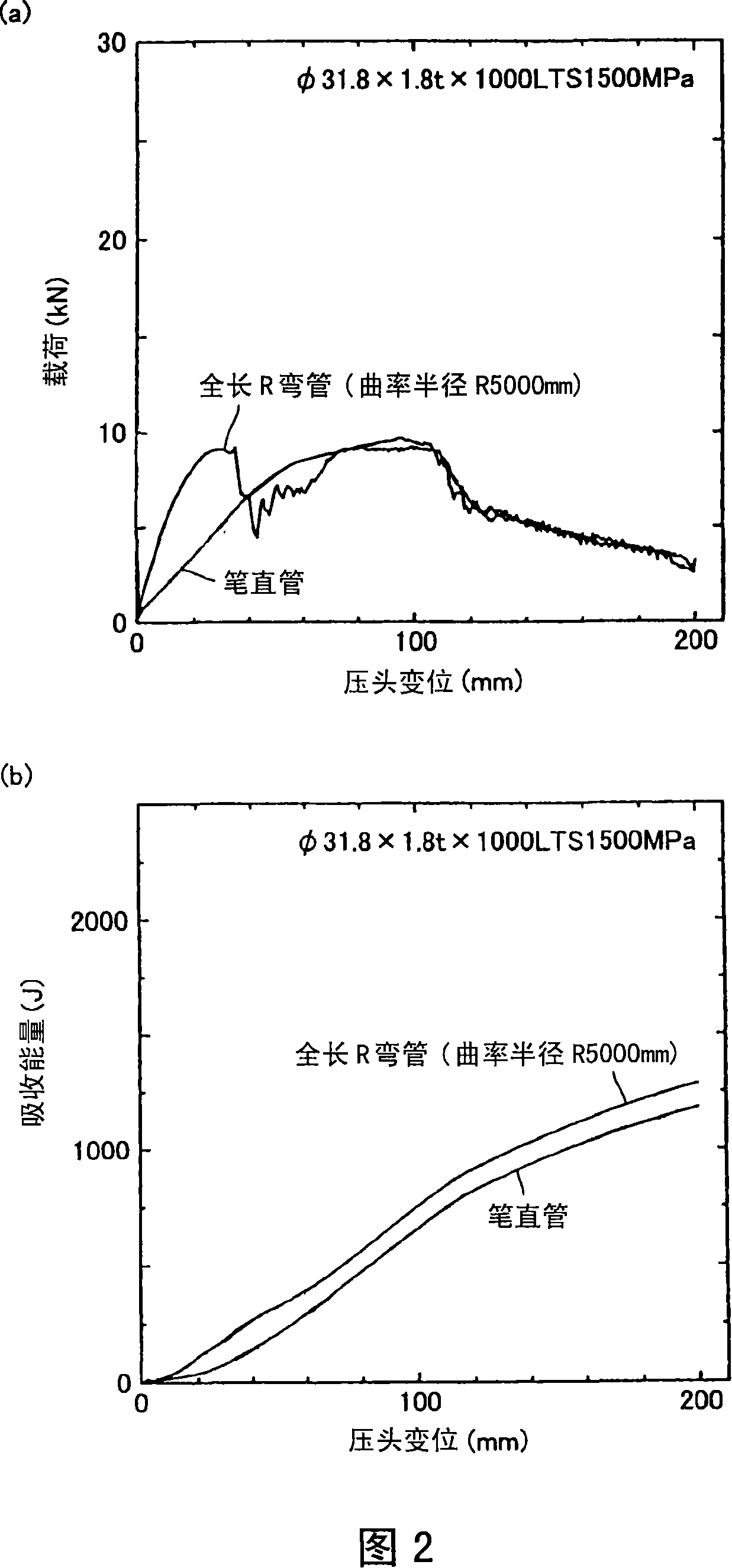

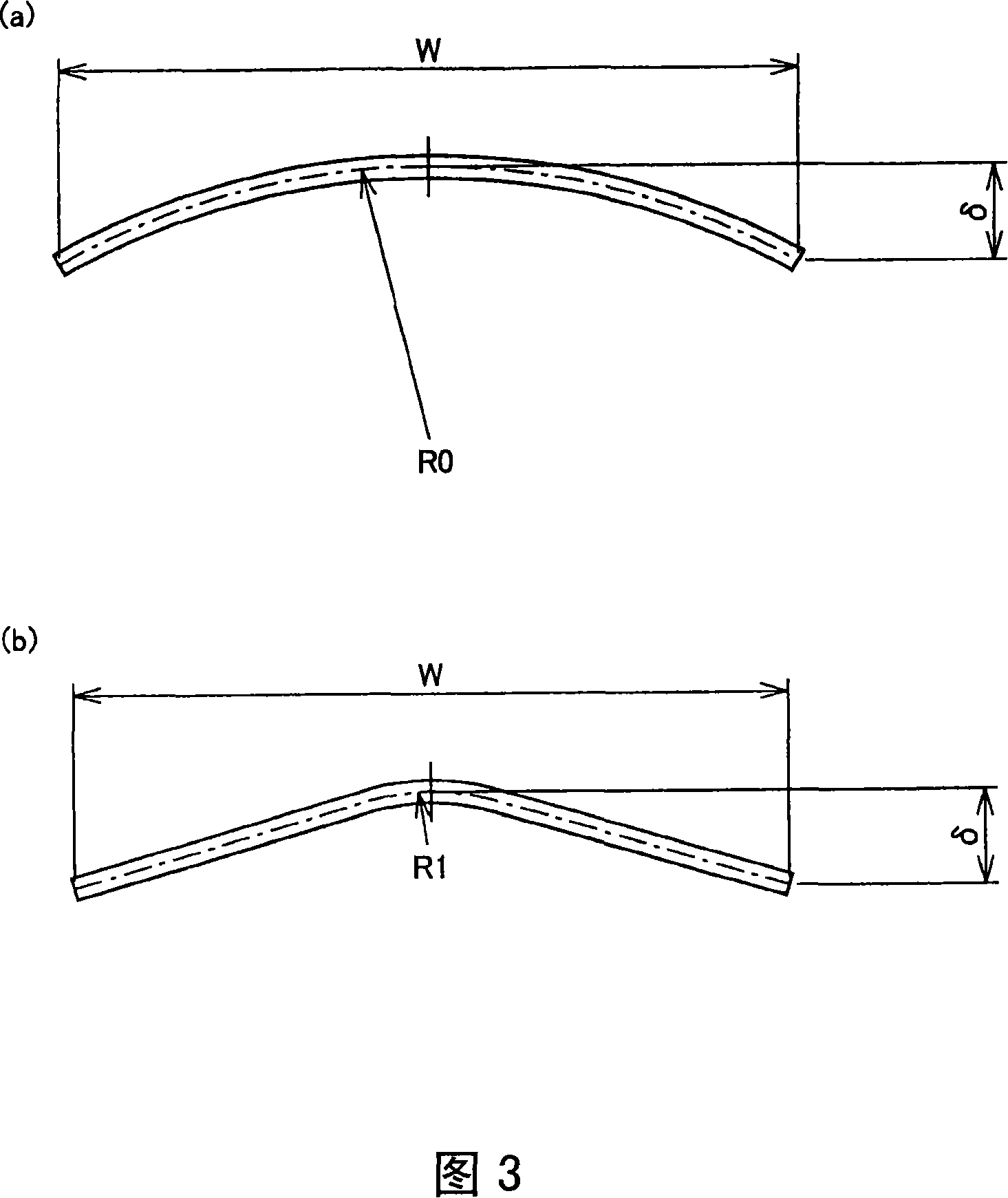

Member for reinforcing vehicle body

ActiveCN101132938AImprove energy absorptionImprove impact resistancePedestrian/occupant safety arrangementFurnace typesStraight tubeImpact resistance

A member for reinforcing a vehicle body capable of absorbing more energy than conventional reinforcement members using straight tubes and ''overall length R-bent tubes'' at the time of collision of the vehicle body by applying either of a ''partially R-bent tube'', a ''multi-portion R-bent tube'' and a ''partially recessed and protruded bent tube'' specified in this invention to the member for reinforcing the vehicle body so as to develop excellent impact resistance for reinforcing the vehicle body. The dimensions (outer diameter, wall thickness) of a metal tube used as the member for reinforcing the vehicle body are reduced while maintaining the impact resistance and the shape thereof is reviewed to reduce the weight and cost of the vehicle body. Also, since the member can cope with a requested level for a more and more increasing impact resistance of the vehicle body, it can be widely used as an occupant protective technology.

Owner:NIPPON STEEL CORP +2

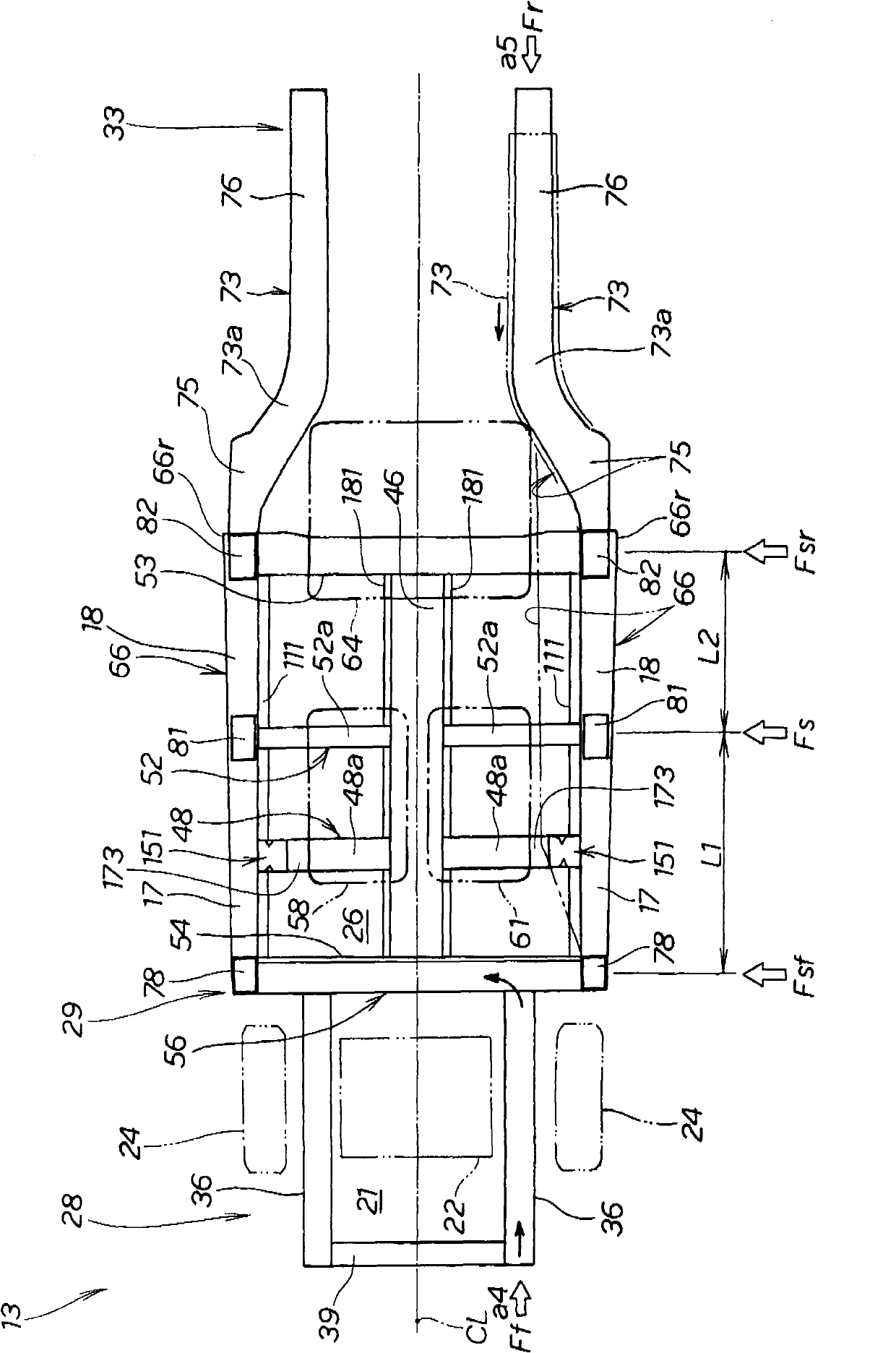

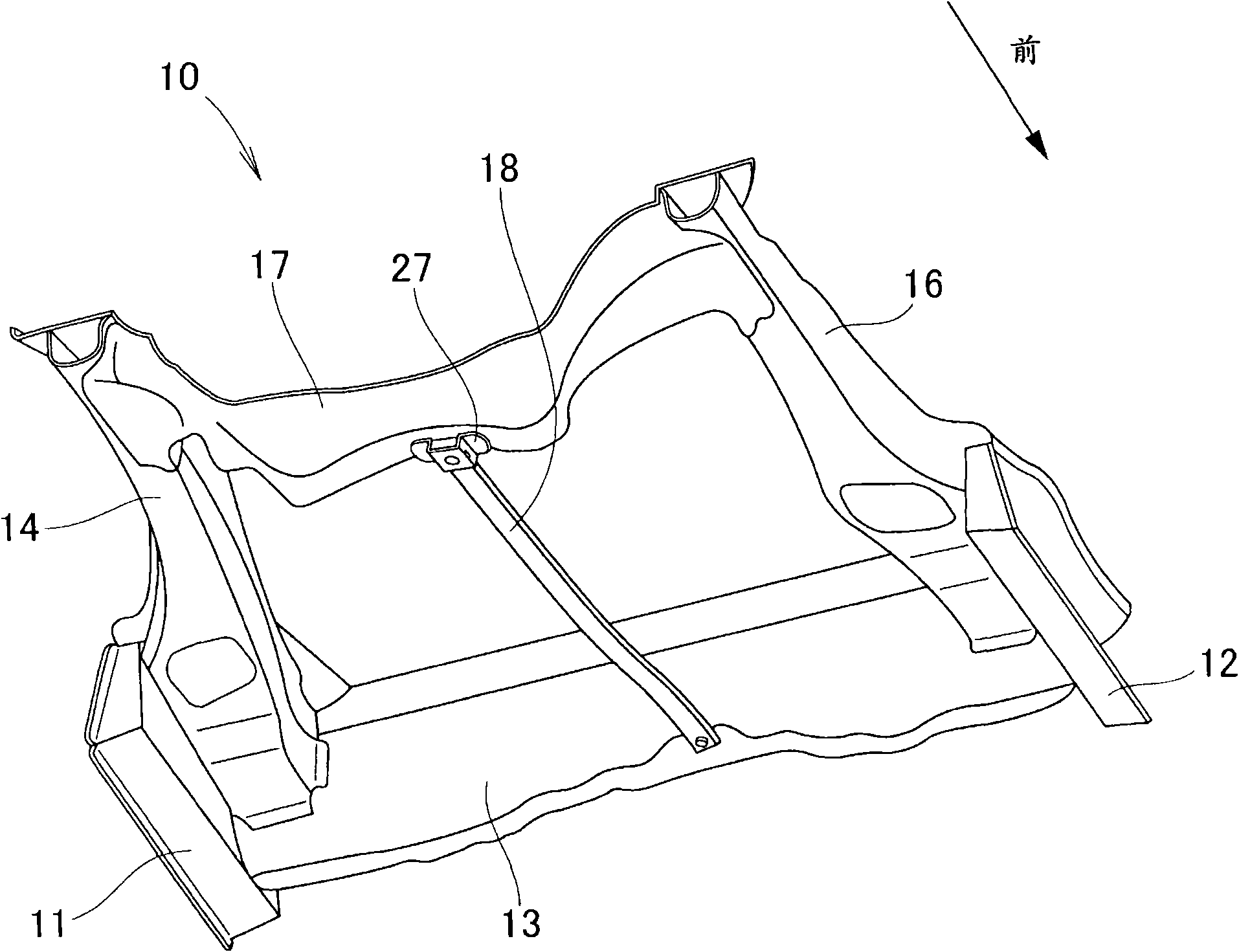

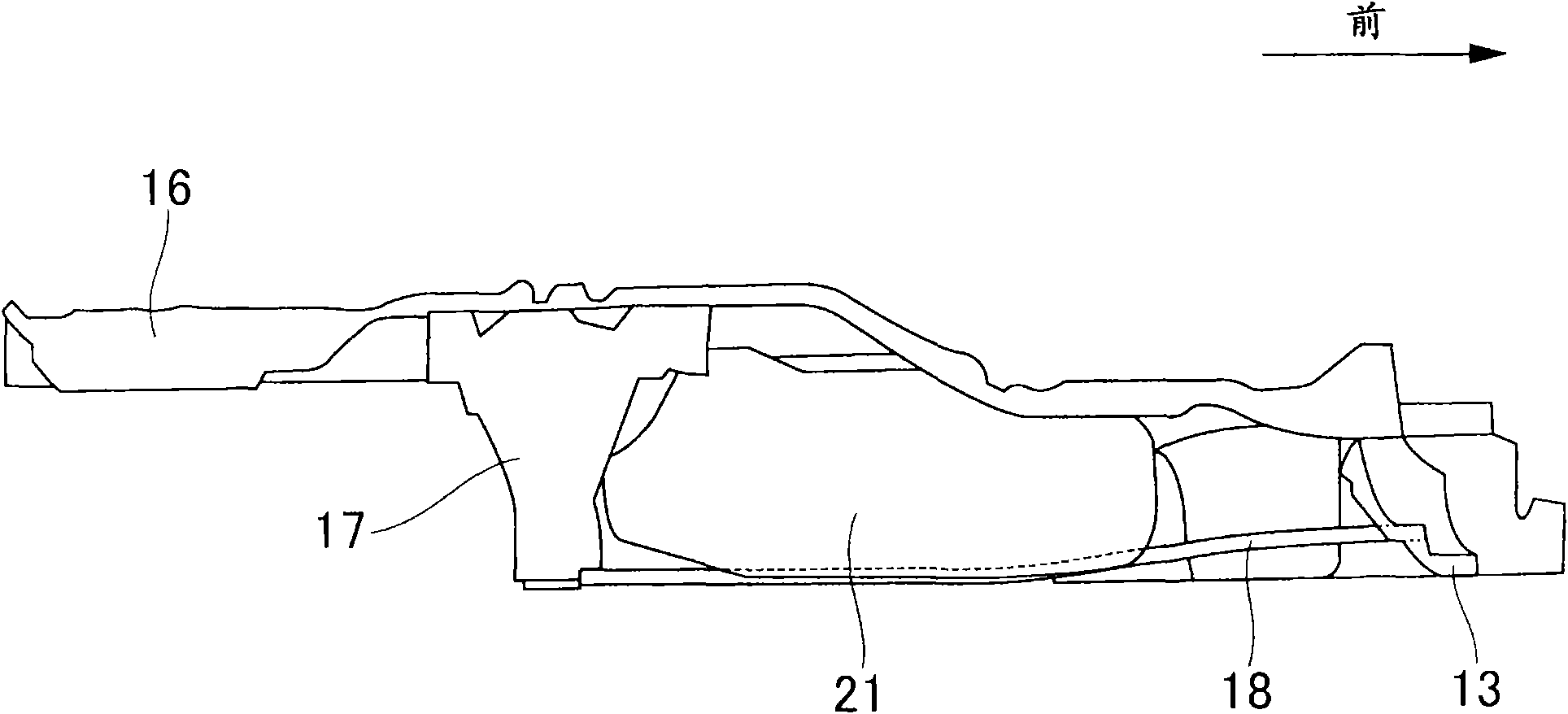

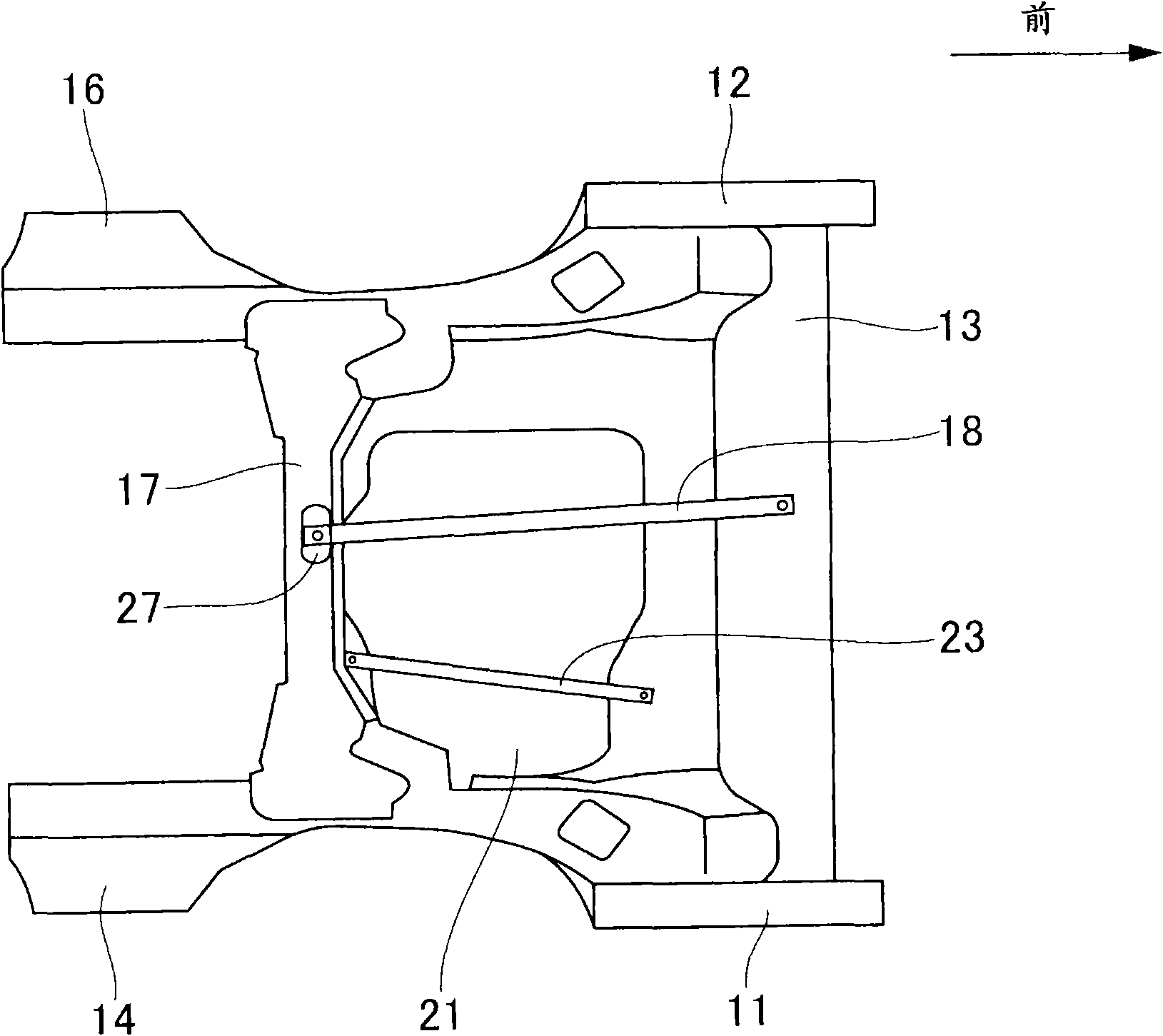

Back structure of vehicle body

The present invention provides a back structure of a vehicle body, capable of generating a great resisting force against collision, and restraining number and weight of parts. The back structure of the vehicle body includes left and right back vehicle frames (14, 16) for supporting a cantalever extending on the back of the vehicle body front and back; a rear cross beam (17) arranged on the back vehicle frames (14, 16) in a striding mode, the rear cross beam (17) and a center cross beam (13) arranged on front of the rear cross beam (17) are linked by a box protection lever (18) extending back and front and bending downwards, a back end part (18d) of the box protection lever (18) is covered by a support bracket (27) from the lower side and is fastened on the rear cross beam (17) through the support bracket (27).

Owner:HONDA MOTOR CO LTD

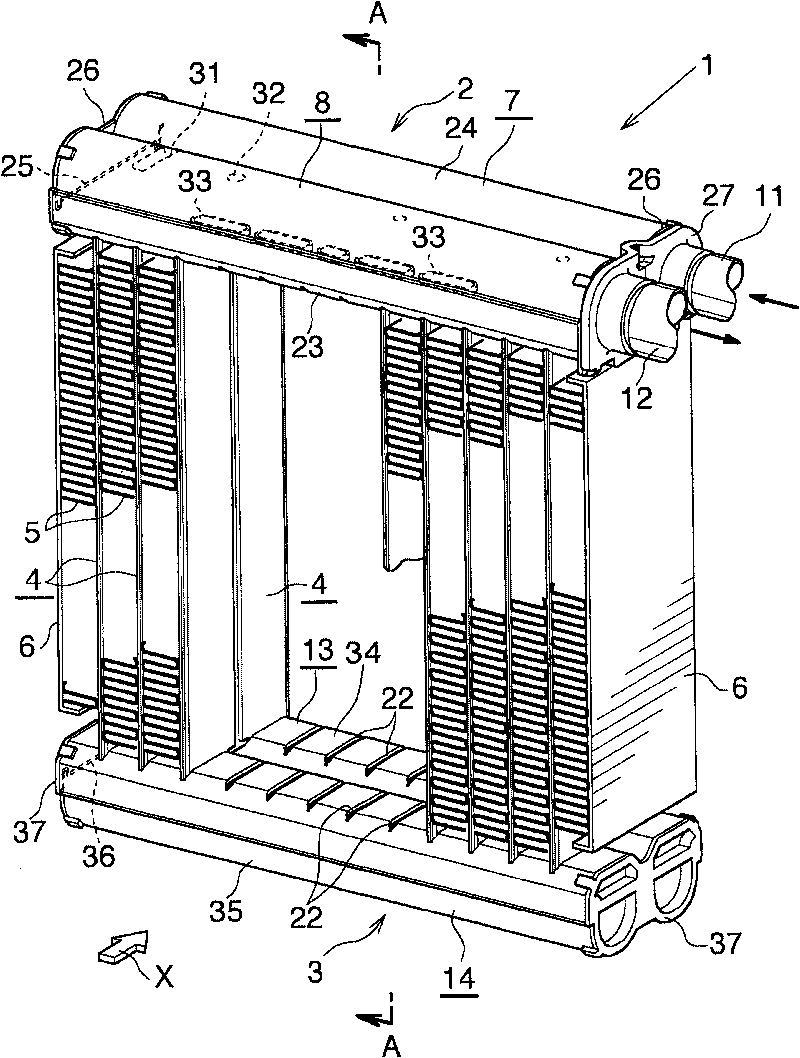

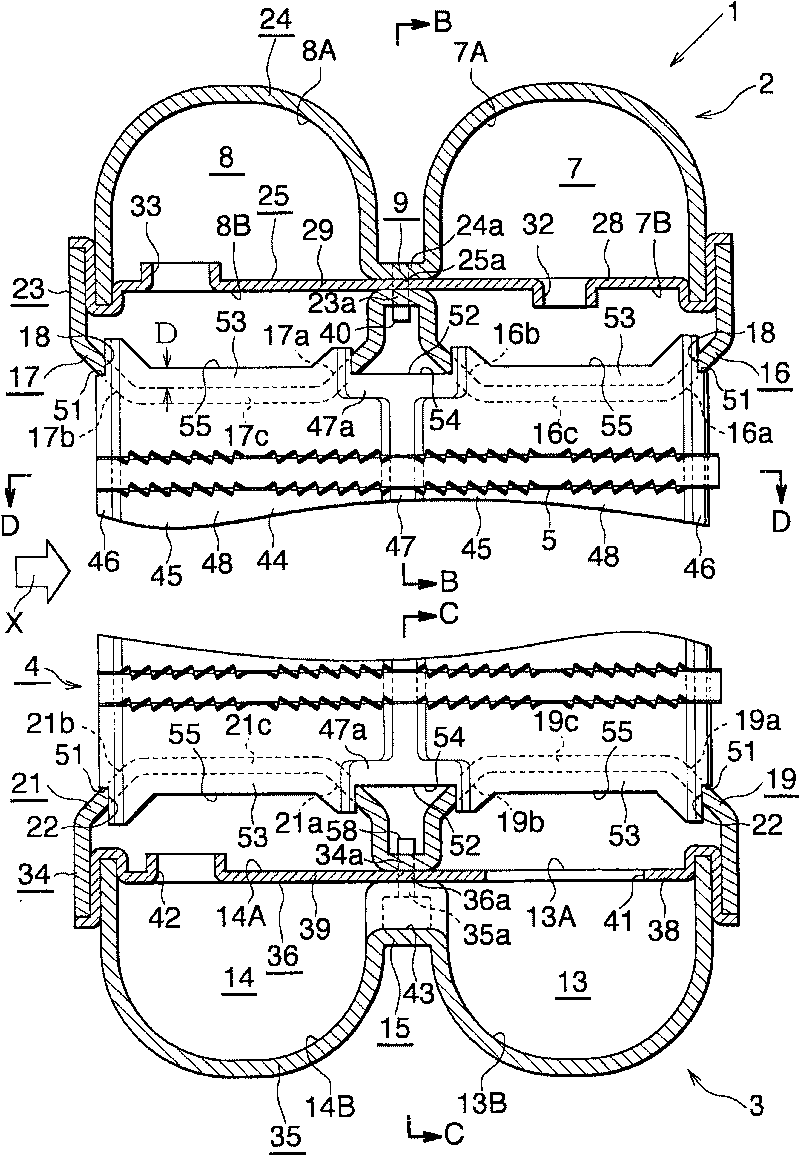

Evaporator

InactiveCN101713605AIncrease exhaust temperatureAvoid performance degradationEvaporators/condensersStationary conduit assembliesEngineeringEvaporator

Each heat exchange tube of an evaporator is composed of two press-worked rectangular metal plates joined together in a stacked condition. The metal plates of the heat exchange tube are swelled outward whereby at least one refrigerant flow space extending in the vertical direction and having opened upper and lower ends is provided in the heat exchange tube. Insertion portions to be inserted into header sections of header tanks of the evaporator via tube insertion holes are provided on upper and lower end portions of each heat exchange tube at positions corresponding to the refrigerant flow space. A concave portion is formed in each of the insertion portions, excluding opposite ends thereof with respect to the front-rear direction, of the upper and lower end portions of each heat exchange tube, the concave portion being concaved inward with respect to a longitudinal direction of the heat exchange tube.

