Formaldehyde detecting material, formaldehyde detector, formaldehyde detecting method and formaldehyde detecting reagent

A detection reagent and detection device technology, applied in the field of formaldehyde detection reagents, can solve the problems of complicated operation, impracticality, poor practicability, etc., and achieve the effect of shortening the reaction time and ensuring discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment —

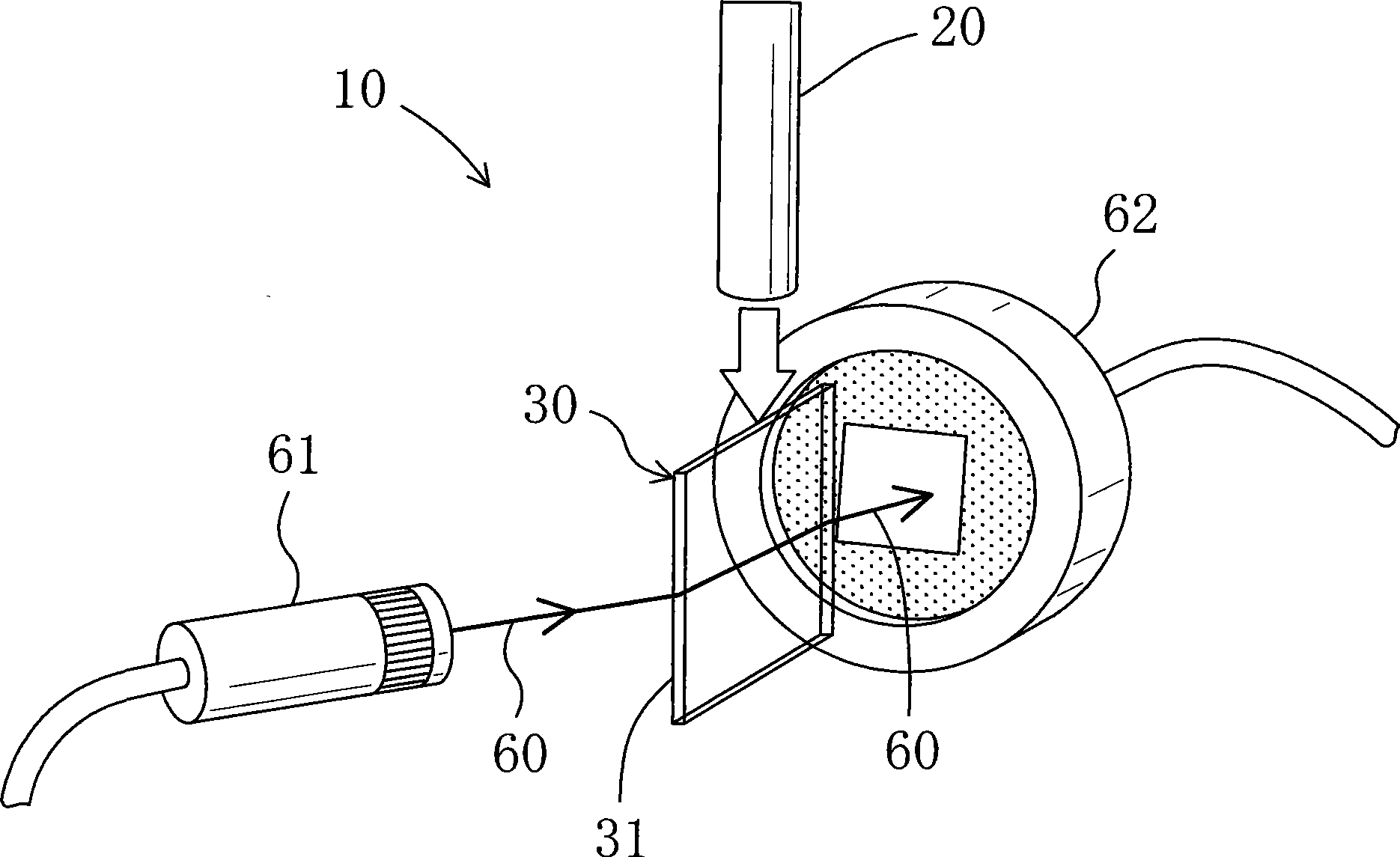

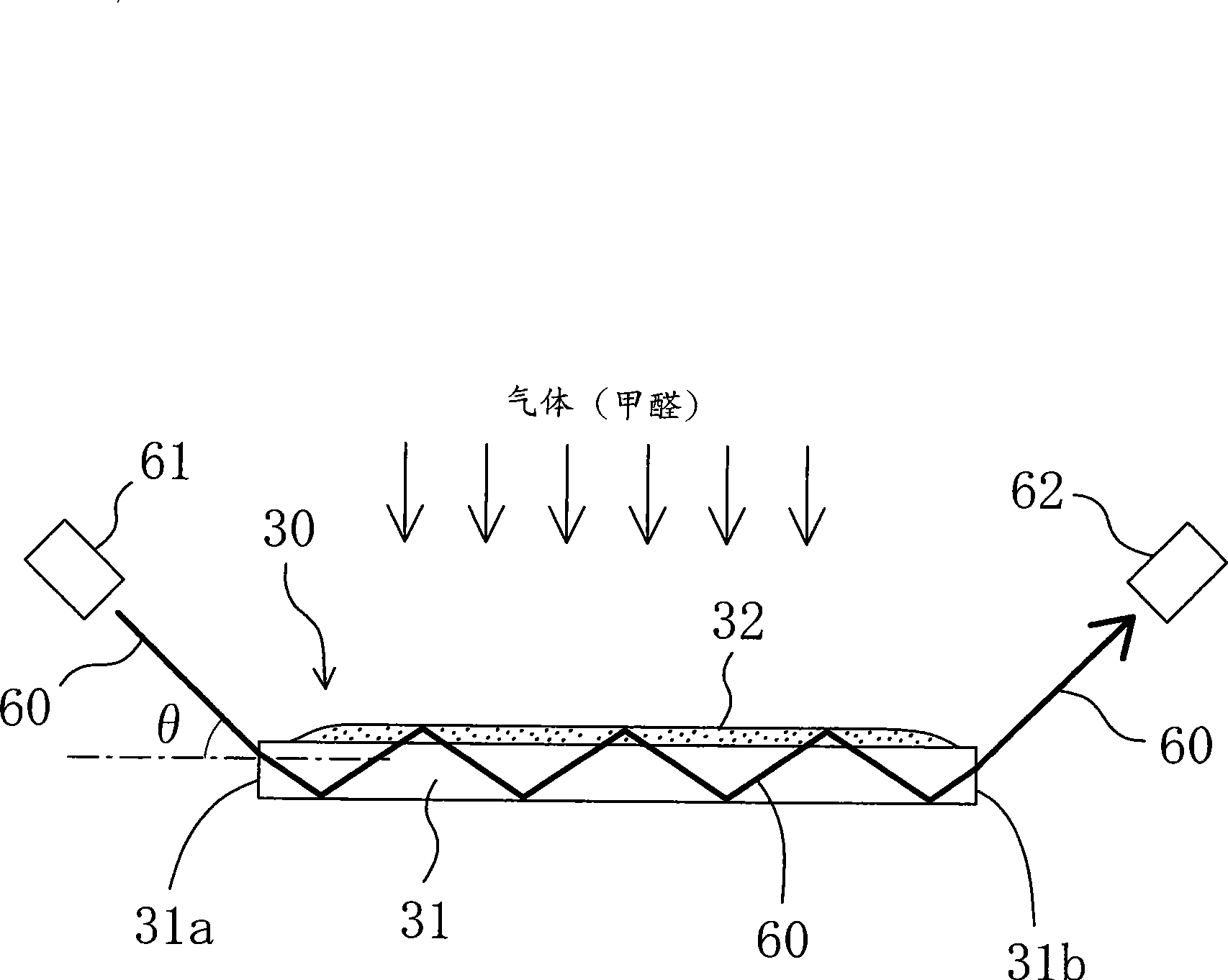

[0138] Next, examples of the detection element 30 will be described.

[0139] (1) Manufacture of mesoporous silica film (mesoporous layer), introducing 2-acetyl-3-ethyl dimethacrylate into the pores of mesoporous silica film (mesoporous layer)

First, as an example of a method for producing a mesoporous silica thin film, a mesoporous silica thin film is formed on a glass substrate. The production method employed is the method described in Non-Patent Document 2 and Non-Patent Document 3.

[0140] Specifically, 1-propanol, dilute hydrochloric acid, and 2-butanol were added to tetraethyl orthosilicate and stirred, and an aqueous solution of cetyltrimethylammonium chloride (C16TMA) was added thereto and Stir, then, drop a few drops of the obtained solution onto the glass substrate, and then use the spin coating technique to make a thin film. Next, the resultant was calcined in an electric furnace at a temperature of 400° C. in the atmosphere. The structure in the thin film was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com