Patents

Literature

36results about How to "Does not reduce bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

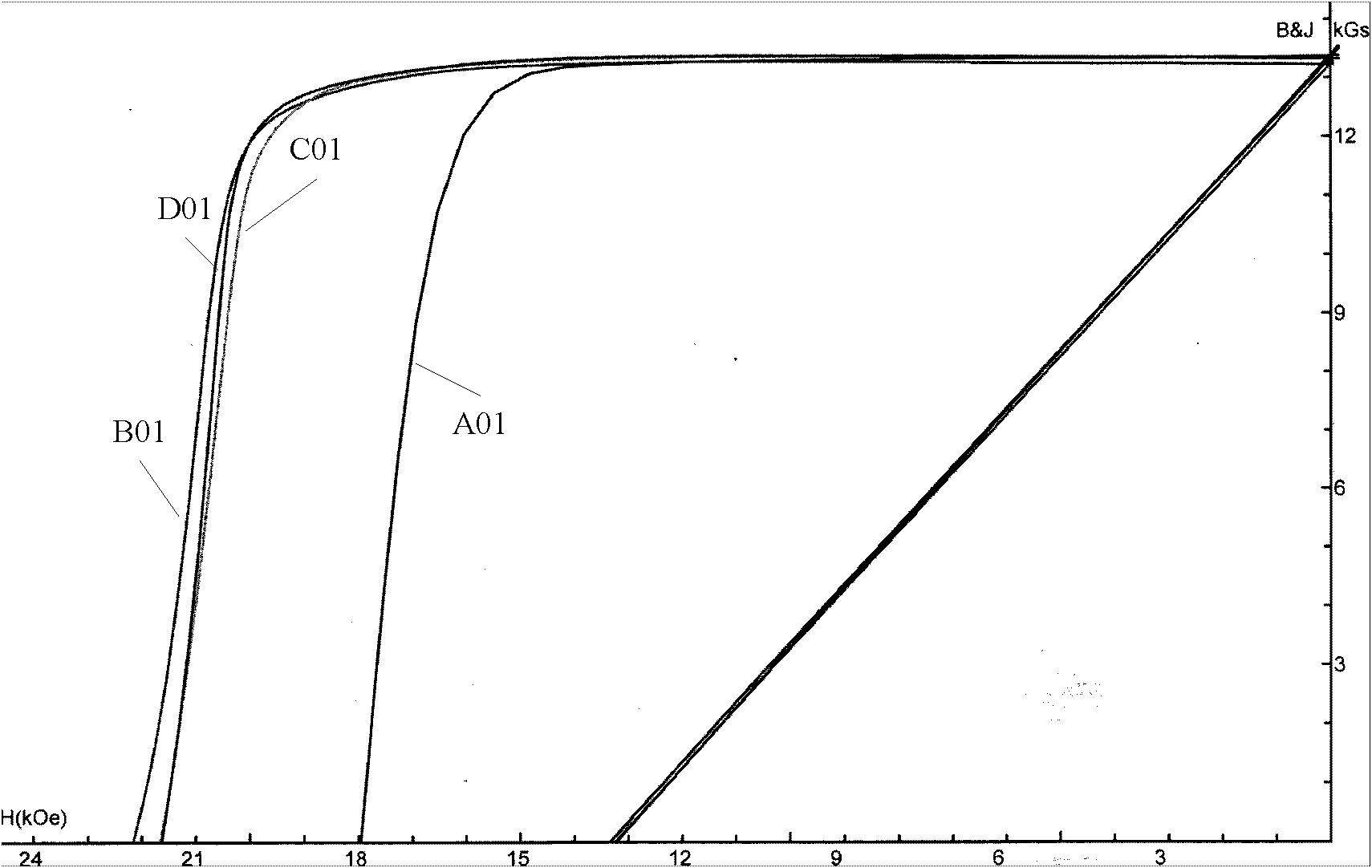

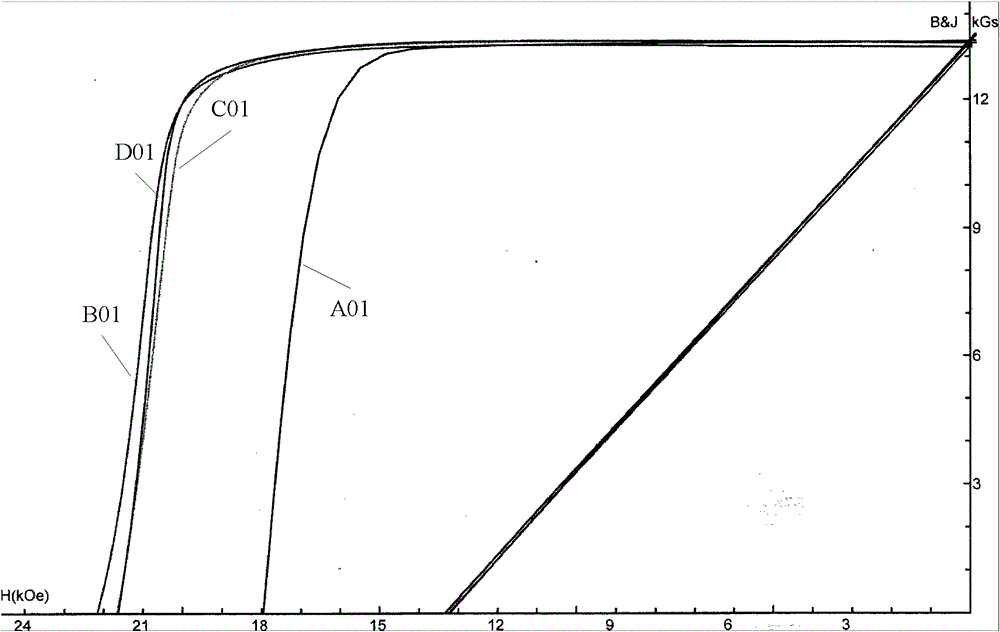

Rare earth permanent magnet and preparation method thereof

ActiveCN102610355AImprove uniformityResidue reductionPermanent magnetsInductances/transformers/magnets manufactureRemanencePhosphate

Disclosed are a rare earth permanent magnet and a preparation method. The preparation method of the rare earth permanent magnet is capable of improving coercivity of the magnet while keeping binding strength of a base body and a plated layer or coated layer after plating or coating on the basis without reducing remanence and magnetic energy product of the magnet and includes: firstly dissolving powder of fluoride containing R2, nitrate containing R3 and phosphate containing R4 into water or alcohol to prepare solution; uniformly applying the solution on the surface of a magnet to be treated; then dewatering or performing alcohol treatment on the magnet to be treated; finally, enabling the magnet to be treated to be subjected to diffusion heat treatment to obtain the treated magnet. By the aid of the preparation method, uniformity of the powder on the surface of the magnet can be improved, powder residues on the surface of the magnet after heat diffusion are reduced, the coercivity of the magnet is improved, and the binding strength of the magnet of the base body and the plated layer or coated layer after plating or coating is kept constant.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