Owner:KEIHIN THERMAL TECH CORP

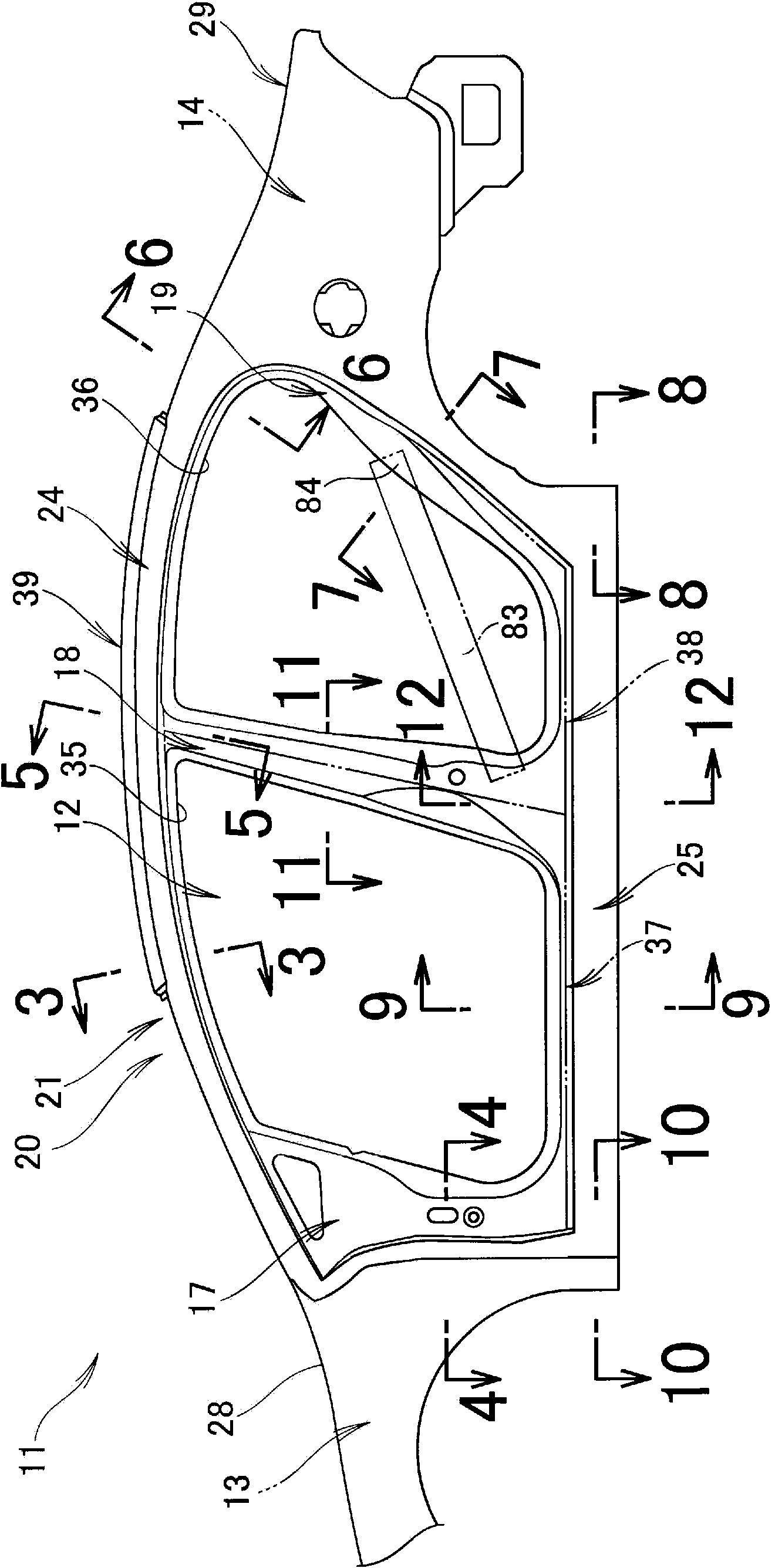

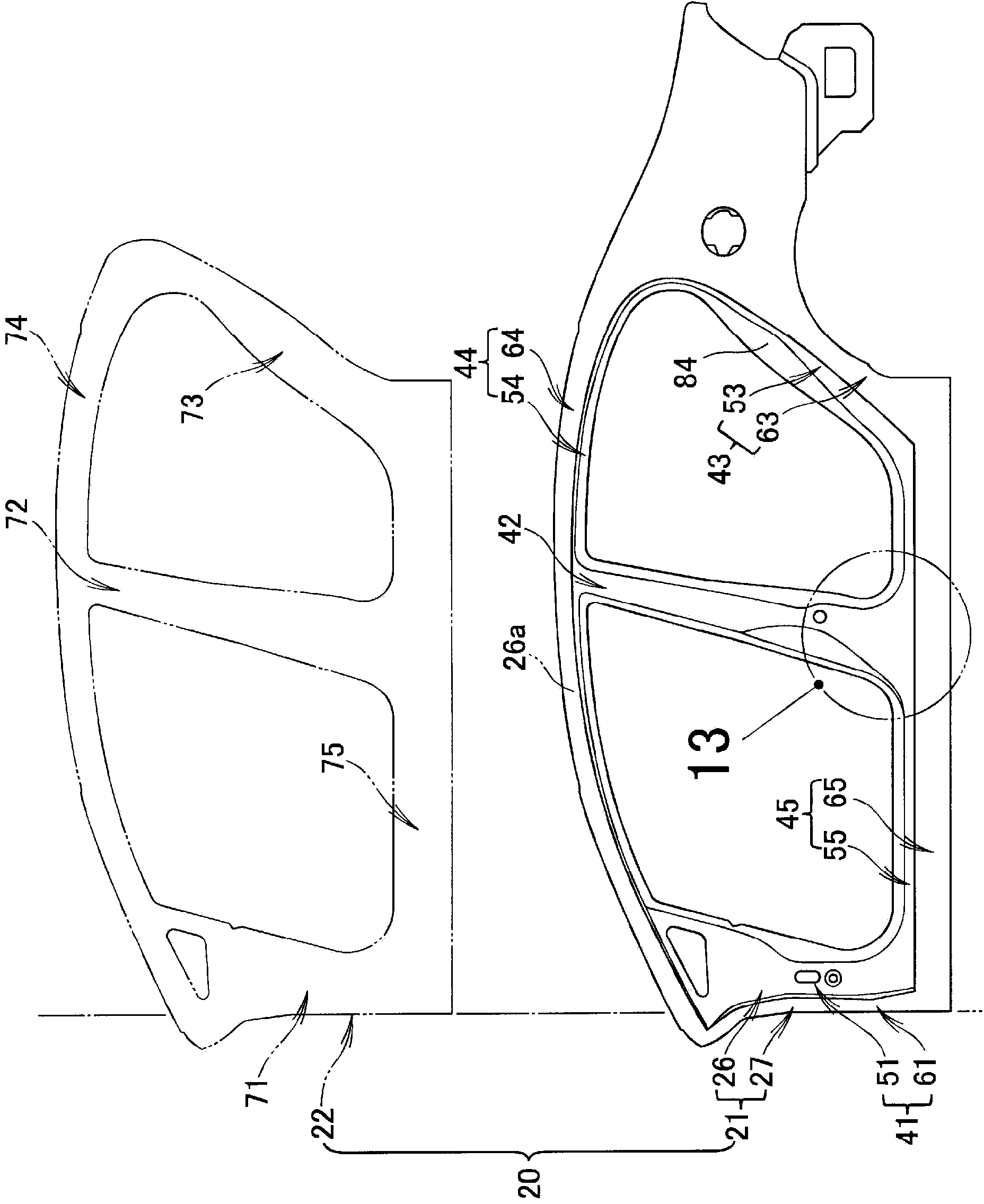

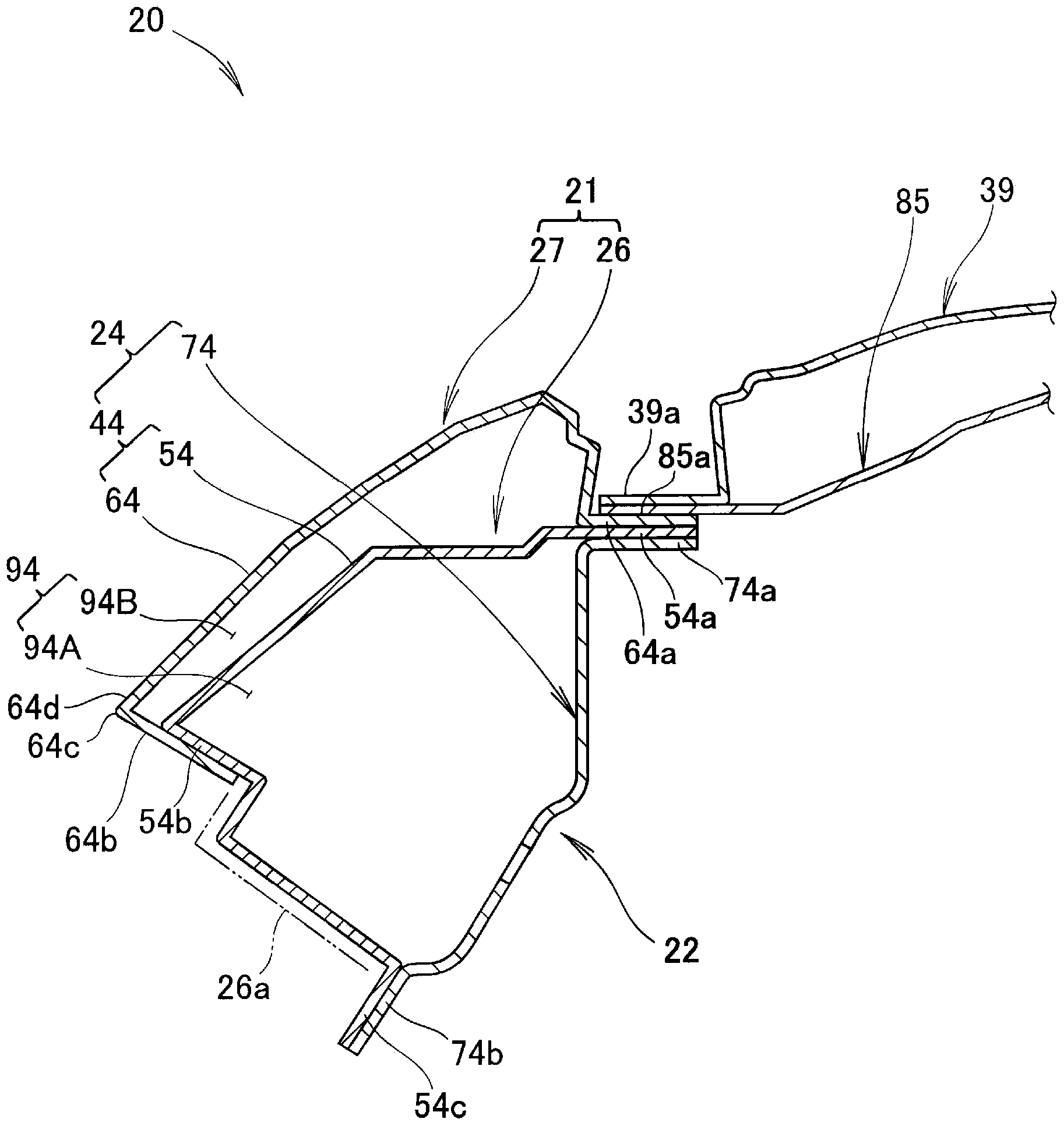

Side panel structure for vehicle

InactiveCN103906674AGood lookingImprove rigiditySuperstructure subunitsRear quarterUltimate tensile strength

A side panel structure (20), includes a side outer panel (21) provided on the vehicle exterior side, and a side inner panel (22) provided on the vehicle interior (12) side. The side outer panel (21) and the side inner panel (22) form, as a closed cross-section structure, a peripheral edge section forming door openings (35, 36). The side outer panel (21) comprises an inner frame (26) formed from a high-strength steel sheet having a high tensile strength, and an outer frame (27) provided to the outer periphery section (26a) of the inner frame (26). The outer frame (27) is formed from a low-strength steel sheet having a low tensile strength.

Owner:HONDA MOTOR CO LTD

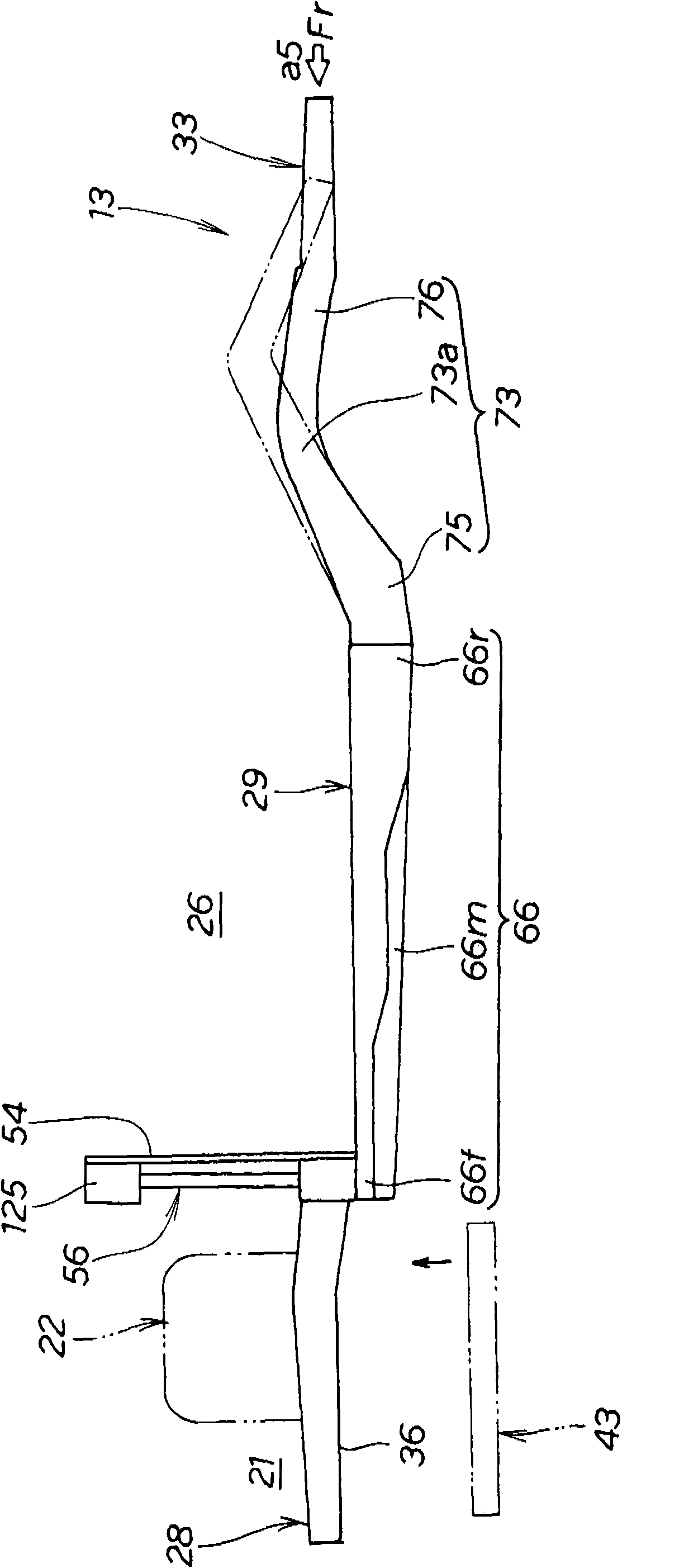

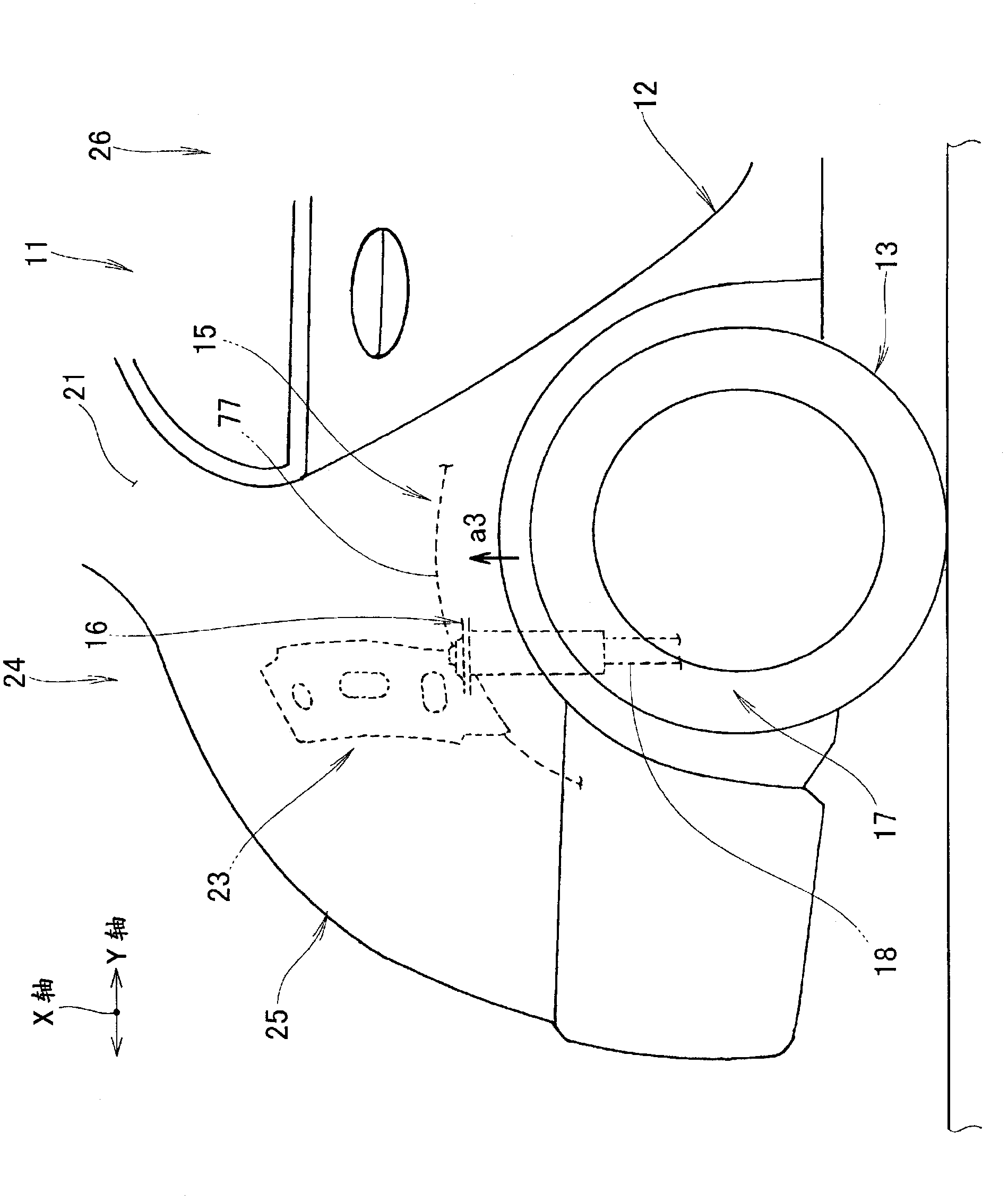

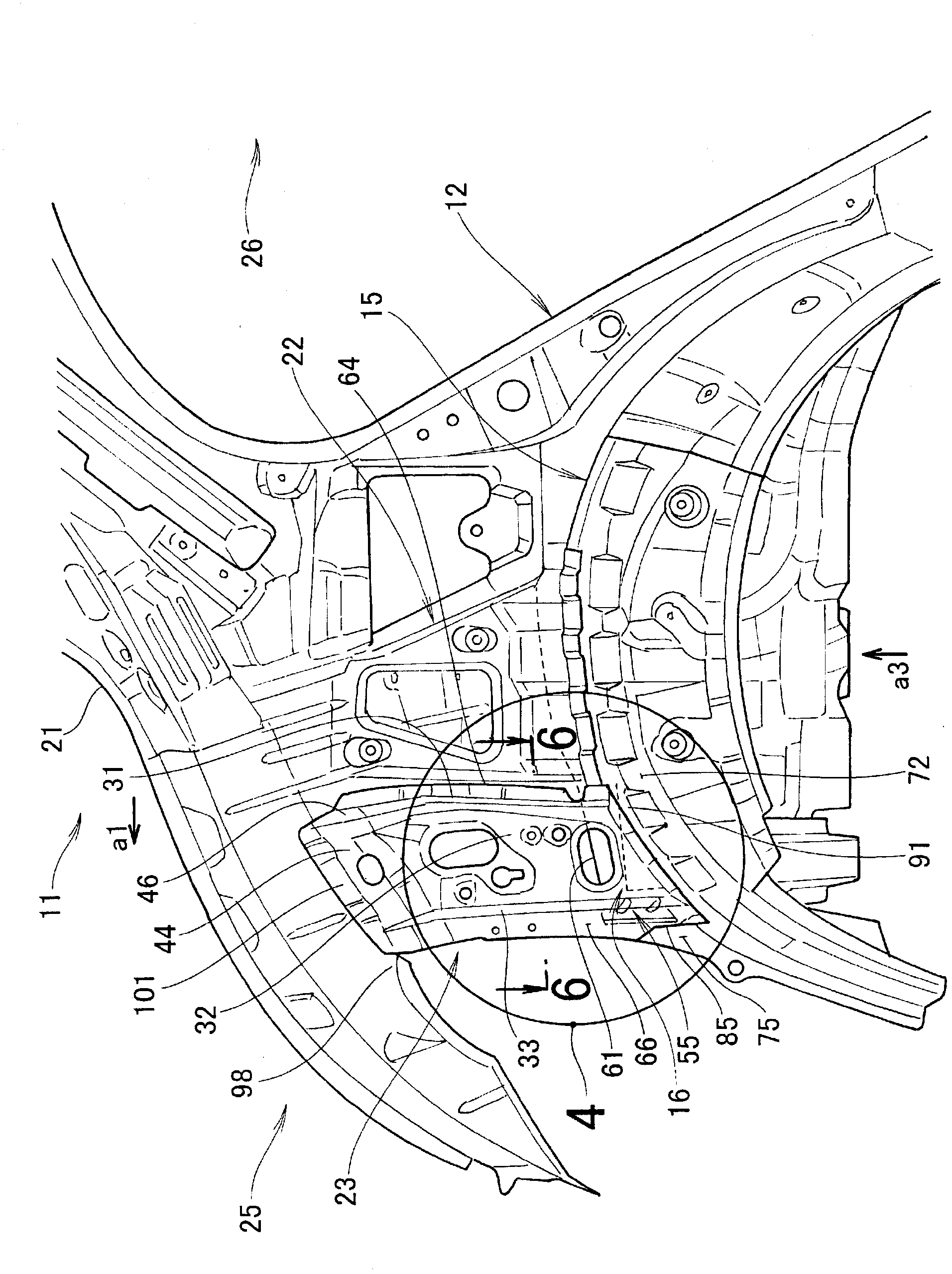

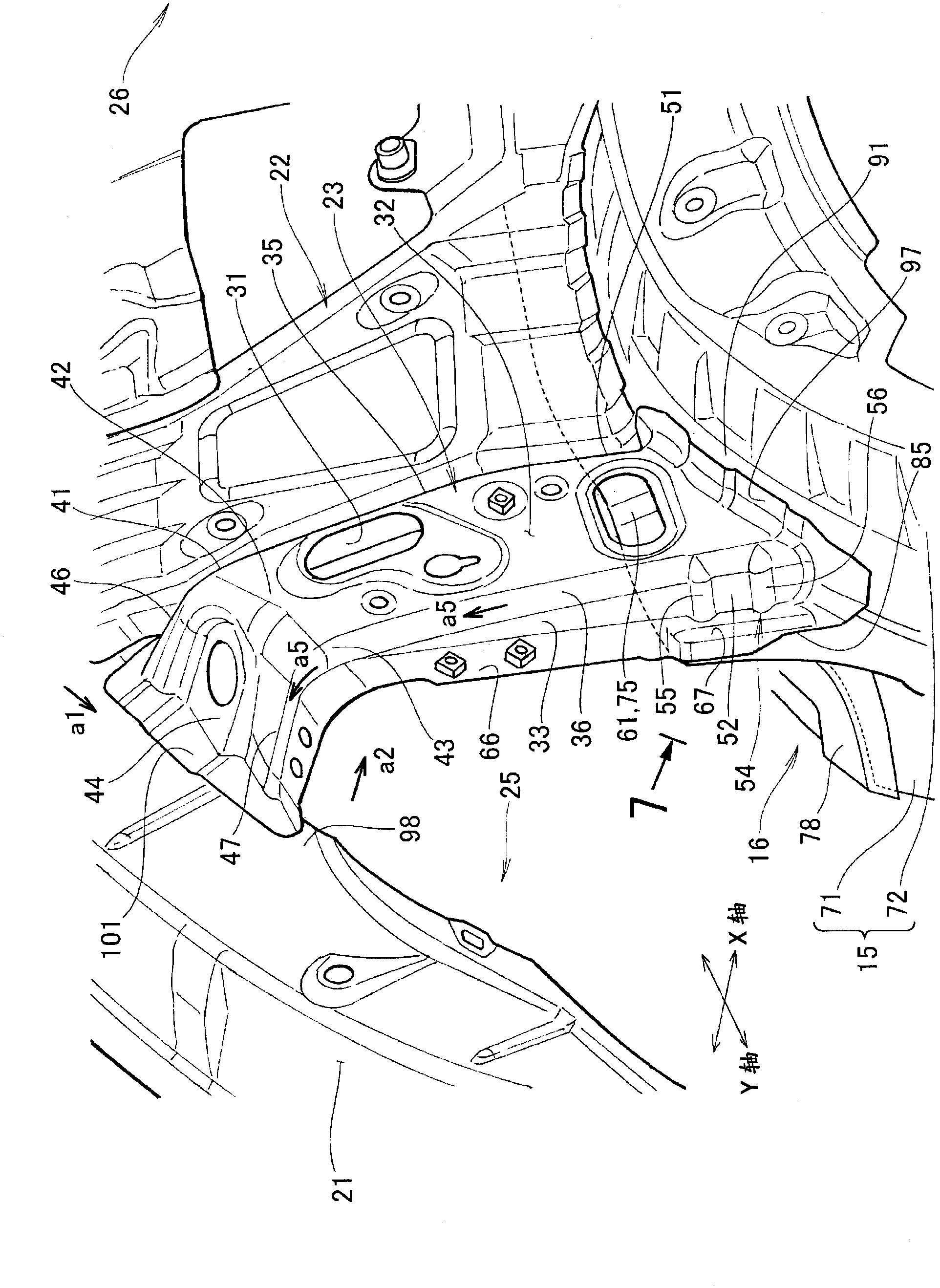

Structure for vehicle body rear portion

ActiveCN103038125AGuaranteed StrengthHigh strengthSuperstructure subunitsEngineeringMechanical engineering

A structure for a vehicle body rear portion has a rear pillar (21), a rear wheel arch (15), a damper stiffener (22) which is connected so that the load of the damper (18) transmitted through the rear wheel arch (15) is dispersed to the rear pillar (21), and a brace (23) which is connected from the rear wheel arch (15) to the rear pillar (21). The brace (23) has a front surface section (31) which faces forward, a side surface section (32), and a rear surface section (33) which faces the front surface section (31). A front ridge line section (35) and / or a rear ridge line section (36) reaches the rear pillar (21) from the rear wheel arch (15).

Owner:HONDA MOTOR CO LTD

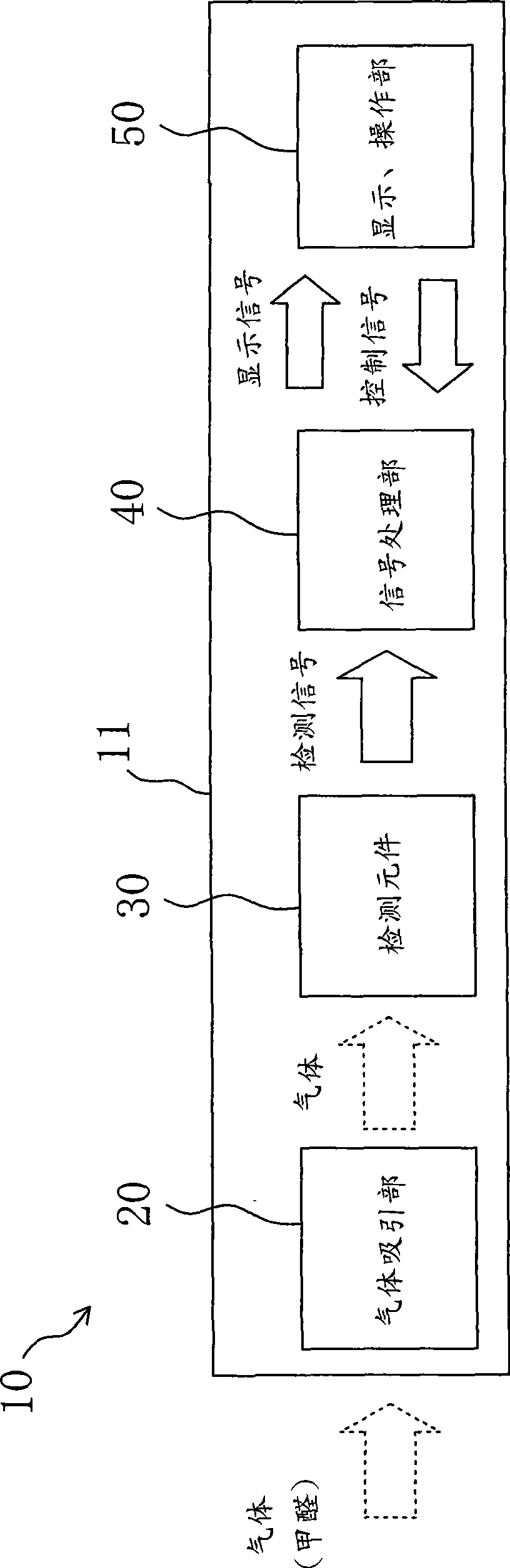

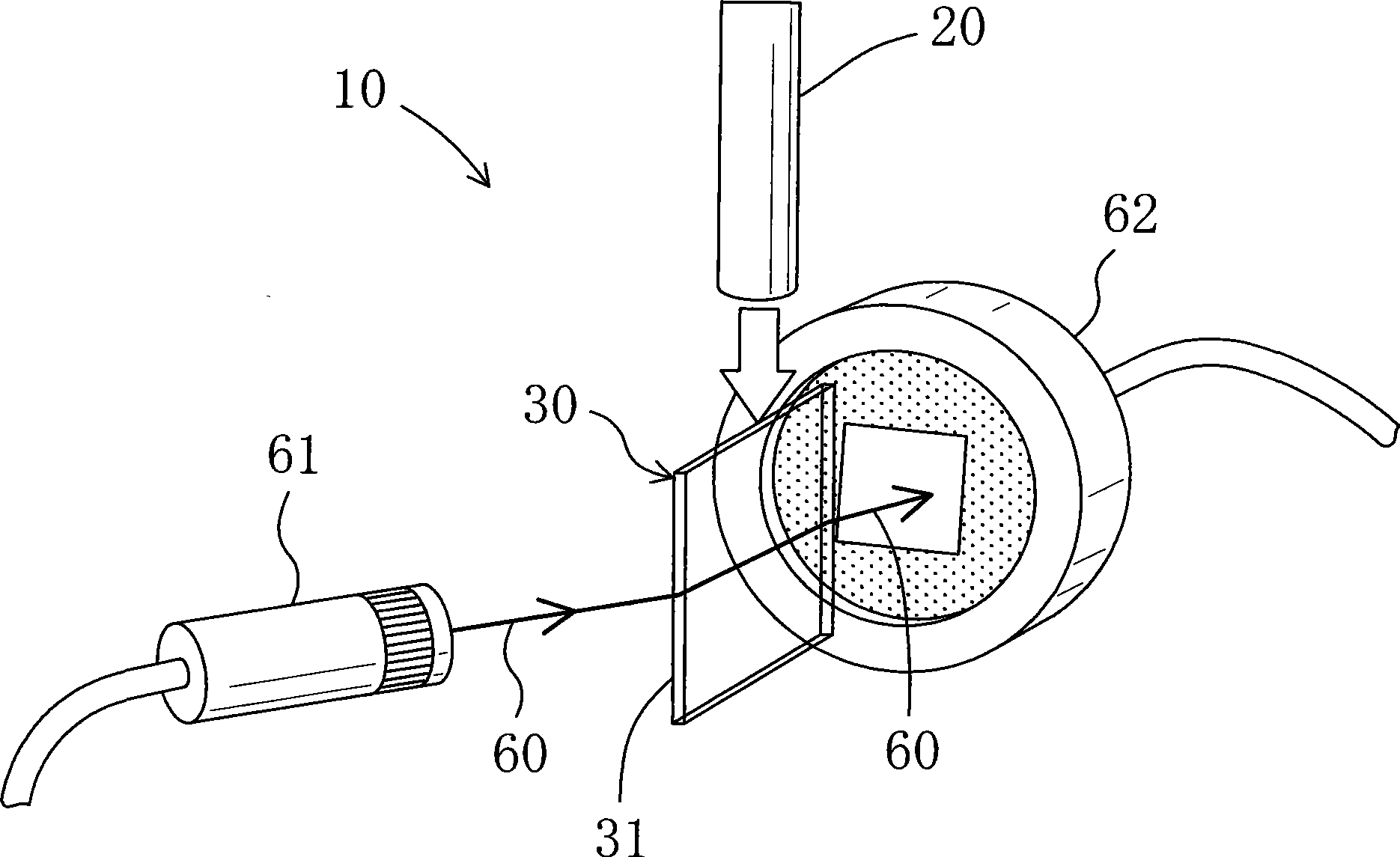

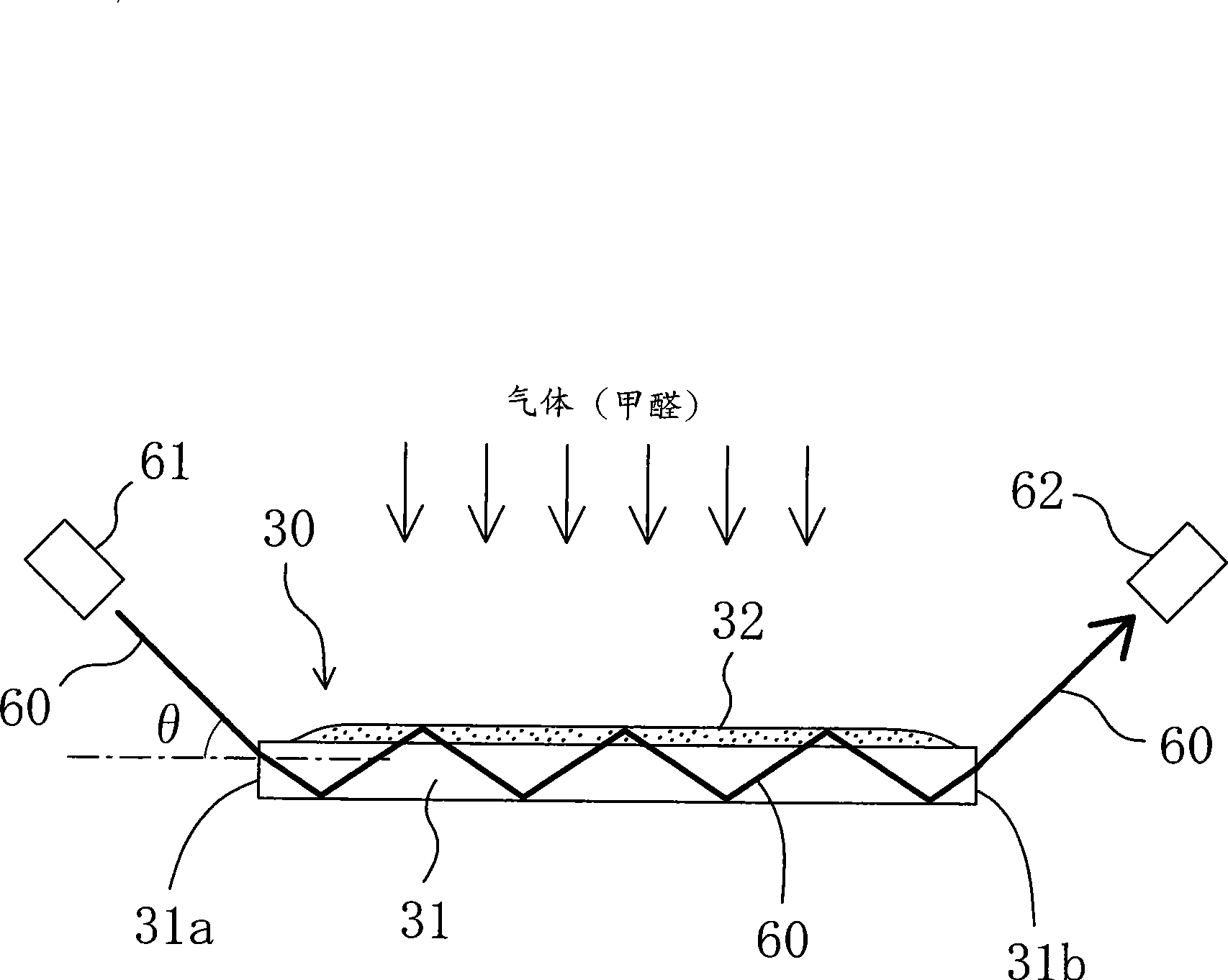

Formaldehyde detecting material, formaldehyde detector, formaldehyde detecting method and formaldehyde detecting reagent

InactiveCN101535798AShort reaction timeMake sure to reactAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorOptical propertyLight signal

A formaldehyde detector (10) provided with a detecting reagent which develops a color in response to formaldehyde. The detector (10) comprises a detection element (30) having a base material (31) which constitutes an optical waveguide transmitting light via repeated total reflection and a mesoporous layer (32) which serves as the surface of the base material (31), is formed by laminating on at least a part of the light reflecting face and carries the detecting reagent as described above. Furthermore, it has a light emitting material which emits an incident light on the base material (31) and a light receiving material which receives the light outgoing from the base material (31). Furthermore, it has a signal processing section wherein the light signal from the light receiving material is received and a change in the optical properties based on the color development due to the reaction of formaldehyde with the detecting reagent is detected to thereby detect formaldehyde and measure its concentration from the change in the optical properties.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

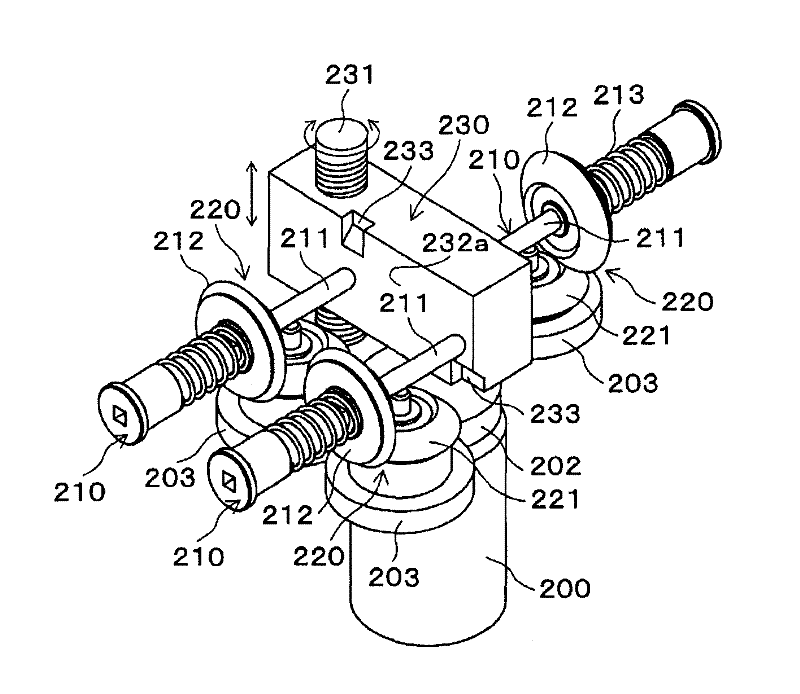

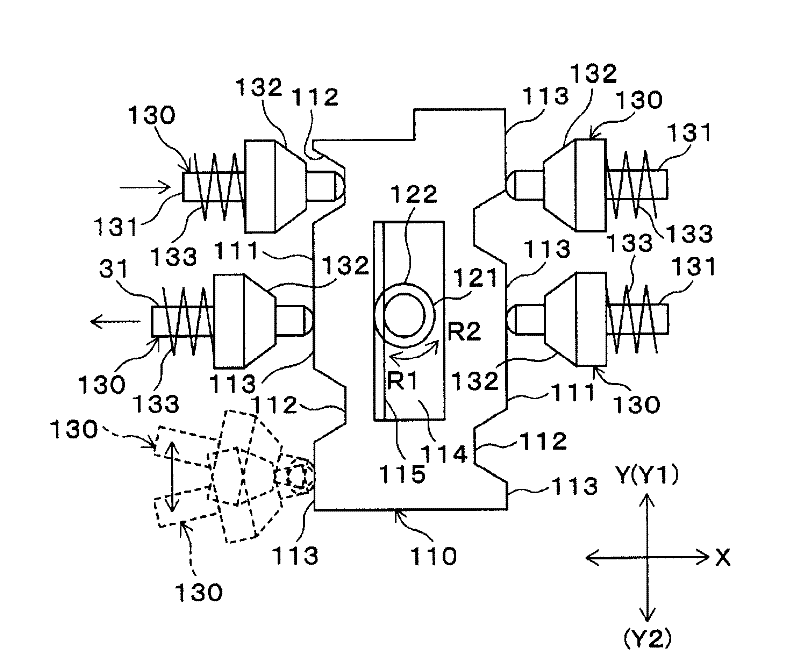

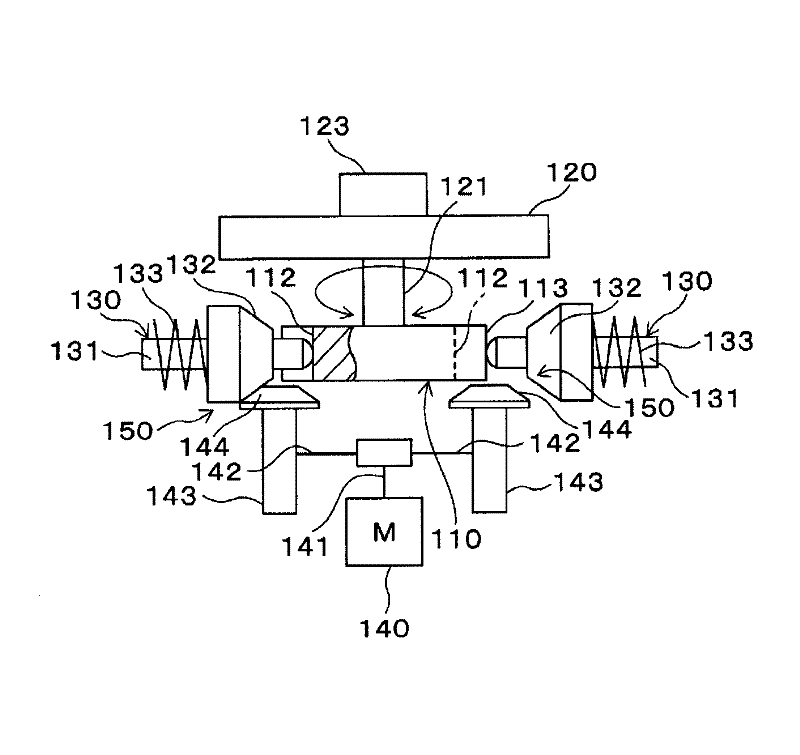

Multi-shaft drive device

A lighter weight and space conservation are achieved by employing a mechanical clutch with a simplified structure when driving a plurality of output shafts by means of a single motor. Output gears (21) are disposed in a manner enabling movement towards and separation from a plurality of second input gears (14) to which the rotation of a motor (10) is transmitted, while a cam (41), which presses toward the second input gears (14) and has a plurality of recesses (42) disposed around the exterior thereof, is disposed on the interior of the output gears (21). By rotating the cam (41) and inserting pins (24) on the output gears (21) into the recesses, the output gears (21) are moved towards the second input gears (14), and the output gears (21) mesh with the second input gears (14).

