PVC wood plastic plate preparation process

A preparation process and technology of wood-plastic panels, applied in the field of wood-plastic panels, can solve the problems of poor heat resistance, poor flame-retardant effect, and insufficient tensile strength of PVC wood-plastic panels, so as to achieve good flame retardancy and curb air pollution , The effect of convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below through specific examples, but the use and purpose of this embodiment are only used to exemplify the present invention, and do not constitute any form of any limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention limited to this.

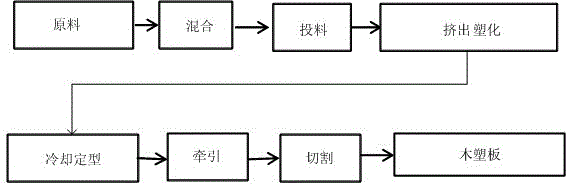

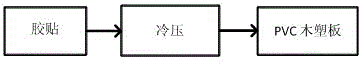

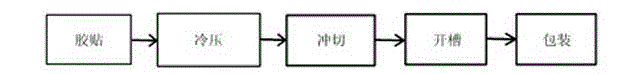

[0032] Such as figure 1 , 2 Shown in and 3, the preparation technology of PVC wood-plastic board of the present invention comprises the steps:

[0033] Step 1. Preparation of wood-plastic panels:

[0034] (1) Raw materials: Prepare raw materials, purchase required PVC resin, plant fiber, heat stabilizer, filler, foaming agent, foam regulator, lubricant, toughener and reinforcing agent;

[0035] (2) Mixing: According to the proportion, manually measure the dosage of each component, and the measurement must be accurate. Start the high-speed mixer, put all the measured raw materials into the high-speed mixer, and mix f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com