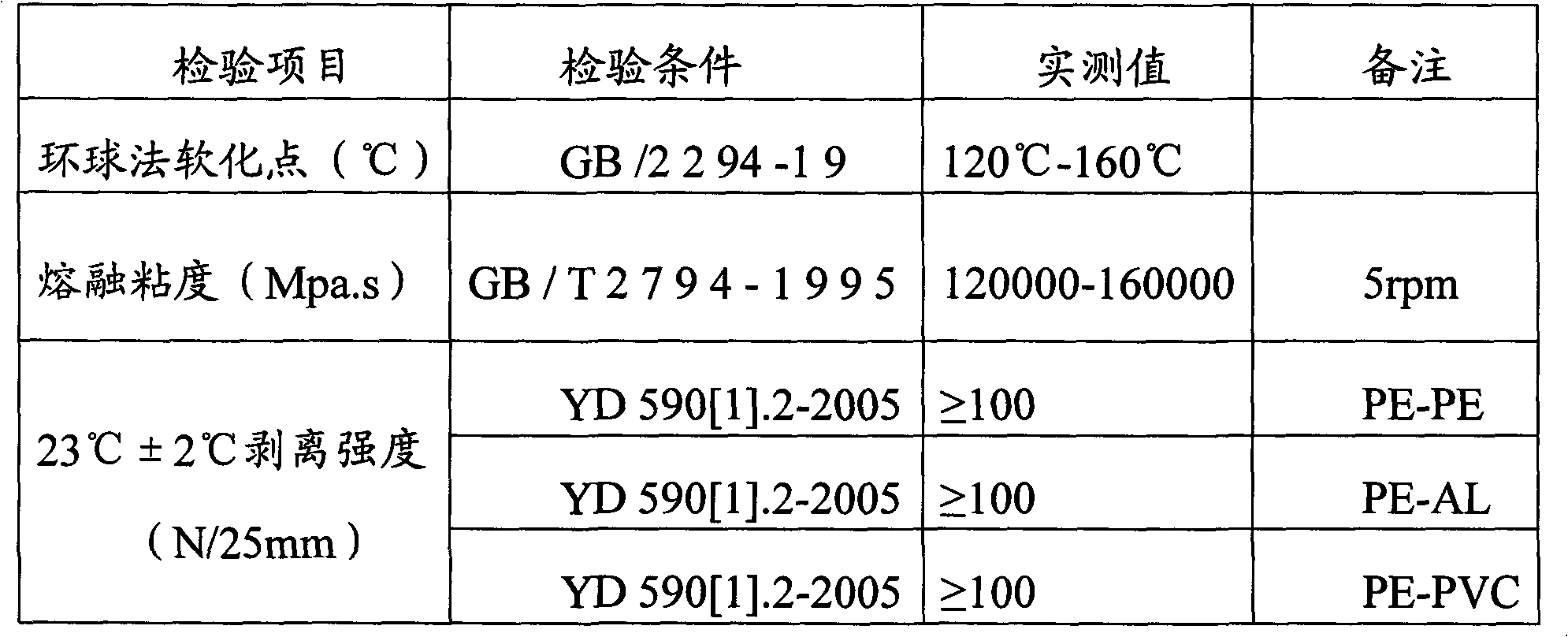

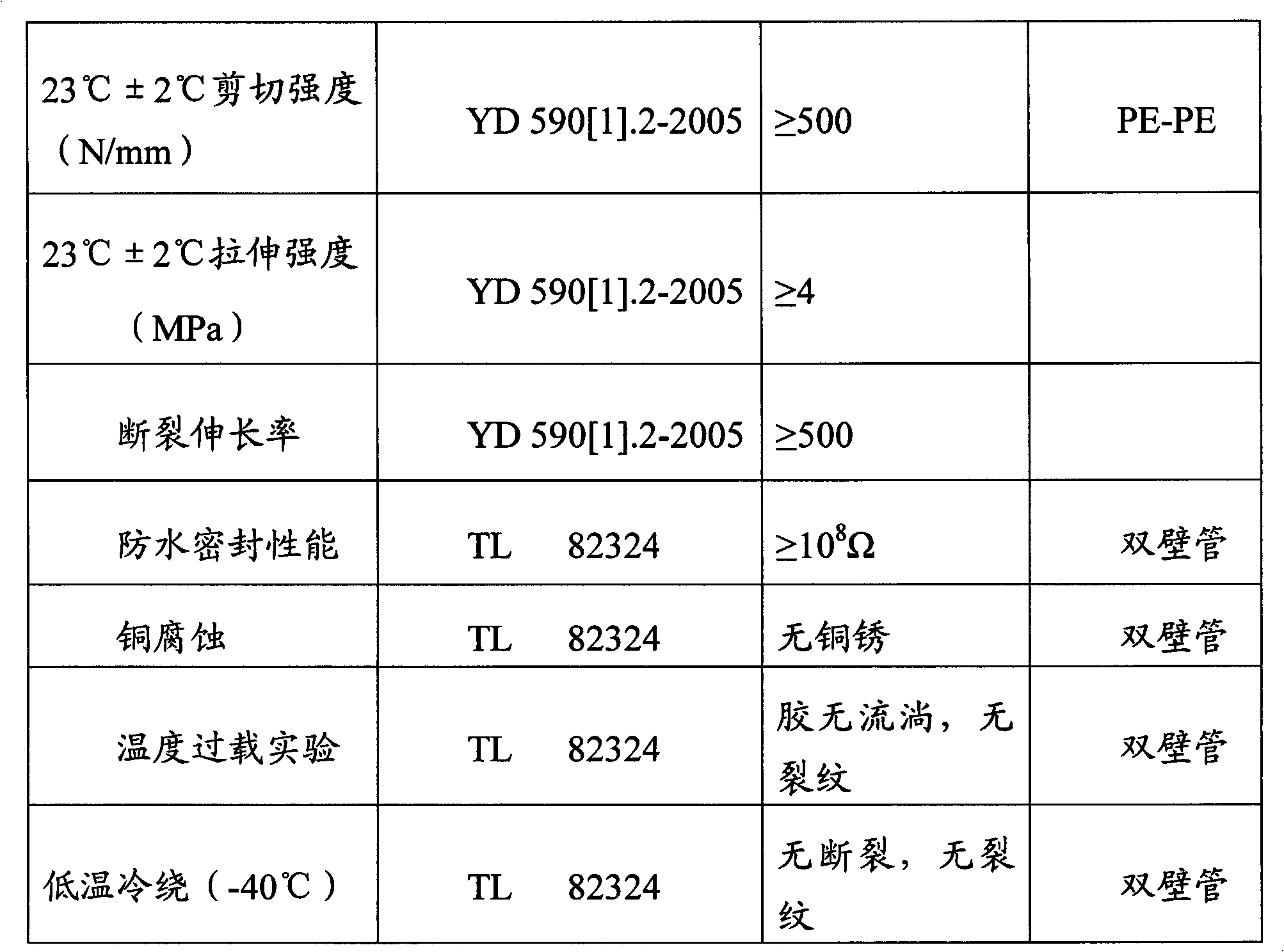

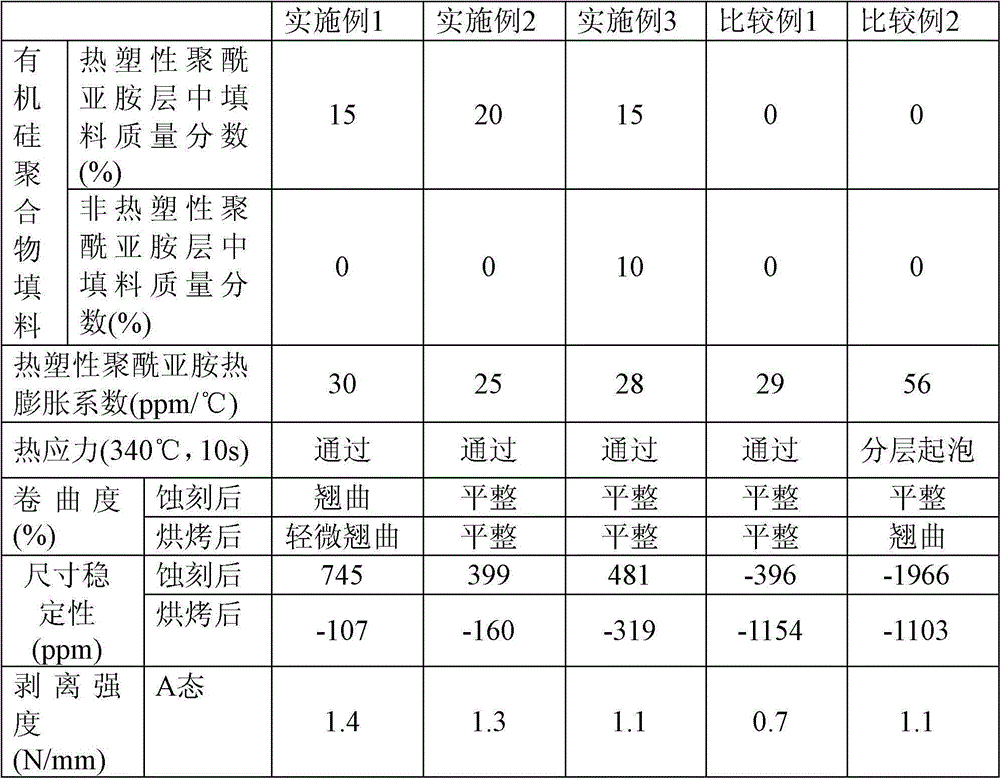

Low-temperature resistant hot melt adhesive and processing technology thereof

InactiveCN103173186AImprove low temperature resistanceNo changeMonocarboxylic acid ester polymer adhesivesWaxAntioxidant