Owner:NHK SPRING CO LTD

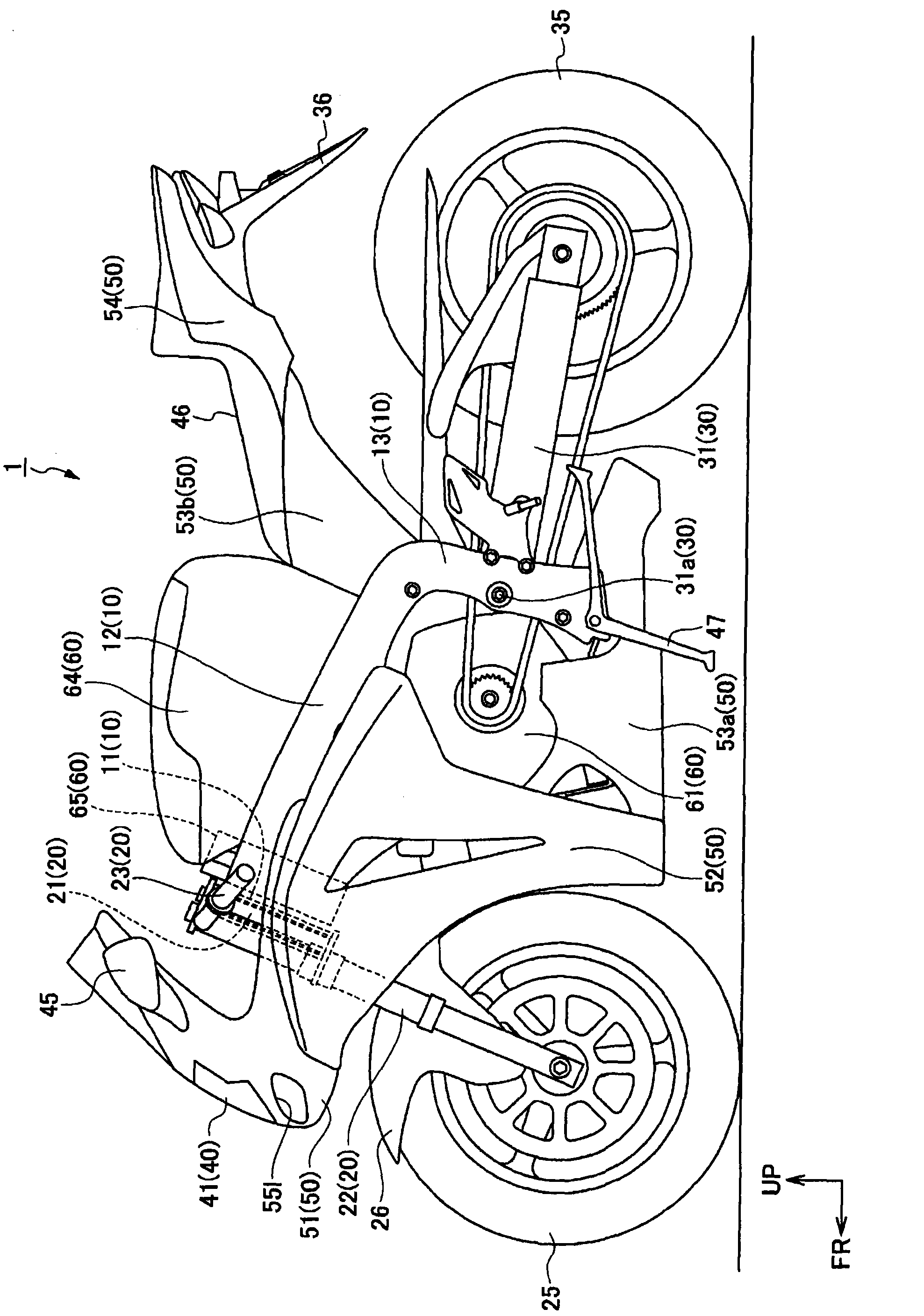

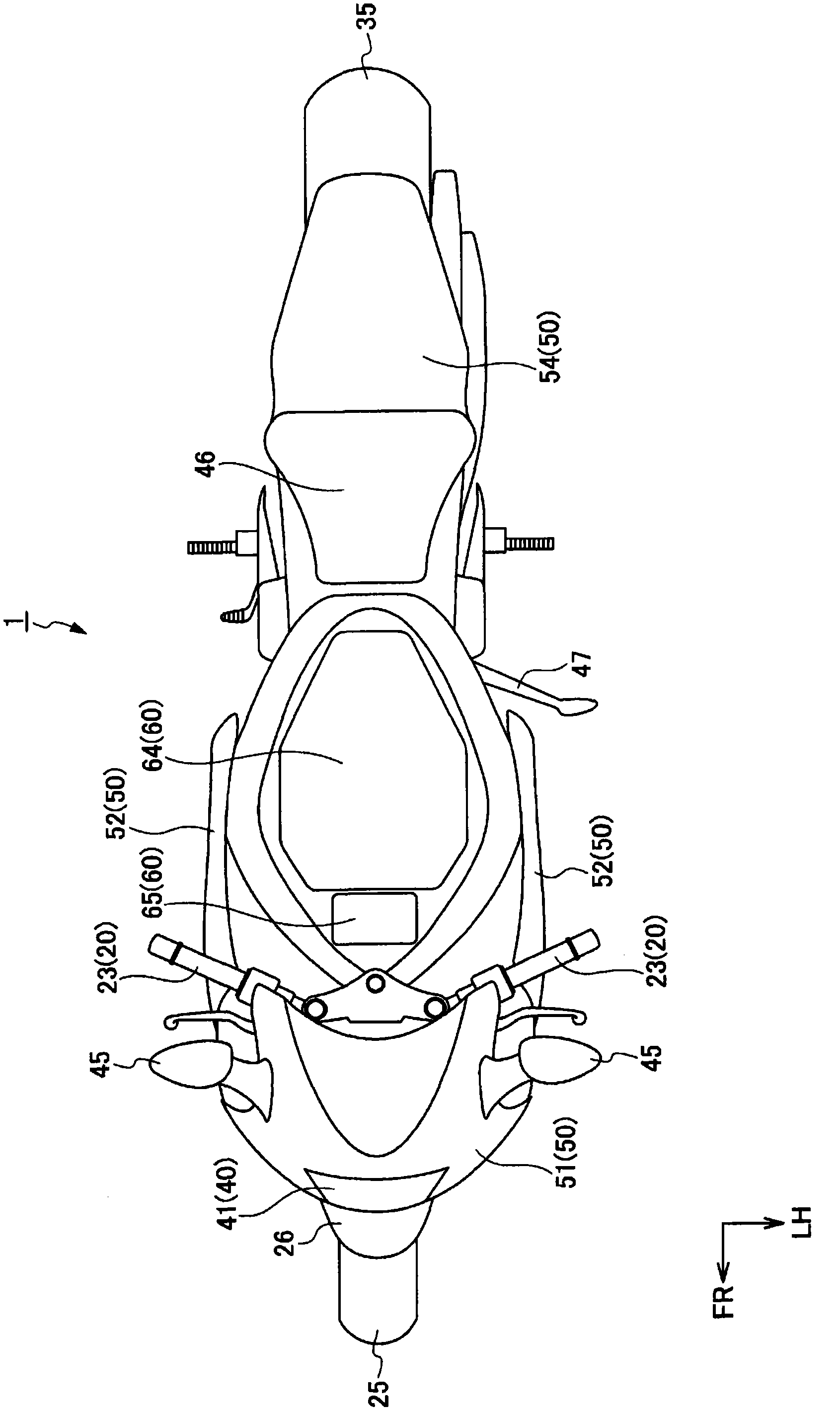

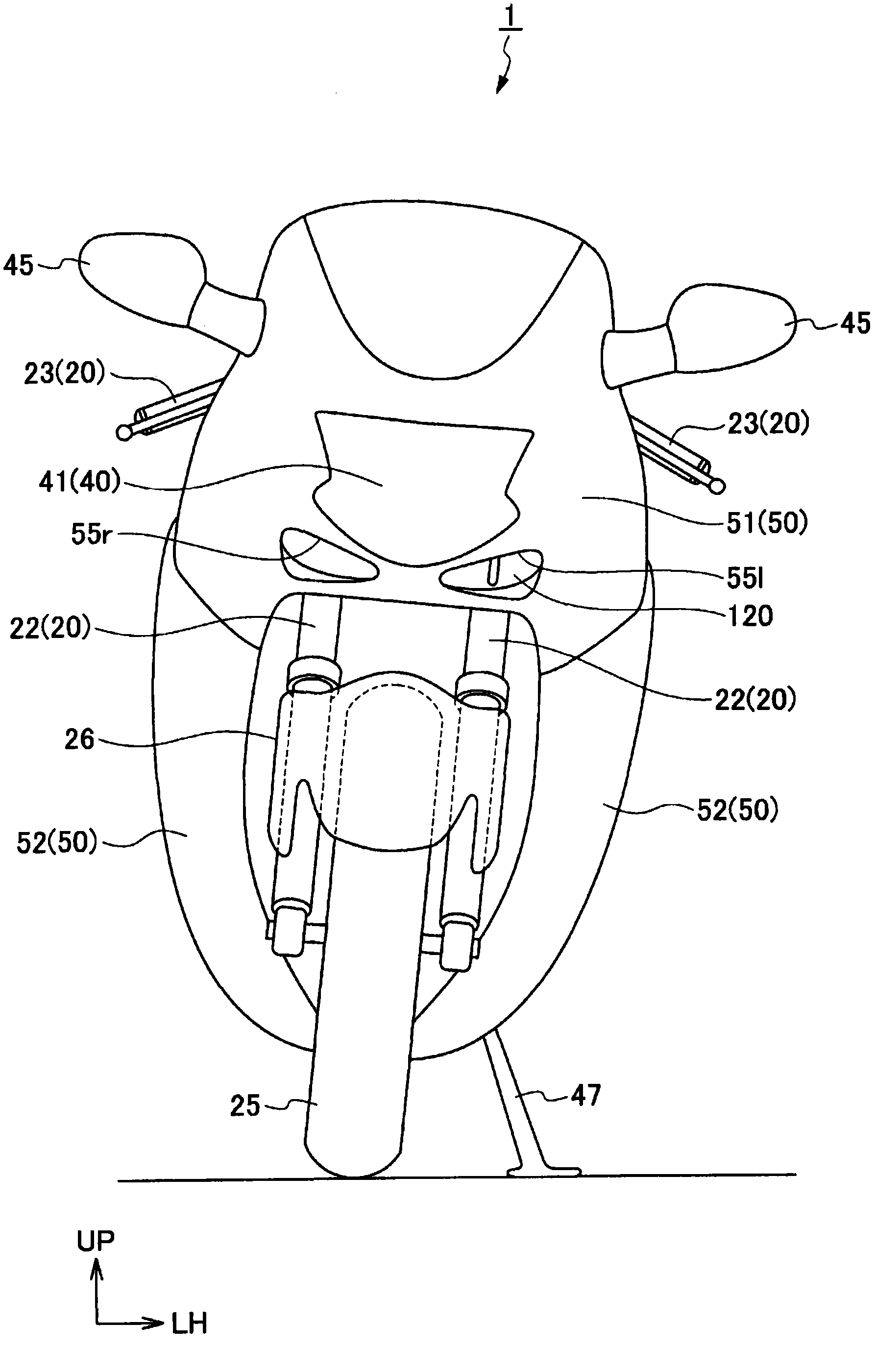

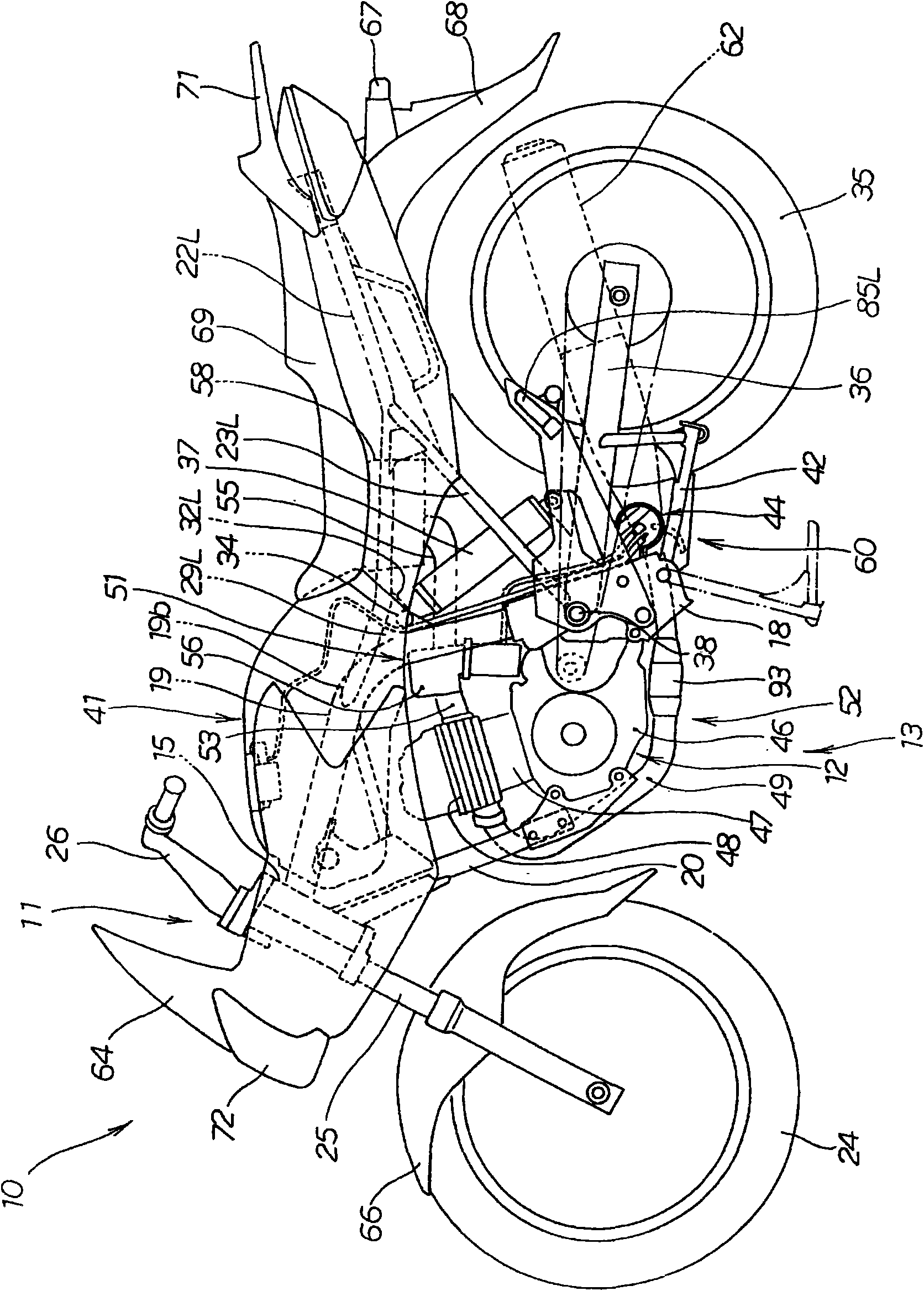

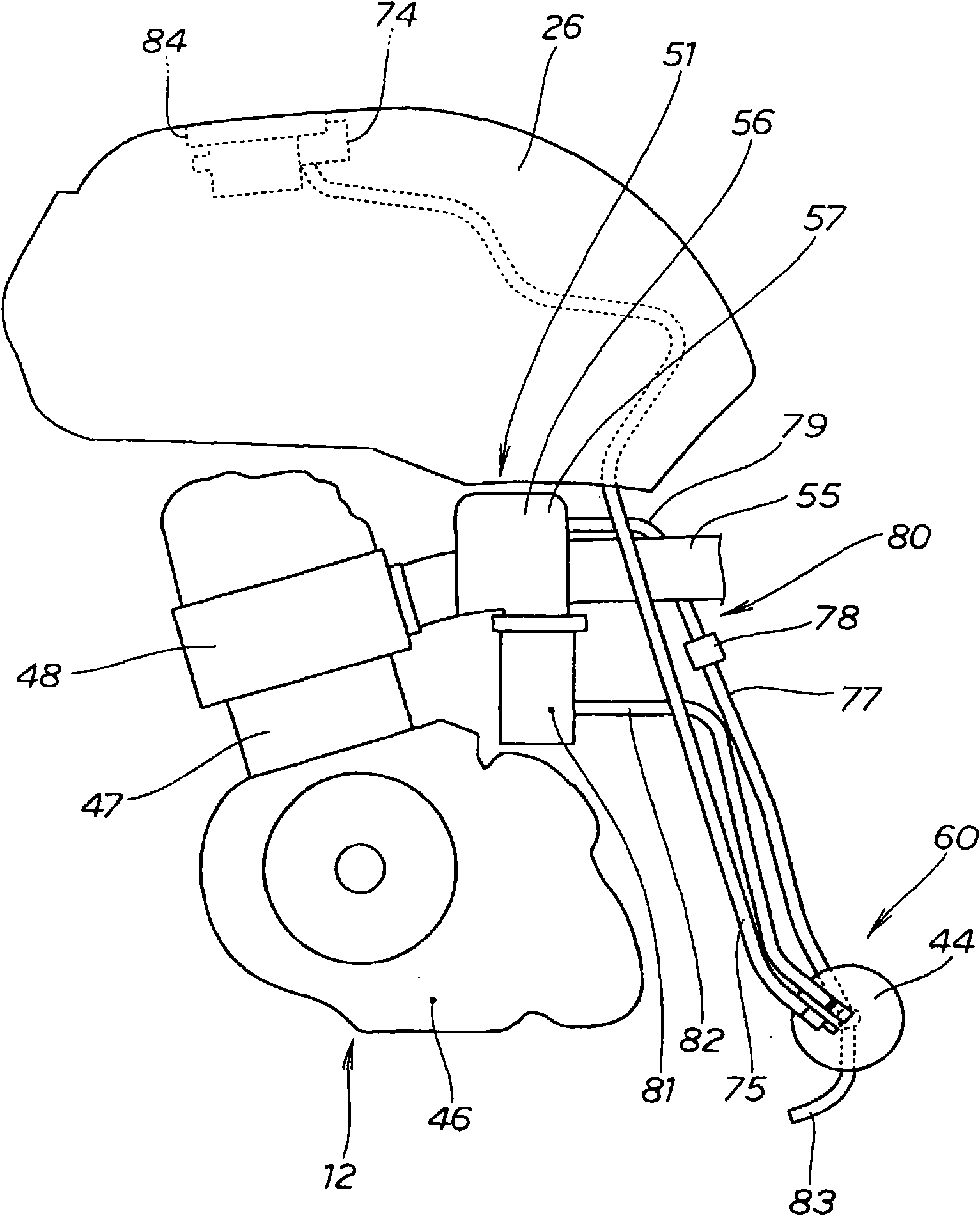

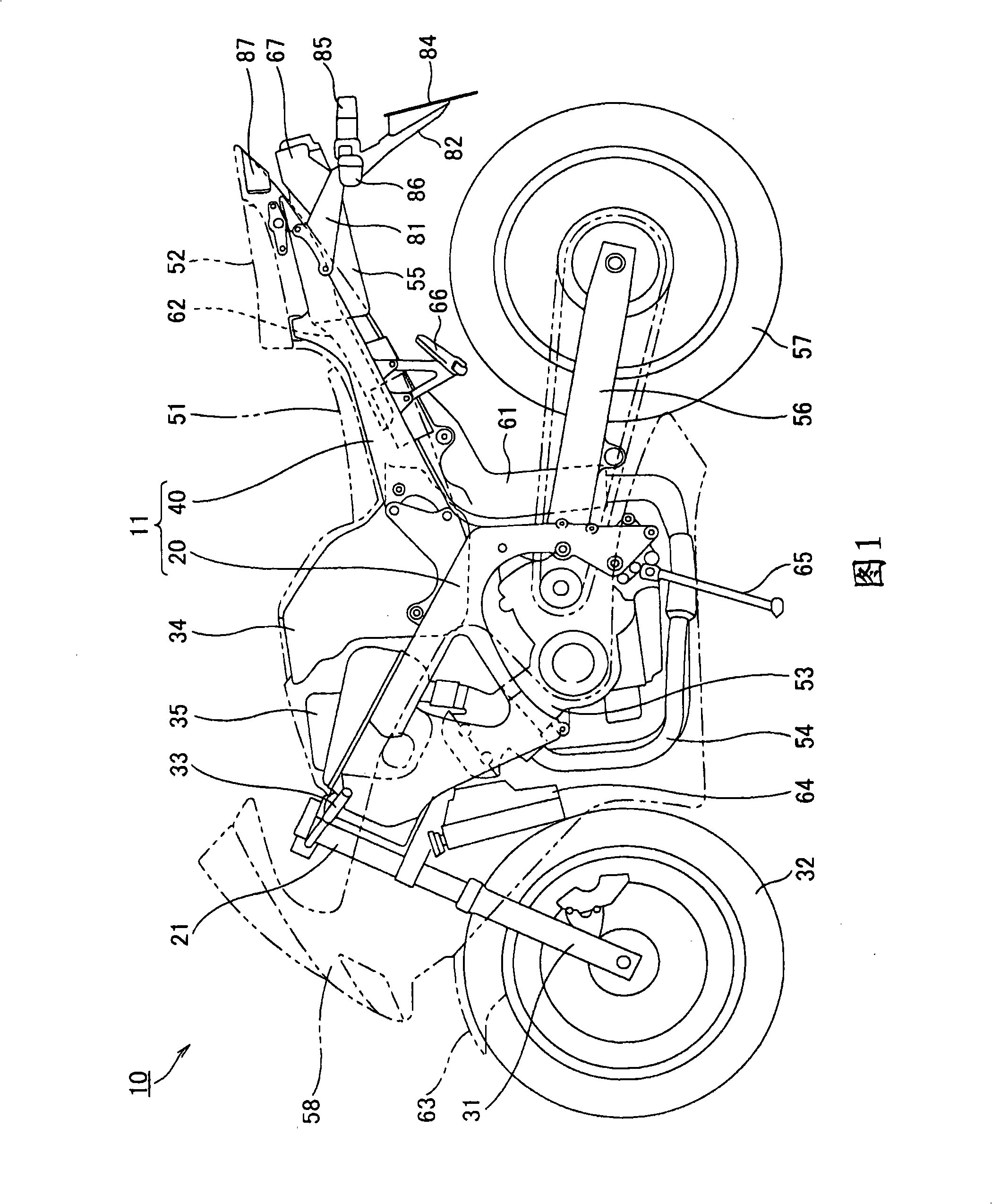

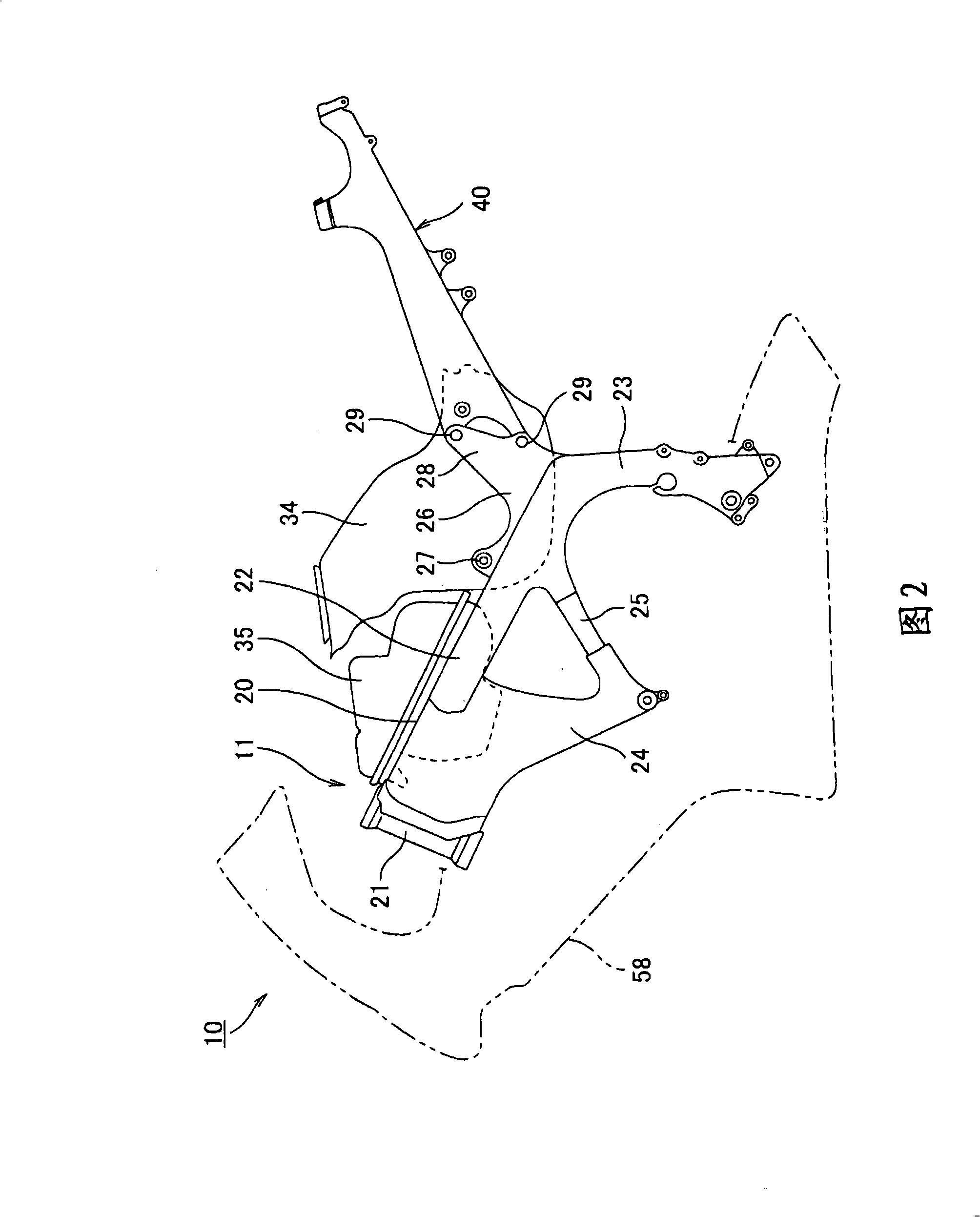

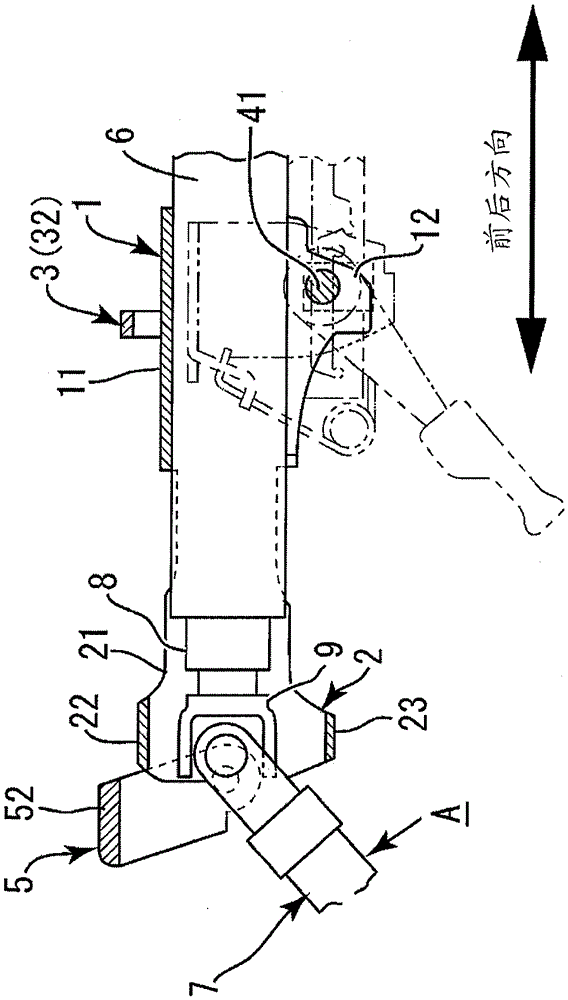

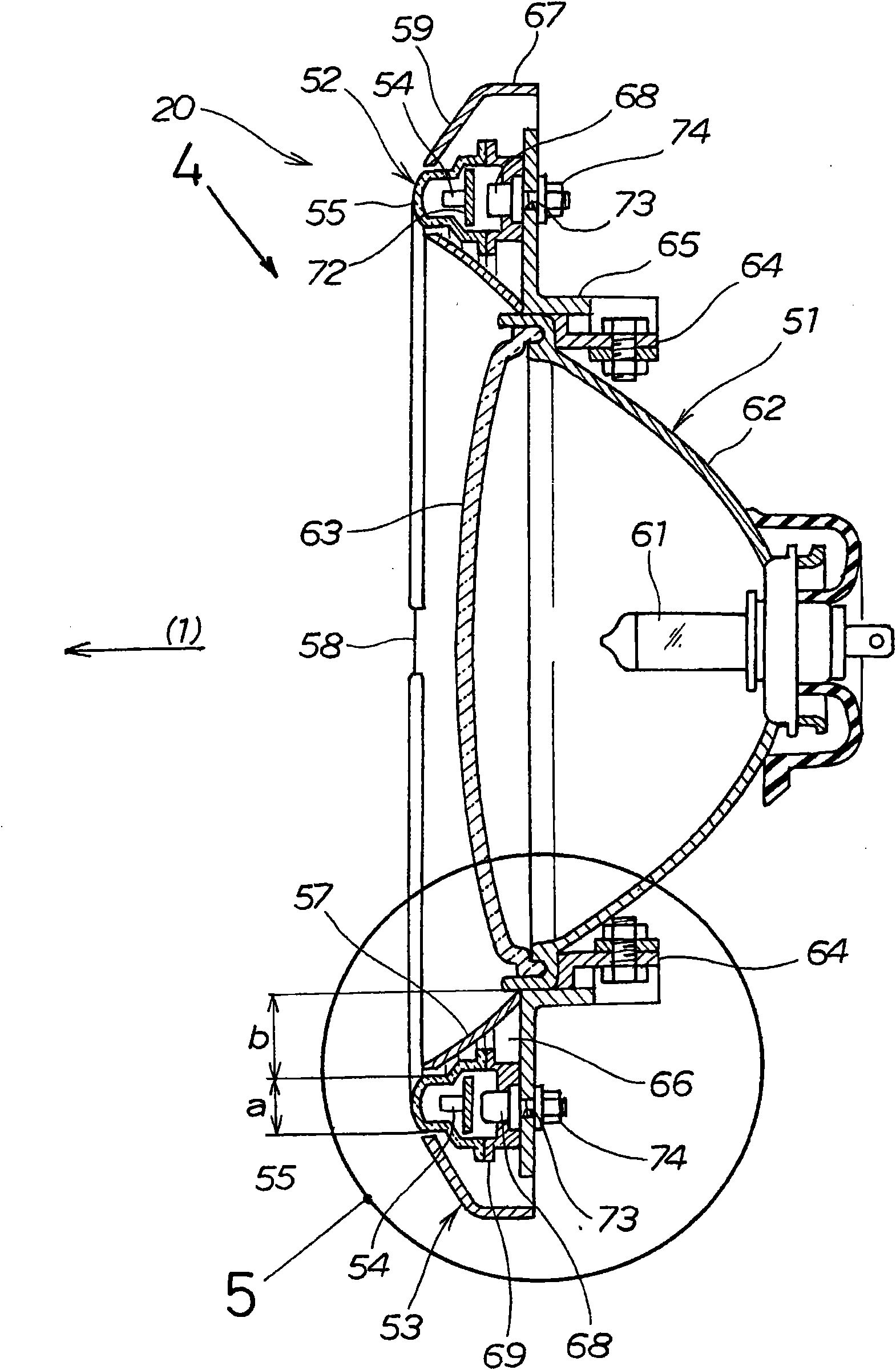

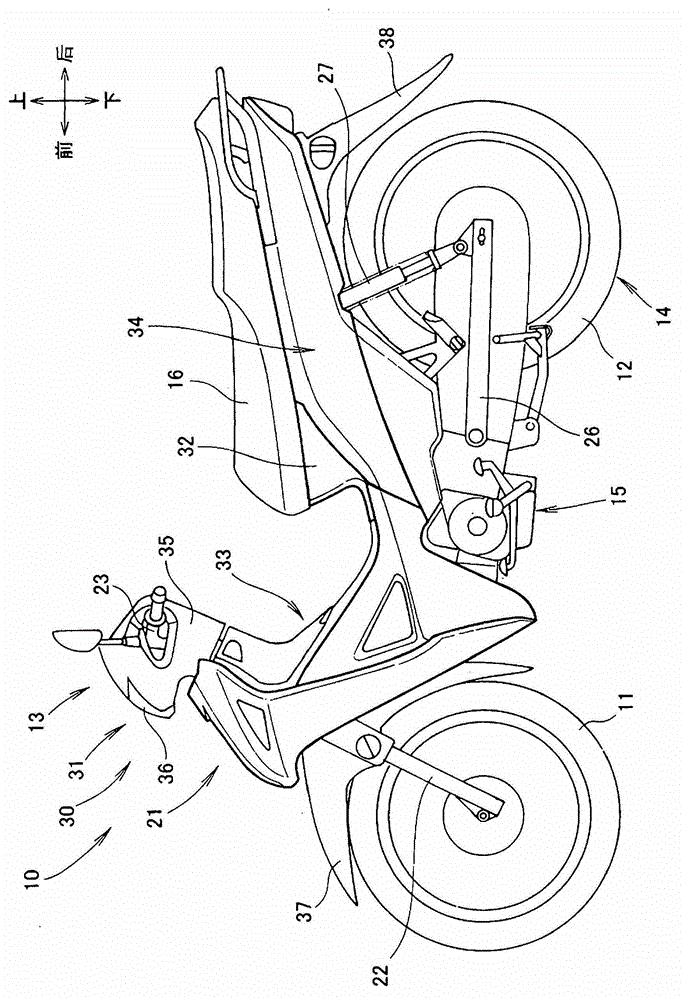

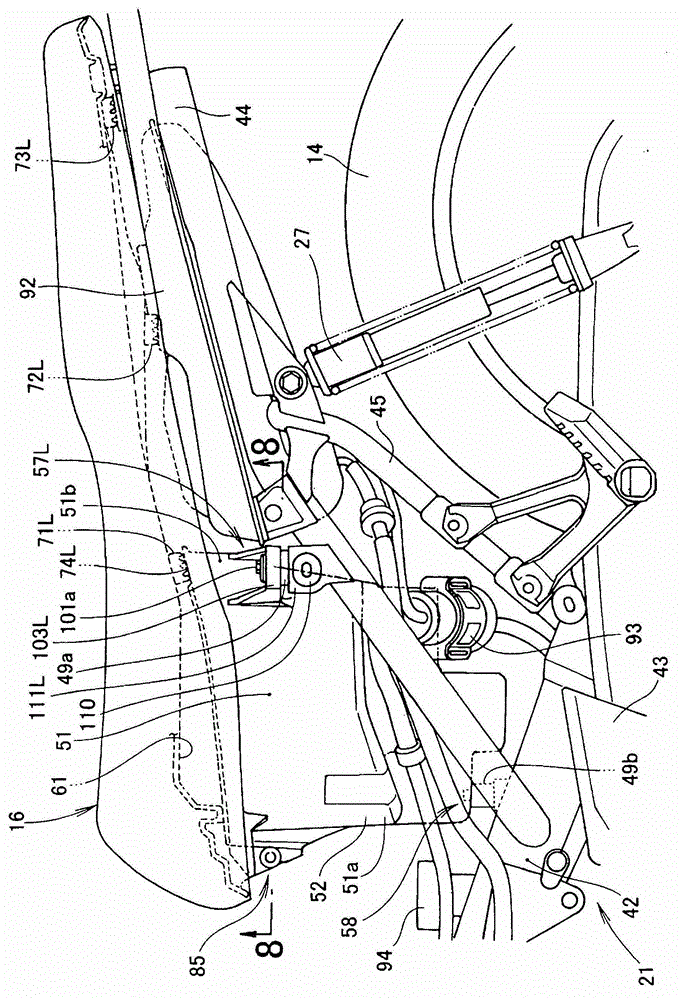

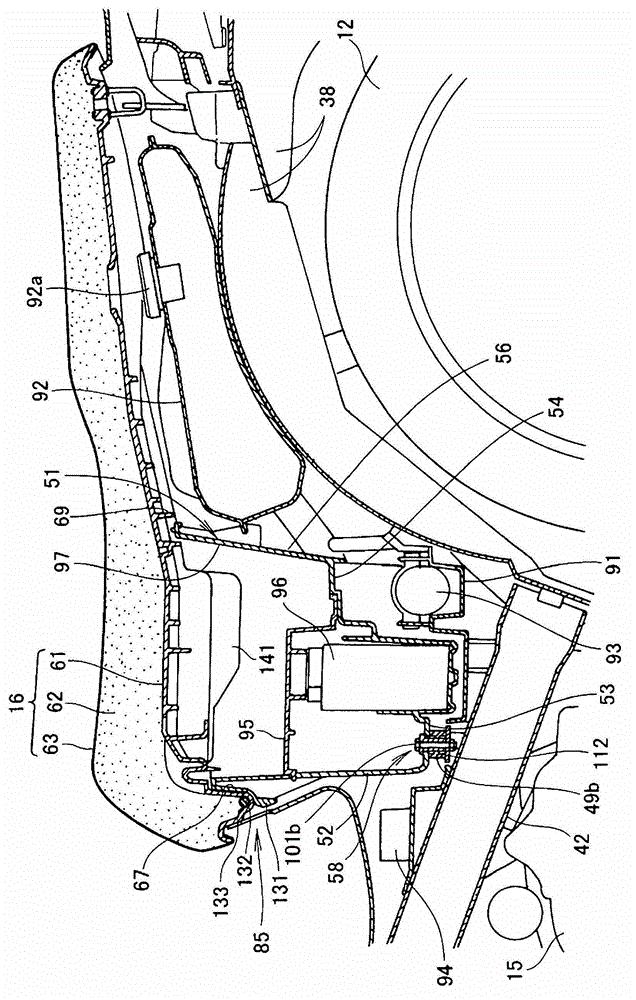

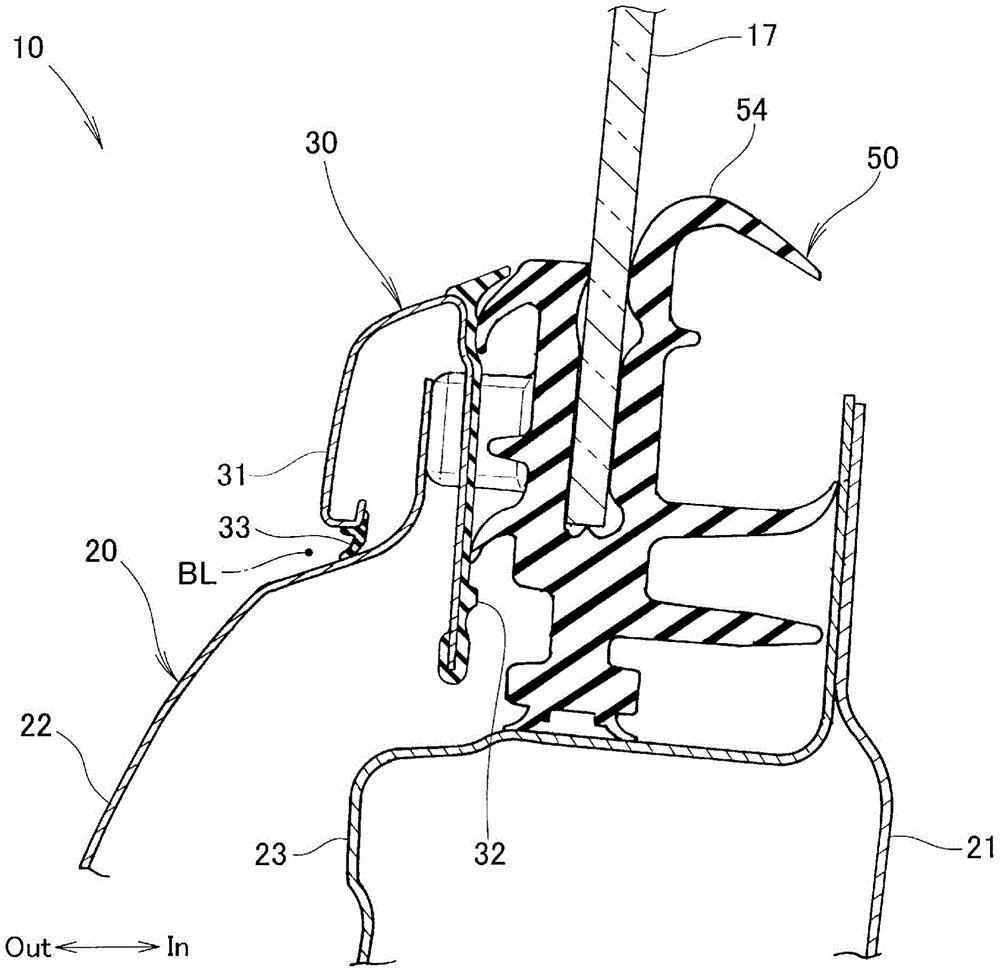

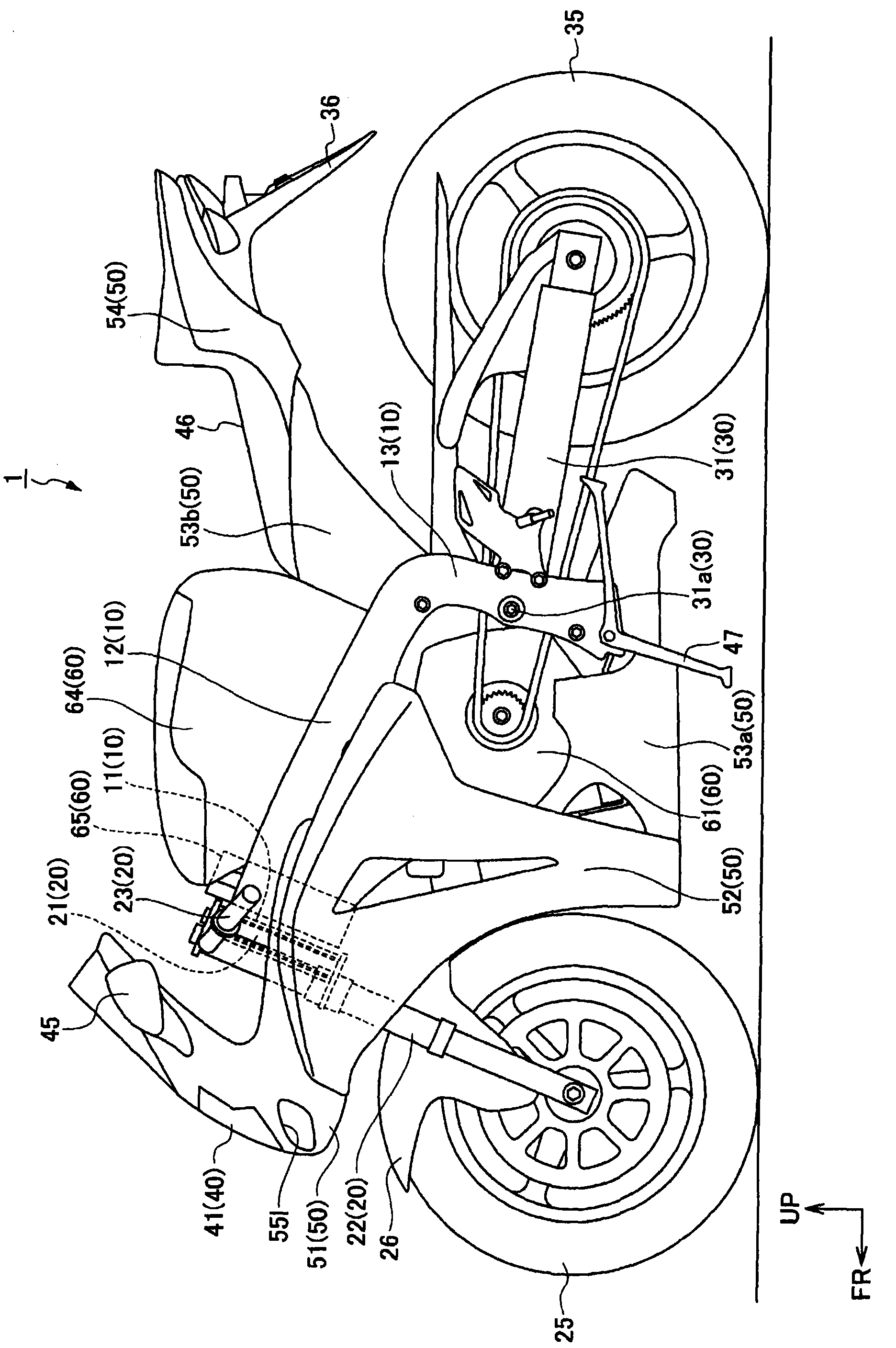

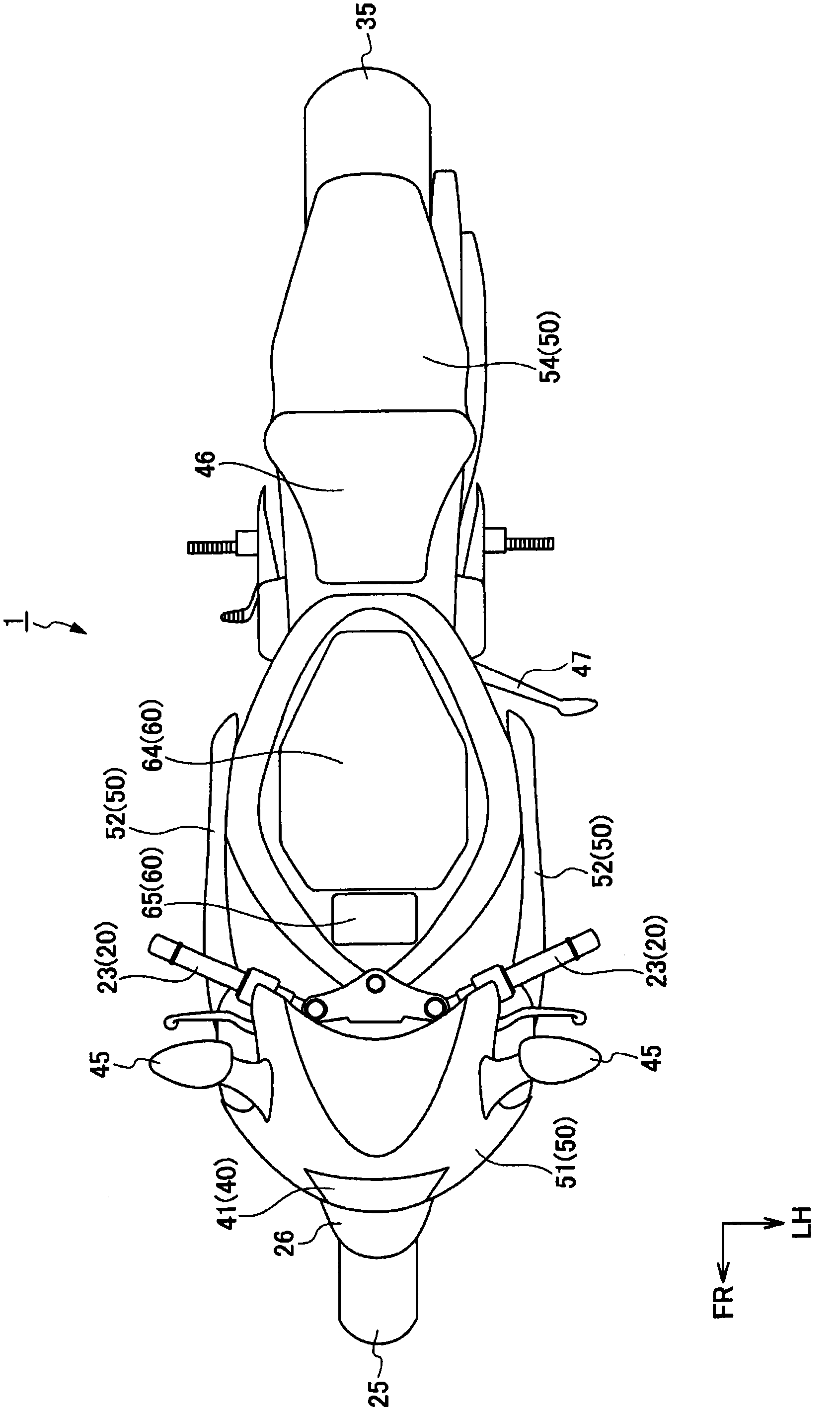

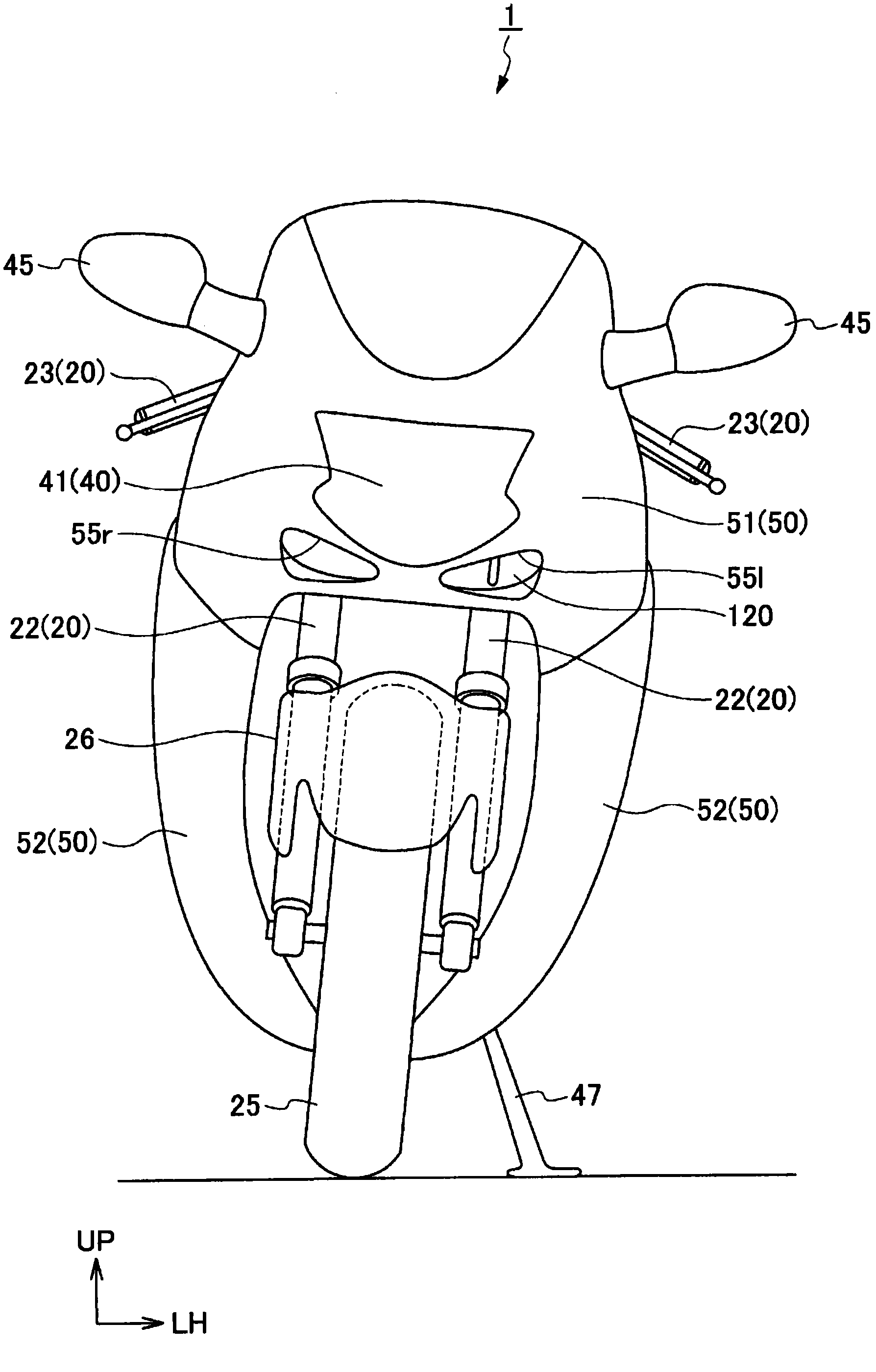

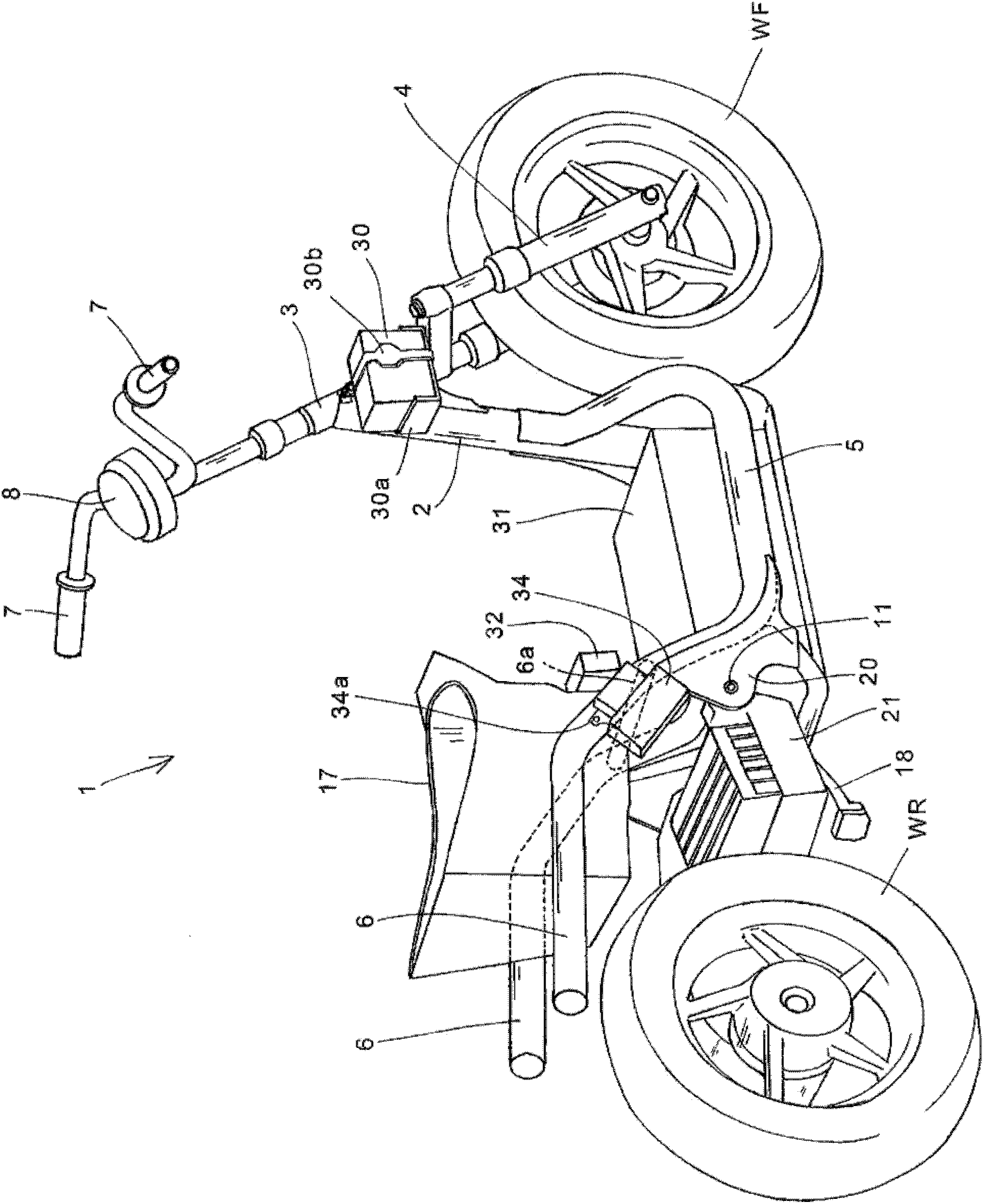

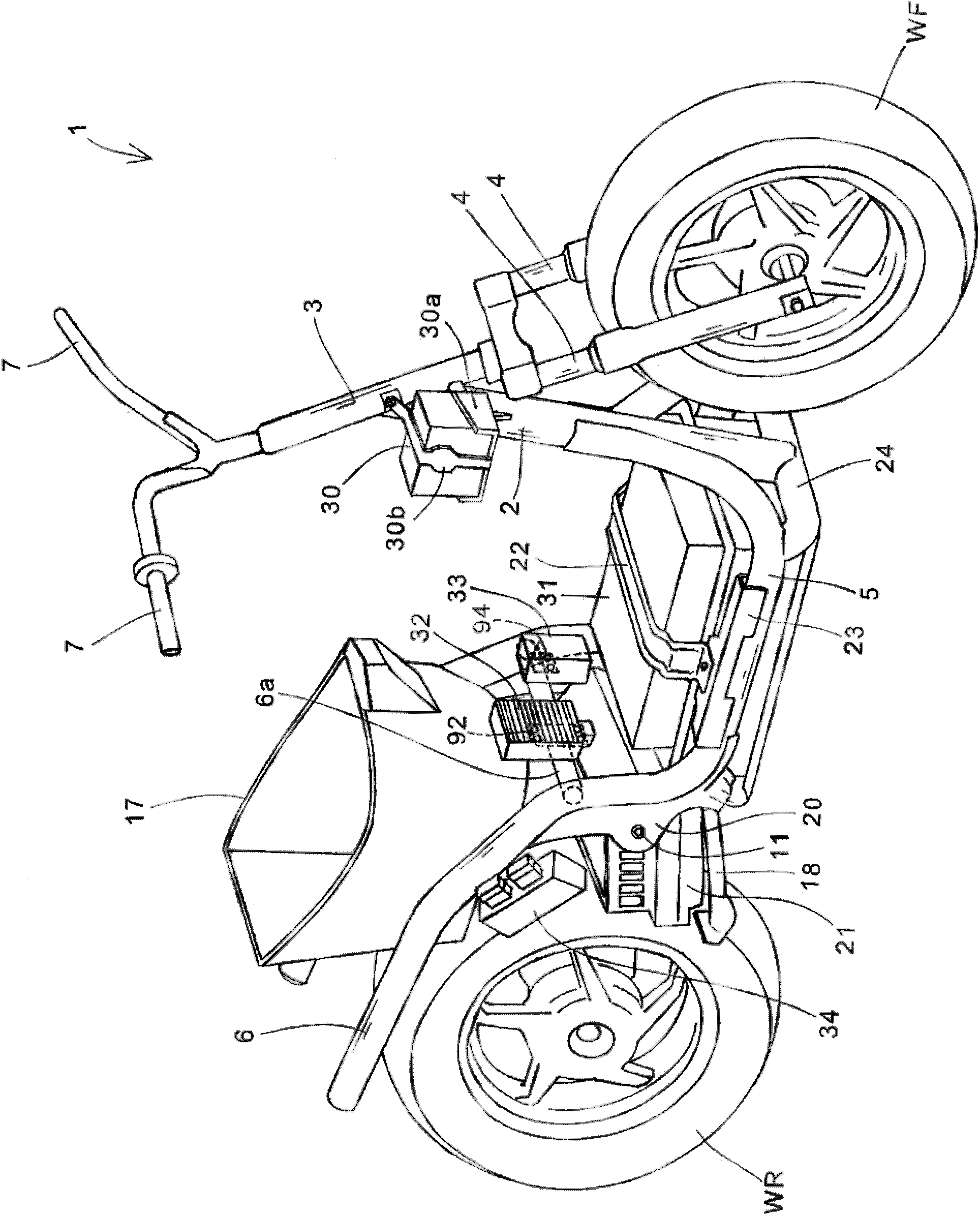

Power connection part receiving structure for straddle type vehicle

ActiveCN102649452AImprove workabilitySeek lightweightVehicular energy storageArticle supporting devicesAutomotive engineeringWater resistance

The invention provides a power connection part receiving structure for a straddle type vehicle, which can reduce the complexity degree of daily charging and achieve good water resistance of the power connection part. The straddle type vehicle comprises a vehicle body rack (10), a steerage device (20) which is maintained on the vehicle body rack with smooth operation, a front wheel (25) which is supported on the steerage device with free rotation, a front rectification cover (51) which covers the front and side parts of the steerage device, a front mud guard (26) which is disposed between the front rectification cover and the front wheel and is fixed on the steerage device, an electric motor (61) disposed on the vehicle body rack, a battery (64) disposed on the vehicle body rack, and a power connection part (130) providing electric power to the battery from the outside of the vehicle. The straddle type vehicle uses the electric motor as the power supply. The front surface side or upper surface side of the front rectification cover at the upper part of the front mud guard is provided with an opening part (110) which can be sealed through a cover component (120). The power connection part (130) is received in the opening part (110).

