Eddy-current-type reduction gear

A reduction gear, eddy current technology, applied in the direction of electromechanical devices, electrical components, electrical components, etc., can solve the problems of insufficient cylinder force, inability to seek low cost and miniaturization, and achieve the effect of reducing the force required for work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

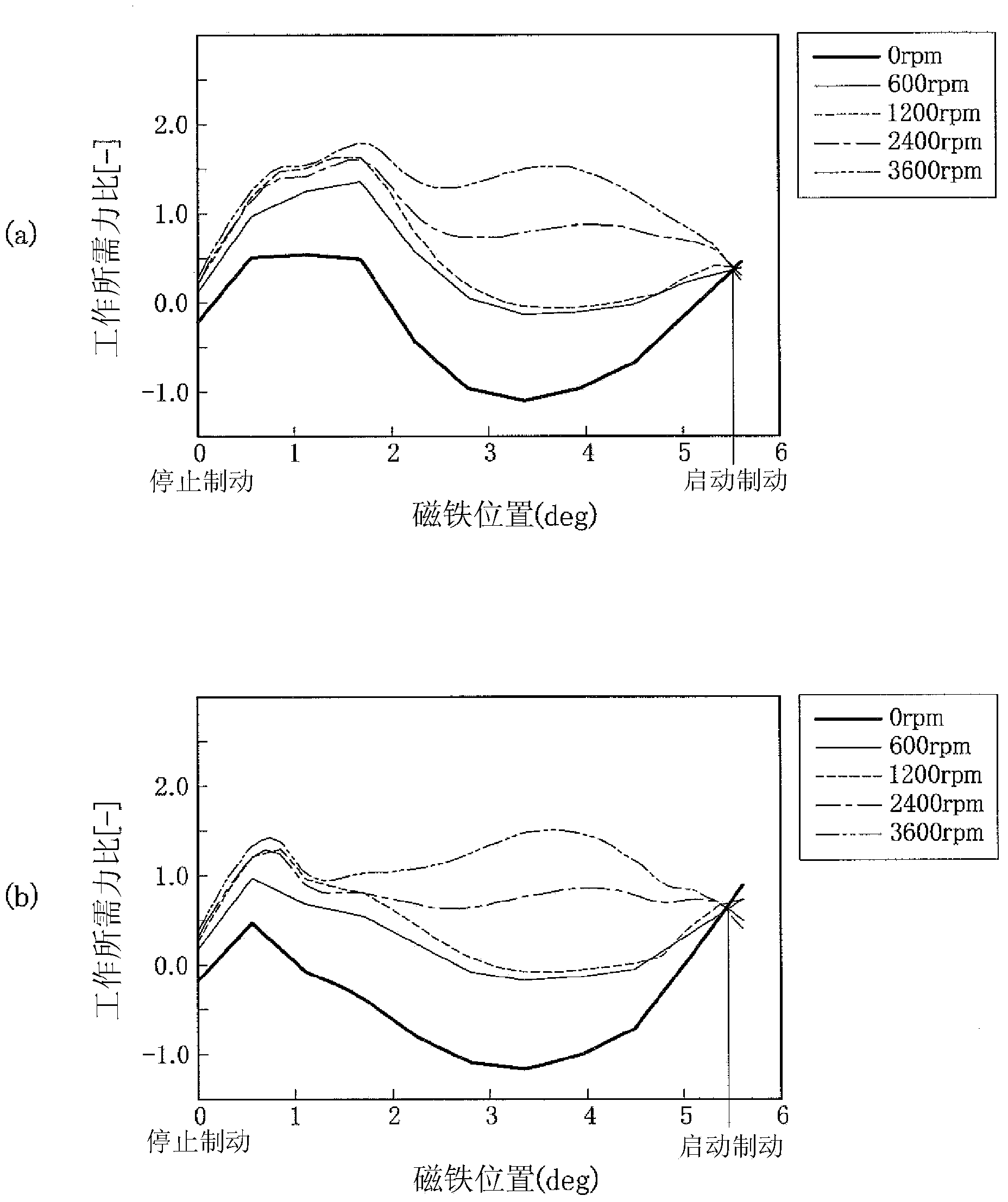

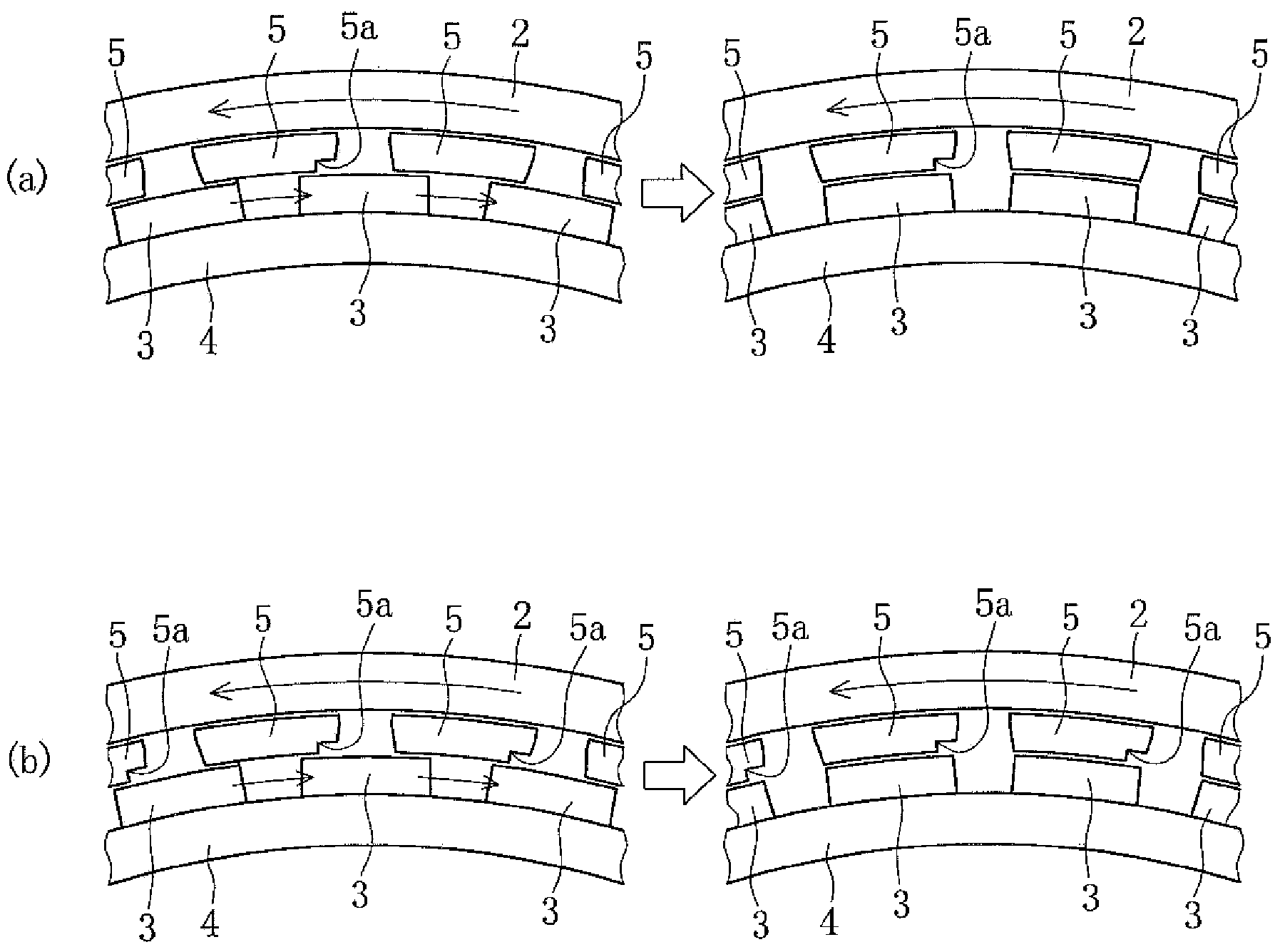

[0048] Figure 12 is used Figure 13 It is a diagram of the moving direction of the magnet supporting member 4 in the conventional speed reducer of the single-row rotation method of the pole piece 5 having the shape shown. in addition, Figure 14 It means that the numerical analysis obtained in Figure 10 A graph showing the results of the required operating force when switching between start braking and stop braking when the technology proposed by the applicant in Patent Document 4 is applied to the conventional speed reducer of the single-row rotary system shown. .

[0049] Figure 14 is the patent document 4 and Figure 6 Equivalent figure, patent document 4 can be obtained with Figure 6 The same result is obtained for the single-row rotary speed reducer shown by the solid line. In this way, it can be confirmed that in the technology proposed in Patent Document 4, when switching from stop braking to start braking, the diamagnetic field accompanied by the eddy current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com