The invention provides low-temperature resistant hot melt adhesive and a processing technology of the low-temperature resistant hot melt adhesive. The low-temperature resistant hot melt adhesive comprises the following components: polyamide, an ethylene vinyl acetate copolymer, an ethylene-acrylate-maleic anhydride terpolymer, wax, tackifying resin and an antioxidant. The low-temperature resistant hot melt adhesive is high in adhesive strength, excellent in insulating seal performance, environmentally-friendly, nontoxic, simple in production technology and high in repeatability, and is mainly applicable to places requiring high low-temperature performance.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

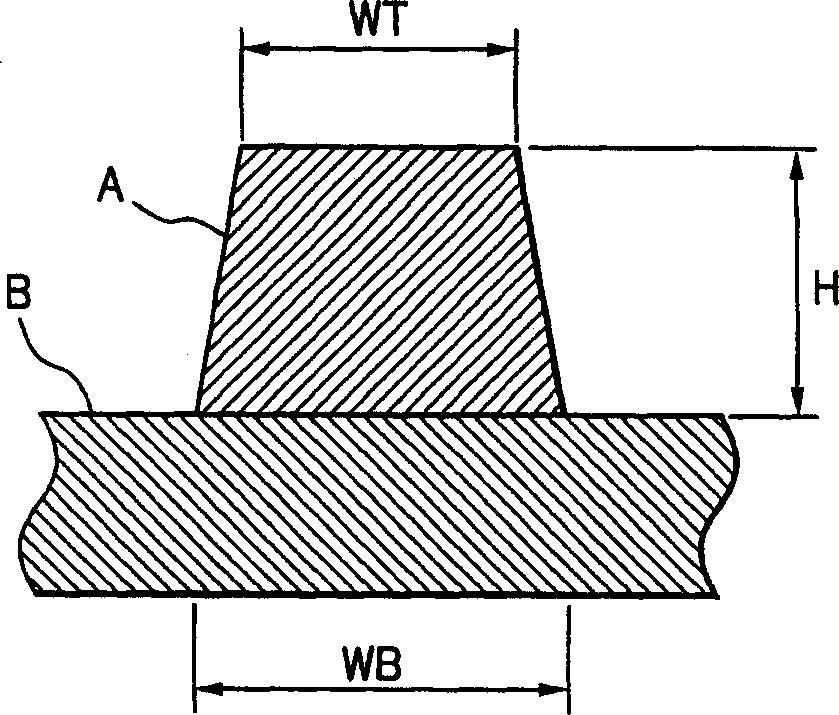

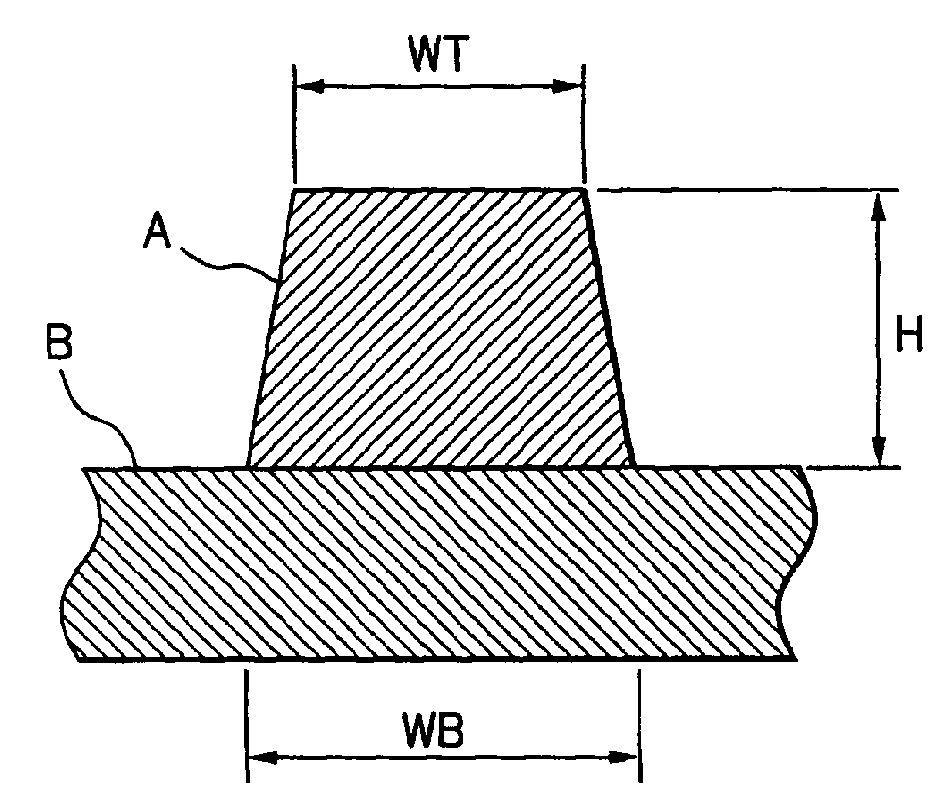

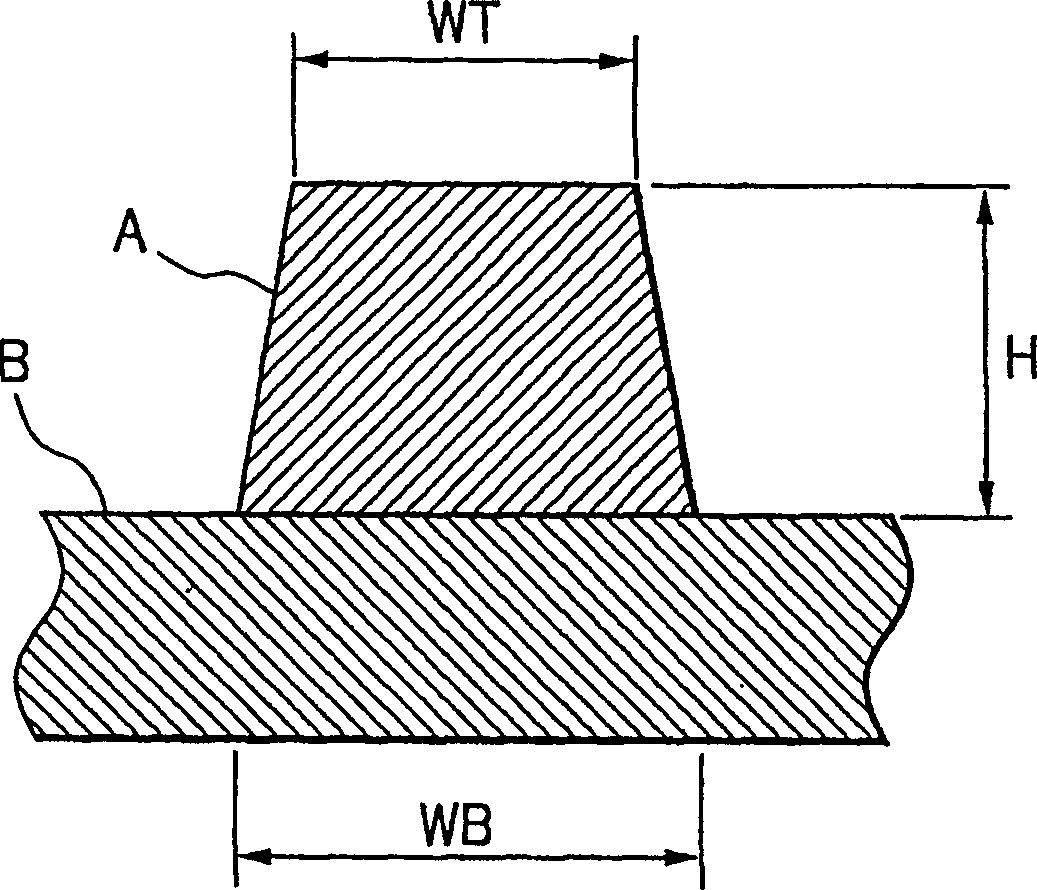

Production method of copper foil for fine line use

InactiveCN1348326AReduce surface roughnessDoes not reduce bond strengthInsulating substrate metal adhesion improvementPrinted circuit aspectsIonCopper foil

A copper foil for micro wiring comprises; forming a composite metal layer on the surface to be bonded of the copper foil, by electrolyzing it in a plating bath which contains copper ion, ion of metals selected from tungsten or molybdenum, ion of metals selected from nickel, cobalt, iron, or zinc, and chloride ion of 1-100 mg / l, at an electric current density of less than limiting current density of the bath; forming a dendritic copper electrodeposited layer on the composite metal layer, by electrolyzing it in a plating bath containing copper ion, at the electric current density of more than the limiting current density of the bath; and forming coarsened layer consisting of copper, by further electrolyzing it at the current density of less than the limiting current density of the bath to form knotty copper.

