TPE (thermoplastic elastomer) material for signal transmission line and preparation method of TPE material

A thermoplastic elastomer, signal transmission line technology, used in plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems of sticky surface, dust absorption, precipitation, and no dry hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a thermoplastic elastomer material for a signal transmission line in an embodiment includes the following steps:

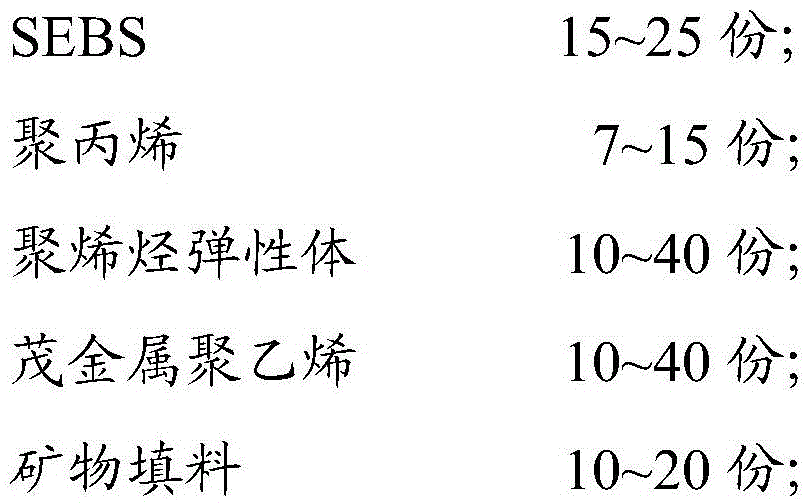

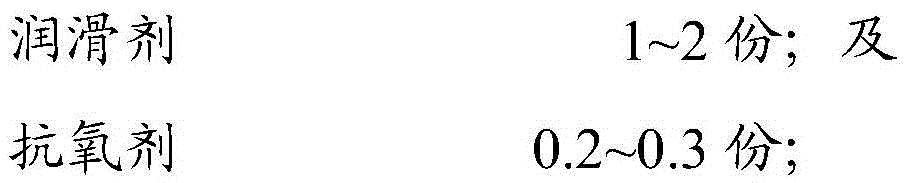

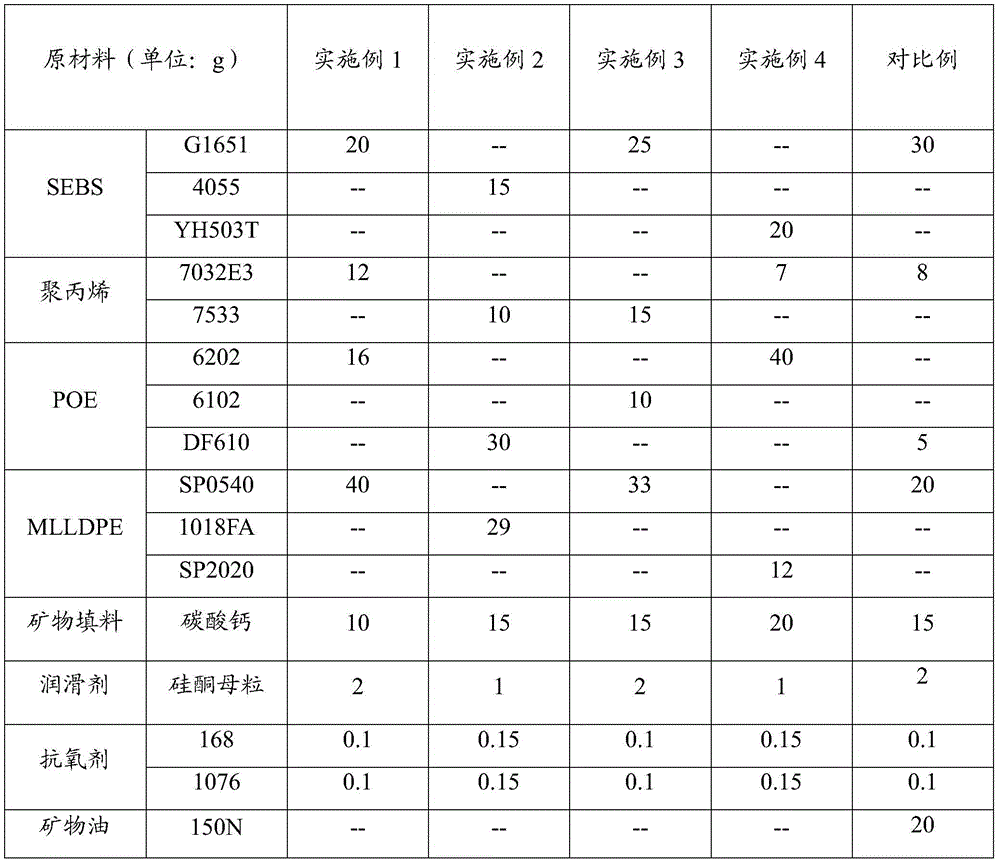

[0032] Step 1, adding 15 to 25 parts by weight of SEBS, 7 to 15 parts by weight of polypropylene, 10 to 40 parts by weight of POE, 10 to 40 parts by weight of MLLDPE, 10 to 20 parts by weight of mineral fillers, 1-2 parts by weight of lubricant and 0.2-0.3 parts by weight of antioxidant are stirred and mixed at a speed of 1000-1400 rpm for 5-10 minutes to obtain a premix; and

[0033] Step 2, placing the premixed material in a twin-screw extruder to extrude, draw, cool, and granulate to obtain a thermoplastic elastomer material for signal transmission lines.

[0034] Preferably, the extrusion temperature of the twin-screw extruder is 170-200°C.

[0035] The above-mentioned preparation method of the thermoplastic elastomer material for the signal transmission line has a simple process flow, low requirements on equipment, and is suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com