Attachment structure of door weather strip for vehicle

A technology of sealing strip and structure, which is applied in the direction of sealing device, engine sealing, vehicle parts, etc., can solve the problems of poor sealing performance, deterioration of door closing performance, and reduction of elastic contact force, and achieve good door closing performance and door closing performance. The effect of good performance and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

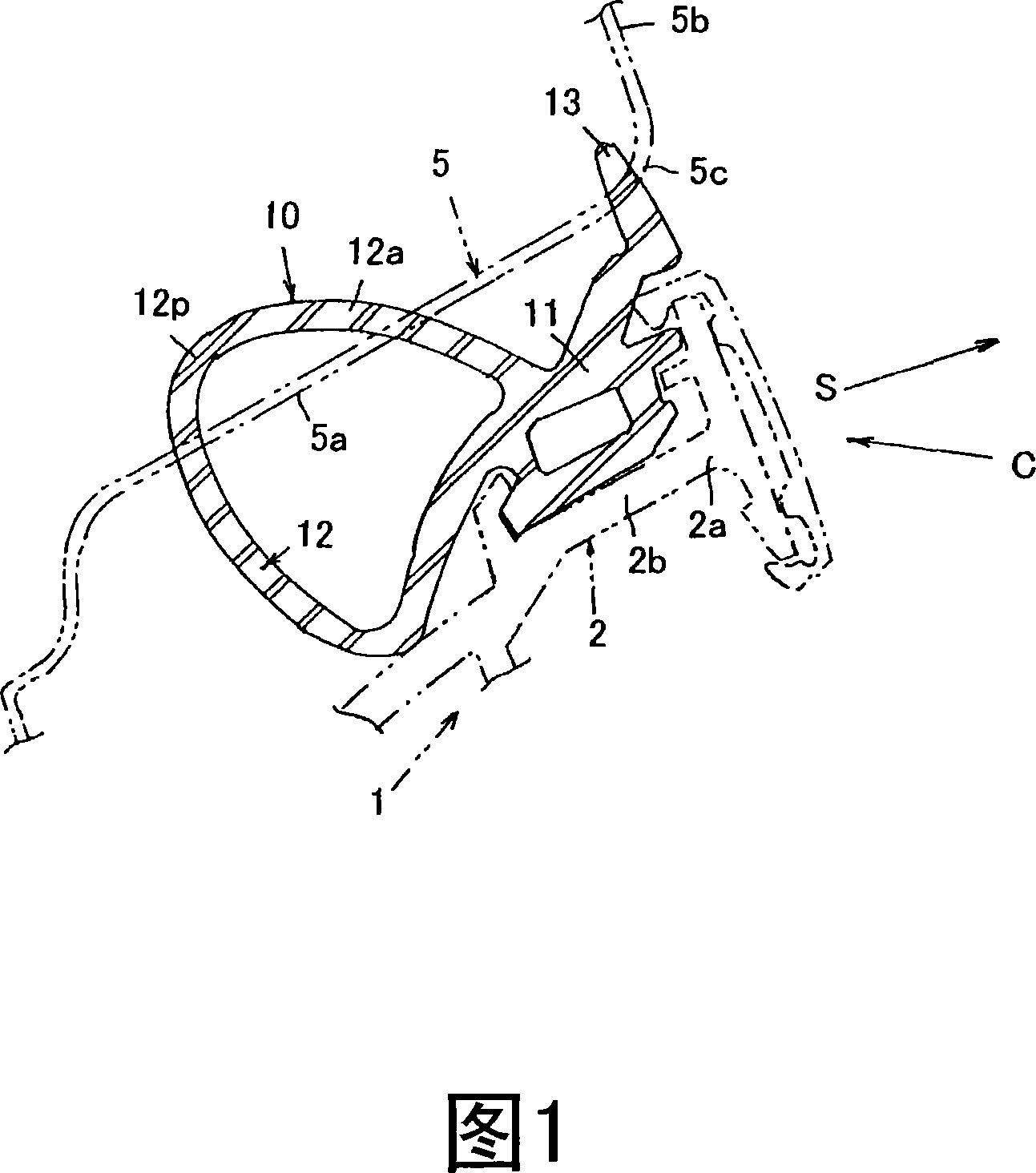

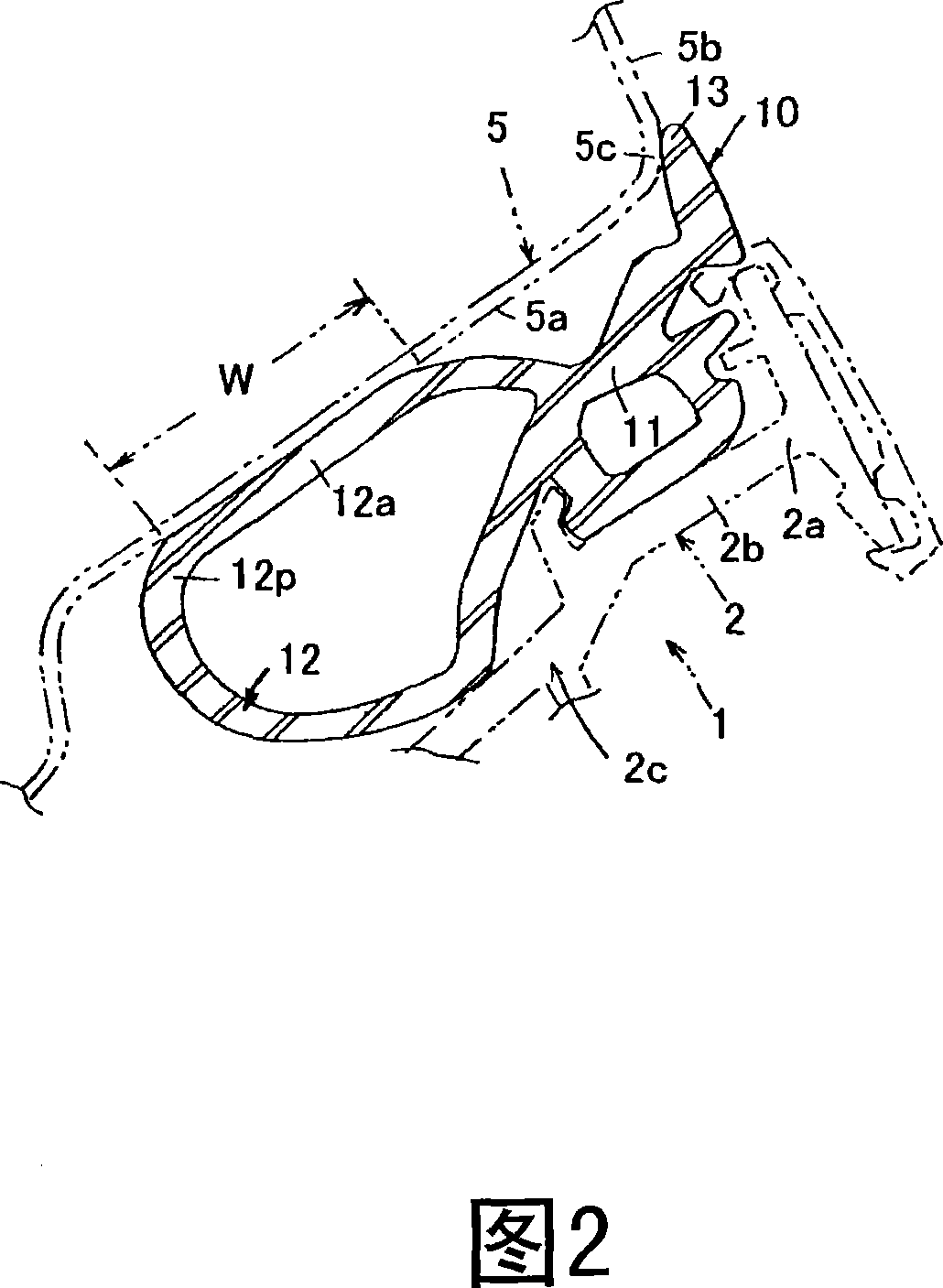