Owner:NIPPON DENKAI

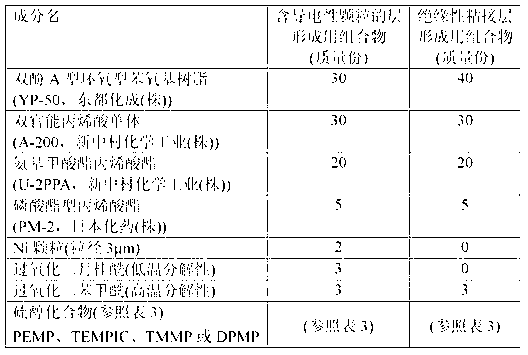

Anisotropic conductive film

ActiveCN102763283AHas captureEasy to squeeze outNon-insulated conductorsNon-macromolecular adhesive additivesAnisotropic conductive filmThiol

An anisotropic conductive film obtained by laminating an insulating adhesive layer that comprises a polymerizable acrylic compound, a film-forming resin and a polymerization initiator with a conductive-particle-containing layer that comprises a polymerizable acrylic compound, a film-forming resin, a polymerization initiator and conductive particles, wherein the insulating adhesive layer and the conductive-particle -containing layer each contain a thiol compound in order to further improve the reliability of connection without lowering the bond strength to an adherend. The thiol compound includes pentaerythritol tetrakis(3-mercaptopropionate), tris-[(3-mercaptopropionyloxy)-ethyl]-isocyanurate, trimethylol-propane tris(3-mercaptopropionate), dipentaerythritol hexakis(3-mercaptopropionate), and so on.