Owner:HONDA MOTOR CO LTD

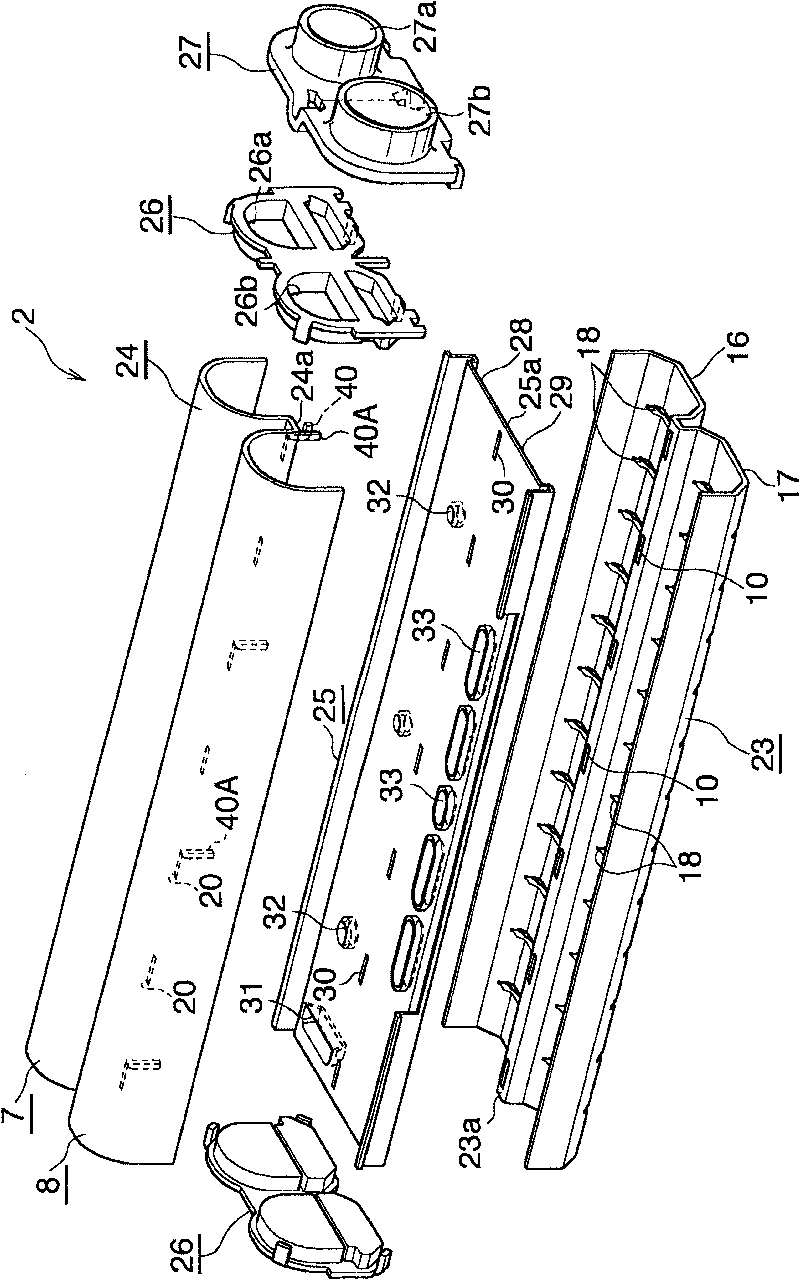

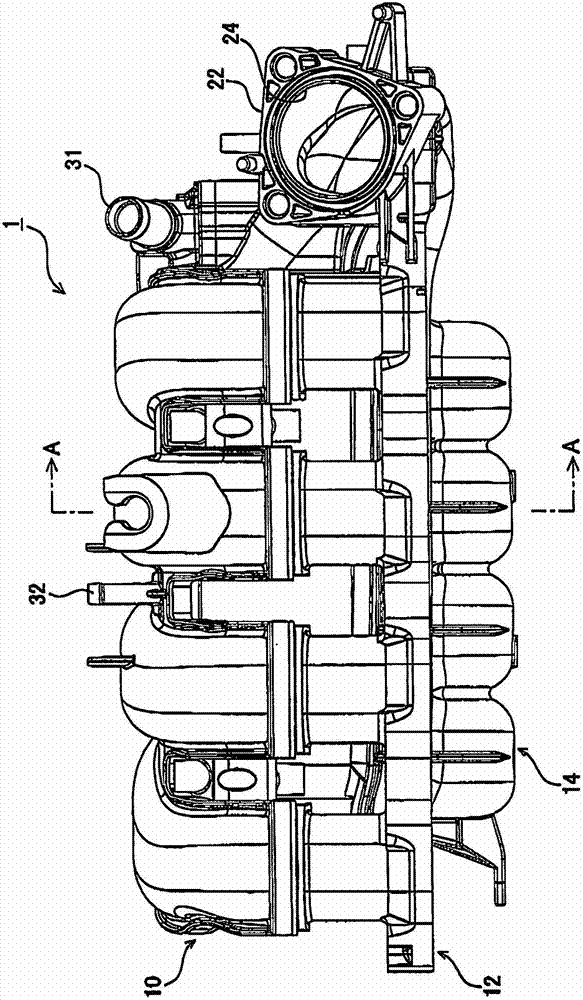

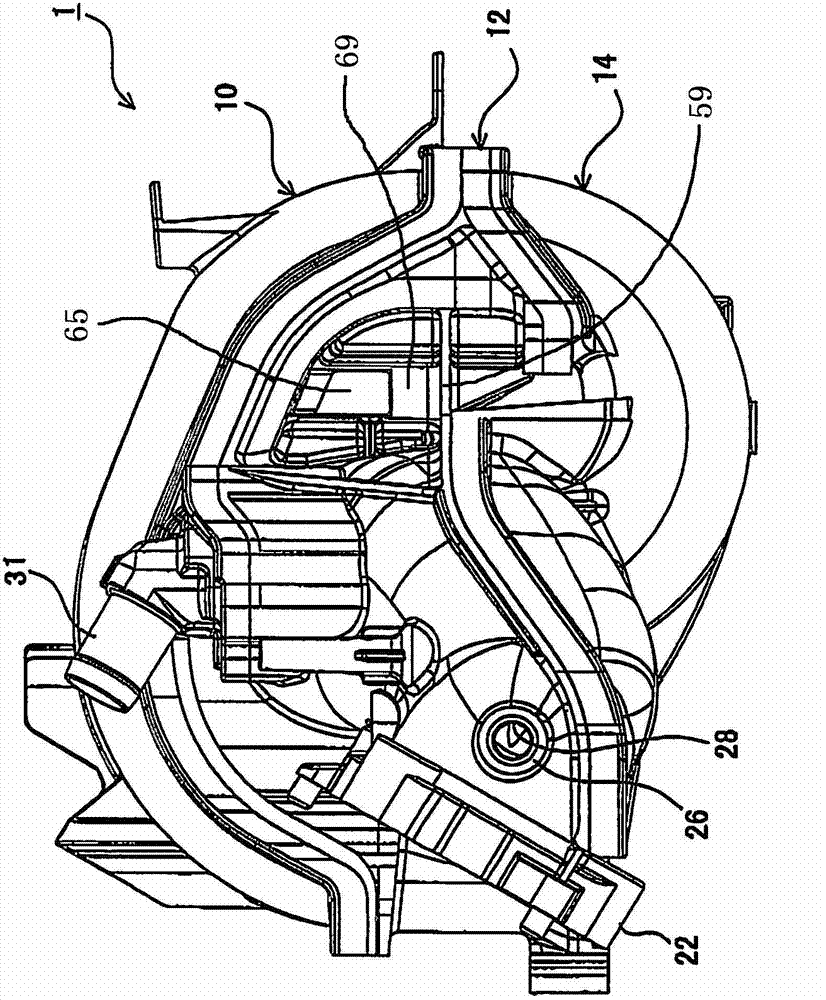

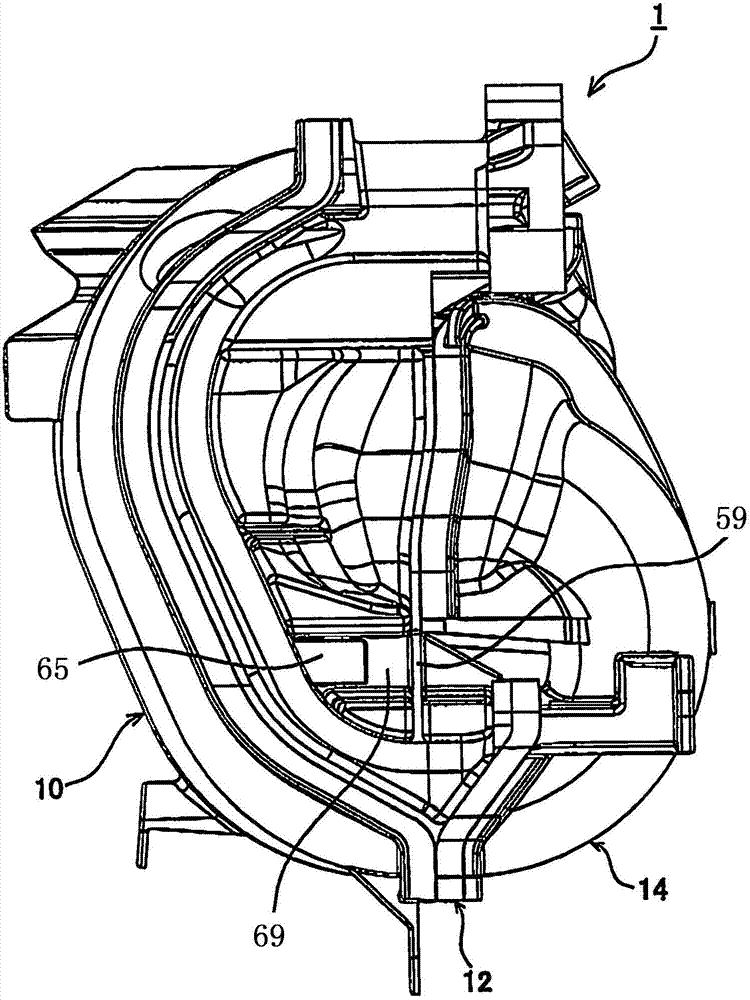

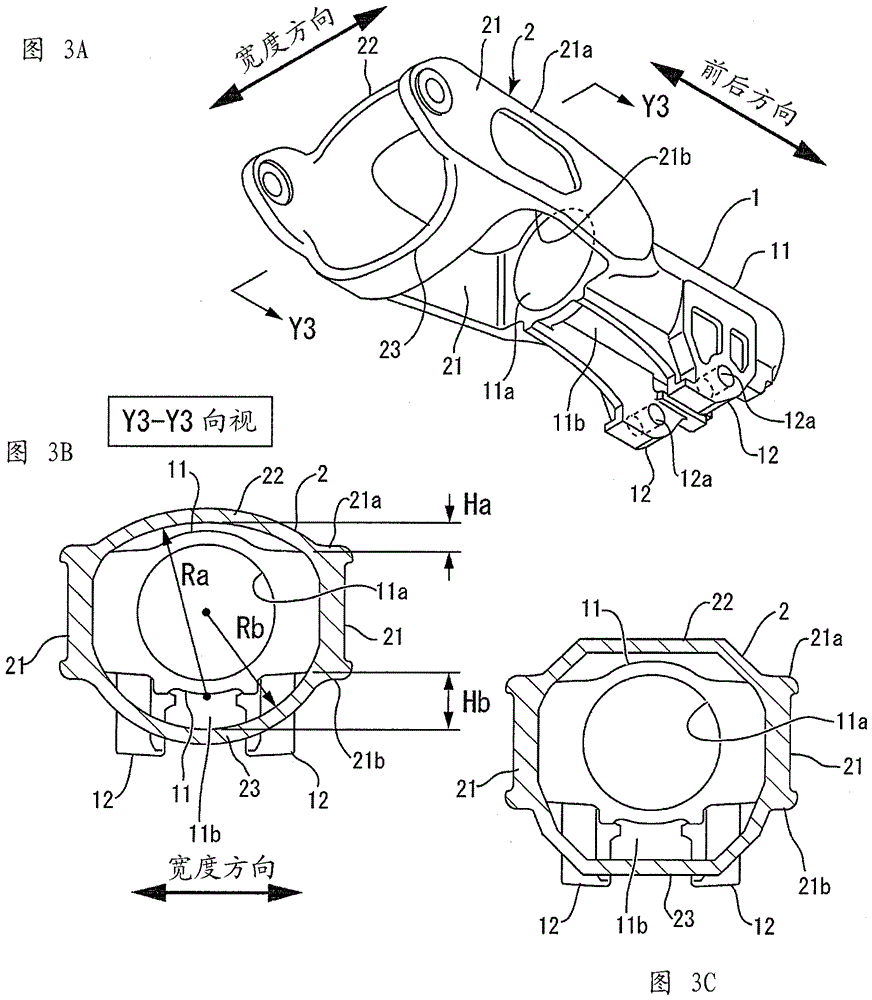

Resin-made intake manifold, method for manufacturing resin-made intake manifold

ActiveCN102817752AInhibition of peripheral wall deformationIncreased durabilityCombustion-air/fuel-air treatmentMachines/enginesCurve shapeBiomedical engineering

The invention provides a resin-made intake manifold and a method for manufacturing resin-made intake manifold. The resin-made intake manifold can reduce manufacturing cost and reduce the volume of a surge tank. The invention provides a resin-made intake manifold (1) which has a central member (12) and a lower member (14), and the surge tank (18) is formed between the central member (12) and the lower member (14). The intake manifold (1) forms a branch passage (16) communicating with the surge tank (18), wherein the lower member (14) is an integrally molded product by the resin and comprises: a curve-shaped curved channel (20) which constitutes a part of the branch passage (16); and a wall portion (52), which is formed at the inner circumferential side of the curved shape of the curved conduit (20), from a passage port (34) of the curved channel (20) and the surge tank (18) to the central member (12) side, and forms the side wall of the surge tank (18).

Owner:AISAN IND CO LTD

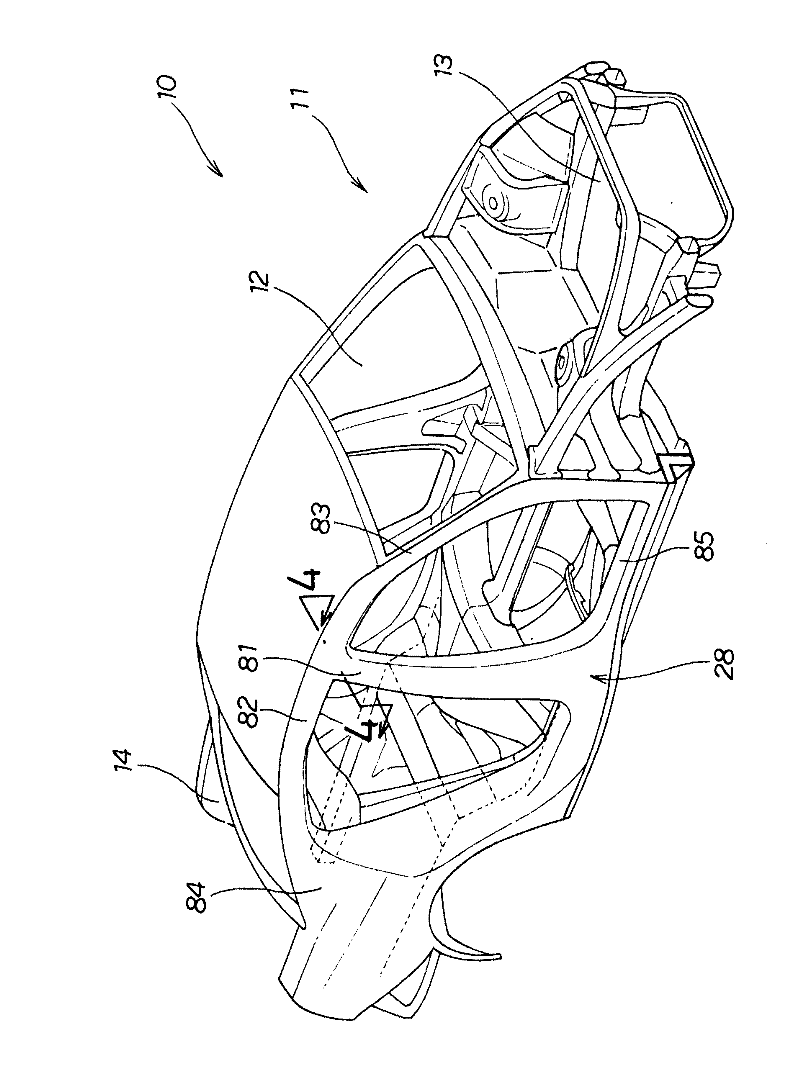

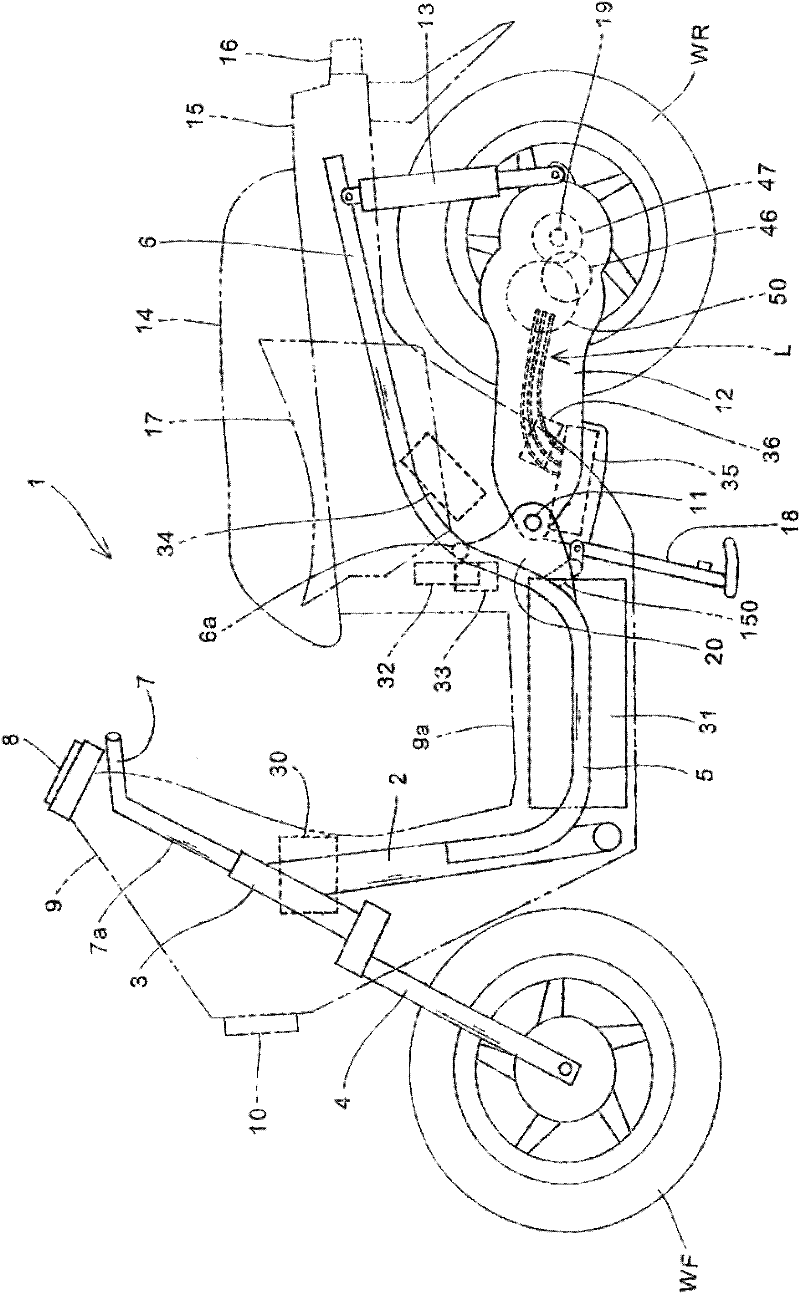

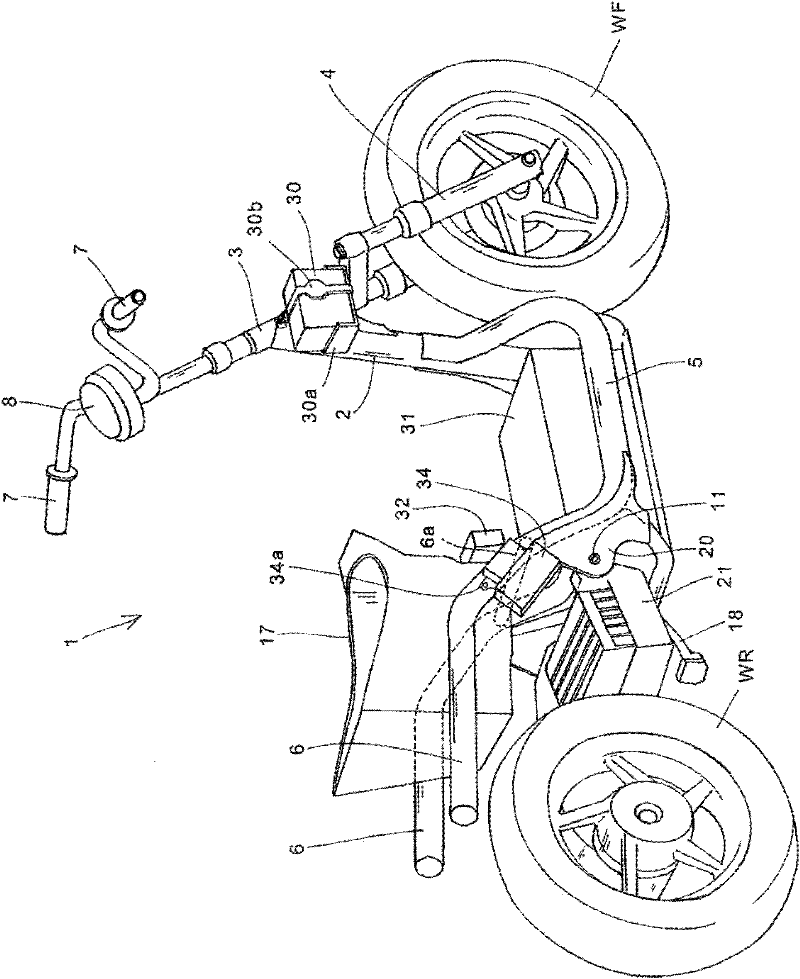

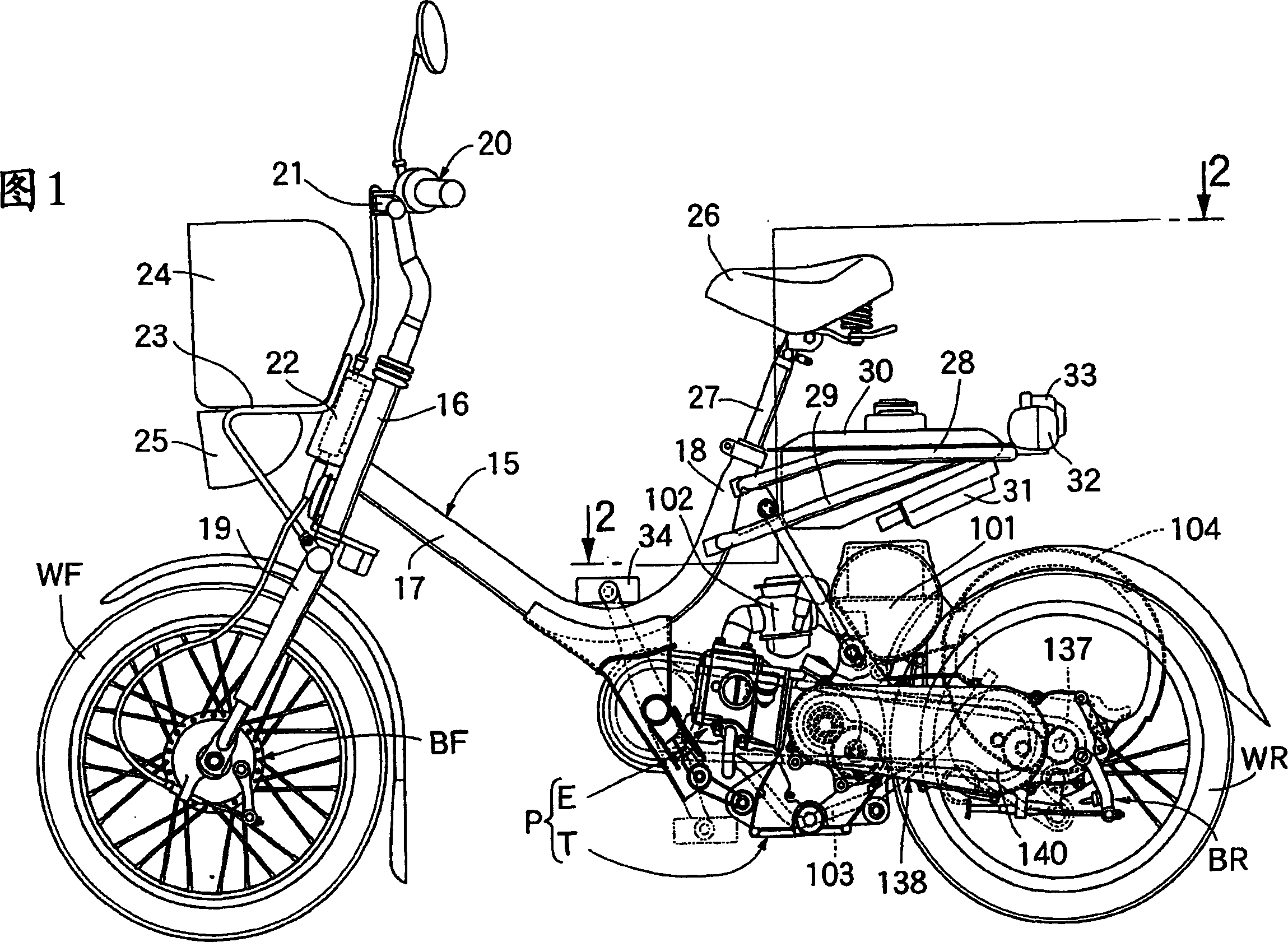

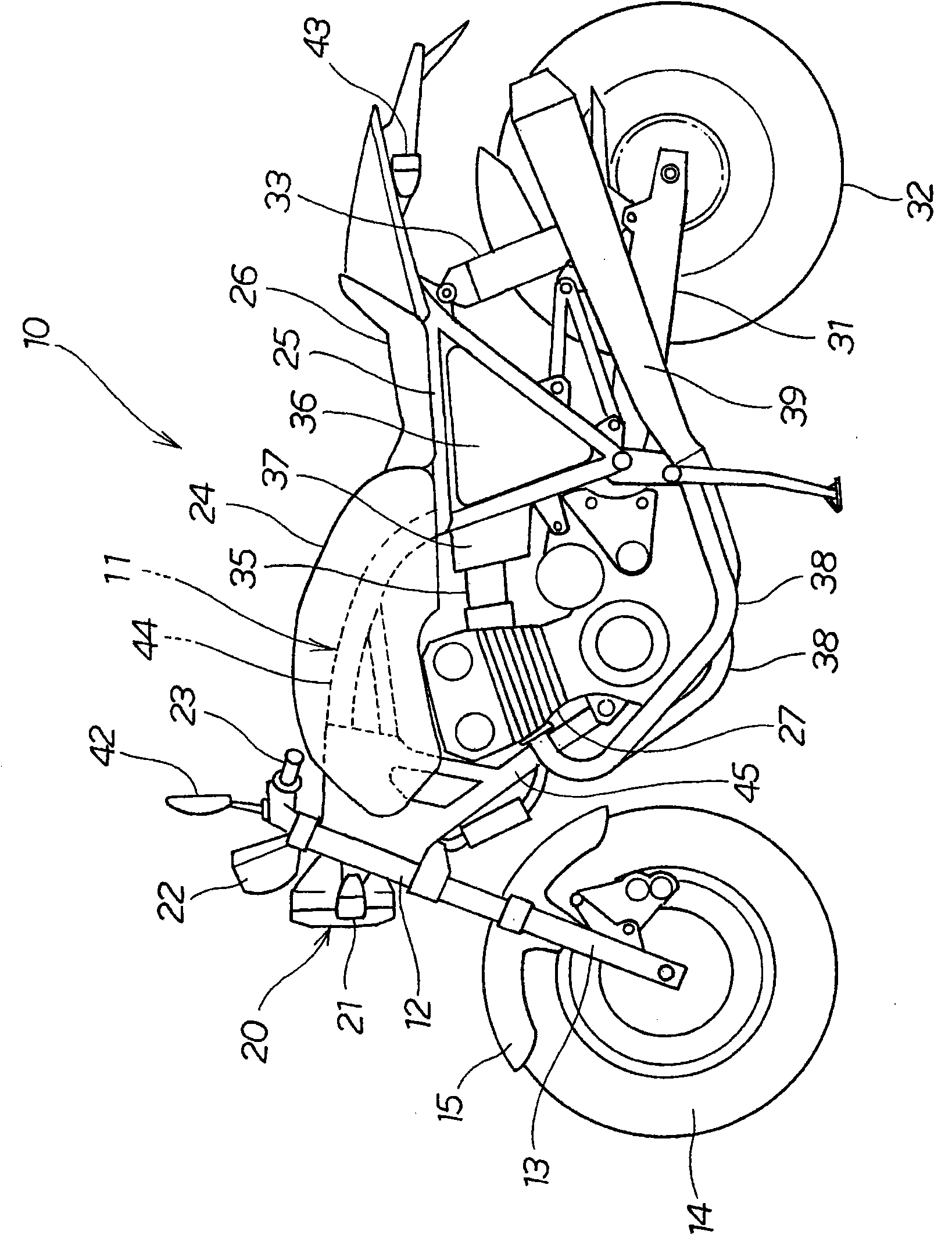

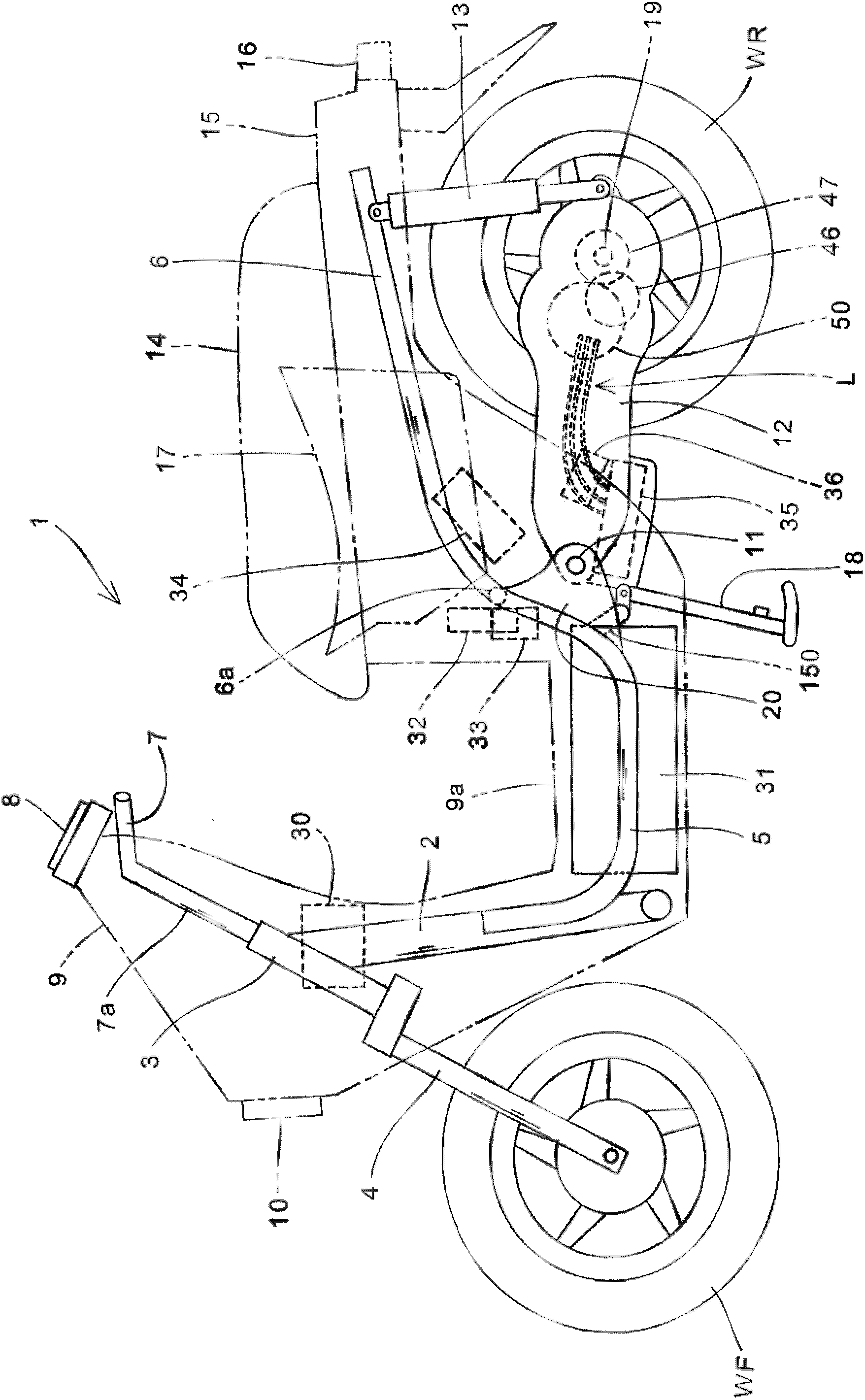

Canister layout structure in motorcycle

ActiveCN101659297AReduce the number of piecesSeek lightweightAxle suspensionsFuel tanksVehicle frameFuel tank

It is an object of the present invention to provide a technique which can reduce the number of parts and the weight of a vehicle body in a motorcycle having a canister at a lower portion of the vehicle body. A canister layout structure in a motorcycle includes a swing arm vertically swingably supported to a rear portion of a body frame and supporting a wheel, a canister located below the swing arm for trapping an evaporative fuel evaporated in a fuel tank, and a center stand pivotably supported to a lower portion of the body frame for making the body frame stand on a road surface when parking. The center stand is retractable to keep a horizontal position substantially parallel to a road surface during running. The canister is located above the center stand in its retracted condition.

Owner:HONDA MOTOR CO LTD

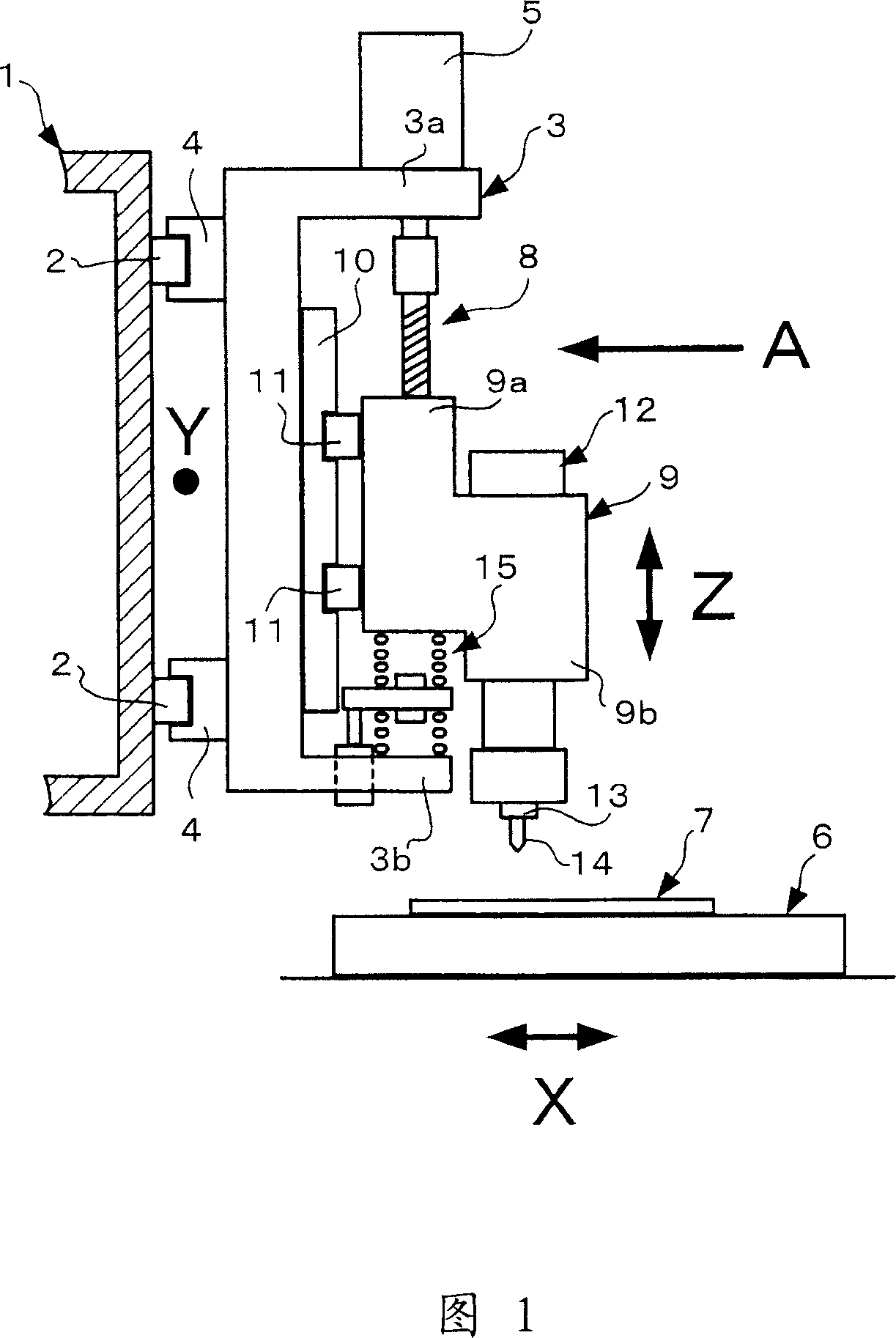

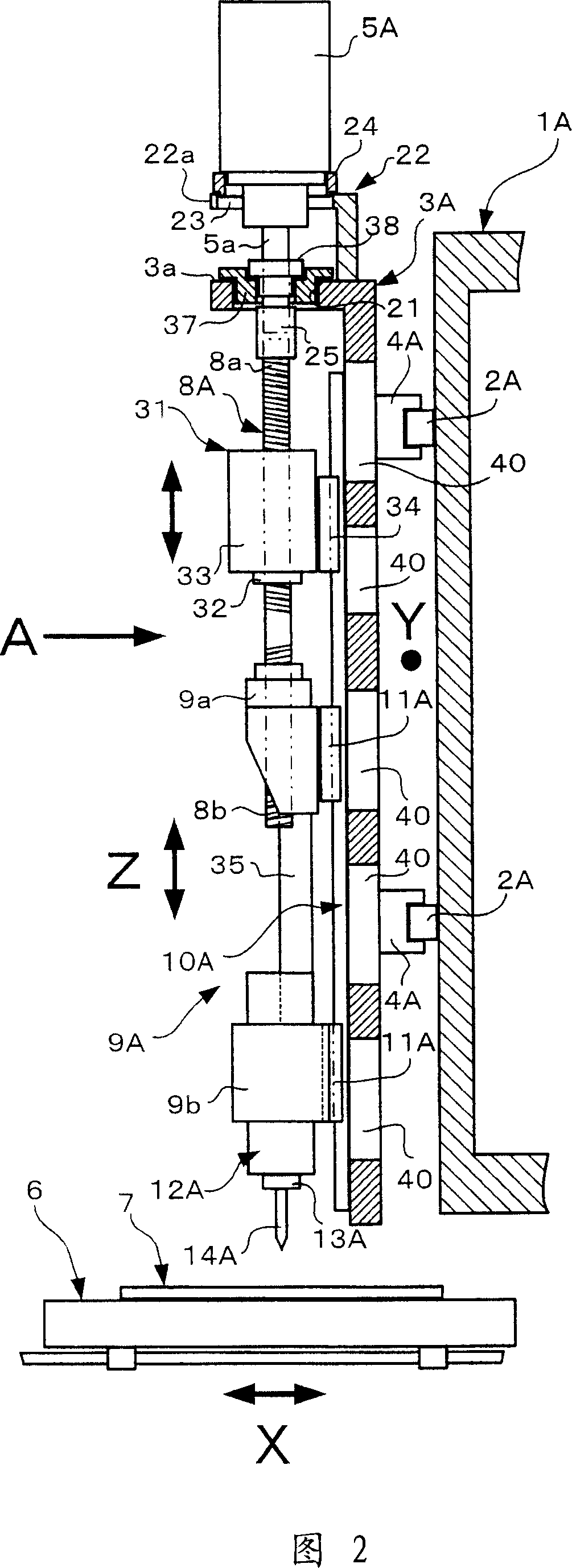

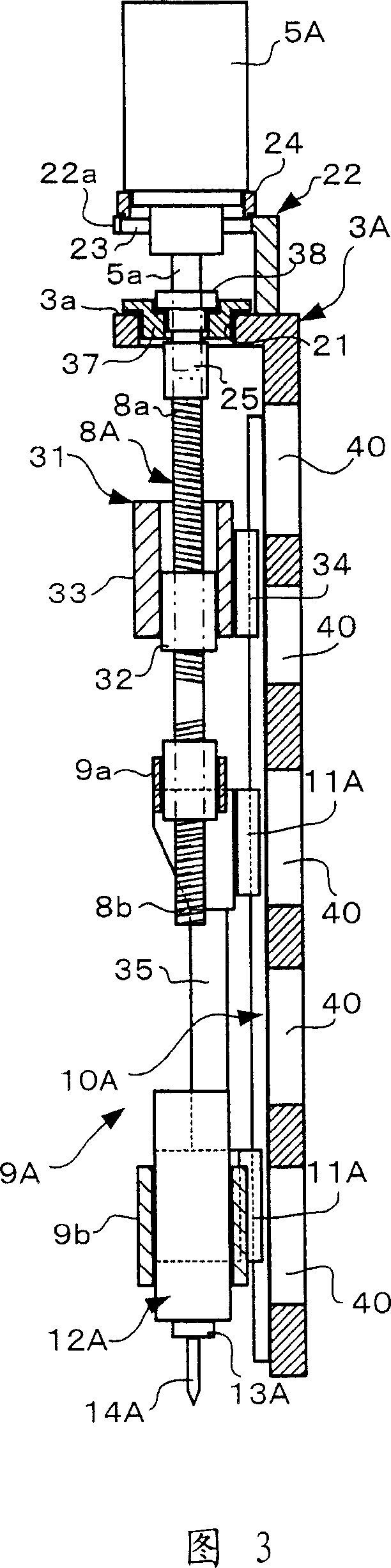

The drilling processing machine for printed circuit boards

InactiveCN101015866AAvoid breakingSimple configurationPrinted circuit manufactureAdverse effect compensationDrive motorDrill bit

