Projection zoom lens and projection type display apparatus

一种变焦透镜、透镜的技术,应用在光学元件、光学、仪器等方向,能够解决广角端狭窄、难以谋求透镜系统小型化、轻量化等问题,达到像差良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

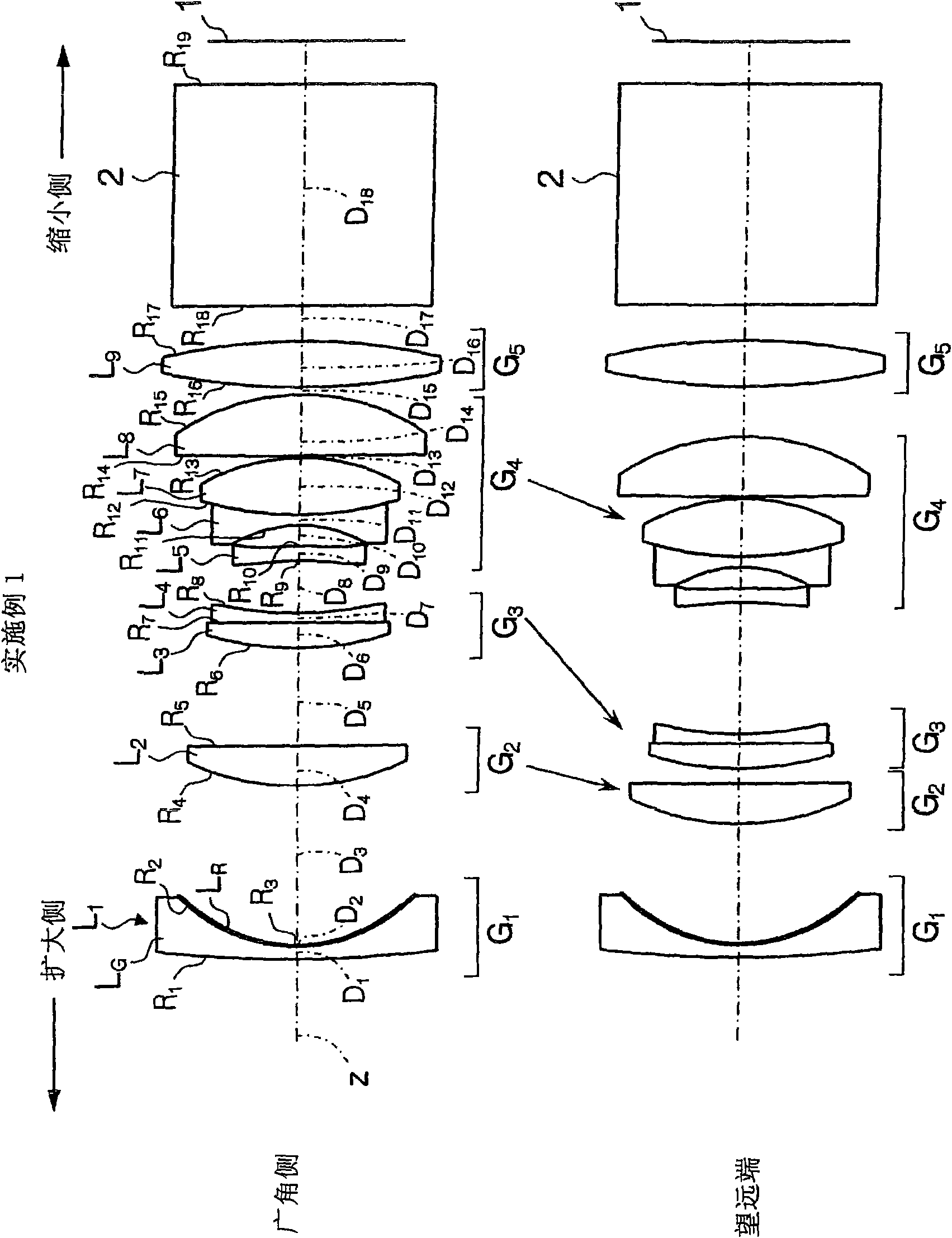

Embodiment 1

[0109] The projection zoom lens related to this Embodiment 1 is set as described above figure 1 structure shown. That is, in the zoom lens for projection, the first lens group G 1 only by passing through the glass lens L G The surface of the resin layer L is closely bonded to form R And the resin layer L R The first lens L composed of a composite aspheric lens formed with an aspheric surface at the interface with air 1 Composition, second lens group G 2 Second lens L consisting only of a positive meniscus lens with a convex surface facing the magnification side 2 Composition, third lens group G 3 Contains third lens L consisting of a positive meniscus lens with a convex surface facing the magnification side 3 And the fourth lens L consisting of a negative meniscus lens whose concave surface faces the reduction side 4 . Furthermore, the fourth lens group G 4 Contains 5th lens L with aspheric surfaces on both sides of the concave surface facing the magnification side ...