Owner:DEXERIALS CORP

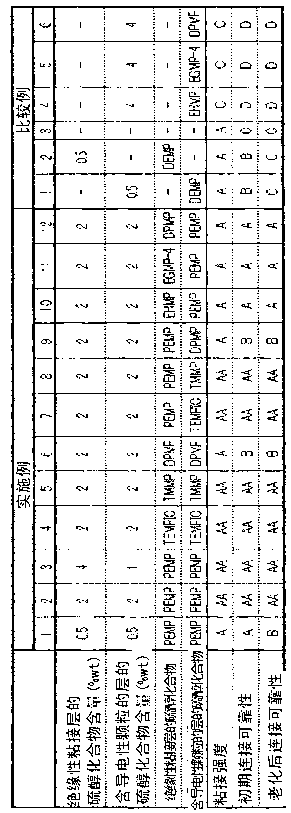

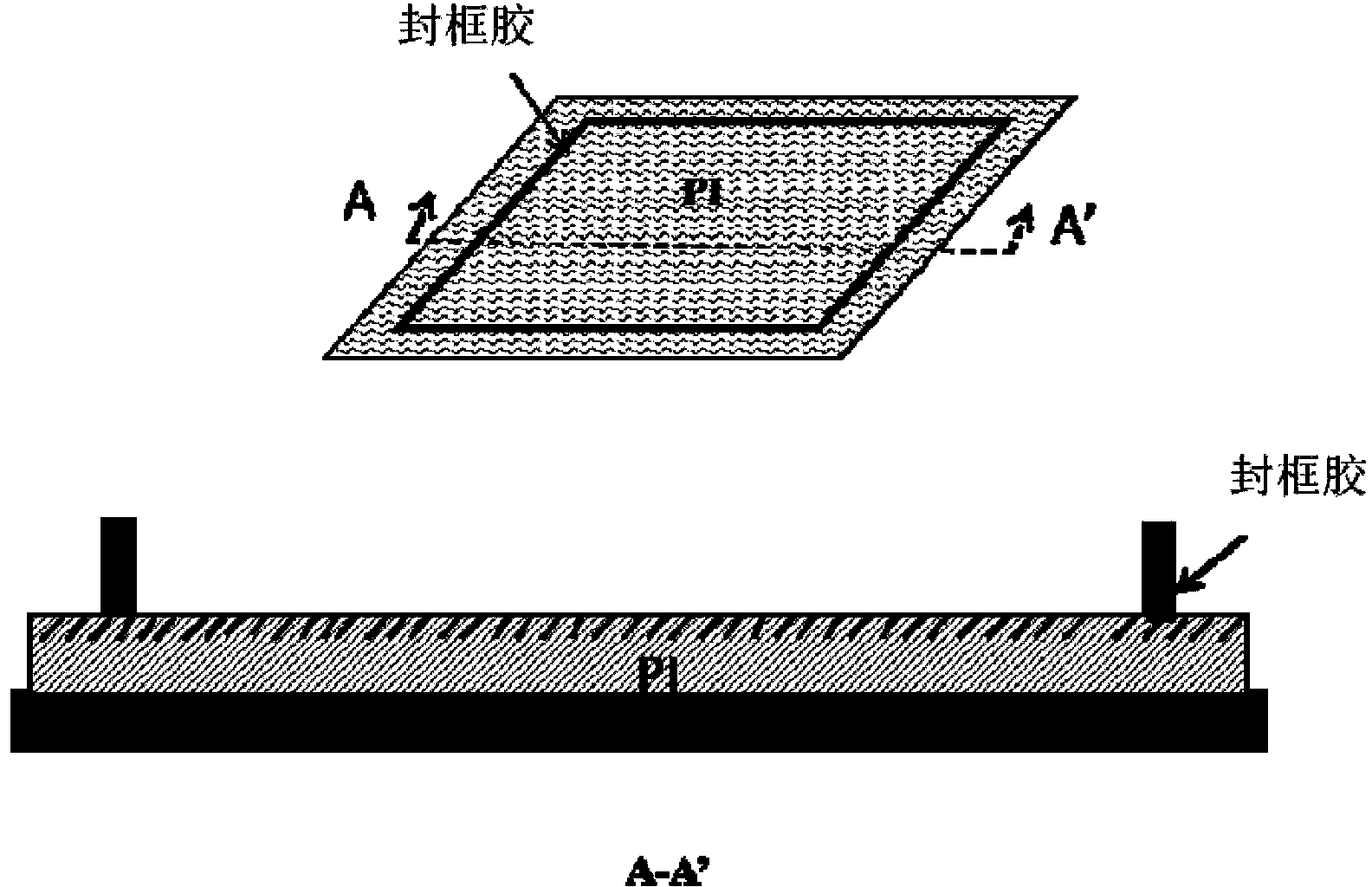

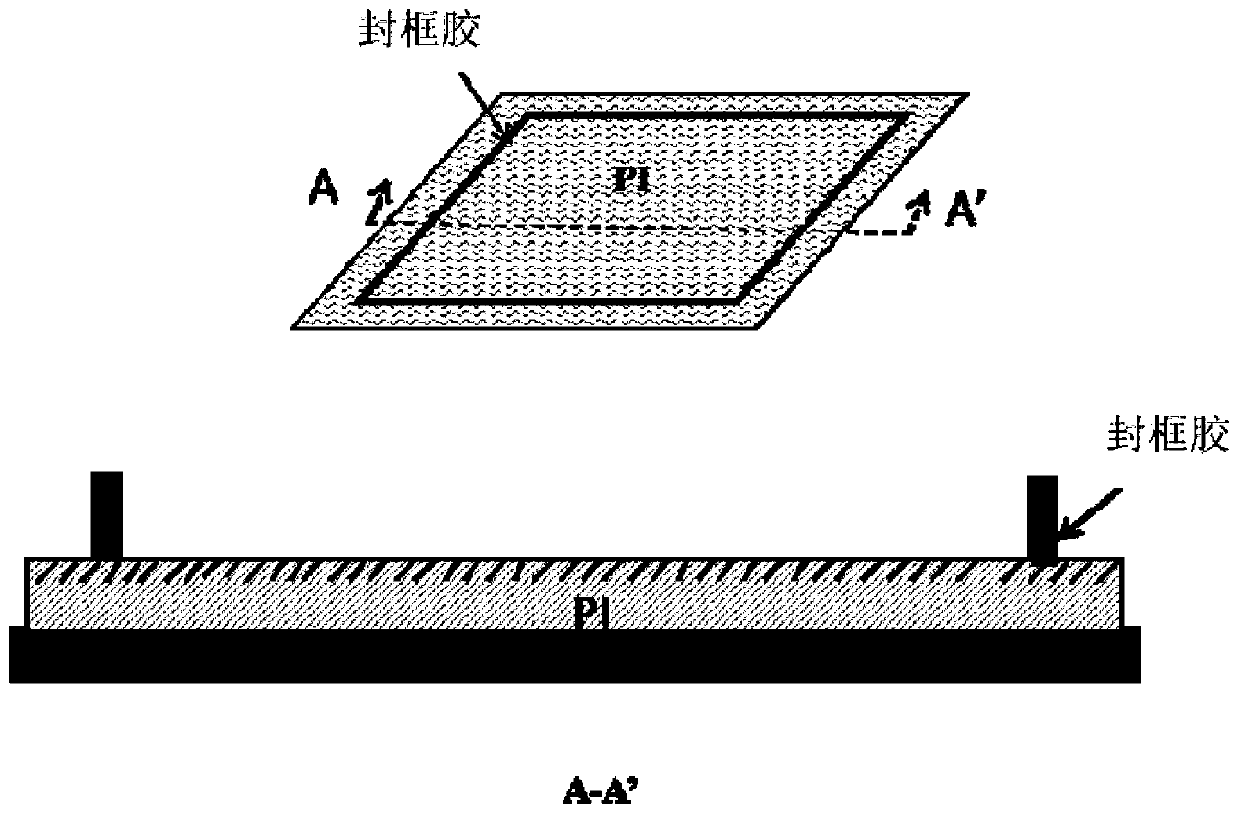

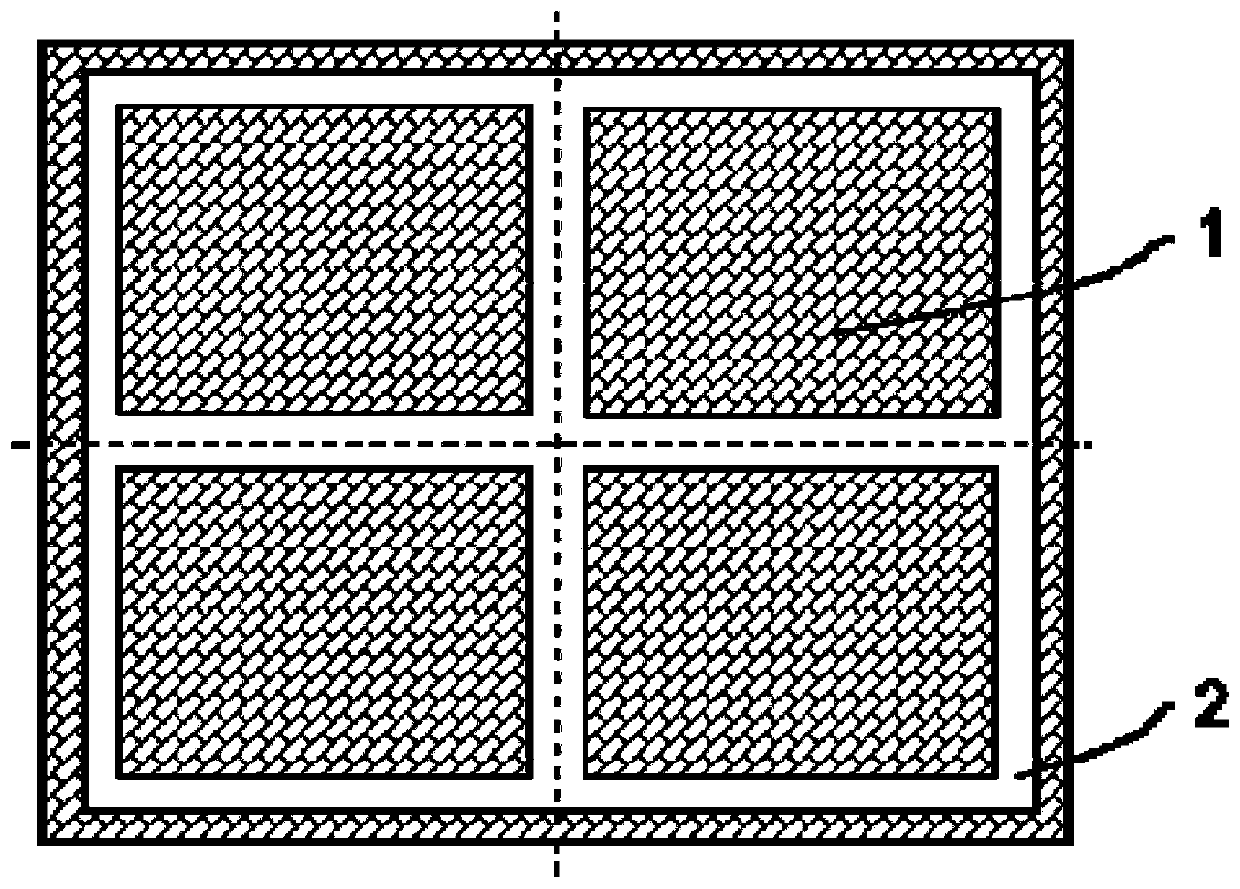

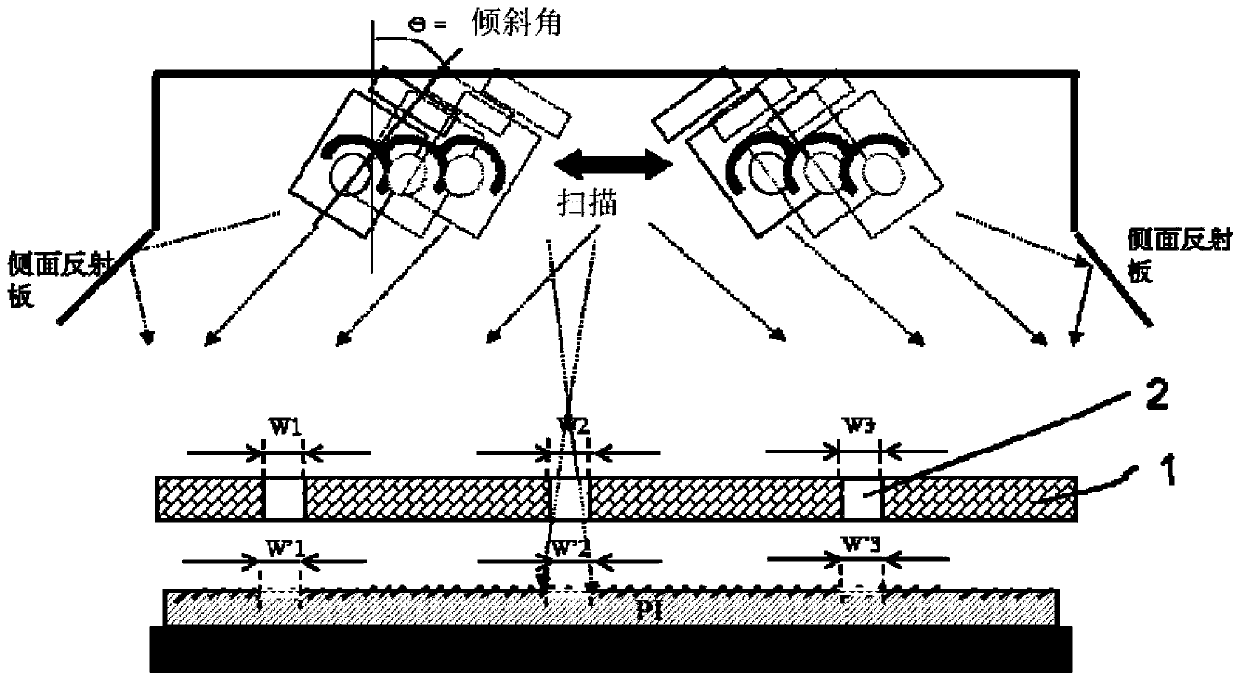

Method for preparing narrow-side display device

ActiveCN104345501AImprove wettabilityImprove adsorption capacityNon-linear opticsDisplay deviceEngineering

