Extrusion molded article for automobiles

一种成形品、主体部分的技术,应用在车辆部件、机械设备、运输和包装等方向,能够解决渗出、有损成形品外观等问题,达到充分密封性、外观良好、减少再循环工序的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0160] Hereinafter, the present invention will be further described through examples and comparative examples, but the present invention is not limited in any way by the following examples. The materials and experimental methods used in the examples and comparative examples are as follows.

[0161] material

[0162] Ingredient (a):

[0163] EPDM: NODEL IP4770R (trade name, produced by Duo La Stoma Co., Ltd.), an ethylene-propylene-5-ethylidene-2-norbornene (ENB) copolymer rubber synthesized with a metallocene catalyst, with a specific gravity of 0.88, Mooney Viscosity ML 1+4 (125°C) is 70, weight average molecular weight is 200,000, ethylene is 70%, and ENB is 4.9%.

[0164] Ingredient (b):

[0165] SEEPS: SEPS4077 (trade name, manufactured by KURARAY Co., Ltd.), a styrene-ethylene·ethylene·propylene-styrene copolymer with a molecular weight of 270,000 and a styrene content of 30%.

[0166] SEBS: KRATON MD6933ES (trade name, produced by KRATON POLYMER Co., Ltd.), a styrene-ethylen...

Embodiment 1~10 and comparative example 1~8

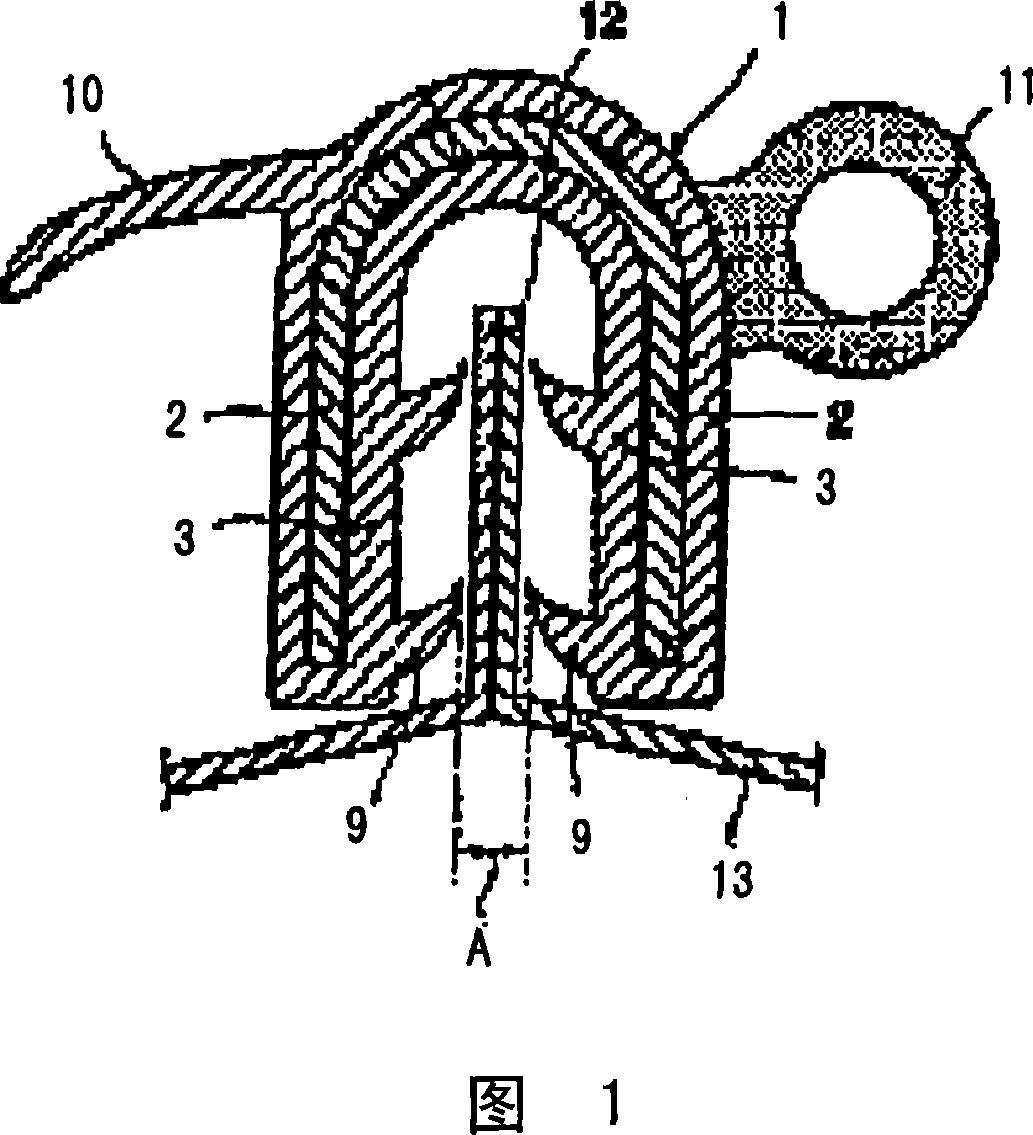

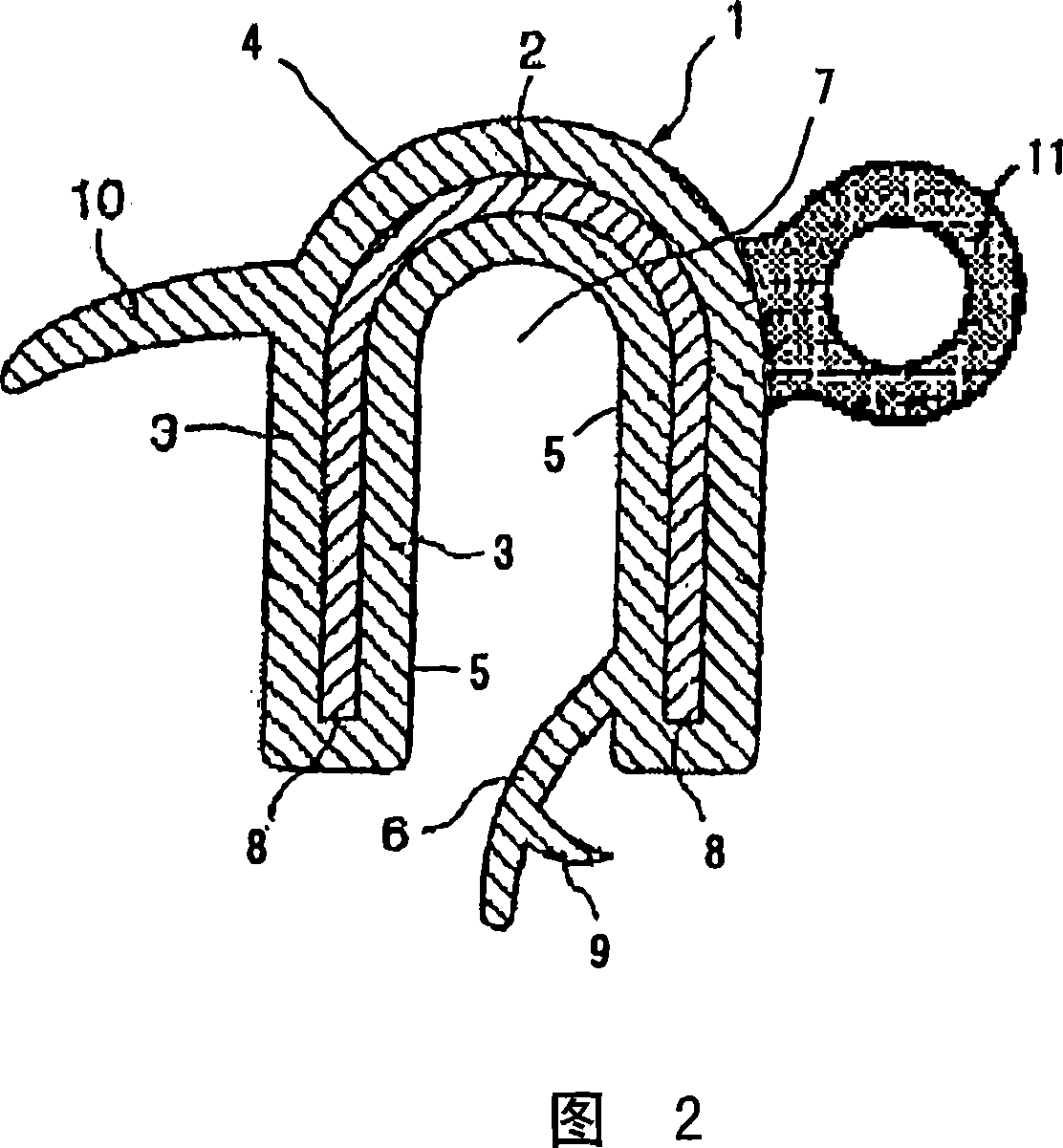

[0204] For the coating layer (3), the composition having the composition (parts by weight) shown in Table 1 was used, and the composition having the composition (parts by weight) shown in Table 2 was used for the hollow sealing portion (11) to produce the composition shown in Fig. 