Exhaust Gas Purification System for Internal Combustion Engine

a technology of exhaust gas purification system and internal combustion engine, which is applied in the direction of machines/engines, mechanical equipment, electric control, etc., can solve the problems of insufficient oxidation-removal of particulate matter trapped in the filter, increased backpressure in the exhaust gas, and reduced engine performance, so as to achieve the effect of simple configuration and increased temperature of the exhaust gas purifying devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

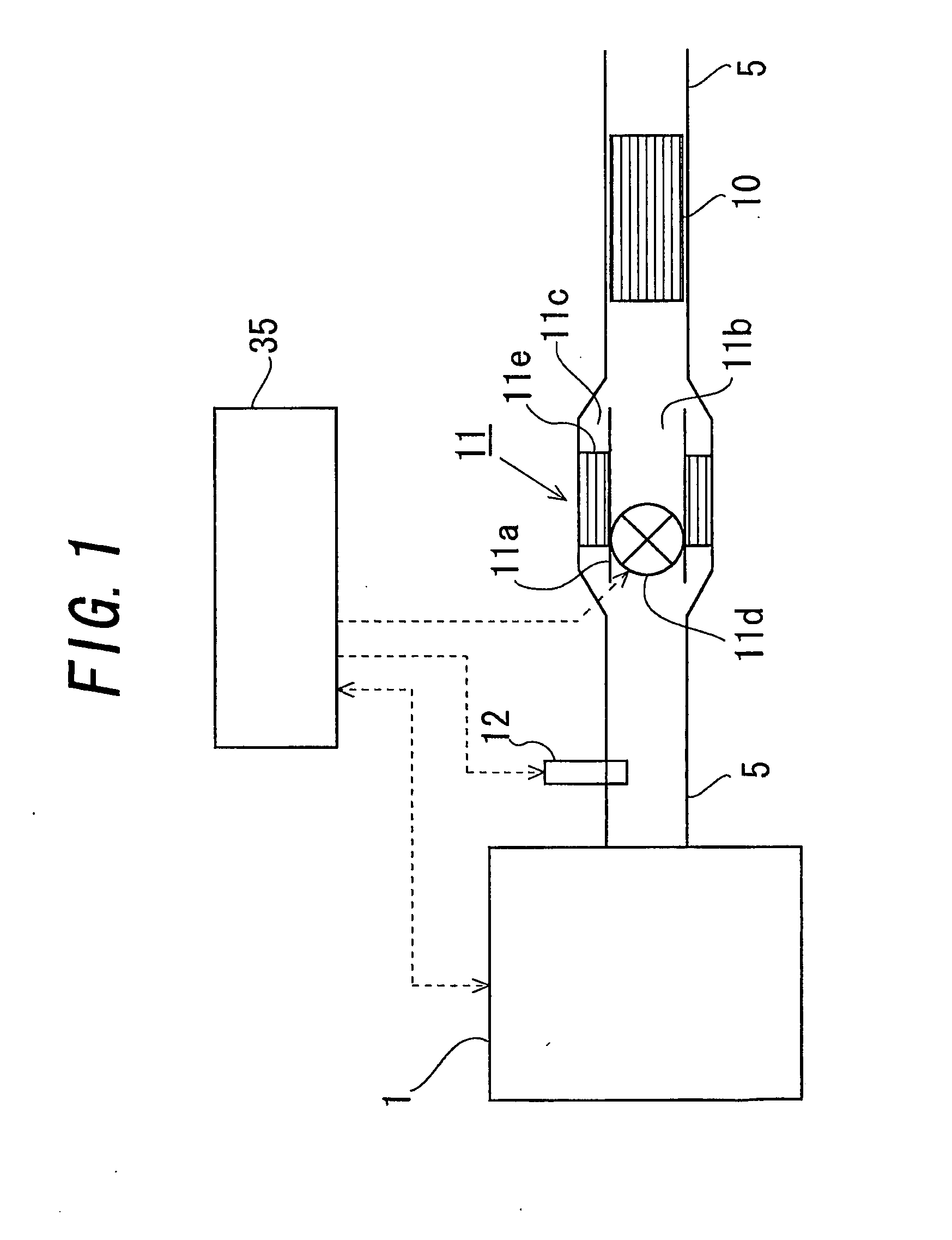

[0049]FIG. 1 is a view showing an internal combustion engine according to a first embodiment and showing outlines of configurations of an exhaust system and a control system thereof. An internal combustion engine 1 shown in FIG. 1 is classified as a diesel engine. Note that an interior of the internal combustion engine 1 and an intake system thereof are omitted in FIG. 1.