A method for manufacturing a display apparatus comprises: performing radiation processing on a polyimide film at a sealed position of a substrate, so as to make the polyimide film at the sealed position of the substrate generate a free radical; and coating frame sealing glue at the sealed position, and performing consolidation. By performing radiation processing on a polyimide film, a cracking reaction of a surface group of the polyimide film occurs to generate a free radical; mutual reactions can occur between the free radical and an active group of the frame sealing glue, so that the bonding strength is increased, and the problems such as liquid crystal puncture, liquid crystal pollution and poor reliability are avoided.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

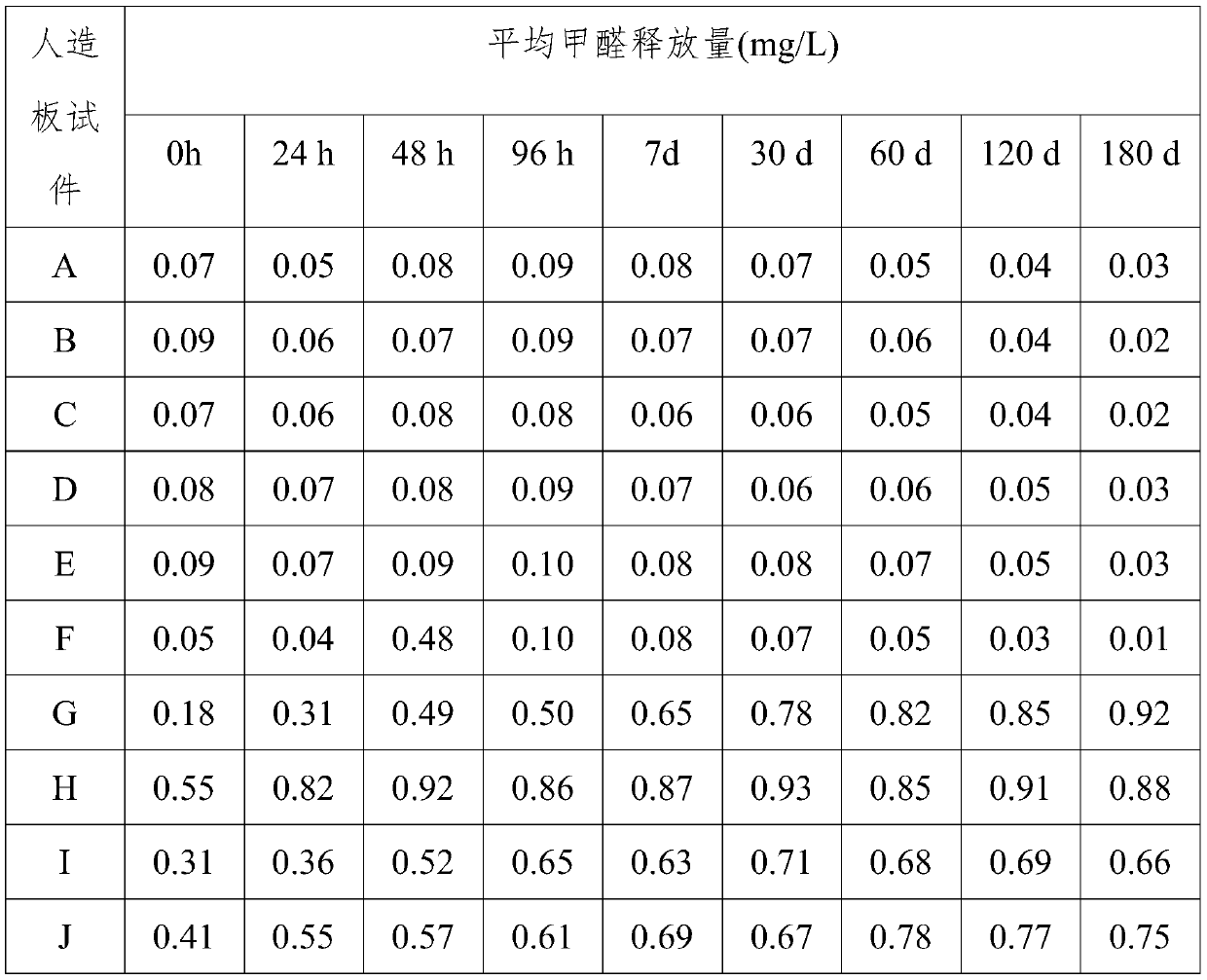

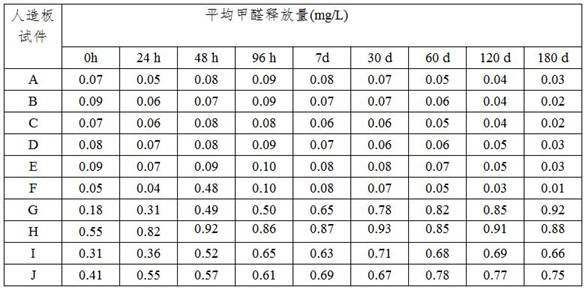

Urea-formaldehyde resin additive, urea-formaldehyde resin containing the same and preparation method thereof

ActiveCN101205348ASolve Exhaust ProblemsSave resource usageAldehyde/ketone condensation polymer adhesivesAluminium sulfateResin adhesive

The invention provides an additive with urea formaldehyde, a preparation method and a urea formaldehyde resin adhesive. The additive is provided by the invention. The raw material of the additive is comprised of the dispersion medium, the dried egg white of the degreased bean and the complexing agent, the weight ratio of the raw material is: 70-80 of dispersion medium, 20-35 of dried egg white of the degreased bean, 1-3 of complexing agent, the complexing agent is consisted of the aluminium sulphate and the zirconium carbonate with the weight ratio of 0.4-2.4:1. The additive provided by the invention contains dried egg white of the degreased bean, and then both the bond strength of the prepared veneer is increased and the formaldehyde emission of the preparing artificial slabs is effective decreased when adding the additive into the urea formaldehyde.

