Components for led light bulbs and manufacturing method thereof

A technology of LED light bulbs and manufacturing methods, which is applied to components of lighting devices, semiconductor devices of light-emitting elements, and damage prevention measures for lighting devices, which can solve the problems of reduced light output power and short life, and achieve improved joint adhesion Sexuality, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] use Figure 1 to Figure 6 , the components for LED light bulbs and the manufacturing methods thereof according to the embodiments of the present invention will be described.

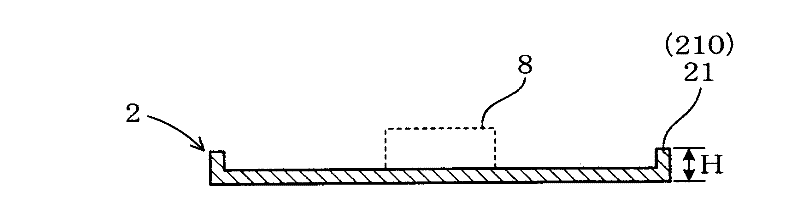

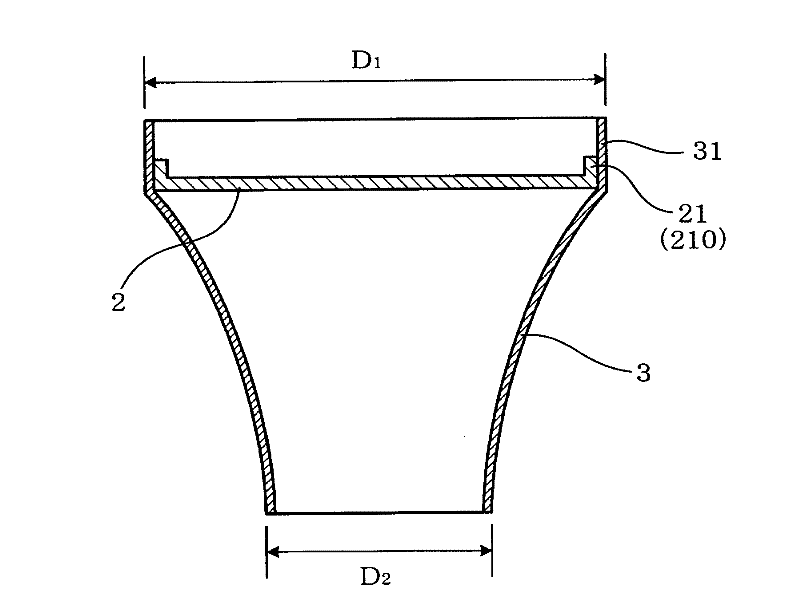

[0084] Parts 1 for the LED light bulb in this example are as follows: Figure 6 As shown, there is a disc-shaped LED mounting substrate 2 made of an aluminum alloy plate on which an LED element 8 is mounted, and a heat dissipation member 3 formed into a substantially conical shape by applying plastic working to the aluminum alloy plate. like Figure 5 As shown, the outer peripheral edge portion 21 of the LED mounting substrate 2 and the opening end portion 31 of the heat dissipation member are bonded by hemming.

[0085] Hereinafter, further details will be given.

[0086]

[0087] As the heat radiating member 3, an unpainted aluminum alloy plate not coated with a synthetic resin film was used as a material. Specifically, A8021-O in material quality and a size of 0.5 mm in thickness×100 mm in ...

Embodiment 2

[0102] This example is based on the structure of Example 1, and differs only in the use of a precoated aluminum alloy plate coated with a synthetic resin film on the material of the heat sink member 3 . Precoated aluminum alloy panels were produced in the following manner.