6 Extrusion molded product showing cross section. For the core (2), EBP9840N (produced by RIKEN TECHNOS, polypropylene mixed with 40% by weight of talc powder, measured according to JIS K7161, the tensile elongation at break is 110%, measured according to ASTM D790 at 23°C The bending elastic modulus of 3500MPa).

[0205]It is manufactured according to the method shown in FIG. 8. That is, first, the resin constituting the core (2) is supplied to the first extruder (EX1) and passed through the inside of the first die (K1) to form the core. After passing the formed core having a substantially U-shaped cross-section through the cooling groove (C1), a punching machine (P1) is used to form a cutout. The extru...

Embodiment 11~13 and comparative example 9~11

[0217] Except for using the composition shown in Table 3 as the resin constituting the core (2) in Example 1, a molded product was produced in the same manner as in Example 1, and evaluation experiments of flange retention and R followability were performed. The results are shown in Table 3.

[0218] 【table 3】

[0219] Example 11

Example 12

Example 13

Comparative example 9

Comparative example 10

Comparative example 11

Make up

(Parts by weight)

ノバテツクPP EC9(*1)

60

70

50

ノバテツクPP EA9(*2)

80

60

クラウン·talc PP(*3)

40

30

50

20

60

40

Evaluation

Result

Proportion

1.23

1.13

1.33

1.04

1.39

1.23

Flexural elasticity (23℃)(Mpa)

3500

2800

4200

2000

4600

4400

Flexural elasticity (80℃)(Mpa)

1200

1000

1300

700

1500

1500

Te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com