Seat rail structure of motorcycle

A technology for motorized two-wheeled vehicles and seats, applied to motor vehicles, bicycle saddles, bicycles, etc., can solve the problems of assembly man-hours, difficulty in manufacturing corrosion-resistant frames, and difficulty in further improving productivity, etc., to achieve increased productivity , the effect of increasing the section coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

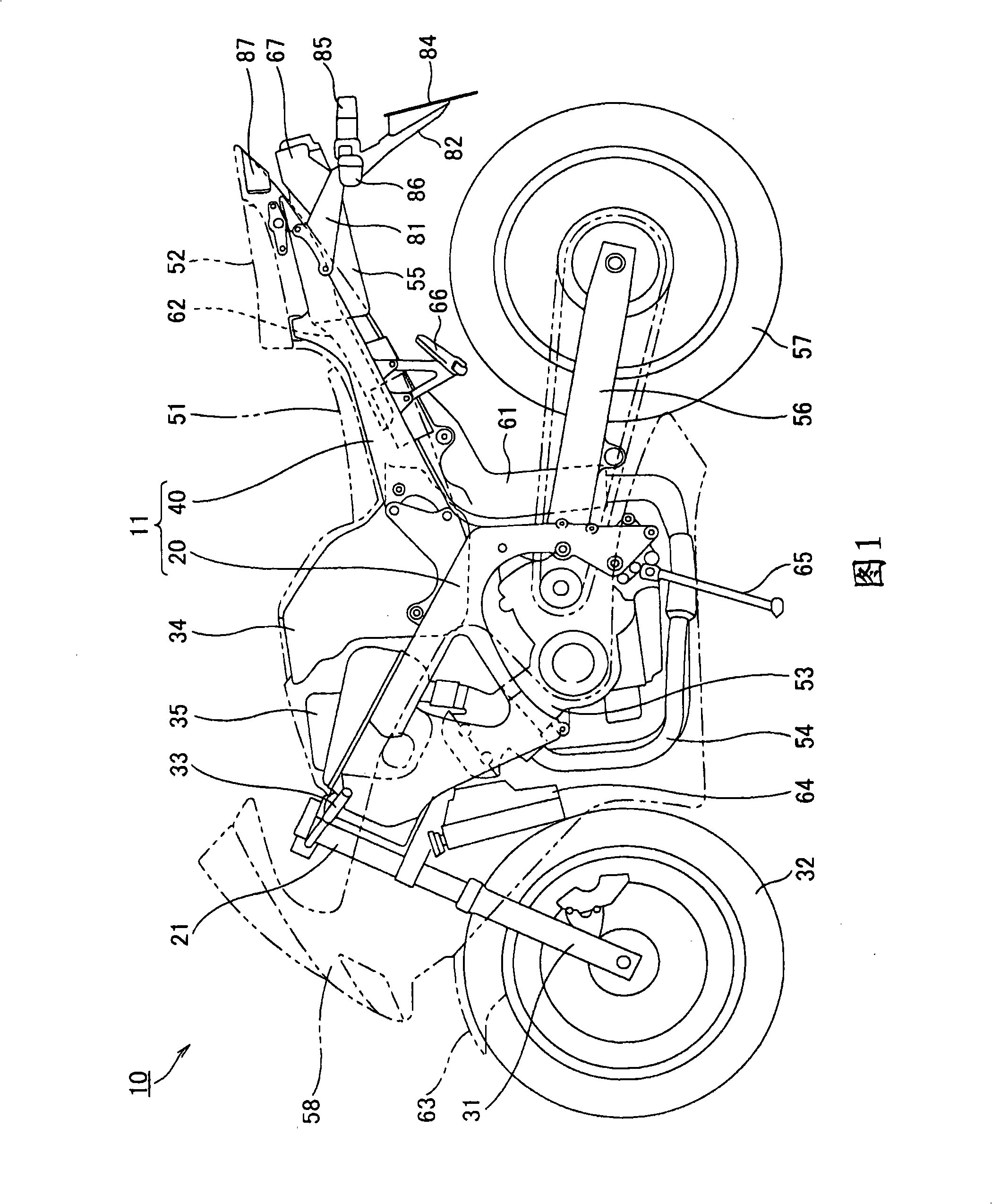

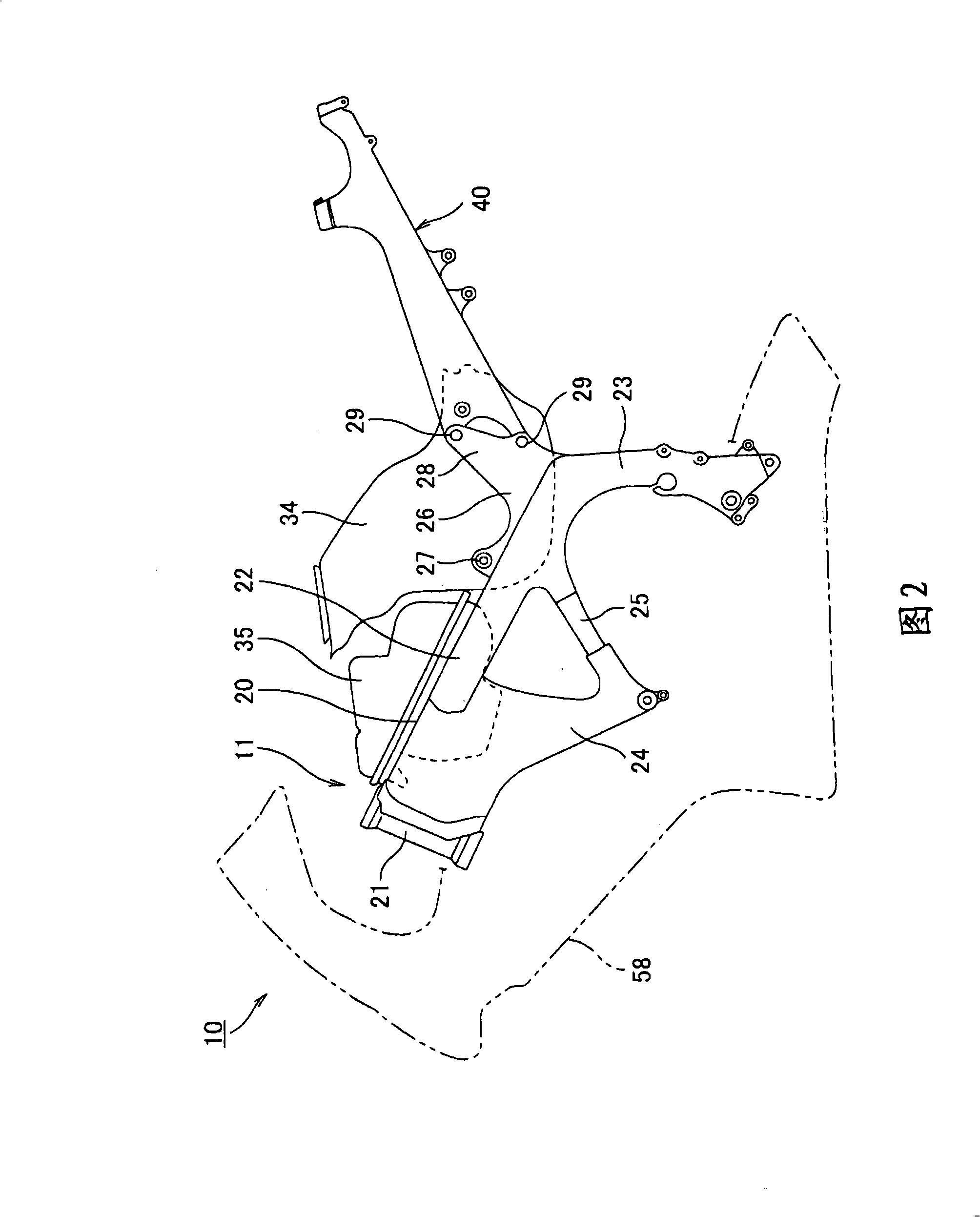