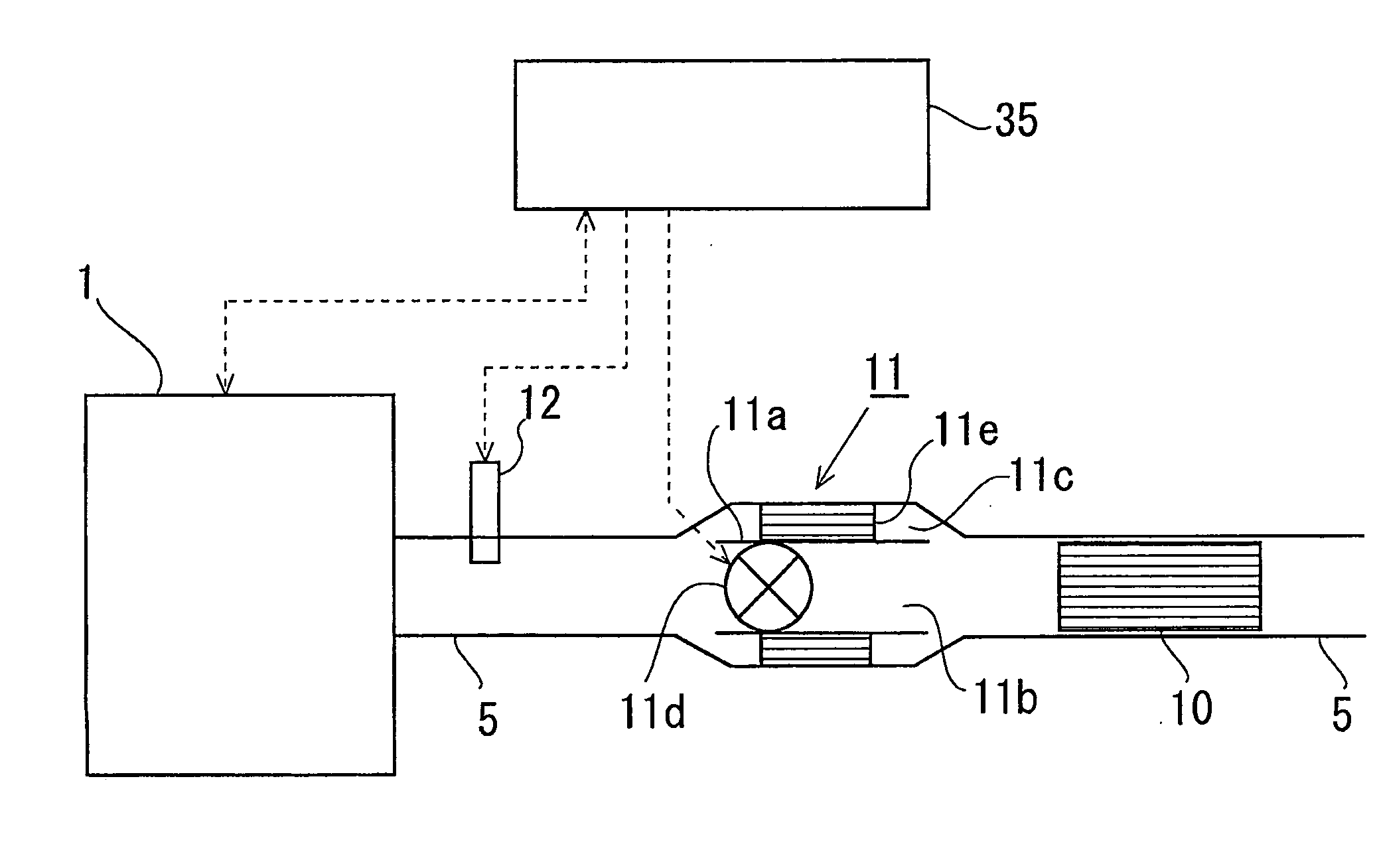

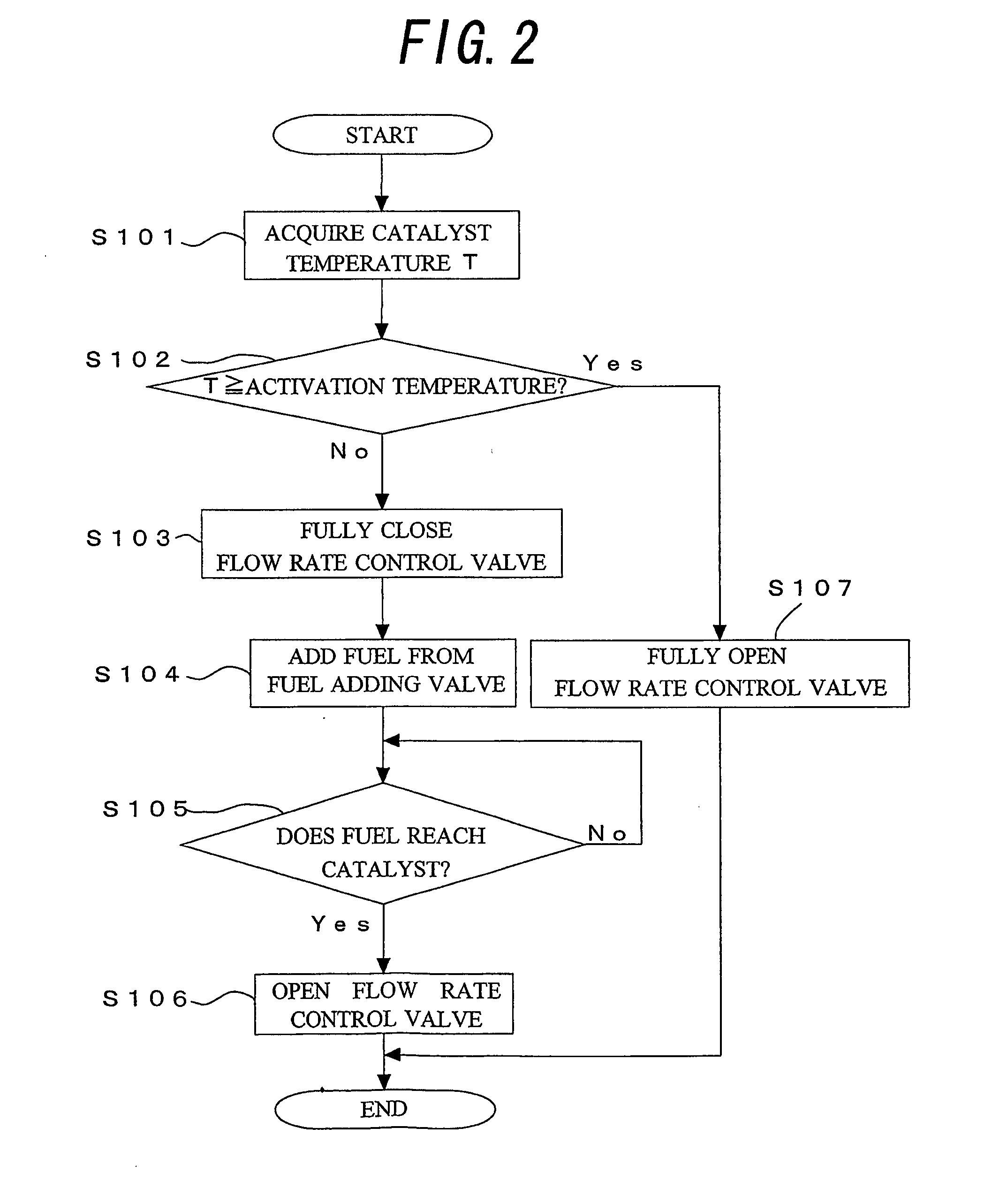

[0050]In FIG. 1, an exhaust pipe 5, through which an exhaust gas discharged from the internal combustion engine 1 flows, is connected to the internal combustion engine 1 and is further connected downstream to an unillustrated silencer. Moreover, an exhaust gas purifying device 10, which purifies the exhaust gas from NOx and particulate matters (e.g., soot), is disposed downstream in the exhaust pipe 5. Then, an exhaust gas temperature increasing device 11, which increases the temperature of the exhaust gas purifying device 10 by increasing a temperature of the exhaust gas flowing into the exhaust gas purifying devic...

second embodiment

[0080]Next, a second embodiment of the present invention will be described. The second embodiment will exemplify another configuration of the exhaust gas temperature increasing device 11 explained in FIG. 1.

[0081]FIG. 4 is a view showing an outline of the configuration of the exhaust gas temperature increasing device 11 in the second embodiment. A first mode of the second embodiment is that as illustrated in FIG. 4 (A), an exhaust gas purifying device 20 and an exhaust gas temperature increasing device 21 are substantially equalized in their diameters and are provided within a pipe having the same diameter. According to the first mode, the exhaust gas can be more smoothly flowed into the exhaust gas purifying device 20 without disturbing the flow of the exhaust gas discharged from the exhaust gas temperature increasing device 21. Further, especially when an oxidation catalyst 21e is provided in an external pipe portion 21c, the high-temperature exhaust gas discharged from the oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com