Sealing member and method of producing the same

A sealing member and foam-making technology, which is applied in the directions of engine sealing, chemical instruments and methods, and engine components, can solve problems such as difficulty in sealing materials, and achieve the effect of reducing specific permittivity and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

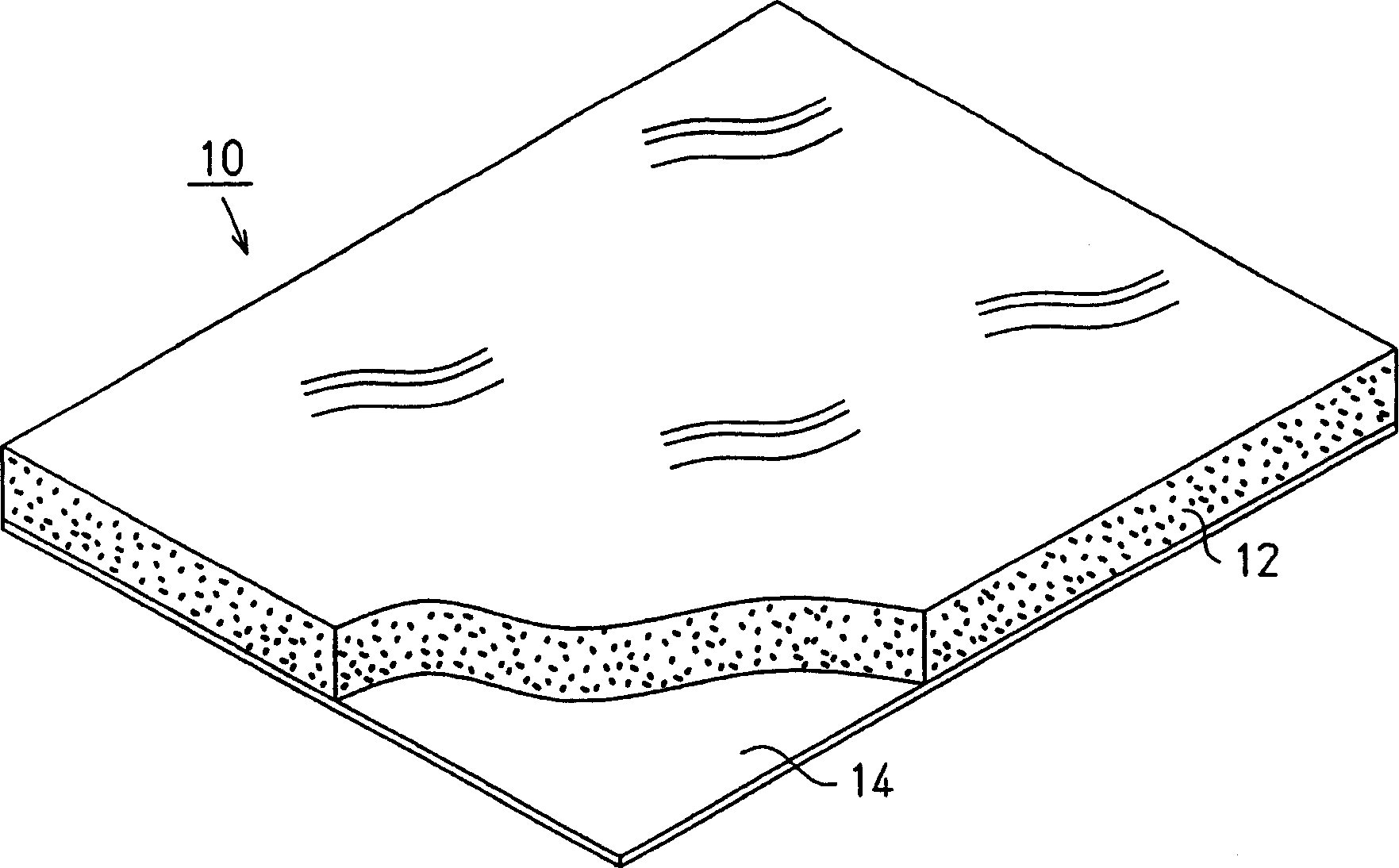

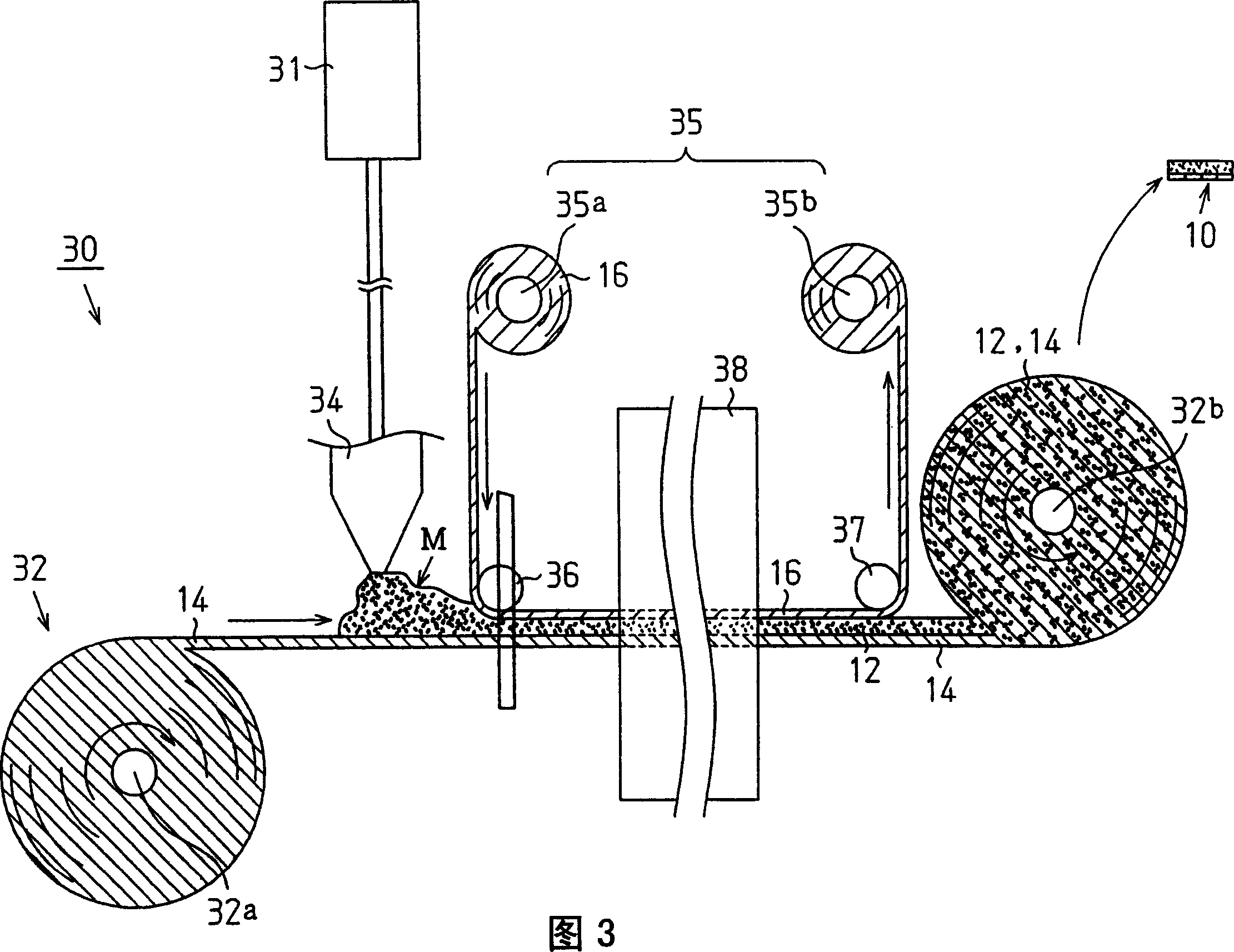

[0035] Next, an experimental example in which the sealing member of the present invention is produced from the foam raw materials under the conditions described in Table 1 and Table 2, and its sealing properties and the like are evaluated.

[0036] (Experiment 1) Regarding the difference in density, 50% CLD and 75% CLD

[0037] In 100 parts by weight of polyether polyol A, mix 3 parts by weight of crosslinking agent (1,4-butanediol), 20 parts by weight of thickener (aluminum hydroxide), 0.1 part by weight of metal catalyst (tin octanoate Stannousoctoate) and 3 parts by weight of a foam stabilizer (silicon-based substance; including a solvent for dilution) to obtain a mixture. Nitrogen (foaming gas) and polyisocyanate (trade name C-1130 ; Nippon Polyurethane Industry Co., Ltd., グルドドMDI, NCO content: 31%) were mixed and sheared to obtain the raw material M. The foam raw material M is supplied from the nozzle 34 onto a substrate film (made of PET) of a desired thickness which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com