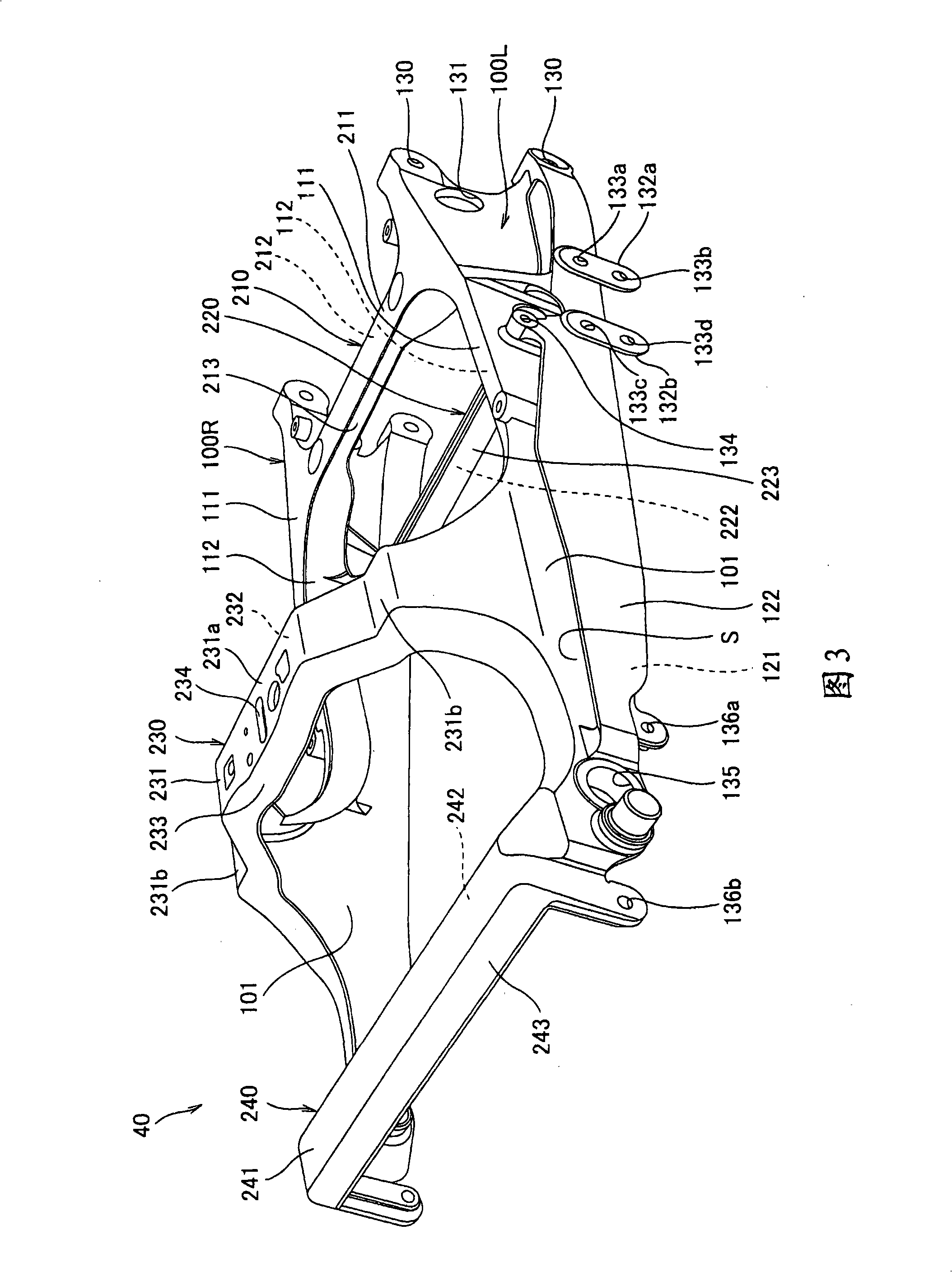

[0096] Next, a seat rail structure of a motorcycle according to an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a left side view showing a motorcycle 10 according to an embodiment of the present invention. The directions used in the following description are based on FIG. 1 . The vertical direction of the vehicle body is the vertical direction in FIG. 1 , the lateral direction of the vehicle body is the direction toward the depth of the drawing in FIG.

[0097] The motorcycle 10 is provided with a double beam frame 20 extending in the front-rear direction, and a head pipe 21 is provided on the front side of the frame 20 . A front fork 31 extending downward is attached to the head pipe 21 , and a handle 33 is connected to the upper side. Furthermore, a front wheel 32 is attached to the lower side of the front fork 31 . A seat rail 40 further extending from the rear end portion toward the rear of the vehicle body is attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com