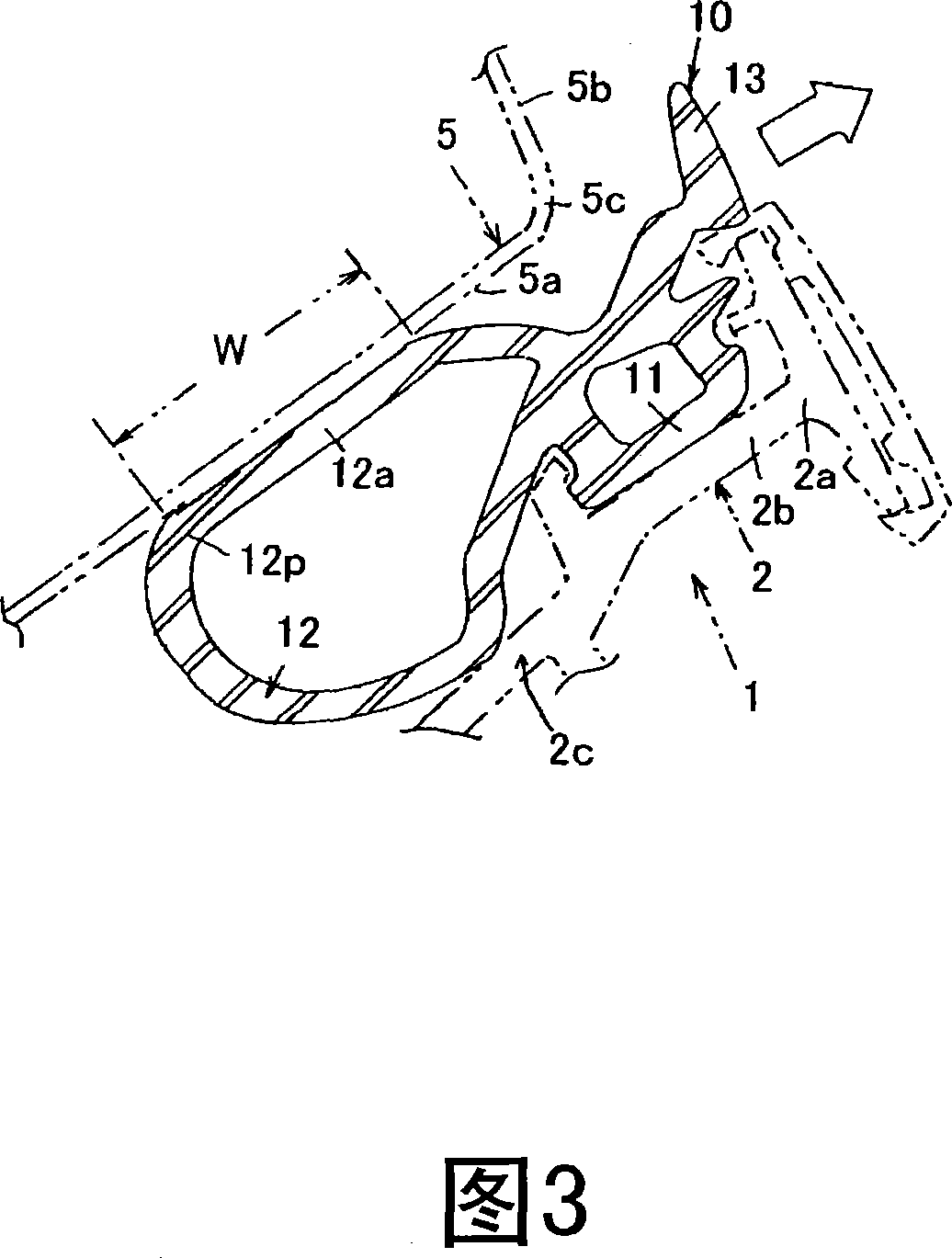

[0032] First, the suction direction S will be described. When the car is running, the speed of the air flowing from front to rear along the side of the car increases, so the air pressure decreases, and the air pressure inside the car sandwiching the door glass and the air pressure outside the car become lower than the air pressure outside the car. On the other hand, the door is provided with hinges above and below the lower half of the metal cladding part, and no hinges are provided at the upper half of the door, that is, the periphery of the door glass in the closed state of the door glass. In addition, among automobiles, there are automobiles in which the upper half of the door (door glass portion) is inclined toward the inner side of the vehicle. In this type of automobile, if the door glass is completely closed and the door glass is completely closed, an external force inclined in a direction perpendicular to the door glass surface, that is, outward and upward, is generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com