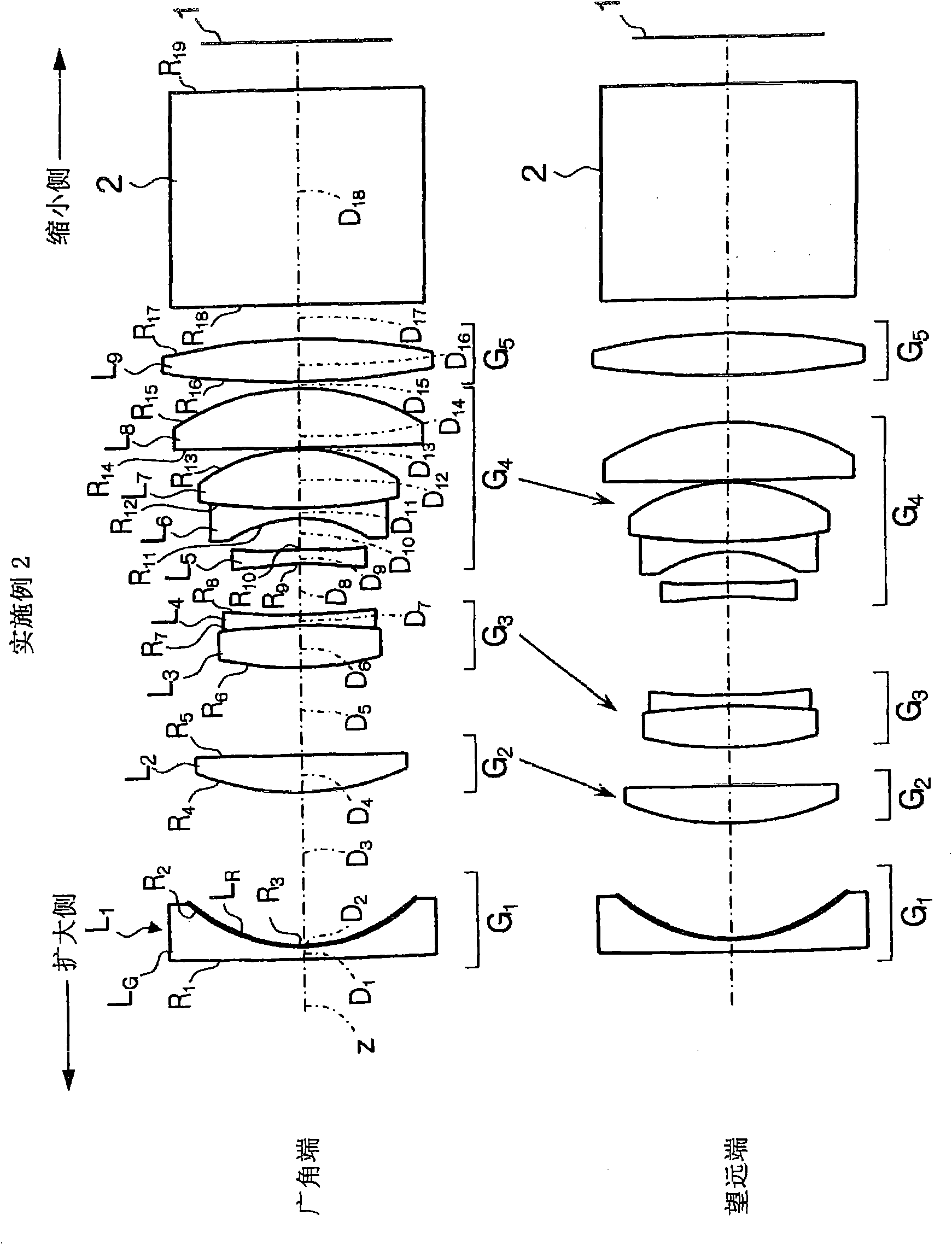

Embodiment 2

[0127] exist figure 2 The schematic configuration of the projection zoom lens according to the second embodiment is shown. The projection zoom lens related to this second embodiment has substantially the same structure as that of the first embodiment, and the main difference is that the second lens L 2 Consists of biconvex lens, third lens L 3 I consist of a biconvex lens, and the fourth lens L 4 Consists of biconcave lenses.

[0128] Table 2 shows the radius of curvature R of each lens surface, the center thickness of each lens, the air space D between each lens, the refractive index Nd of the d-line of each lens, and the Abbe number vd of each lens in Example 2.

[0129] [Table 2]

[0130] face number

R

D

N d

v d

1

25.778

0.072

1.58913

61.1

2

0.952

0.008

1.52771

41.8

3*

0.829

(variable 1)

4

1.520

0.216

1.83400

37.2 ...

