High light-transmittance and high flame-retardant polycarbonate material and preparation method of polycarbonate material

A technology of polycarbonate and high light transmittance, which is applied in the direction of lighting and heating equipment, lighting devices, parts of lighting devices, etc. It can solve the problems of low flame retardant efficiency, inability to produce synergistic effects, and large amount of main flame retardants. problem, to achieve the effect of good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

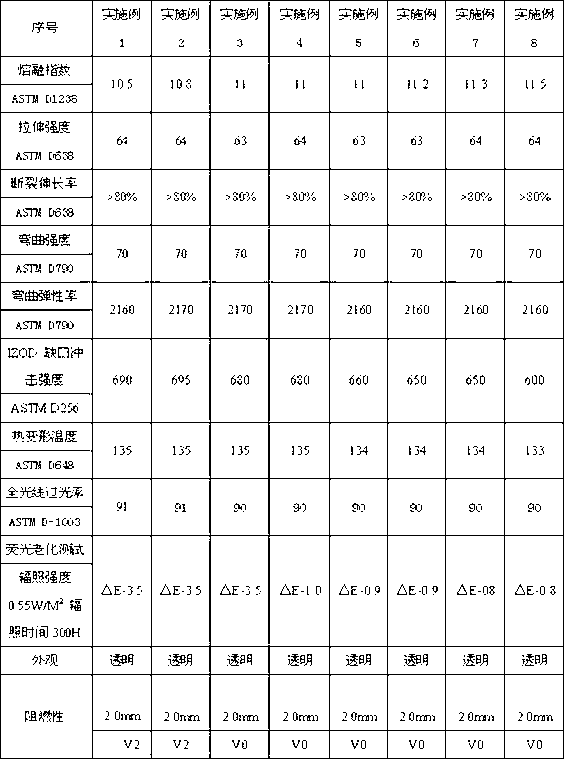

Examples

Embodiment 1

[0078]A kind of high light transmittance, high flame retardant polycarbonate material of the present embodiment, comprise the raw material of following composition and mass percentage: 99.5% of Bayer's 2805 bisphenol A type polycarbonate, 0.1% di Phenylsulfone sulfonate, 0.1% brominated carbonate oligomer, 0.1% tris(2,4-di-tert-butylphenyl) phosphite, 0.1% β-(3,5-di-tert-butyl n-octadecyl-4-hydroxyphenyl) propionate, 0.1% octadecanoic acid-2-(hydroxymethyl)-2-[[(1-oxoctadecyl)oxy] Methyl]-1,3-propanediyl ester.

[0079] Its preparation method is as follows: the first step: put the raw materials with the above-mentioned mass percentage ratio except bisphenol A polycarbonate into a high-speed mixer and stir evenly, the stirring speed is 100r / min, and the stirring time is 4min; the second step: Put the bisphenol A polycarbonate and the material mixed in the first step into a high-speed mixer for three-stage mixing. The stirring speed of the first stage is 20r / min, and the stirri...

Embodiment 2

[0082] A kind of high light transmittance, high flame retardant polycarbonate material of the present embodiment, comprise the raw material of following composition and mass percentage: the bisphenol A type polycarbonate of 1250Z of the Teijin Company of 99.1%, the bisphenol A polycarbonate of 0.1% Sulfone sulfonate, 0.3% brominated carbonate oligomer, 0.1% tris(2,4-di-tert-butylphenyl) phosphite, 0.1% β-(3,5-di-tert-butyl -4-Hydroxyphenyl)propanoic acid n-octadecyl ester, 0.2% octadecanoic acid-2-(hydroxymethyl)-2-[[(1-oxoctadecyl)oxy]methanoate base]-1,3-propanediyl ester and 0.1% of 2-hydroxy-4-n-octyloxybenzophenone.

[0083] Its preparation method is as follows: the first step: put the raw materials with the above-mentioned mass percentage ratio except bisphenol A polycarbonate into a high-speed mixer and stir evenly, the stirring speed is 140r / min, and the stirring time is 3min; the second step: Put the bisphenol A polycarbonate and the material mixed in the first step ...

Embodiment 3

[0085] A kind of high light transmittance, high flame retardant polycarbonate material of the present embodiment, comprise the raw material of following composition and mass percentage: the bisphenol A type polycarbonate of 1201-10 of Dow Company of 98.6%, 0.2% Diphenyl sulfone sulfonate, 0.7% brominated carbonate oligomer, 0.1% tris(2,4-di-tert-butylphenyl) phosphite, 0.1% β-(3,5-di tert-Butyl-4-hydroxyphenyl) propanoic acid n-octadecyl ester, 0.2% octadecanoic acid-2-(hydroxymethyl)-2-[[(1-oxoctadecyl)oxy base]methyl]-1,3-propanediyl ester and 0.1% of 2-hydroxy-4-n-octyloxybenzophenone.

[0086] Its preparation method is as follows: the first step: put the raw materials with the above mass percentage ratio except bisphenol A polycarbonate into a high-speed mixer and stir evenly, the stirring speed is 180r / min, and the stirring time is 3.5min; the second step : Put the bisphenol A polycarbonate and the material mixed in the first step into a high-speed mixer for three-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com