Owner:TAKEUCHI

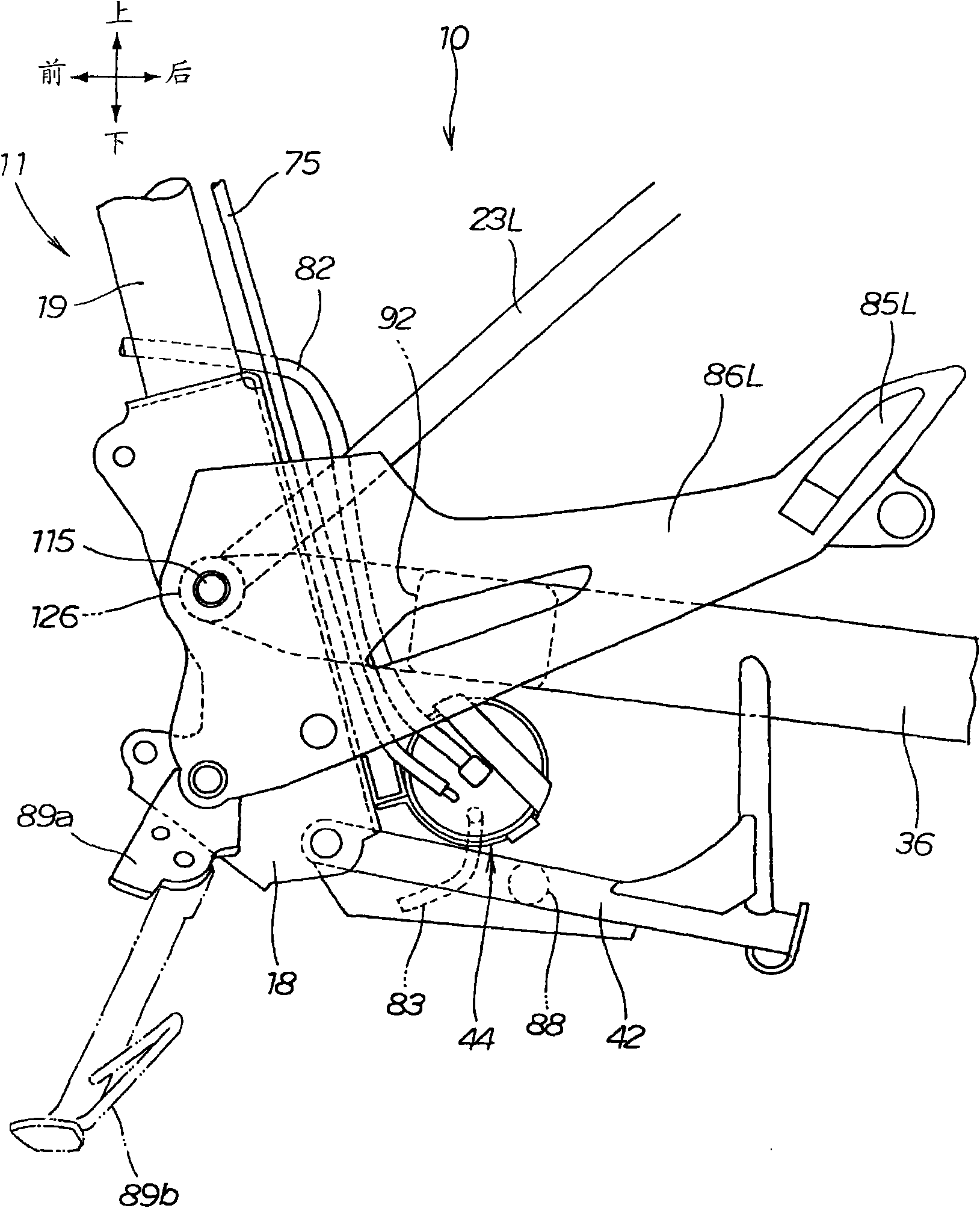

Electric straddled vehicle

ActiveCN102448806AImprove versatilityImproved weight balanceMotorised scootersAxle suspensionsAutomotive engineeringEngineering

An electric straddled vehicle which has, despite the fact that the vehicle is a lightweight and inexpensive vehicle using a small-sized, highly versatile motor, the balance of weight in the left-right in the width direction of the vehicle relative to the vehicle body centerline is optimized. An electric motor (250) is disposed within a cantilever swing arm (214) at a position at which, when viewed from a side of the vehicle body, the electric motor is superposed on the region in which a rear wheel (WR) is projected. A motor driver (216) is disposed within the swing arm (214) so as to straddlethe vehicle body centerline (C) at a position in front of the rear wheel (WR) relative to the vehicle body. The motor driver (216) is disposed in such a manner that the position (G2) of the center ofgravity thereof is offset to the side opposite to the side to which the electric motor (250) is offset from the vehicle body centerline (C). The motor driver (216) is provided behind a rocking shaft (215) relative to the vehicle body at a position close to the rocking shaft (215) and is inserted and mounted to a recess (308) open to the upper surface side of the swing arm (214). An FET (316) for conducting and interrupting an electric current to the motor is at least supported on the lower surface of a lid member (264) of the motor driver (216).

Owner:HONDA MOTOR CO LTD

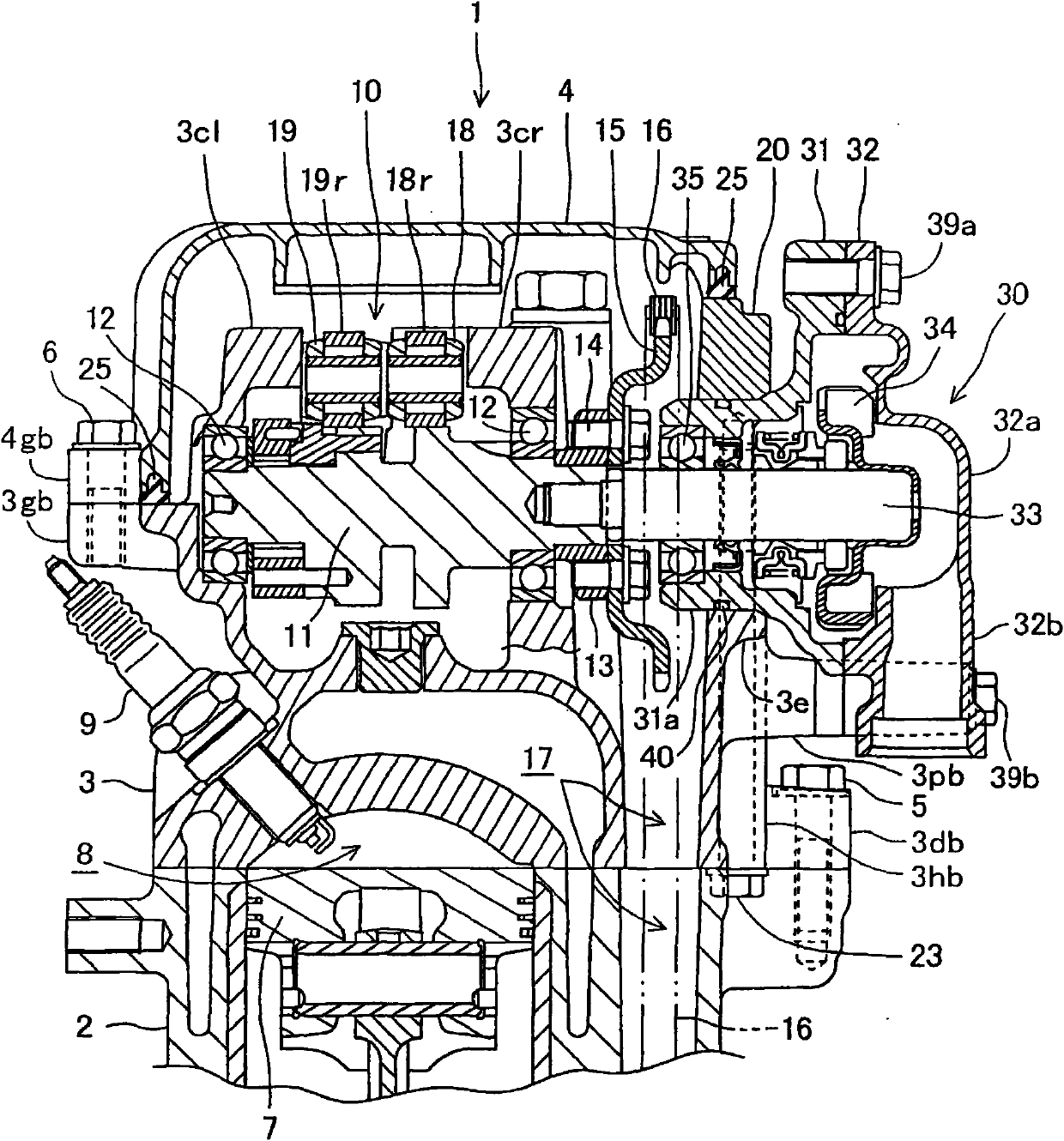

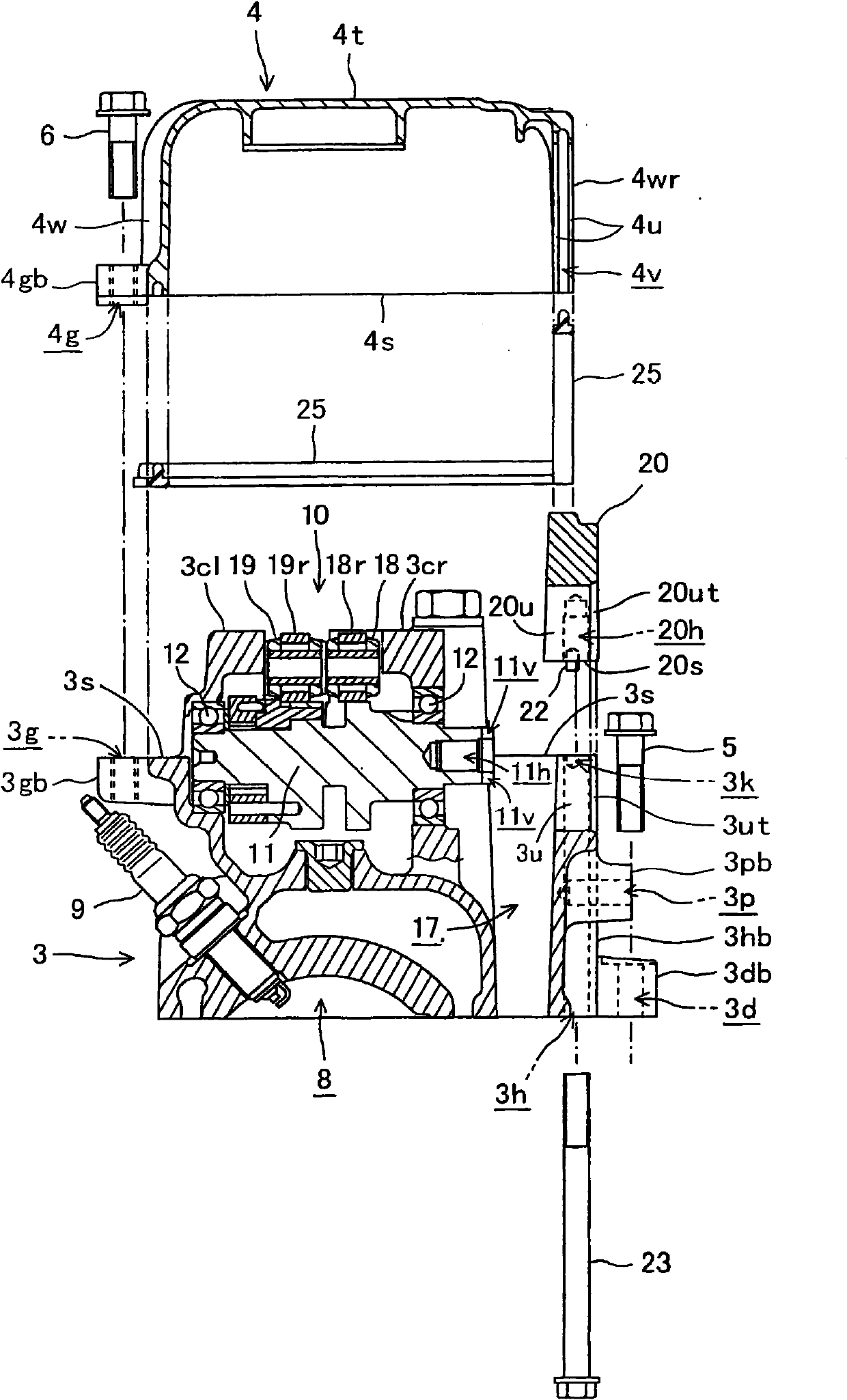

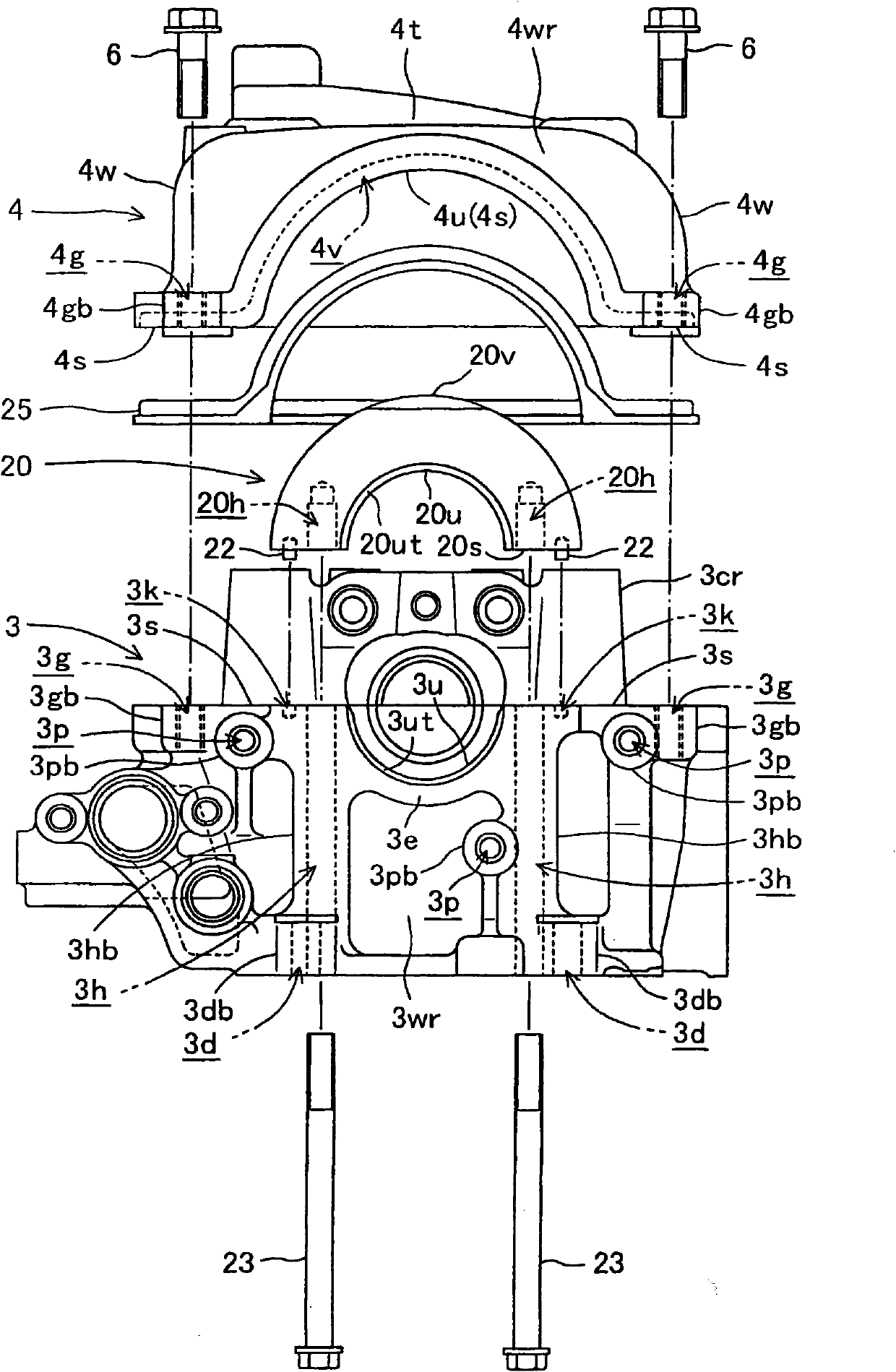

Water pump attachment structure of water-cooled internal combustion engine

A water pump attachment structure of a water-cooled internal combustion engine is provided that can facilitate the maintenance of a valve train. A water pump attachment structure of a water-cooled internal combustion engine is as below. A semicircular cut-away surface (20u) of a water pump holder (20) is opposed to a semicircular surface (3u) of a cylinder head (3) to form a water pump support circular hole (21). Screw members (39b) are passed through respective screw through-holes (3h) of the cylinder head (3) and threadedly engaged with internal thread holes (20h) of the water pump holder (20). Thus, the water pump holder (20) is fastened to the cylinder head (3). A water pump (30) is fitted into and secured to the water pump support circular hole (21). A cylinder head cover (4) is attached to the cylinder head (3) by allowing their mating surfaces to conform with each other with the water pump holder (20) liquid-tightly sandwiched therebetween.

Owner:HONDA MOTOR CO LTD

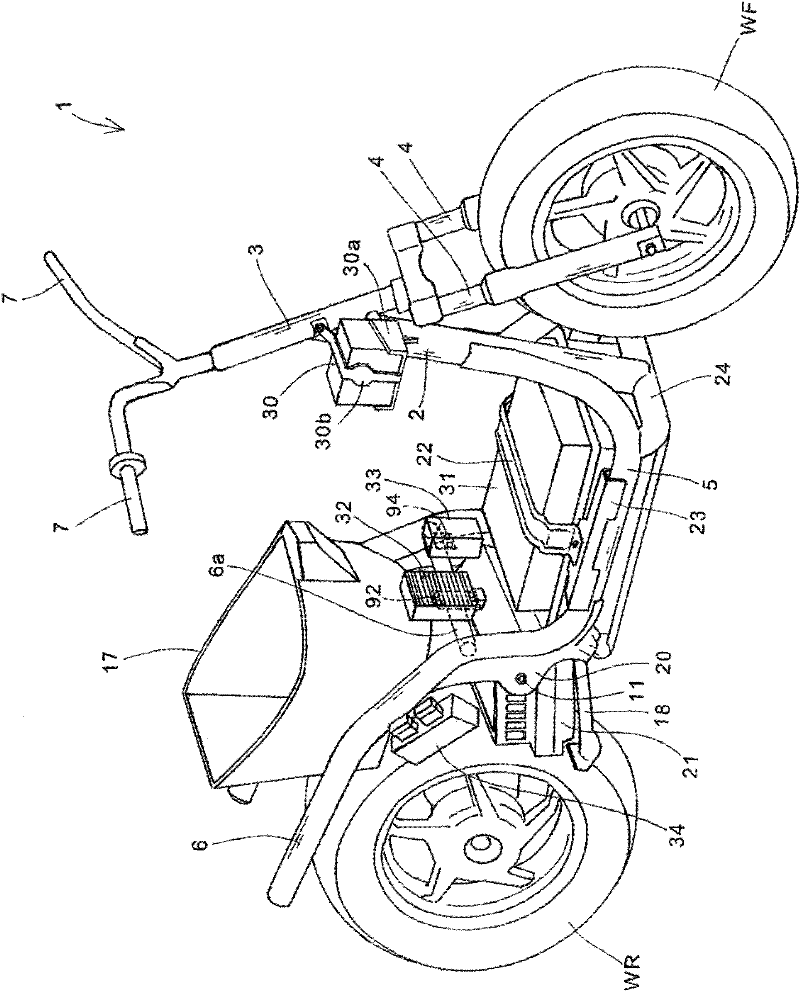

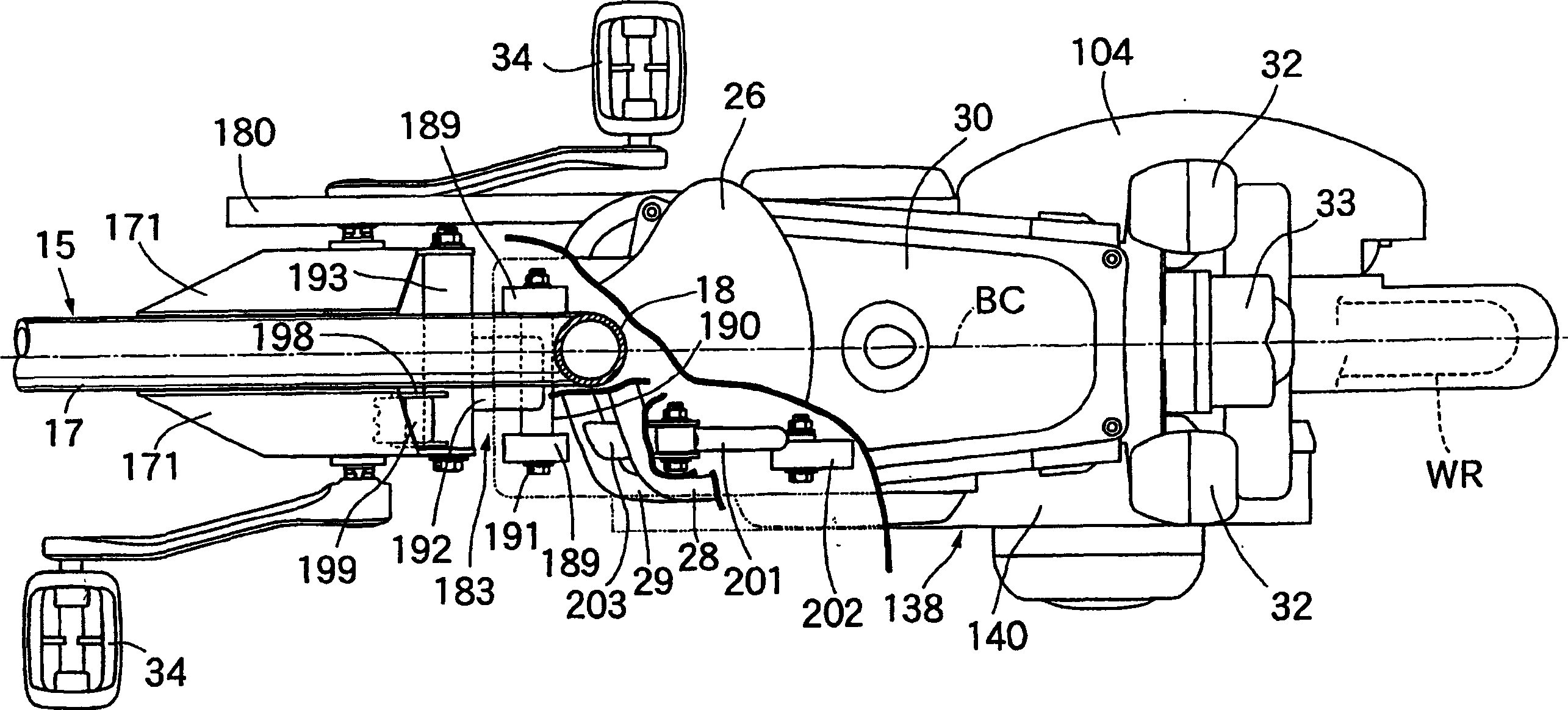

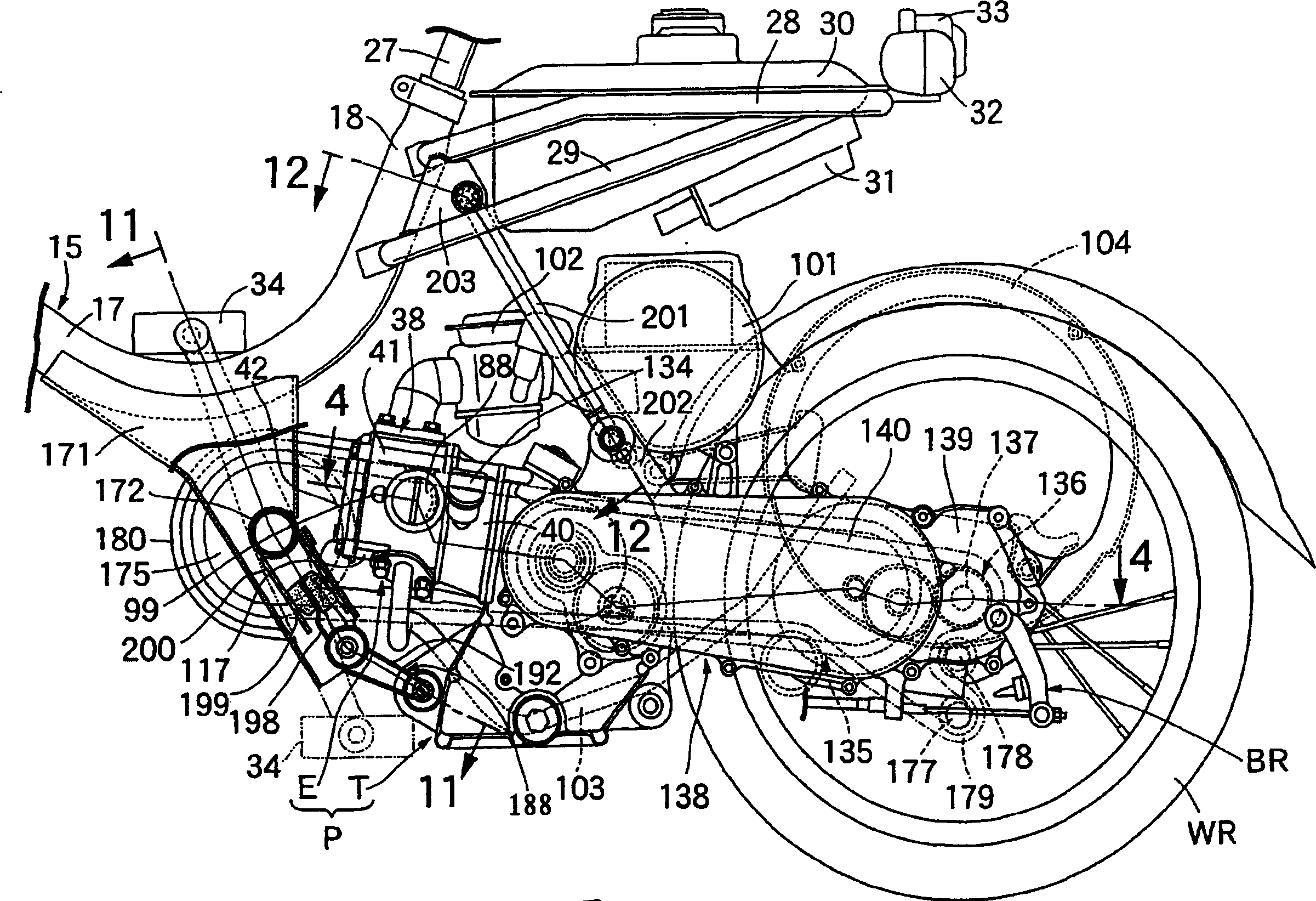

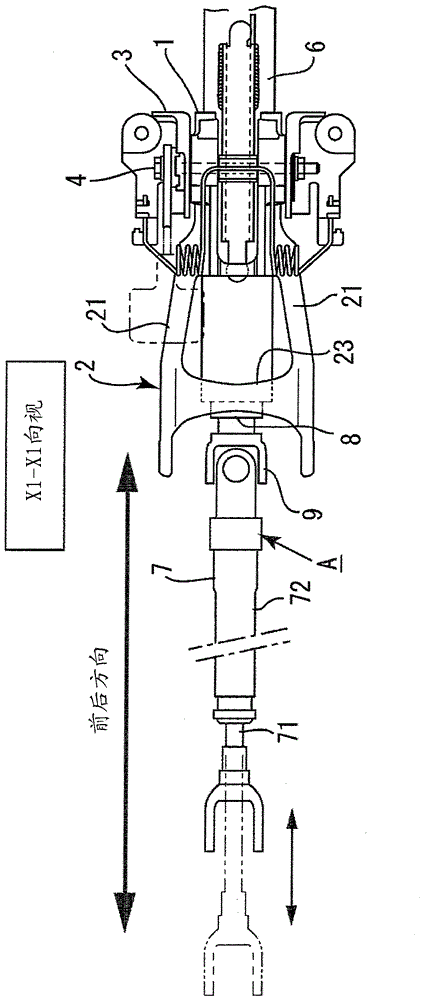

Two-wheel motorcycle power unit support structure

InactiveCN1470409ASeek lightweightLow costAxle suspensionsJet propulsion mountingDegrees of freedomPower unit

In a motorcycle which comprises a power unit comprising an engine and a transmission for transmitting the output of the engine to a rear wheel through speed change, the power unit being vertically oscillatably borne on a vehicle body frame, and an axle of the rear wheel being shaft-supported on a rear portion of the power unit, the power unit on the vehicle body frame is supported in such a manner as to enable reductions in size, weight and cost while contriving an increase in space efficiency and an increase in the degree of freedom in designing. A vibration-proofing link (188) for vertically oscillatably connecting a front portion of the power unit (P) to the vehicle body frame (15) is provided with an elastic member (199) for restricting the vertical oscillation range of the power unit (P) by making springy contact with a contacted body (200) provided in the vehicle body frame (15), and a non-expandable support member (201) for connecting the power unit (P) and the vehicle body frame (15) to each other while permitting vertical oscillation of the power unit (P) is provided between an upper portion of the power unit (P) and the vehicle body frame (15).