Owner:CHANGZHOU JOEL PLASTIC

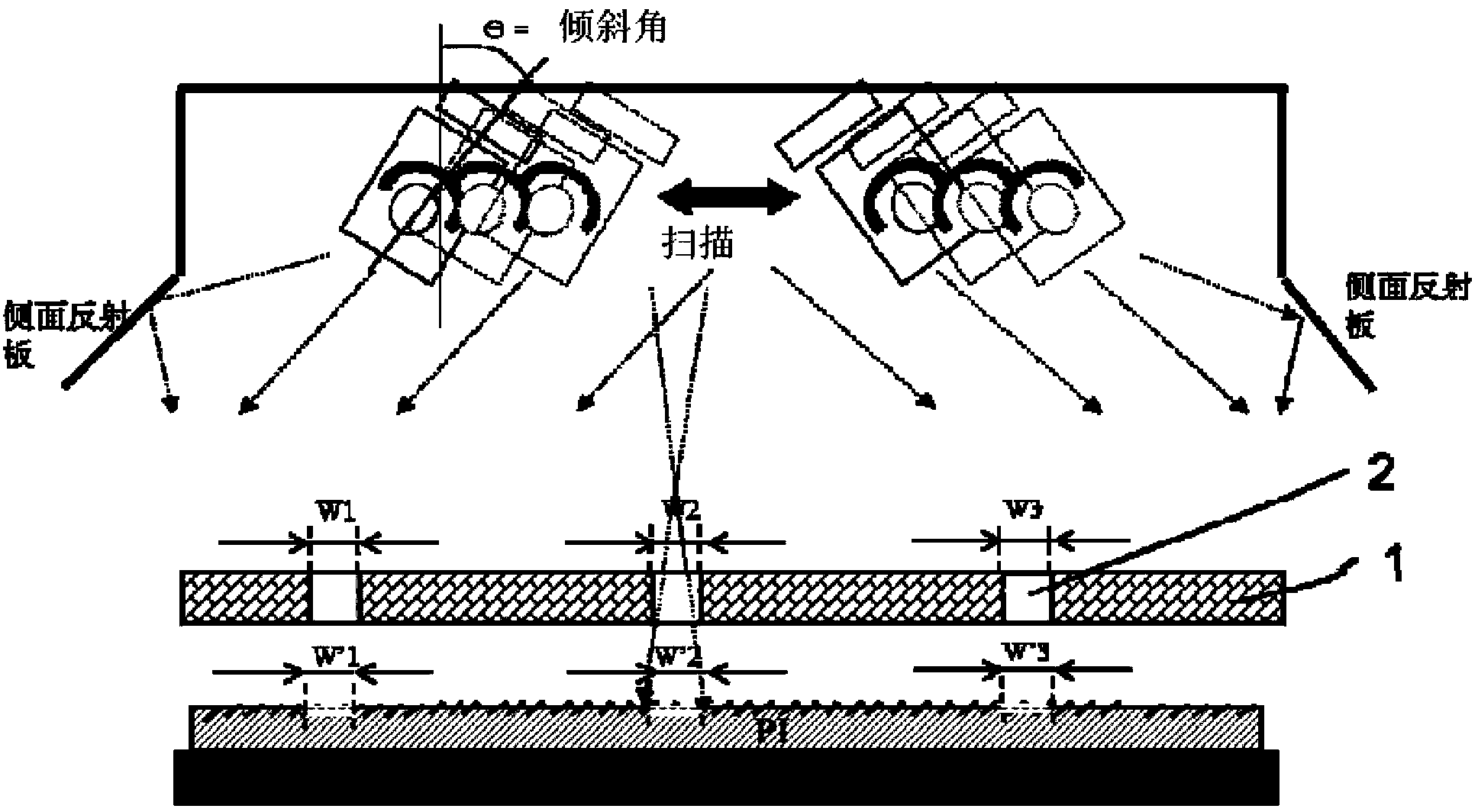

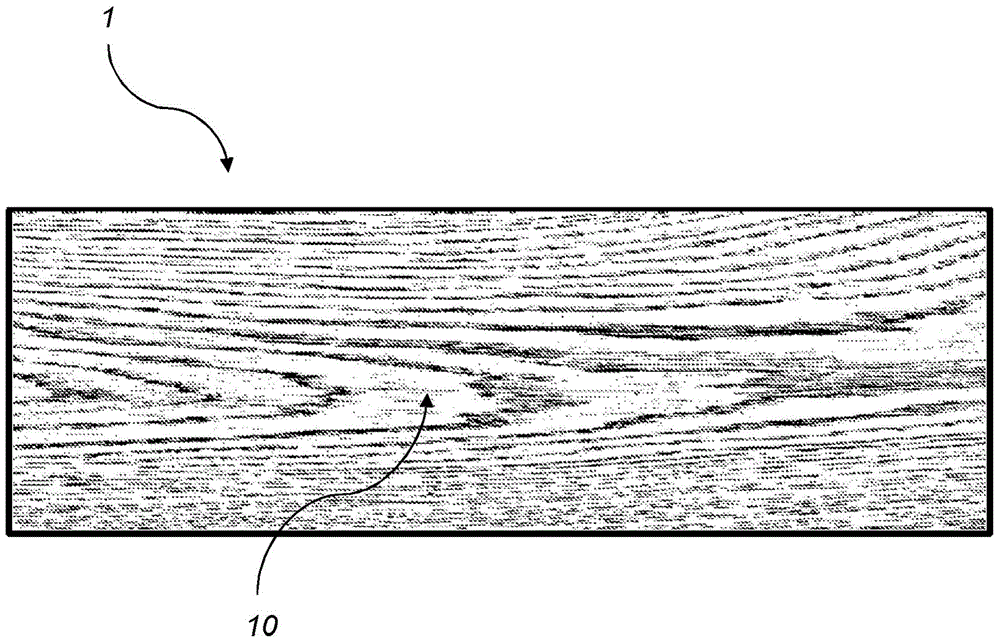

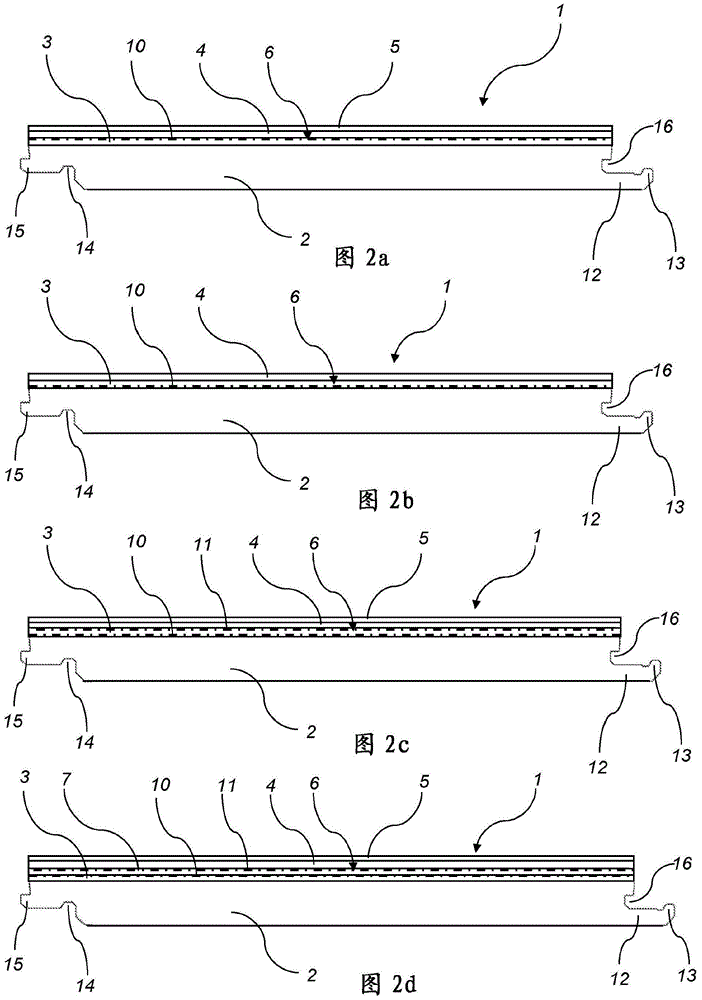

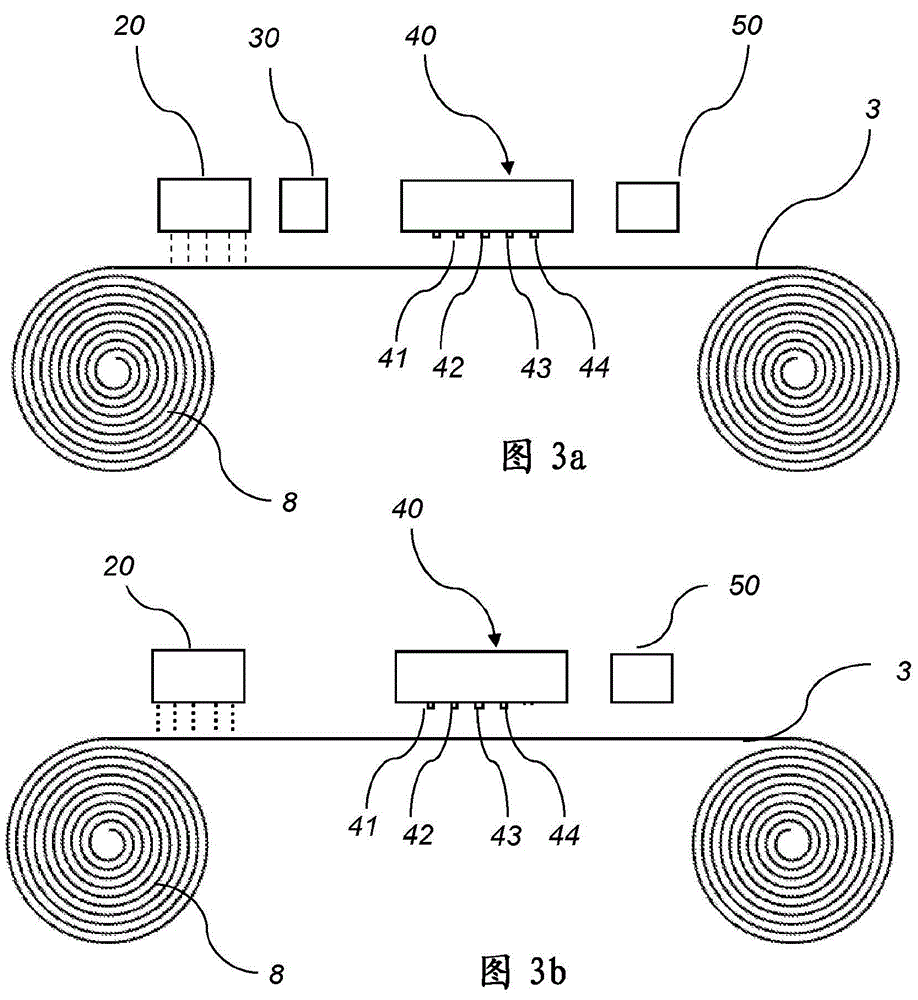

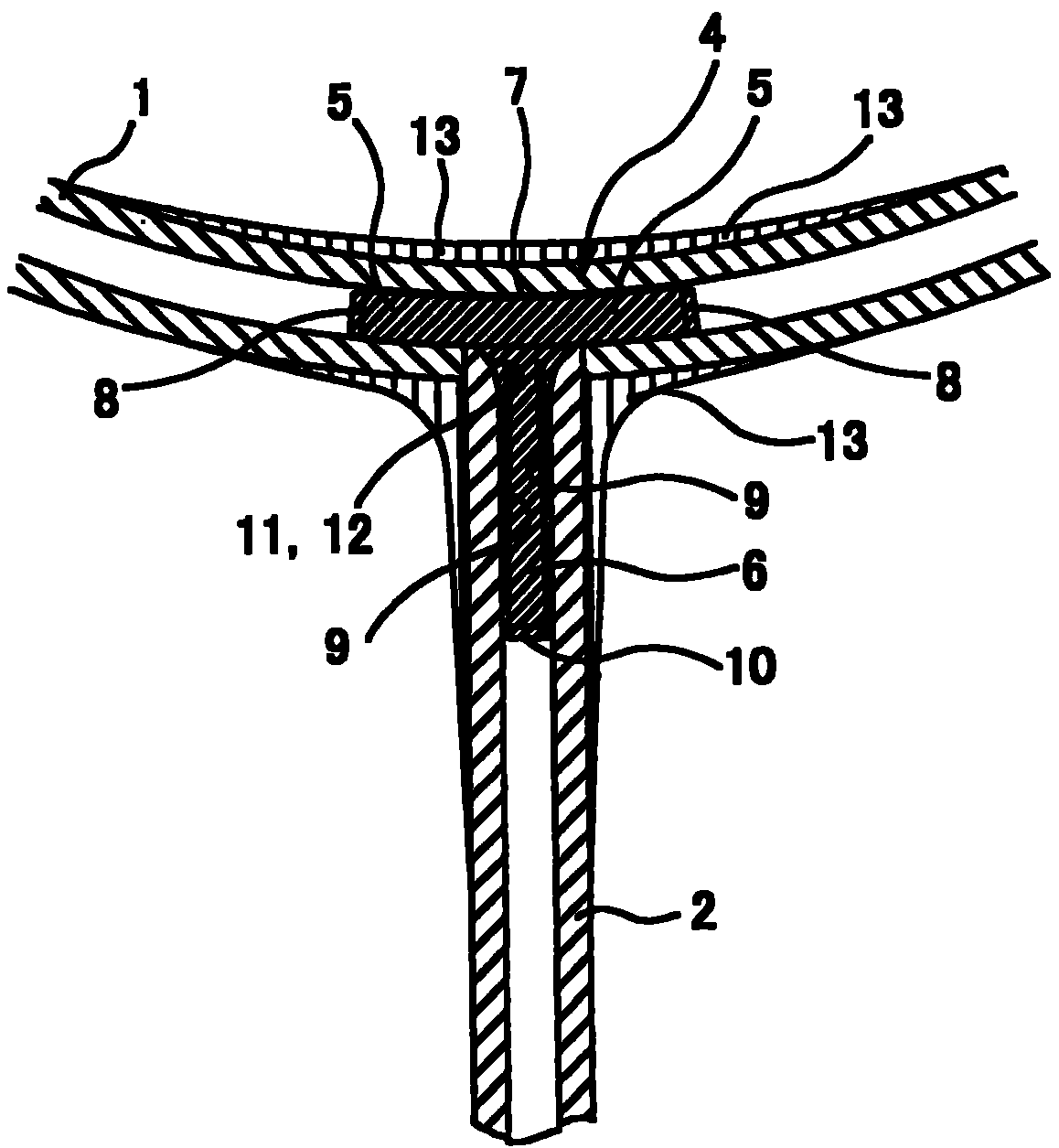

Method of producing a building panel using digital printing

ActiveCN104822533AAvoid repetitionImprove qualityDuplicating/marking methodsSpecial ornamental structuresDigital printingBiomedical engineering

The present invention relates to a method of producing a building panel (1)such as a floor panel, comprising providing a carrier (3) comprising a thermoplastic material,applying a primer comprising at least one salt, preferably