[0103]

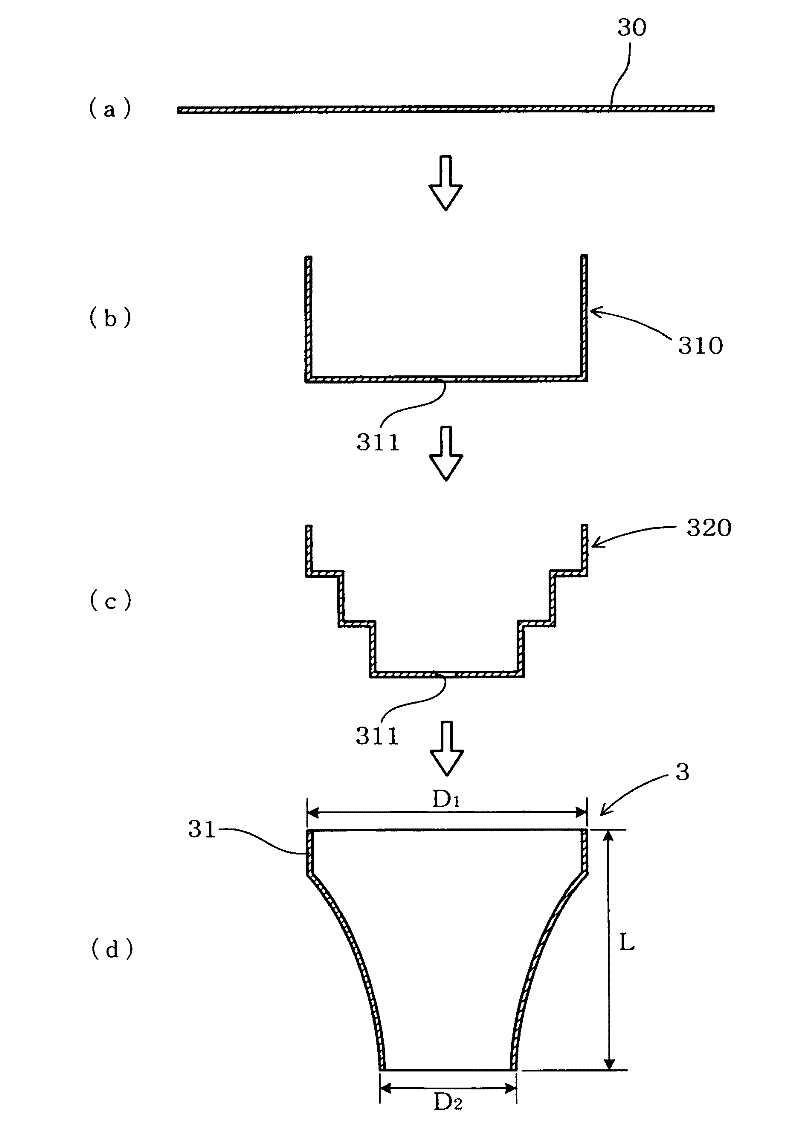

[0104] like Figure 7 As shown, a pre-coated aluminum alloy plate 300 for the heat dissipation component 3 is fabricated.

[0105] As the aluminum alloy plate 30 , an aluminum alloy plate having a material quality of A8021-O and a size of 0.5 mm thickness×100 mm width×100 mm length was prepared.

[0106] Next, after degreasing both surfaces of the aluminum alloy plate 30 with an alkaline degreasing agent, the aluminum alloy plate 30 was immersed in a phosphoric acid chromate solution to perform a chemical generation treatment. The obtained chemically formed film (phosphoric acid chromate film) 302, as the Cr content in the film, is 20 ± 5 mg / m 2 In the range.

[0107] Next, a synthetic resin...

Embodiment 3

[0111] This example Figure 8 ~ Figure 10 Shown is an example based on the structure of Embodiment 1, adopting the following method: changing the form of the hemming process of the outer peripheral edge portion 21 of the LED mounting substrate 2 and the opening end portion 31 of the heat dissipation member 3, and Orientation performs hemming at six locations only.

[0112] like Figure 8 , Figure 9 As shown, in the heat radiating member 3 used in this example, after forming the radiating member 3 in the same manner as in Example 1, the opening end 31 is notched at six places in the circumferential direction, and six remaining convex shapes are provided. The opening end tab portion 315 of the first position. On the other hand, the board|substrate 2 for LED mounting is made into the shape which has the flange part 210 in the whole circumference similar to Example 1. As shown in FIG. Furthermore, the hemming process is performed only on the opening-end protrusion part 315 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com