Owner:HONDA MOTOR CO LTD

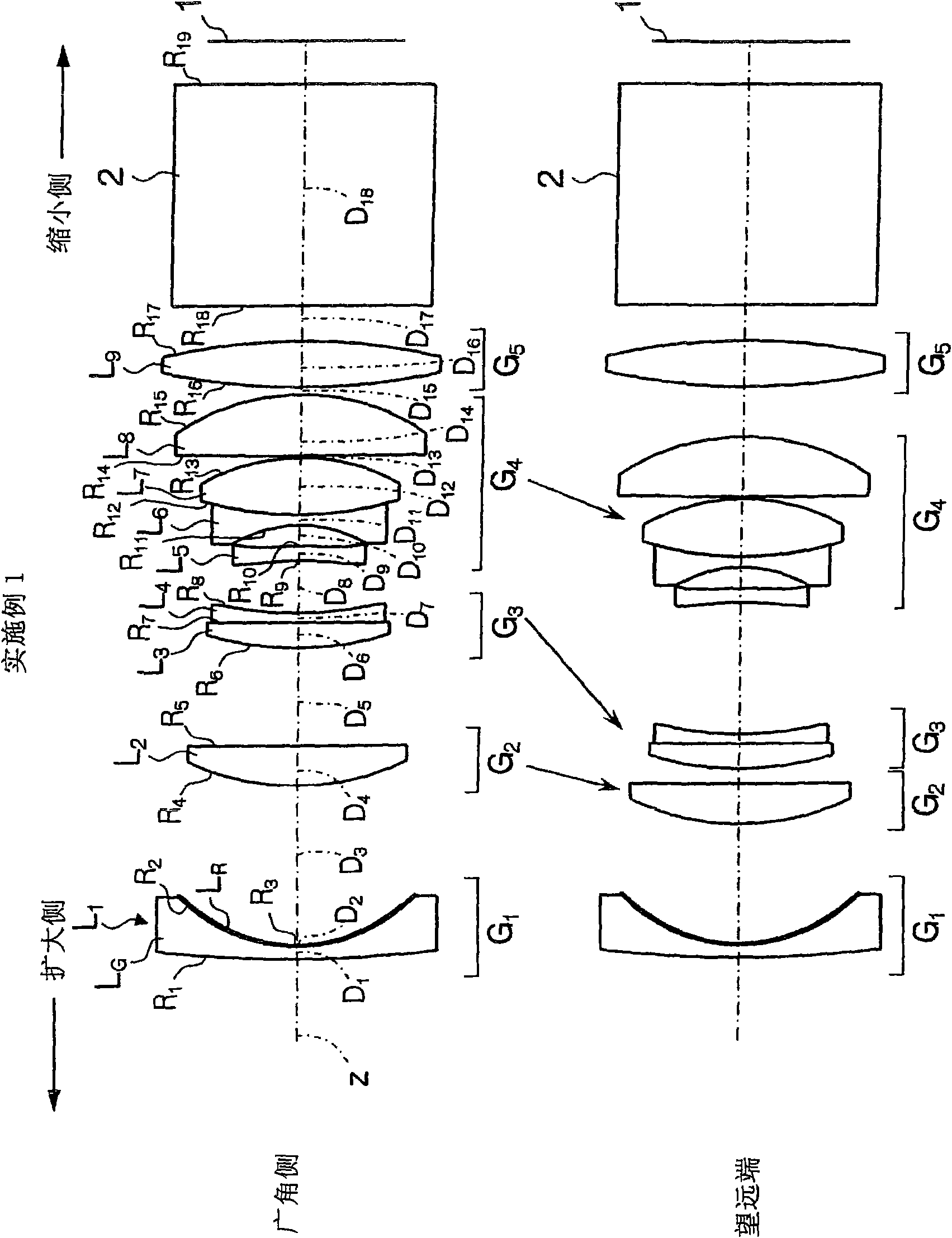

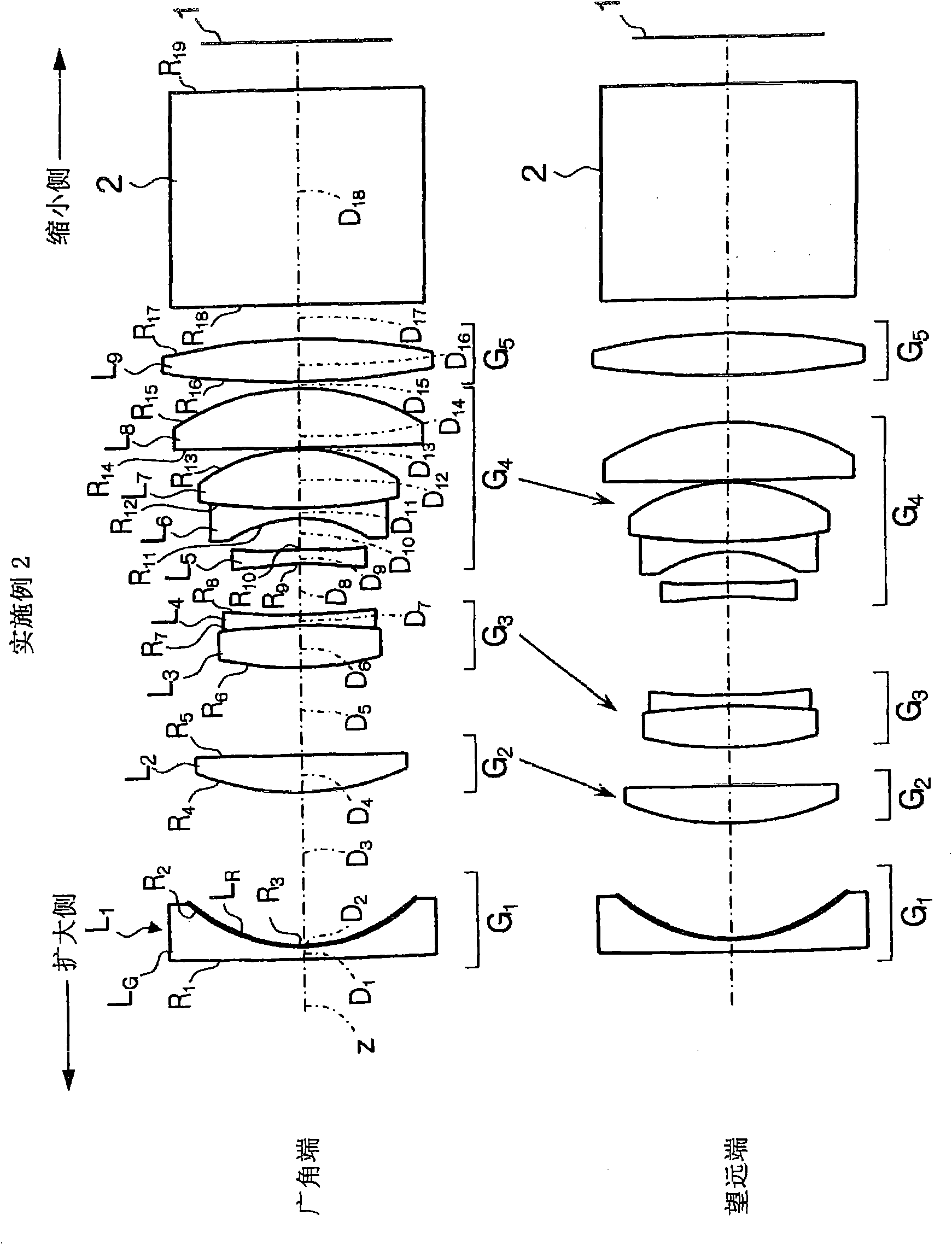

Projection zoom lens and projection type display apparatus

Owner:FUJI PHOTO OPTICAL CO LTD

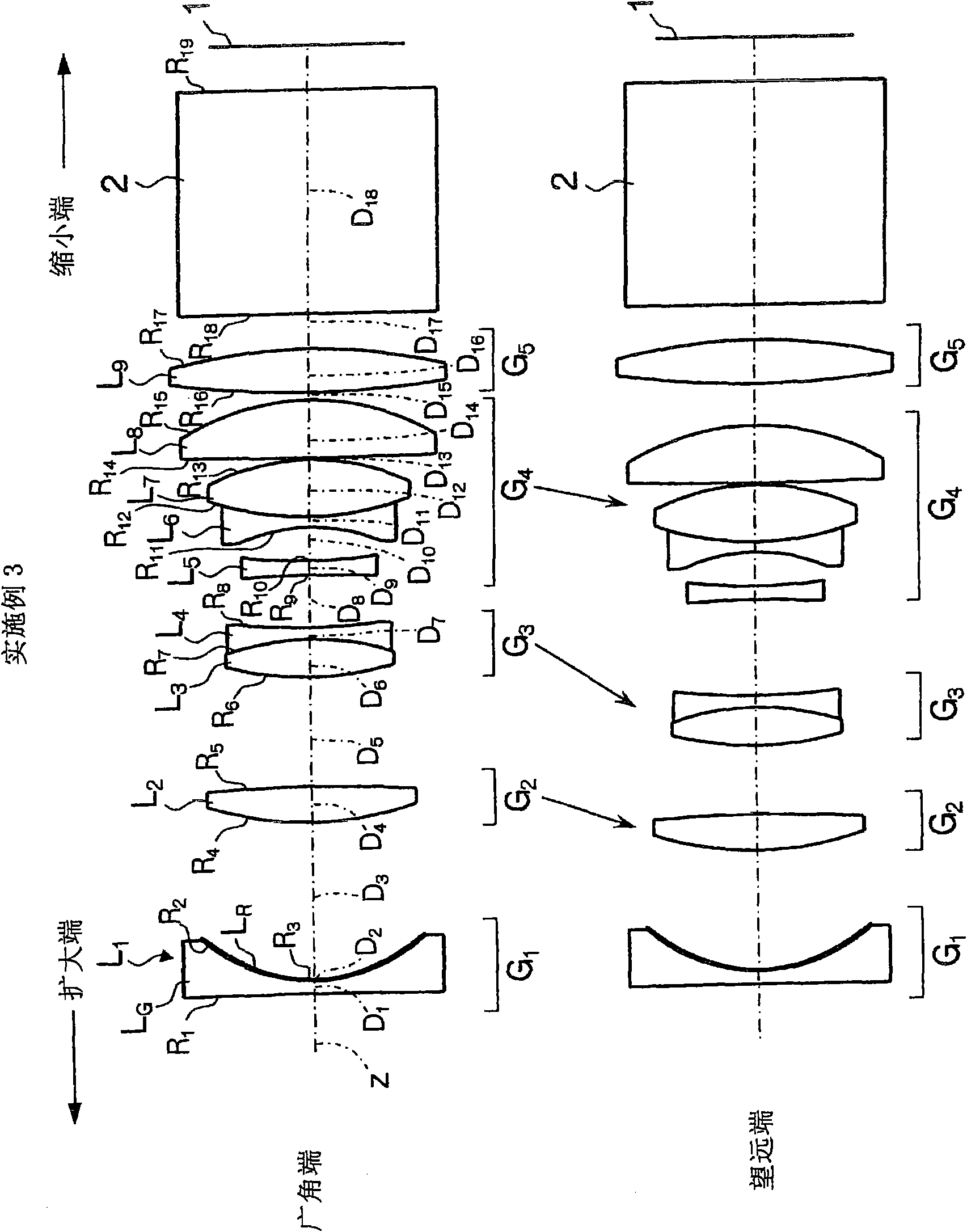

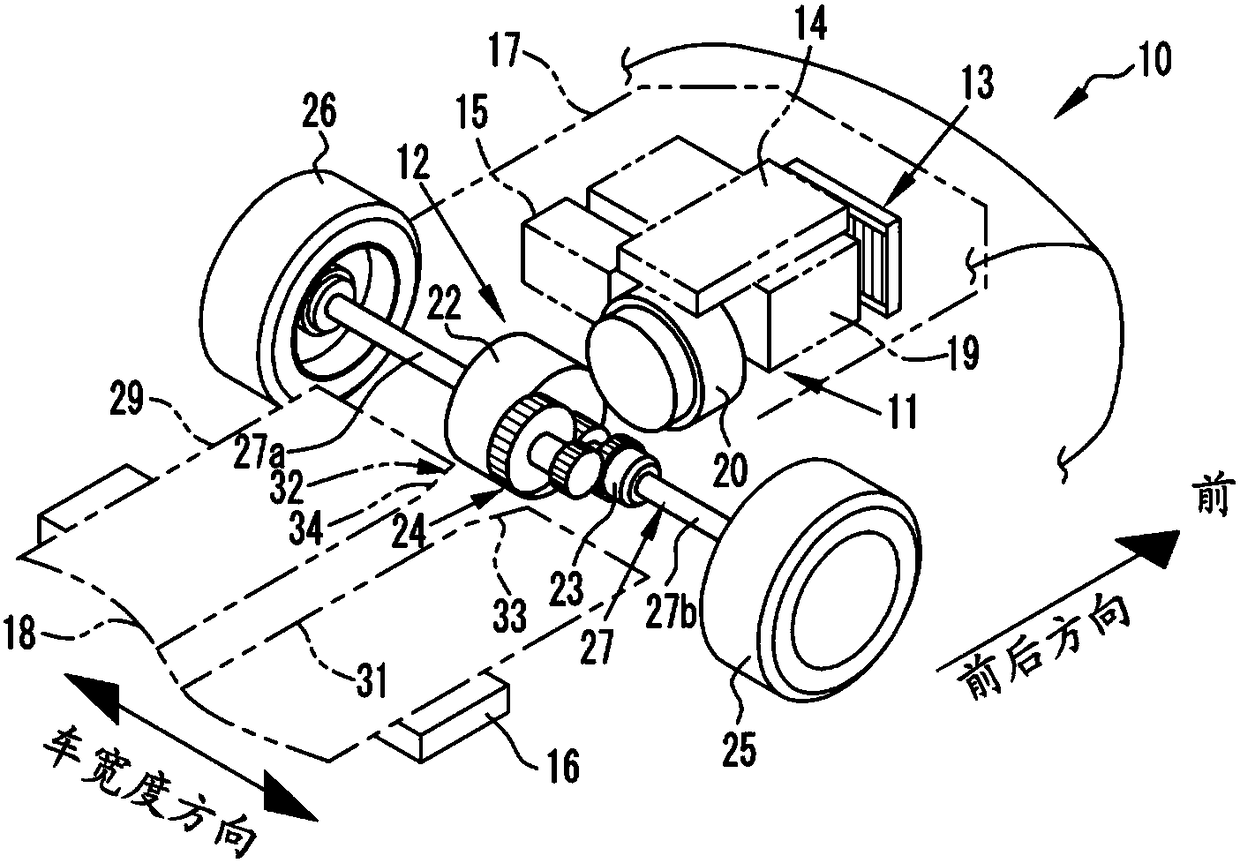

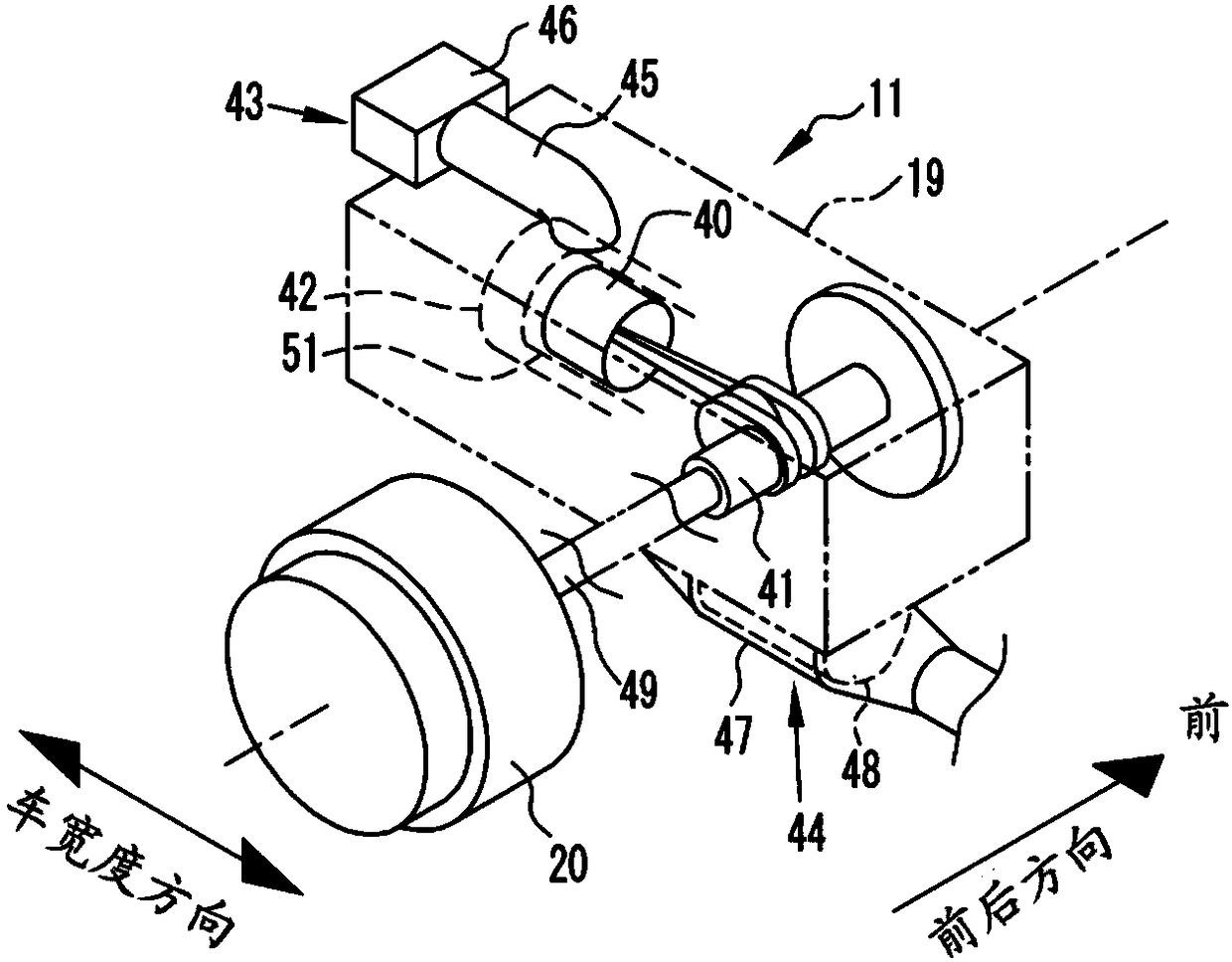

Vehicle

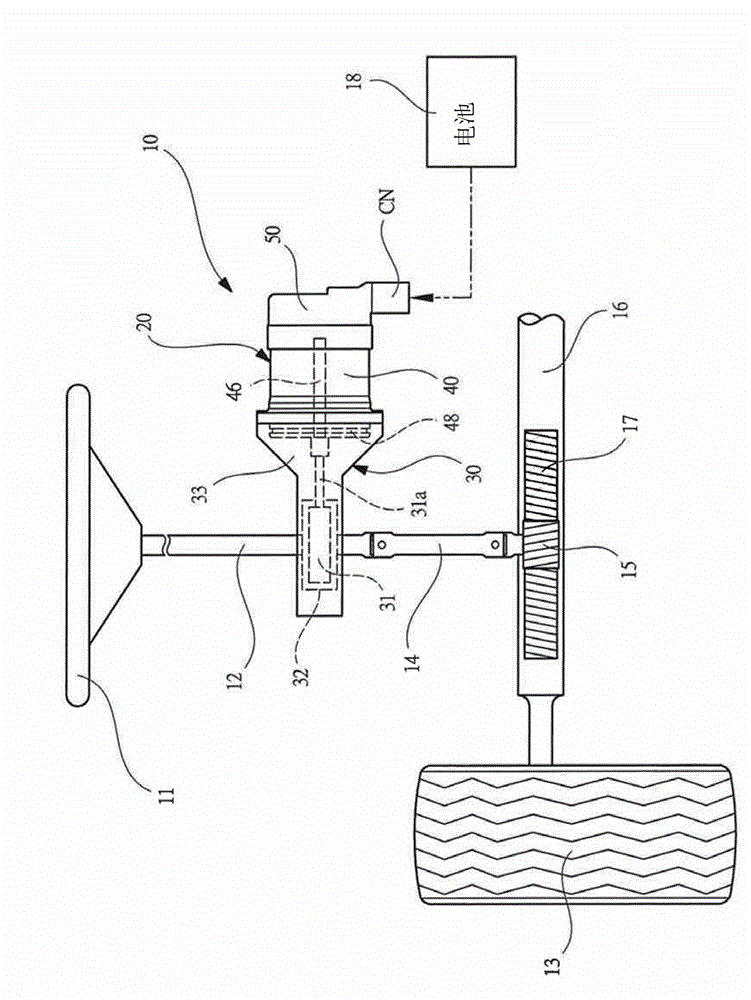

ActiveCN108407600ASmall sizeSeek lightweightHybrid vehiclesElectric propulsion mountingBattery chargeMiniaturization

The present invention provides a vehicle that can achieve miniaturization in the front-rear direction of the vehicle. A vehicle (10) includes an engine (19), a generator (20), and a motor (22). The engine (19) burns a gaseous mixture in a cylinder to output a drive force. The generator (20) generates electricity by being rotated by the drive force outputted from the engine (19). The motor (22) drives by utilizing electric power (20) generated by the generator or electric power that has accumulated in a battery charged with electric power generated by the generator, and the motor (20) thereby outputs a vehicle-running drive force. A case (61) covering the motor (22) is of larger diameter than a case (65) covering a differential. The motor (22) has an output shaft outputting the vehicle-running drive force, and has the output shaft disposed parallel to a vehicle width direction. The generator (20) is disposed such that part of the generator overlaps an upper section (65a) of the case covering the differential.

Owner:TOYOTA JIDOSHA KK

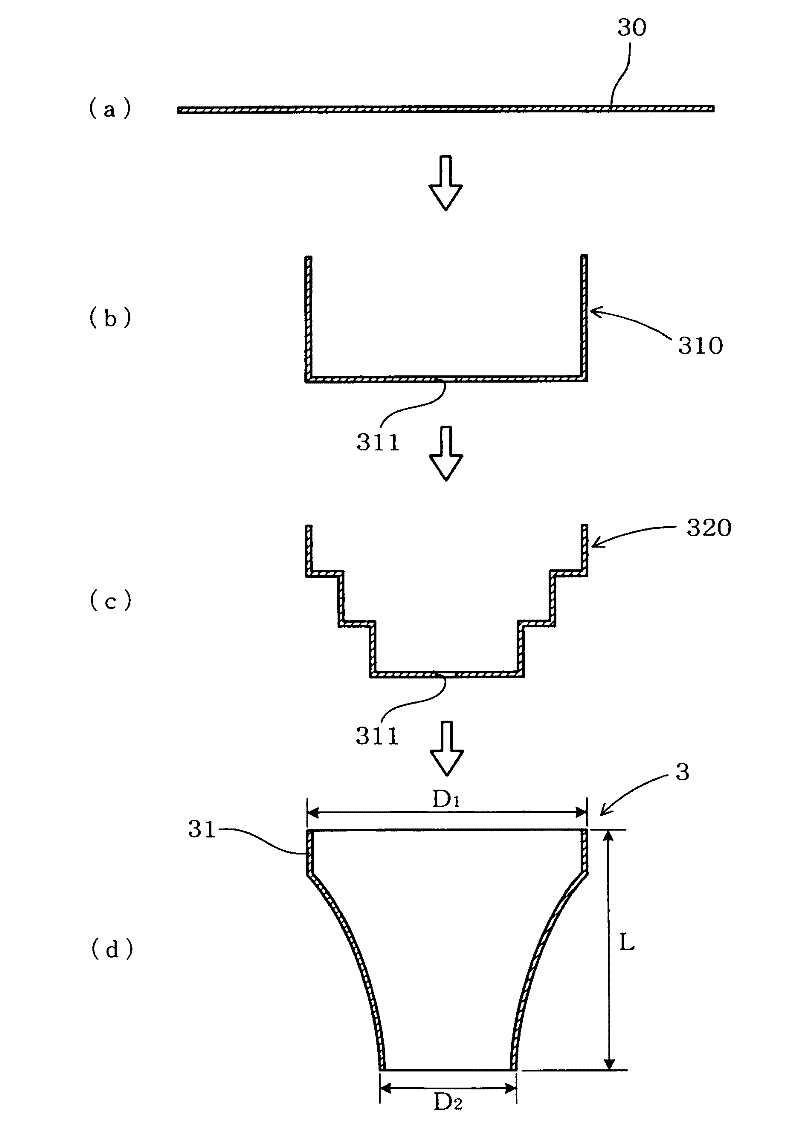

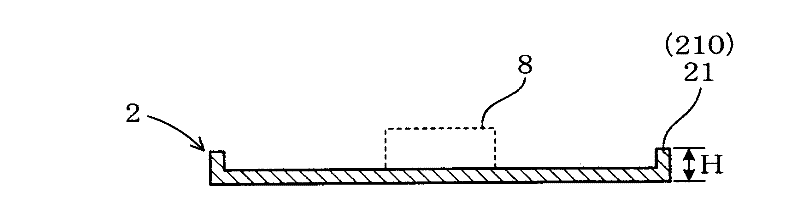

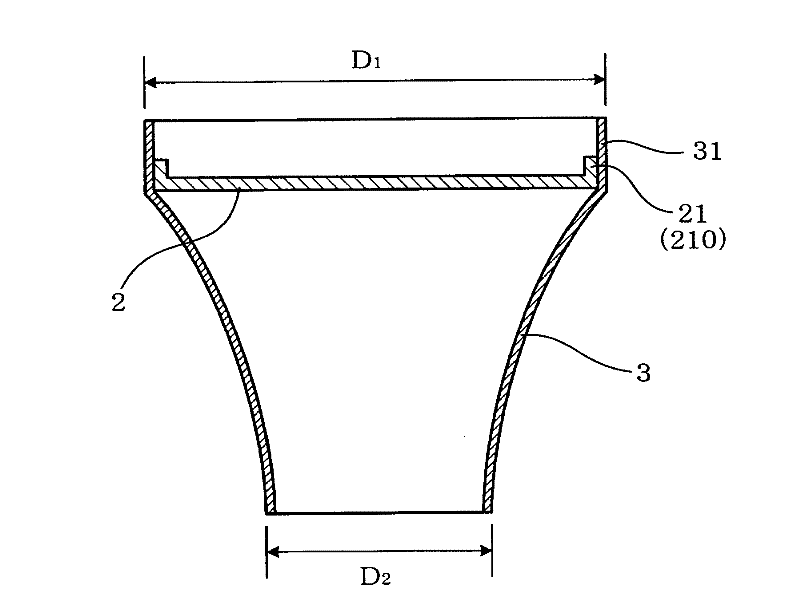

Components for led light bulbs and manufacturing method thereof

InactiveCN102261586AReduce raw material costsImprove joint adhesionPoint-like light sourceElongate light sourcesRadiationPlastic property

The invention provides a part used for an LED bulb, which is excellent in heat radiation performance and productivity, simple in structure and low in cost. The part comprises a disc-shaped substrate used for carrying LED components and composed of aluminum alloy plates (2) and a roughly cylindrical or cone-shaped heat radiation component (3) prepared by applying plasticity to an aluminum alloy plate. An outer peripheral portion (21) of the substrate (2) and an opening end portion (31) of the heat radiation component are engaged via flanging manufacturing. Preferably, the outer peripheral portion (21) of the substrate (2) are provided with roughly right-angle-shaped flanges (210), flanging manufacturing is conducted on the opening end portion (31) of the heat radiation component towards the inside direction, the heat radiation component (3) is shaped by using a precoated aluminum alloy plate, and the precoated aluminum alloy plate is prepared by precoating a heat radiating film containing heat radiation substances on two sides or one side of an aluminum alloy plate.

Owner:SUMITOMO LIGHT METAL INDS LTD +1

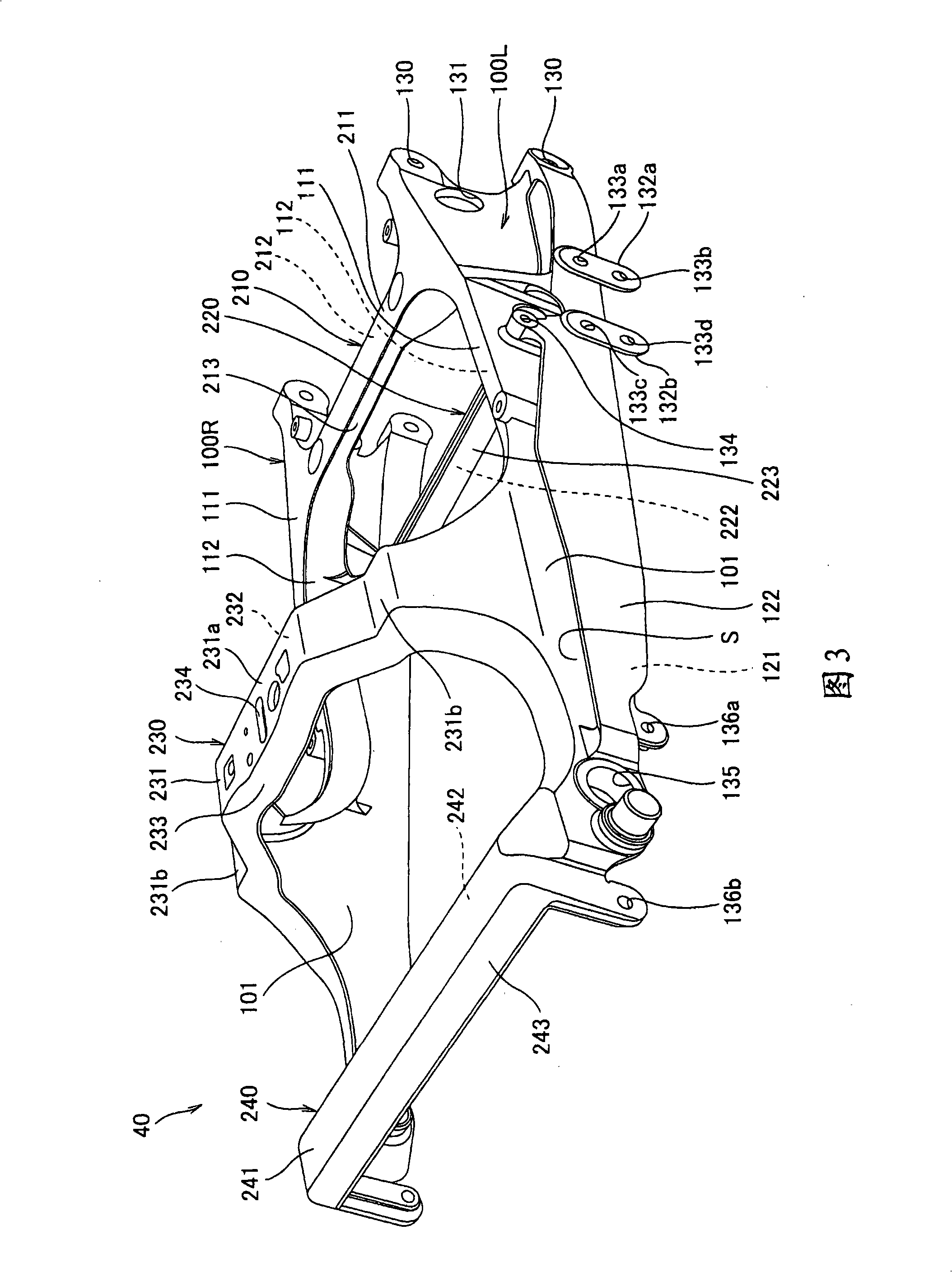

Seat rail structure of motorcycle

InactiveCN101254803AImprove productivityIncrease the section factorMotorcyclesCycle saddlesDie castingEngineering

The present invention provides a seat rail structure for a motorcycle in which sufficient strength and rigidity are secured while achieving weight reduction of a vehicle body. Means for Resolution A seat rail structure of a motorcycle includes a main frame and a seat rail (40) formed of magnesium alloy to be secured to the main frame, and the seat rail (40) includes a pair of left and right side wall portions (100L,100R) extending rearward from the main frame, and a plurality of connecting portions (210,220,230,240) formed into a substantially angular C-shape in cross section or into a substantially H-shape in cross section for connecting the left and right side wall portions (100L,100R), wherein at least part of the connecting portions (210,220,230,240) are connected at a level flush with or above the upper surface of the side wall portions (100L,100R), and the side wall portions (100L,100R) and the connecting portions (210,220,230,240) are integrally formed by die casting.

Owner:HONDA MOTOR CO LTD

Steering apparatus

Owner:YAMADA SEISAKUSHO KK

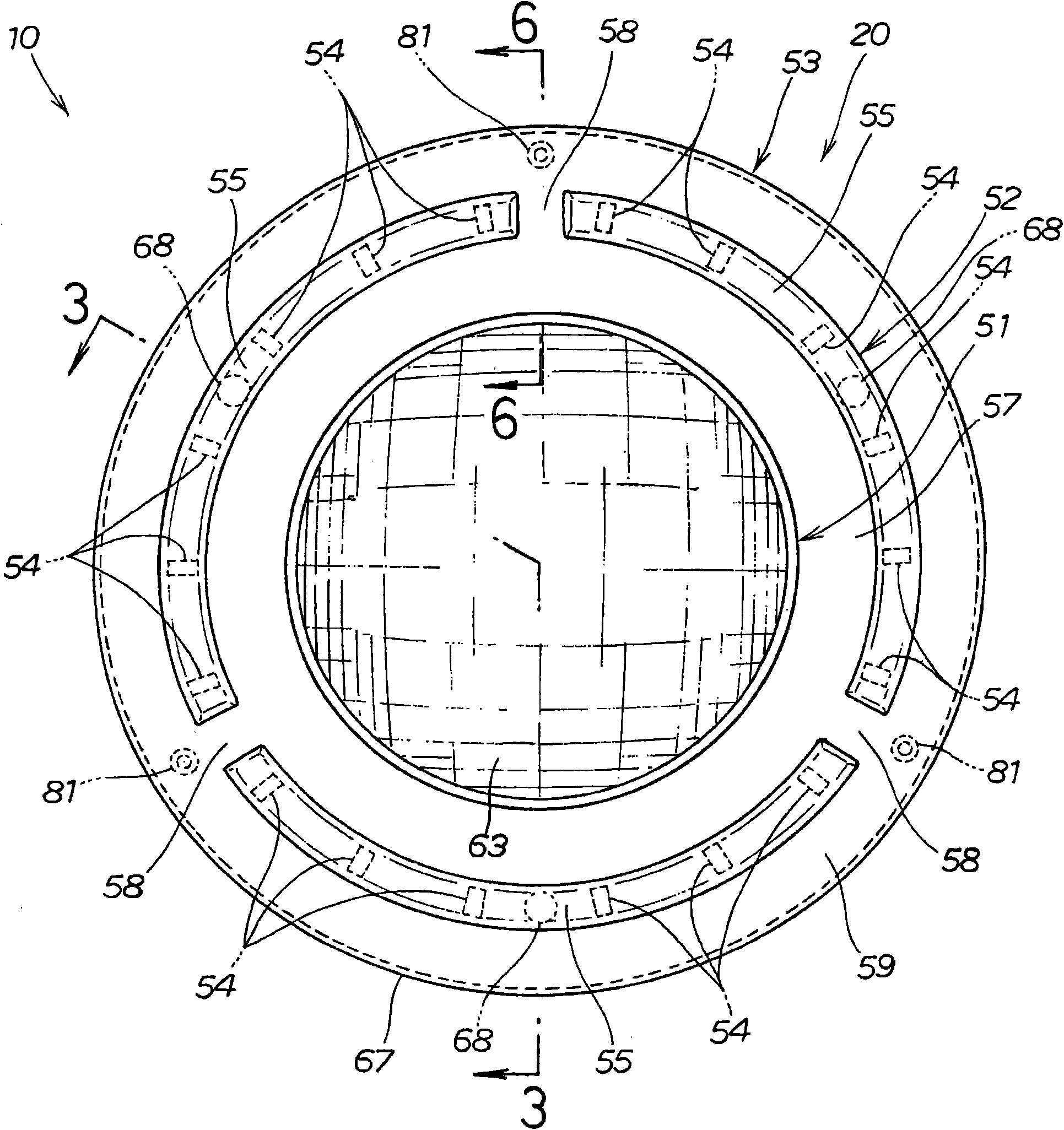

Lighting system

InactiveCN101934834ASeek lightweightLuminous overallOptical signalOptical signallingLighting systemMechanical engineering

The invention provides a lighting system, aims to reduce the weight of the lighting system. A headlight (20) includes a first lighting apparatus (51) including a light source (61) covered with a housing (62) and an annular second lighting apparatus (52) disposed around the housing (62). In the headlight (20), the second lighting apparatus (52) is supported by an annularly formed annular stay (65) that is supported by the housing (62) and includes a plurality of light-emitting elements (54) disposed annularly so as to be radially spaced apart from an outer periphery of the first lighting apparatus (51) in a front view. The second lighting apparatus (52) is supported by the housing (62). This eliminates the need for using a housing for the exclusive use for supporting the second lighting apparatus (52). This promotes reduction in weight of the headlight (20).