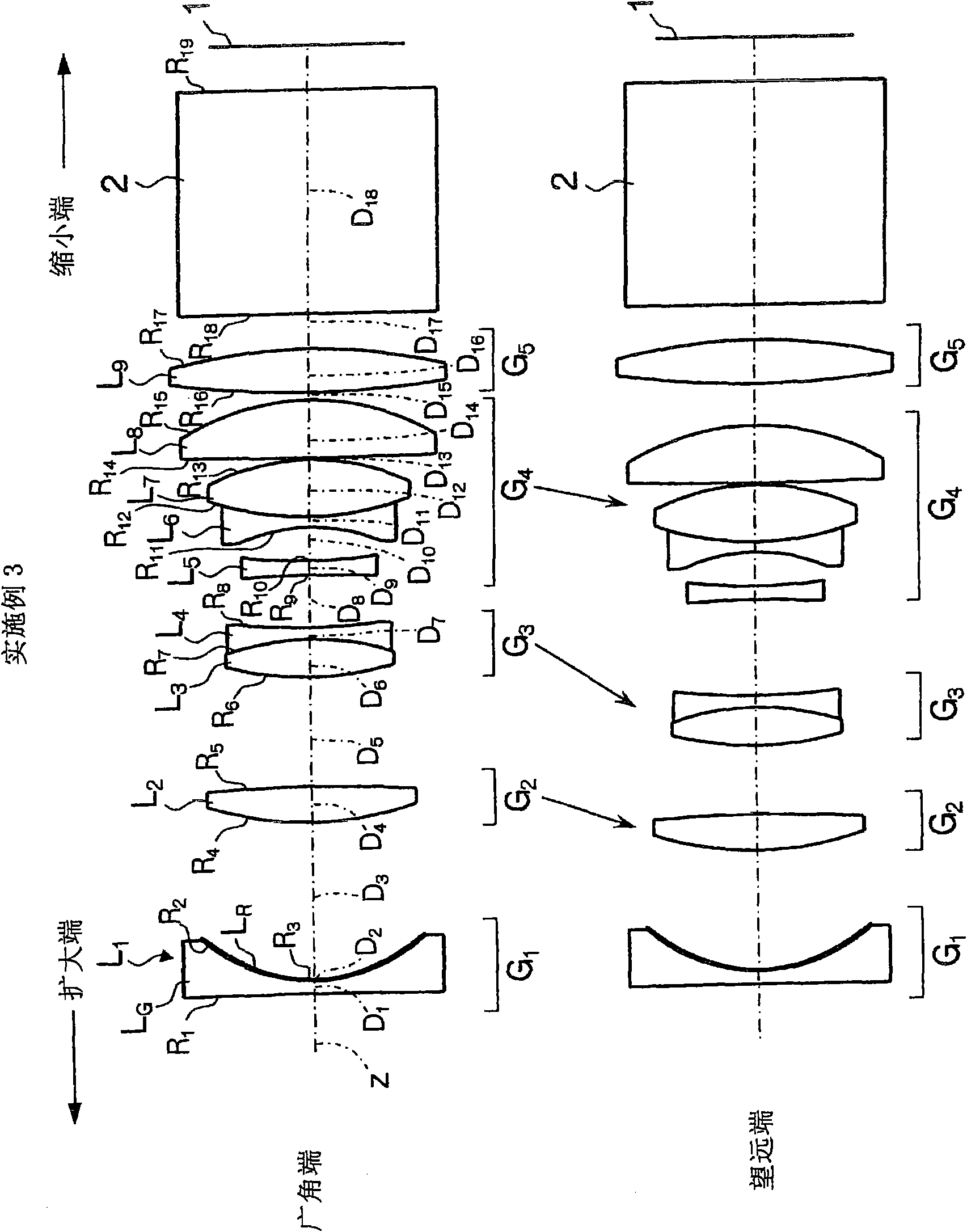

Embodiment 3

[0141] exist image 3 The schematic configuration of the projection zoom lens according to the third embodiment is shown. The projection zoom lens according to the third embodiment has substantially the same configuration as that of the second embodiment, but the main difference from the second embodiment is that the first lens L 1 Consists of biconcave lenses.

[0142] Table 3 shows the radius of curvature R of each lens surface, the center thickness of each lens, the air space D between each lens, the refractive index Nd of the d-line of each lens, and the Abbe number vd of each lens in Example 3.

[0143] [table 3]

[0144] face number

R

D

N d

v d

1

-62.674

0.072

1.58913

61.1

2

0.924

0.008

1.52771

41.8

3*

0.804

(variable 1)

4

1.817

0.200

1.83400

37.2

5

-8.443

(variable 2)

6

1.769 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com