Resin-made intake manifold, method for manufacturing resin-made intake manifold

An intake manifold and resin-made technology, which is applied in the manufacture of resin-made intake manifolds and the field of resin-made resin-made intake manifolds, can solve the problem of increasing the weight of resin-made intake manifolds and reducing the weight of intake manifolds. increase, cost increase, etc., to achieve the effect of increased durability, ensured strength, and suppressed deformation of the surrounding wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments embodying the present invention will be described in detail with reference to the drawings.

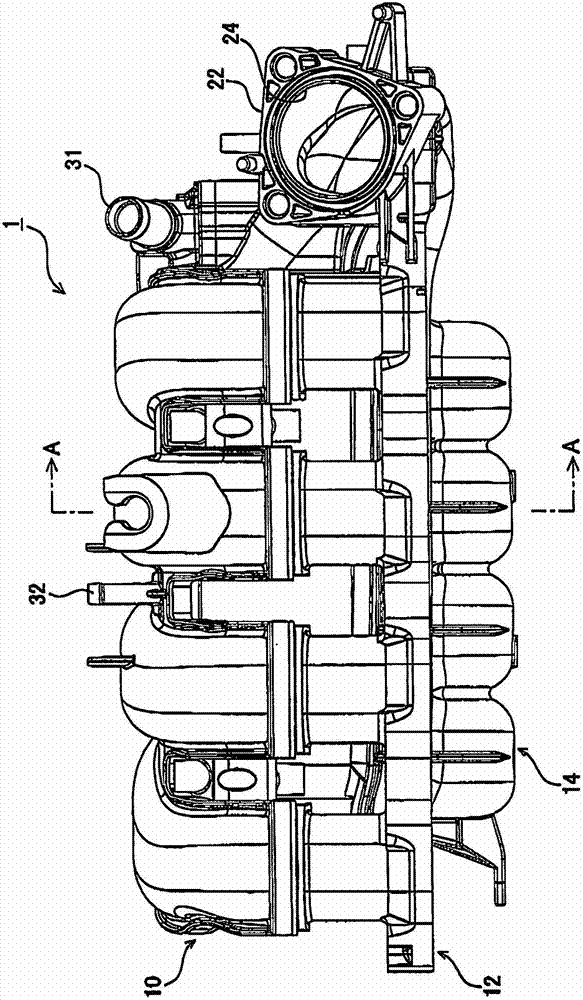

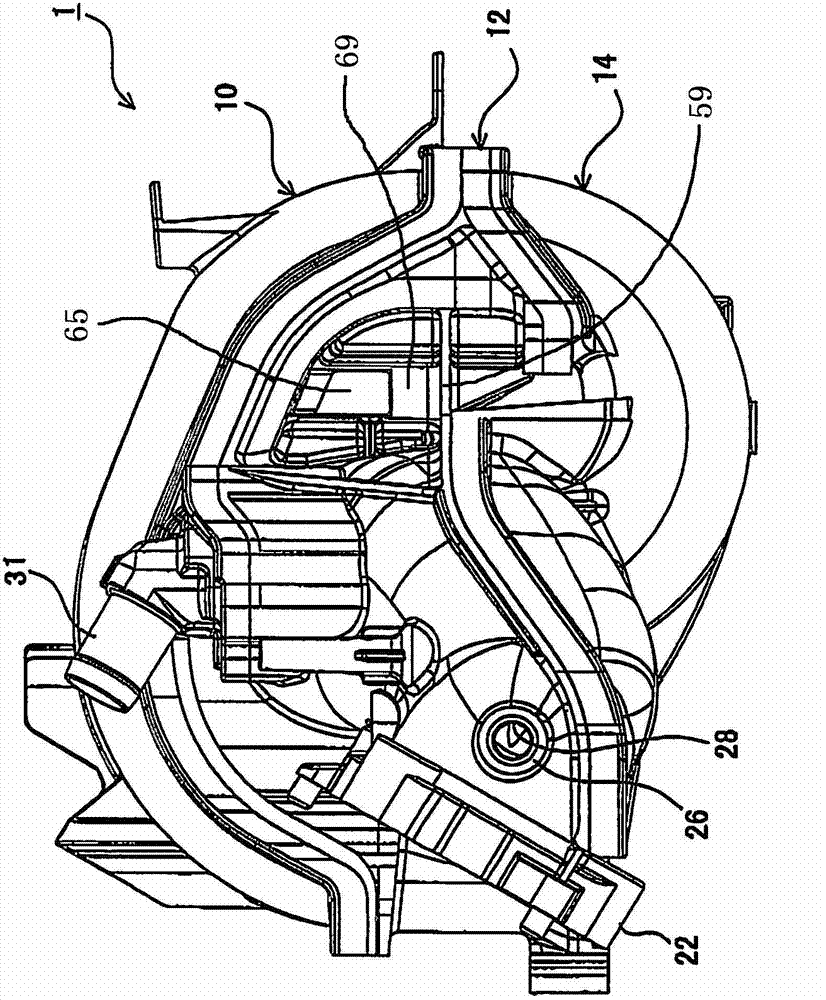

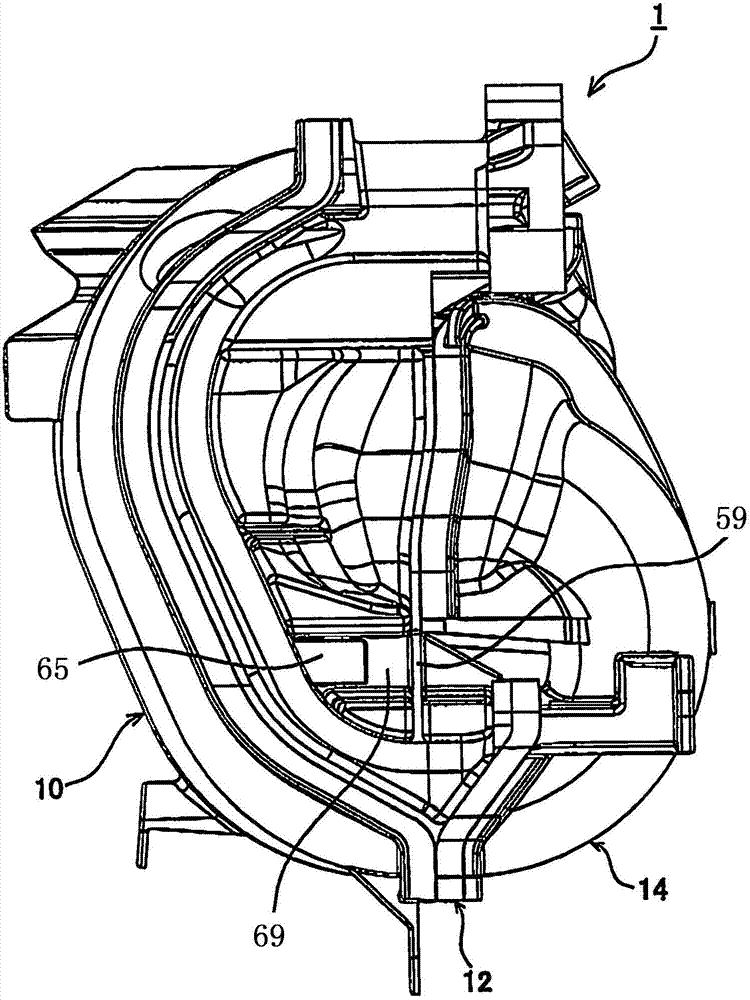

[0053] Description of resin intake manifold

[0054] First, the overall outline of the resin-made intake manifold 1 will be described. here, figure 1 It is a front view of the intake manifold 1 made of resin. In addition, Figure 2(a) is viewed from the right side of the accompanying drawing figure 1 Figure 2(b) is a view of the resin intake manifold 1 shown from the left side of the drawing figure 1 The figure of the intake manifold 1 made of resin shown in Figure 2(c) is viewed from the upper side of the drawing figure 1 A diagram of the intake manifold 1 made of resin is shown. in addition, image 3 It is an exploded view of the resin intake manifold 1, Figure 4 yes figure 1 A-A sectional view of .

[0055] Such as Figure 1 ~ Figure 3 As shown, the intake manifold 1 made of resin is composed of an upper member 10 , a middle member 12 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com