Owner:HONDA MOTOR CO LTD

ride-on vehicle

Owner:HONDA MOTOR CO LTD

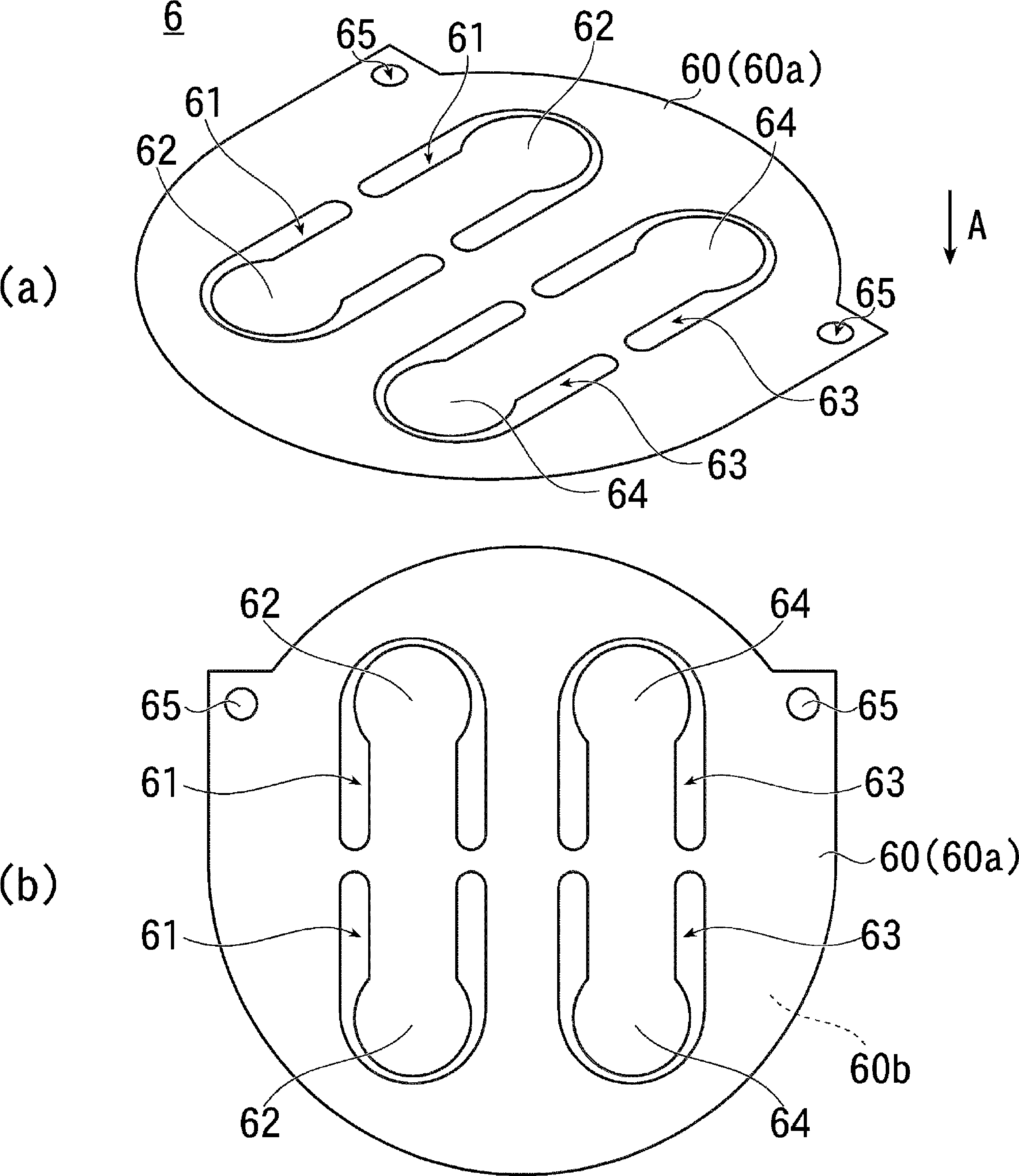

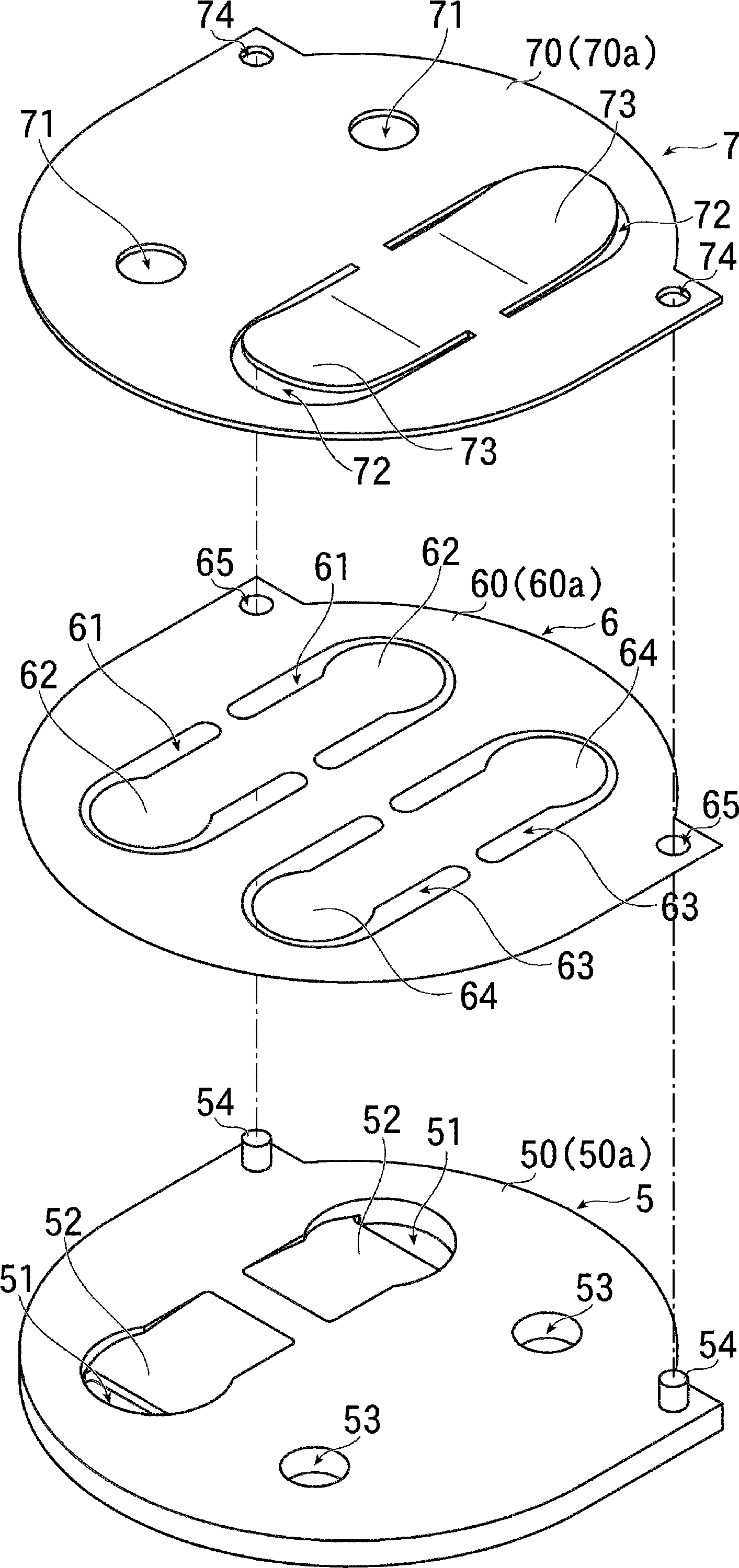

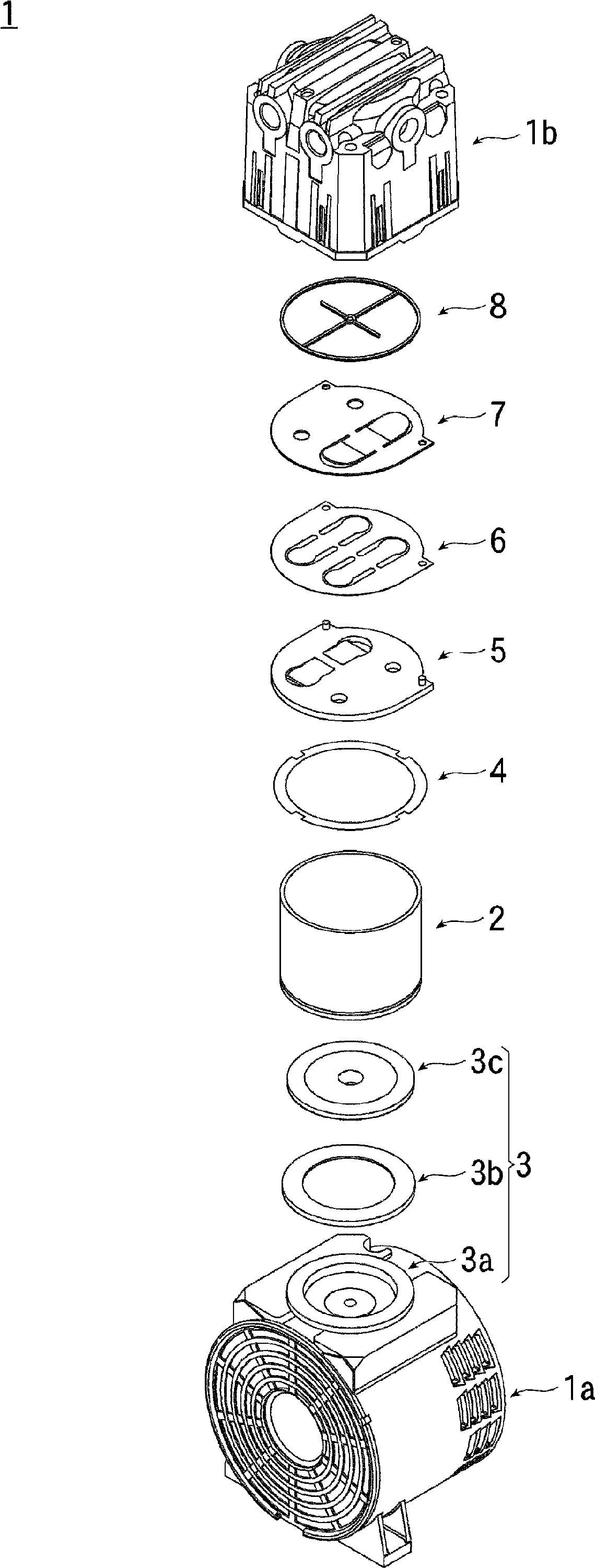

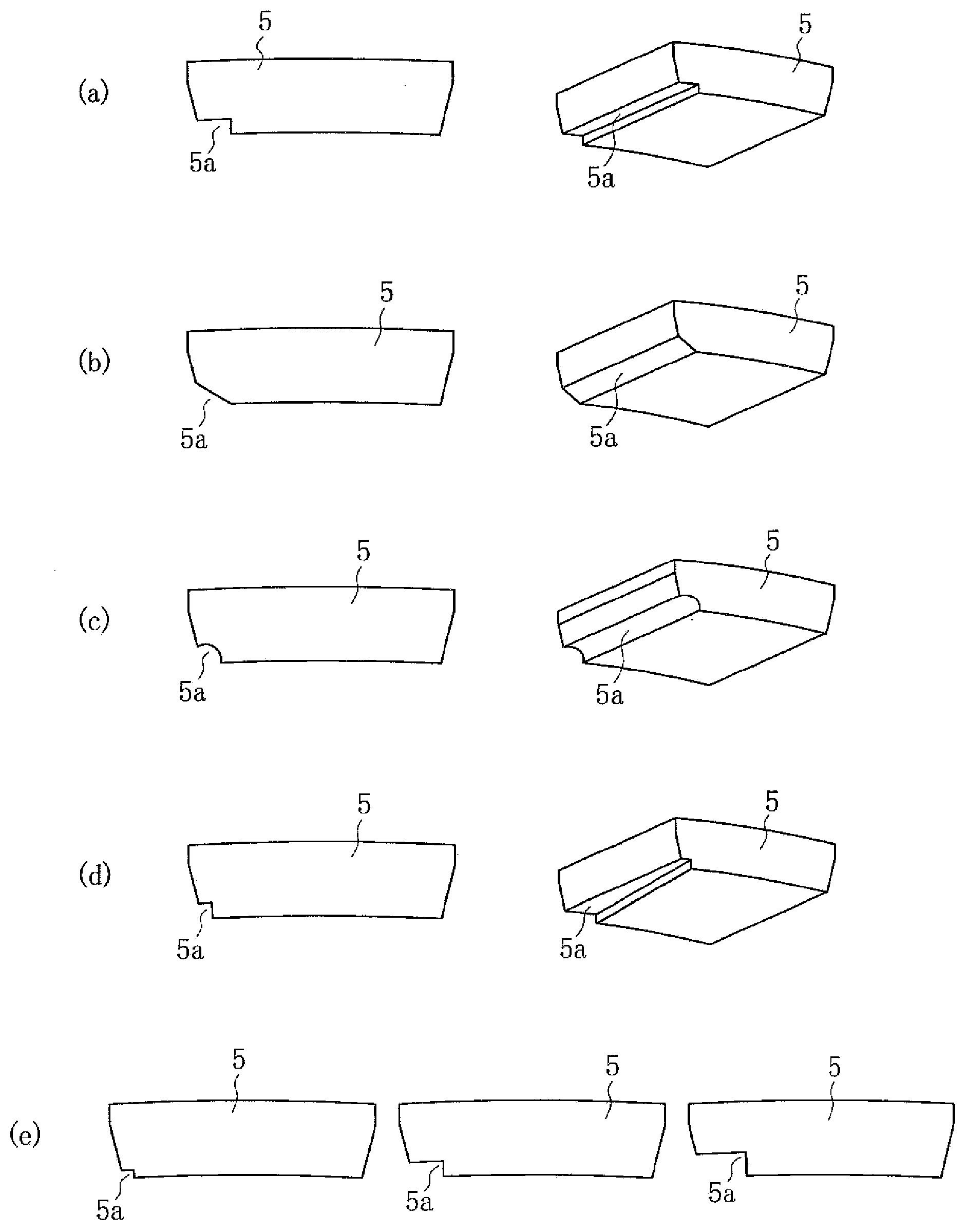

Pump

ActiveCN104234979AReduce dead spaceHigh trafficPositive displacement pump componentsEngine fuctionsExhaust valvePump chamber

The invention provides a pump which is provided with a suction / exhaust valve that is composed of reed valves. Compression ratio can be improved through reducing a useless space in a pump chamber. Simultaneously number reduction of elements and assembling process simplification can be realized. An exhaust side surface (50a) of a body part (50) of a top panel (5) arranged at the upper part of a pump chamber (2) is provided with a recessed suction valve compressing part (52). The suction valve compressing part (52) inclines in a manner that the thickness reduces in a direction to a suction port (51) and is continuous with the suction port (51). The pump is provided with a suction / exhaust valve component (6) which is provided with a panel-shaped body part (60) that is positioned and configured in a manner of closely abutting with the exhausting side relative to the top panel (5). The pump is furthermore provided with a suction valve (62) which is arranged integrally with the body part (60) of the suction / exhaust valve component (6) in a manner of superposing with the suction port (51) of the top panel (5) and the suction valve compressing part (52).

Owner:ULVAC KIKO

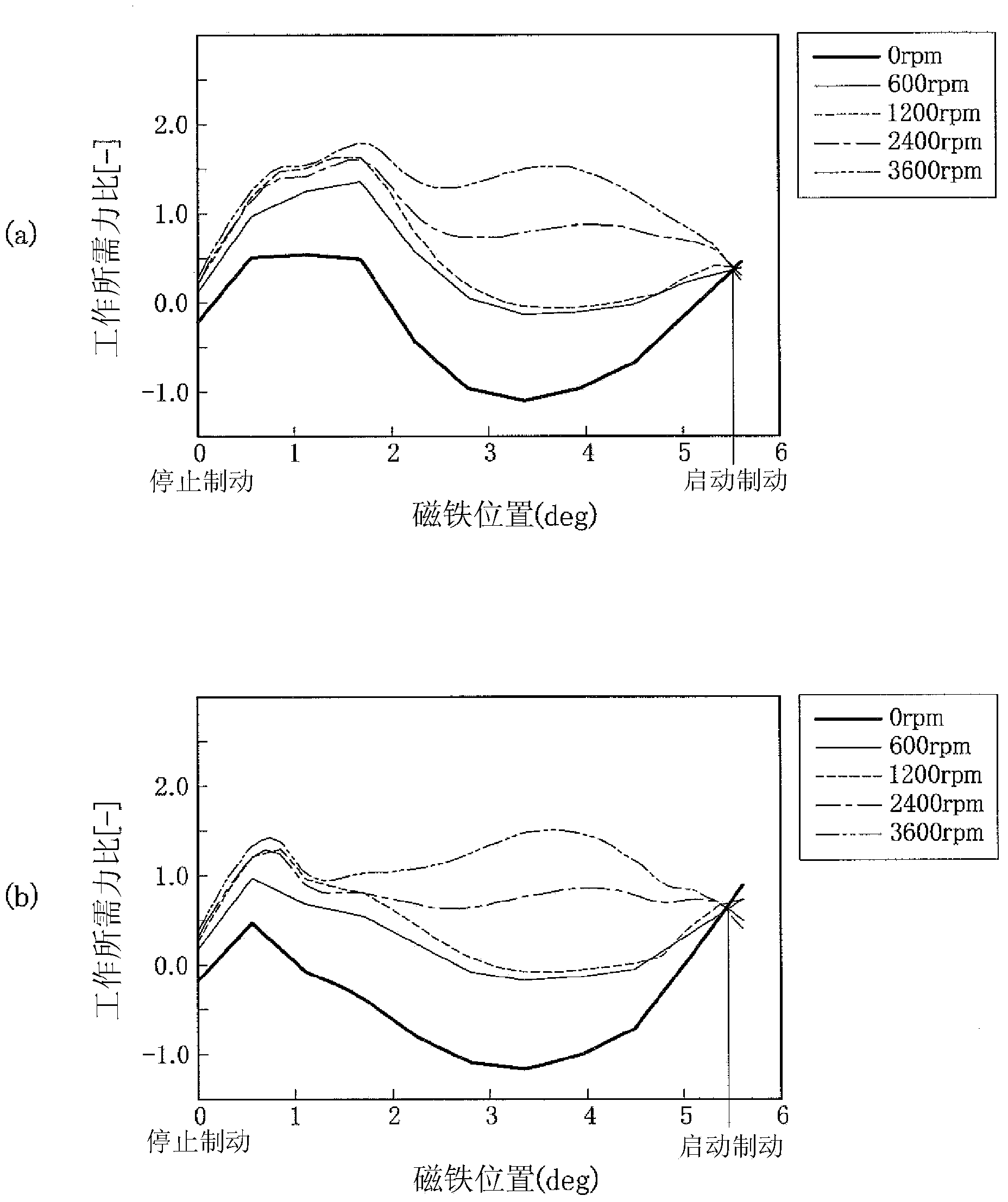

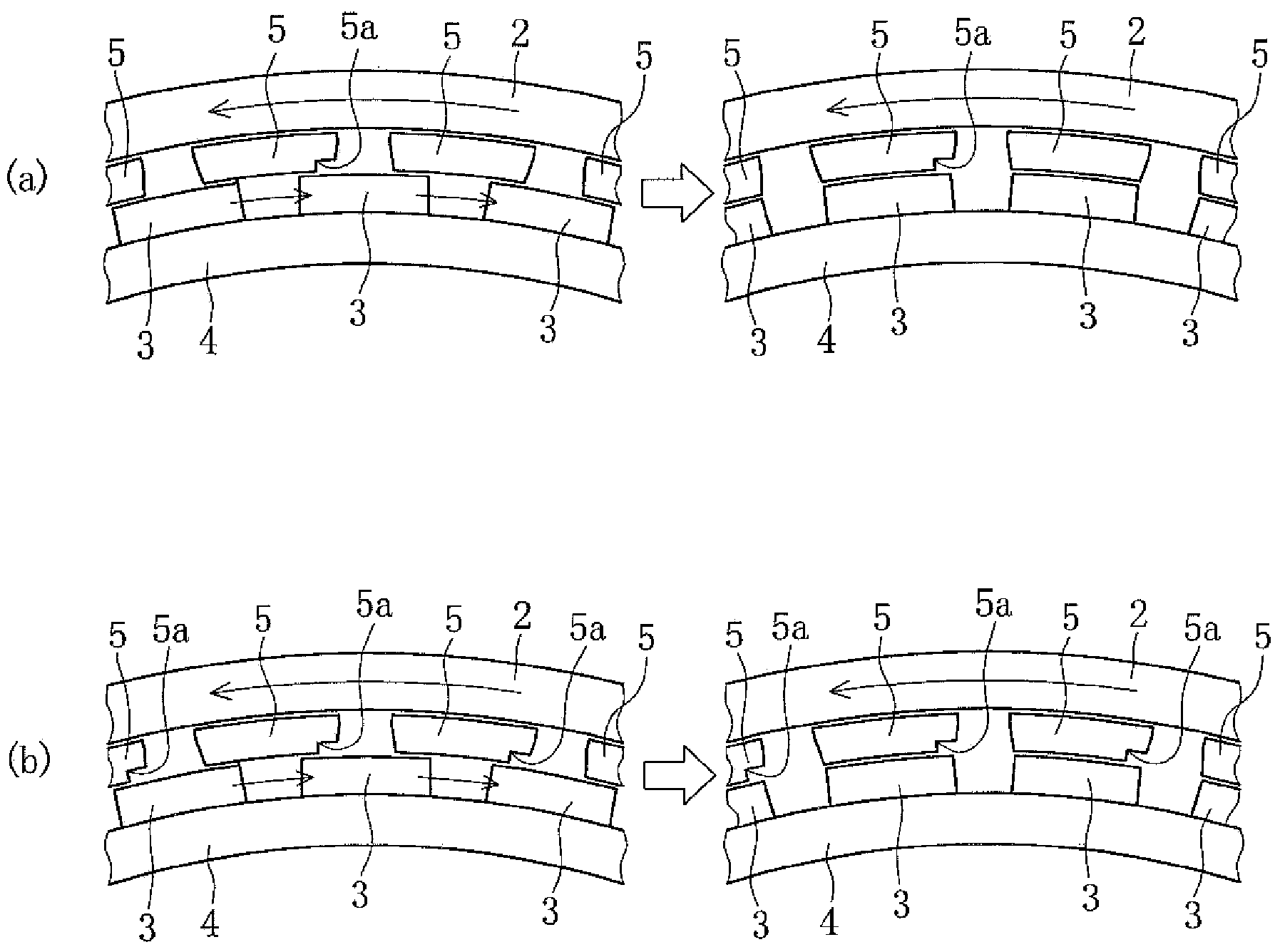

Eddy-current-type reduction gear

ActiveCN104205590AReduce work forceLow costAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesMagnetic polesEngineering

A single-row rotating-type eddy-current-type reduction gear, wherein the number of components is not large, and low cost is achieved and the amount of operating power needed during switching between braking on and braking off is reduced while further reduction in the size of the device is achieved. A magnet support member (4) for a ferromagnetic material in which permanent magnets (3) are arranged with a constant interval therebetween is provided facing a braking drum (2) so as to be able to rotate through a necessary angle, so that magnetic poles are in opposite orientations to each other in the circumferential direction of the braking drum (2), which is attached to a rotating shaft (1). A support (3) in which a group of pole pieces (5) of a ferromagnetic material arranged at basically the same angle positions as the permanent magnets (3) is provided with support members (6a) of a non-magnetic material interposed between the pole pieces (5) is provided between the group of permanent magnets and the braking drum (2). Notch parts (5a) are provided in sides of the plurality of pole pieces (5) facing the permanent magnets (3), on front end sides in the direction in which the magnet support member (4) moves during switching from braking off to braking on.

Owner:NIPPON STEEL CORP

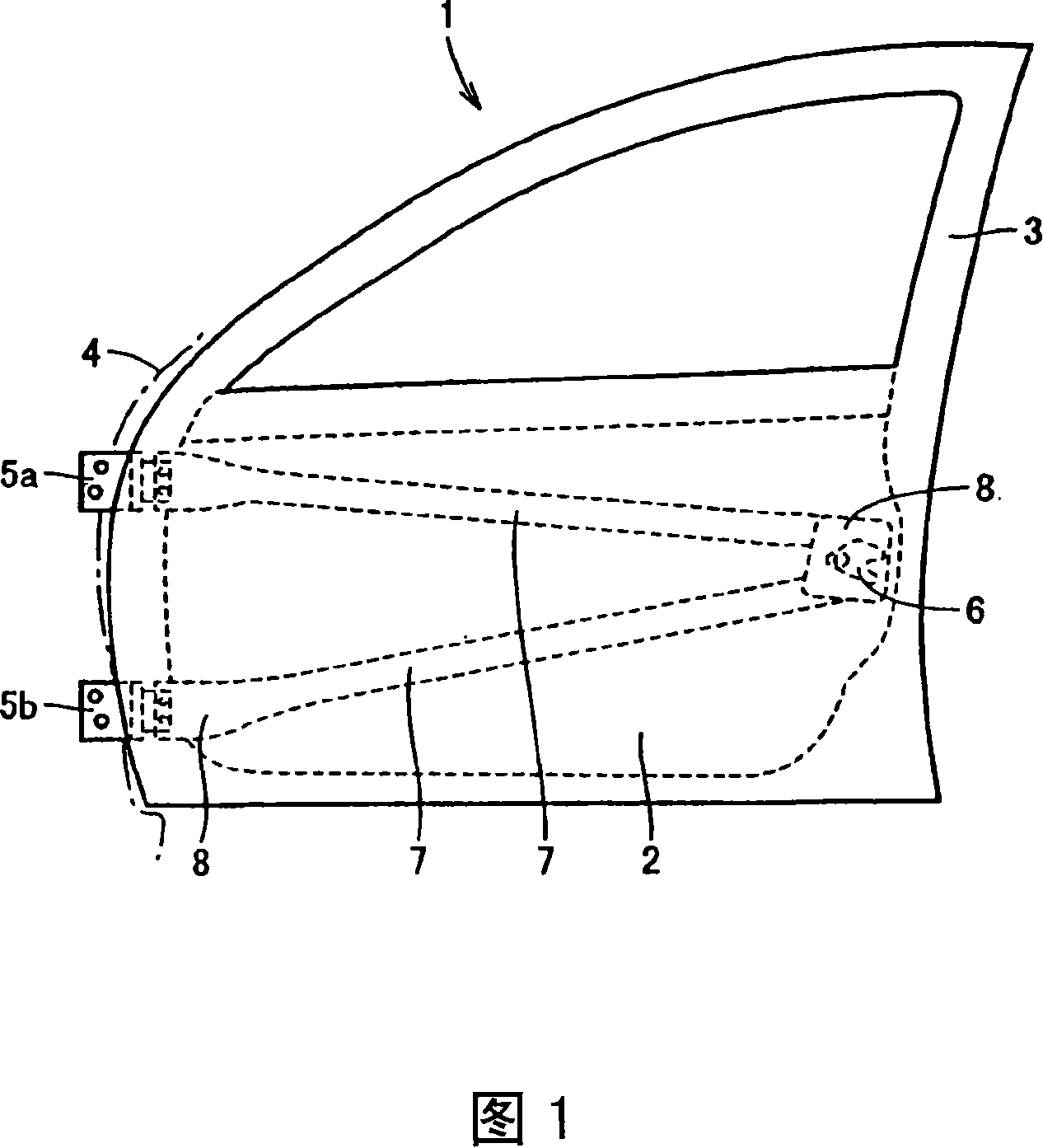

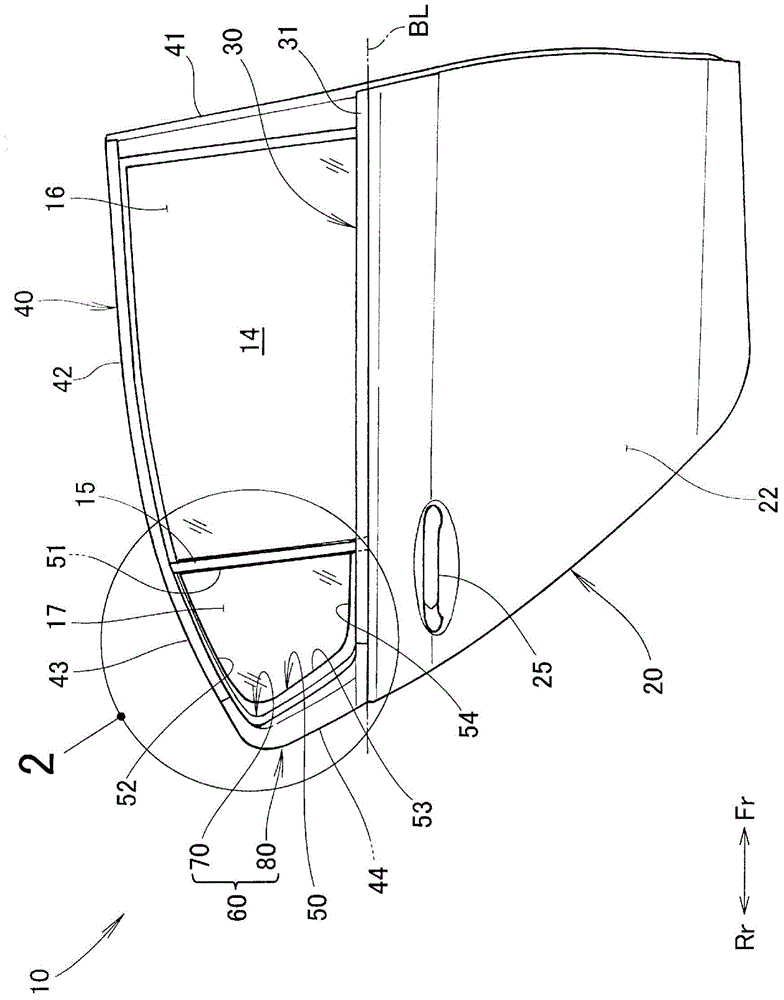

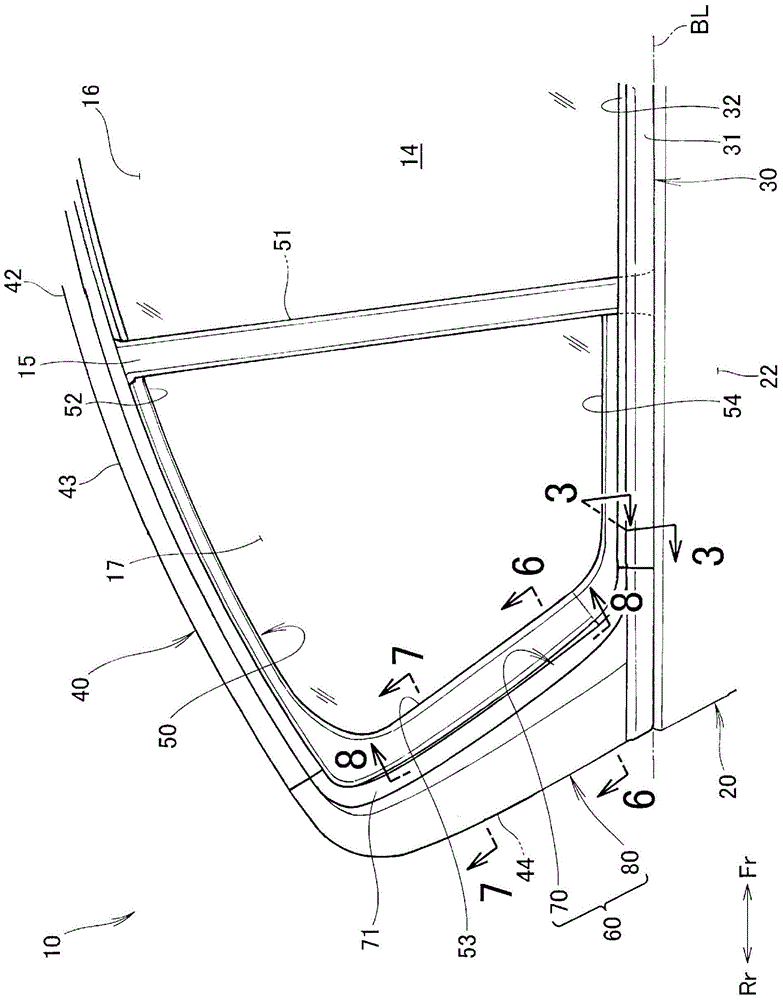

Vehicle door

ActiveCN104602931ASeek lightweightSimplify the manufacturing processVehicle sealing arrangementsDoorsWindow openingEngineering

This vehicle door (10) has: a door main body (20) comprising an inner panel (21) and an outer panel (22); a door sash (40) provided to the top of the door main body (20); a window opening section (14) encircled by the door sash (40) and the upper edge of the door main body (20); a window panel (17) that occludes at least a portion of the window opening section (14); a panel support frame (50) that supports at least a portion of the margin of the window panel (17); and a belt line reinforcing member (100) attached to the inner panel (21) or the outer panel (22) along the upper edge of the door main body (20). The belt line reinforcing member (100) has an upper extension section (102) extending along the door sash (40) above the upper edge of the door main body (20), and the panel support frame (50) is sandwiched by the door sash (40) and the upper extension section (102).

Owner:HONDA MOTOR CO LTD

Storage structure for power connector for straddle-type vehicles

ActiveCN102649452BImprove workabilitySeek lightweightElectric vehicle charging technologyVehicular energy storageFree rotationFender

The invention provides a power connection part receiving structure for a straddle type vehicle, which can reduce the complexity degree of daily charging and achieve good water resistance of the power connection part. The straddle type vehicle comprises a vehicle body rack (10), a steerage device (20) which is maintained on the vehicle body rack with smooth operation, a front wheel (25) which is supported on the steerage device with free rotation, a front rectification cover (51) which covers the front and side parts of the steerage device, a front mud guard (26) which is disposed between the front rectification cover and the front wheel and is fixed on the steerage device, an electric motor (61) disposed on the vehicle body rack, a battery (64) disposed on the vehicle body rack, and a power connection part (130) providing electric power to the battery from the outside of the vehicle. The straddle type vehicle uses the electric motor as the power supply. The front surface side or upper surface side of the front rectification cover at the upper part of the front mud guard is provided with an opening part (110) which can be sealed through a cover component (120). The power connection part (130) is received in the opening part (110).

Owner:HONDA MOTOR CO LTD

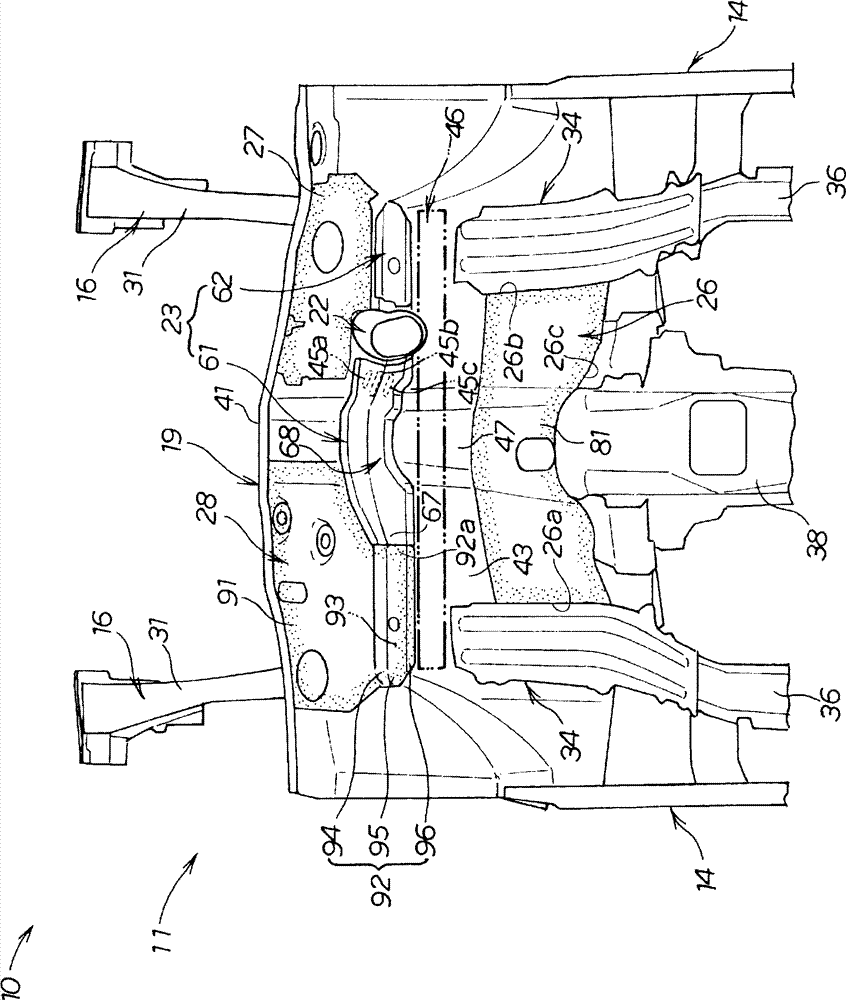

Structure for front section of vehicle body

ActiveCN102791566BImprove rigidityReduce plate thicknessSuperstructure subunitsEngineeringSurface plate

A dash-board lower panel (19) in a vehicle body (11) includes a vertical plate-shaped partition plate (41) which partitions the vehicle body into a front and a rear section, and an inclined plate (43) which inclines downward and rearward from the bottom end of the partition plate. At least part of the rear surface (19a) of the partition plate is reinforced by a reinforcement plate (28). The reinforcement plate has an extended section (92) at the bottom end thereof. The extended section extends from above a bent section (42), which is between the partition plate and the inclined plate, to below the bent section, and is joined to the inclined plate. A closed cross-section body (93), which is long and narrow in the vehicle-width direction, is formed by the extended section and the dash-board lower panel.

Owner:HONDA MOTOR CO LTD

Electric straddled vehicle

ActiveCN102448806BImprove versatilityReduce the burden onMotorised scootersAxle suspensionsGravity centerElectric vehicle

Provided is an electric vehicle that realizes a light electric straddled vehicle using a motor with a small size, and optimizes the left and right weight balances in the width direction of the vehicle with respect to the vehicle body centerline. The electric motor (250) is disposed inside a swing arm (124) of a cantilever type at a position overlapping a projection area of a rear wheel WR when seen from the side portion of the vehicle body. The motor driver (216) is disposed inside the swing arm (124) so that the vehicle body centerline (C) passing through at the front side of the vehicle body in the rear wheel (WR). The position (G2) of the center of gravity of the motor driver (216) is disposed to be offset in the direction opposite to the offset direction of the electric motor (250) with respect to the vehicle body centerline (C).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com