Anisotropic conductive film

An anisotropic, conductive film technology, applied in the direction of conductive connections, conductive adhesives, circuits, etc., can solve the problems that anisotropic conductive films cannot correspond to TCP substrates and COF substrates, etc., to improve connection reliability and delay polymerization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

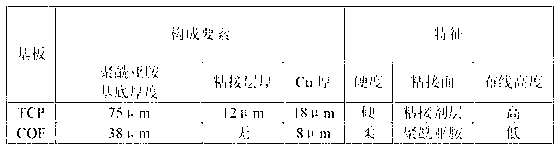

Method used

Image

Examples

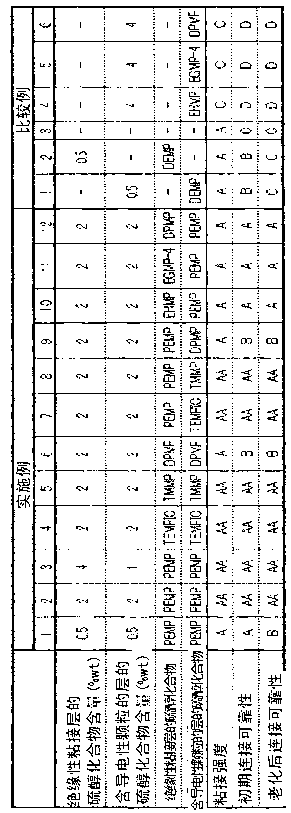

Embodiment 1-12、 comparative example 1-6

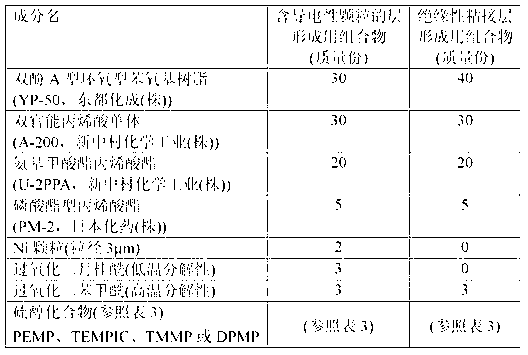

[0060] The compounding composition of Table 2 was uniformly mixed according to the conventional method, respectively, and the composition for layer formation containing electroconductive particle and the composition for insulating adhesive layer formation were prepared. Next, the composition for forming an insulating adhesive layer was coated on the release-treated polyester film with a bar coater to a dry thickness of 18 μm, and was dried by blowing hot air at 70° C. for 5 minutes. Form an insulating adhesive layer. Next, the layer-forming composition containing conductive particles was coated on the insulating adhesive layer with a bar coater to a dry thickness of 17 μm, and dried by blowing hot air at 70° C. for 5 minutes, thereby A layer containing conductive particles is formed. Thus an anisotropic conductive film was obtained.

[0061] [Table 2]

[0062]

[0063]

[0064] PEMP: Pentaerythritol tetrakis(3-mercaptopropionate), SC Organic Chemical Co., Ltd.

[0065...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com