Evaporator

A technology of evaporator and liquid collection tank, which is applied in the direction of evaporator/condenser, indirect heat exchanger, heat exchanger type, etc. It can solve the problems of increased flow path resistance, performance degradation, and large ratio, and achieve refrigerant flow The effect of increasing the cross-sectional area of the passage, preventing the rapid rise of the exhaust gas temperature, and preventing the increase of the flow passage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

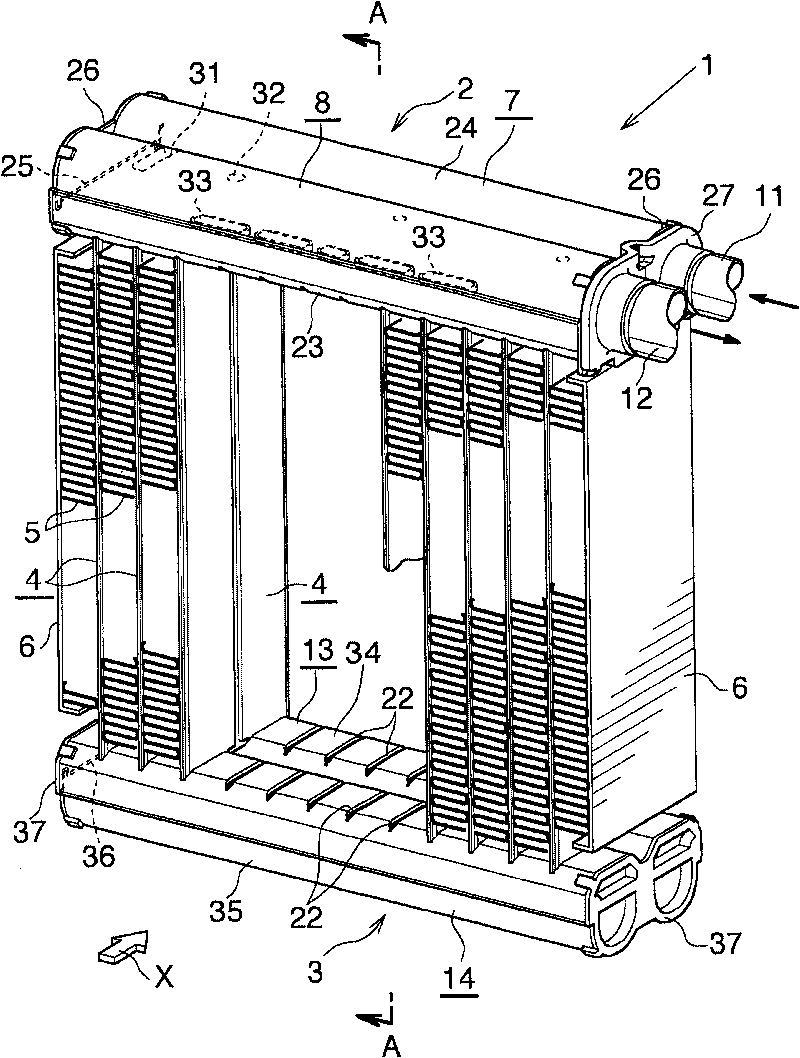

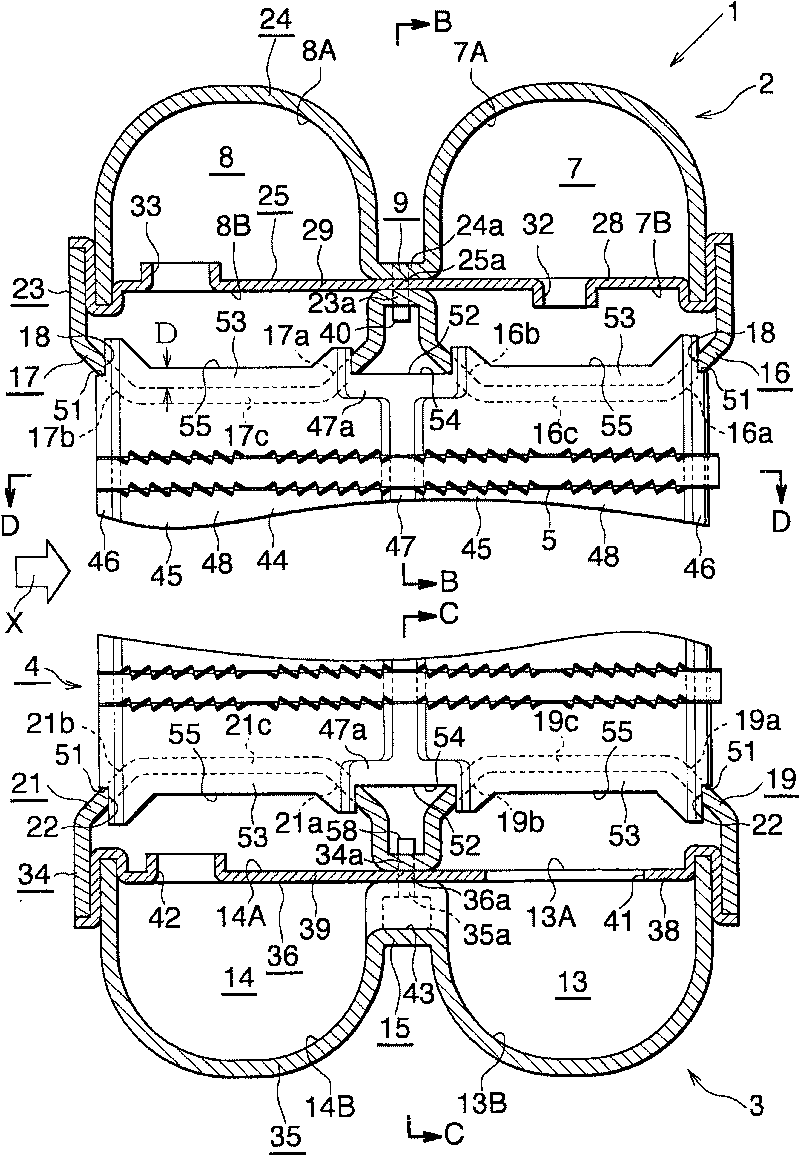

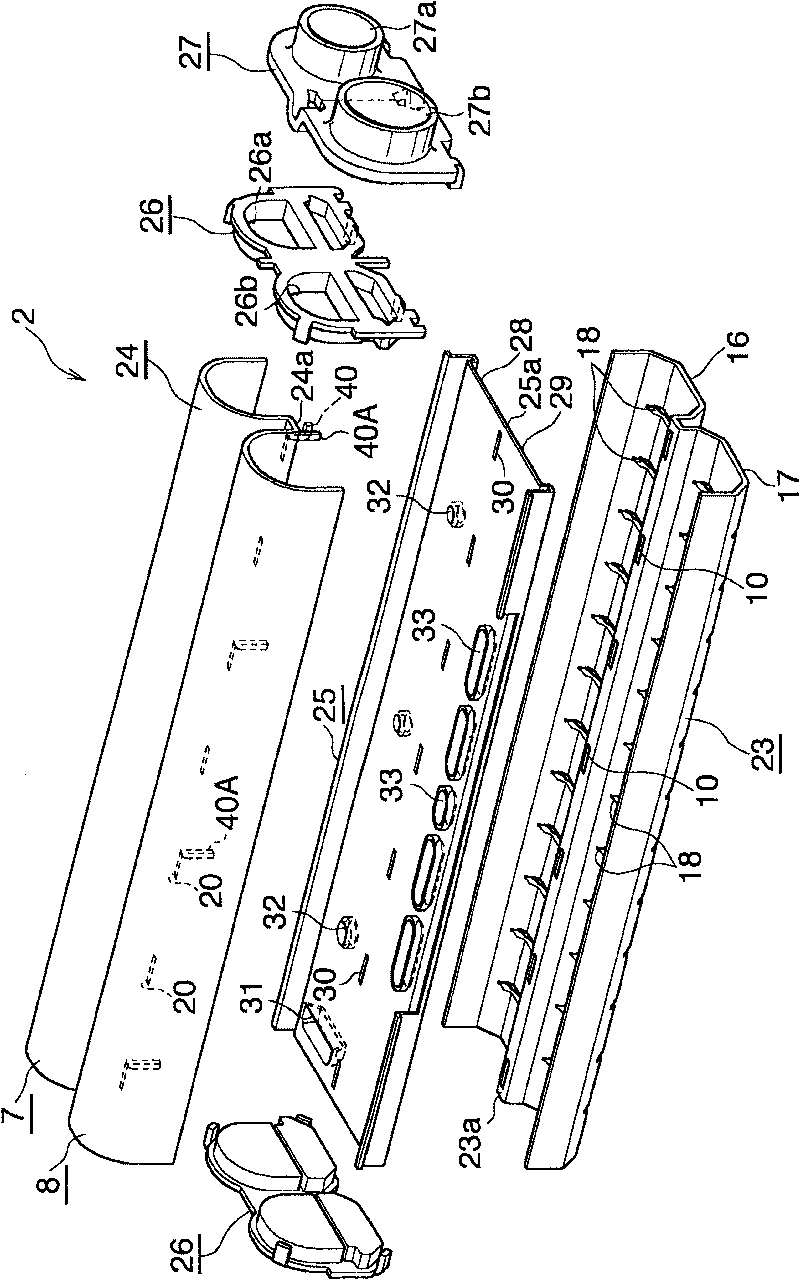

[0055] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0056] In addition, in the following description, the term "aluminum" includes aluminum alloys in addition to pure aluminum. In addition, in the following description figure 1 The left and right are called left and right.

[0057] figure 1 Indicates the overall composition of the evaporator, Figure 2 to Figure 9 Shows the main components of the evaporator.

[0058] Such as figure 1 as well as figure 2 As shown, the evaporator 1 has: a first header tank 2 made of aluminum and a second header tank 3 made of aluminum that are arranged at intervals in the up-down direction and extend in the left-right direction; in the two headers 2 , 3, the width direction is oriented in the front and rear direction and in the left and right directions (the length direction of the header tanks 2, 3) are arranged at intervals in a plurality of aluminum flat heat exchange tubes 4; The ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com