a metal salt,on a first surface of the carrier (3),printing by means of digital printing a first print (10) on said first surface of the carrier (3) with an aqueous pigment ink composition, and applying a protective layer (4) on the carrier (3) and applying the carrier (3) on a core (2) comprising a thermoplastic material, and pressing by applying heat and pressure the protective layer (4), the carrier (3) and the core (2) together to form a building panel (1).The present invention also relates to a method for forming a decorative substrate.

Owner:VÄLINGE INNOVATION AB

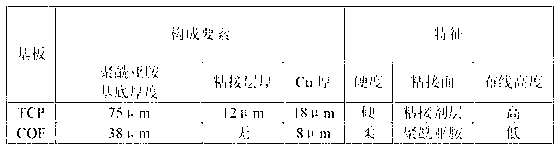

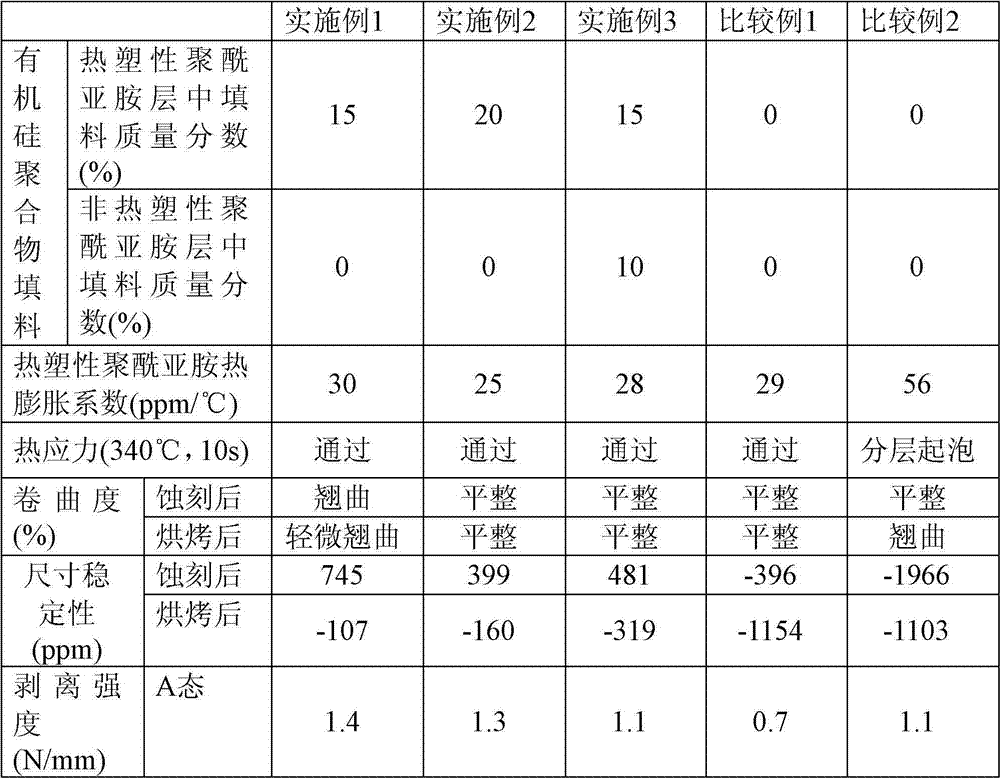

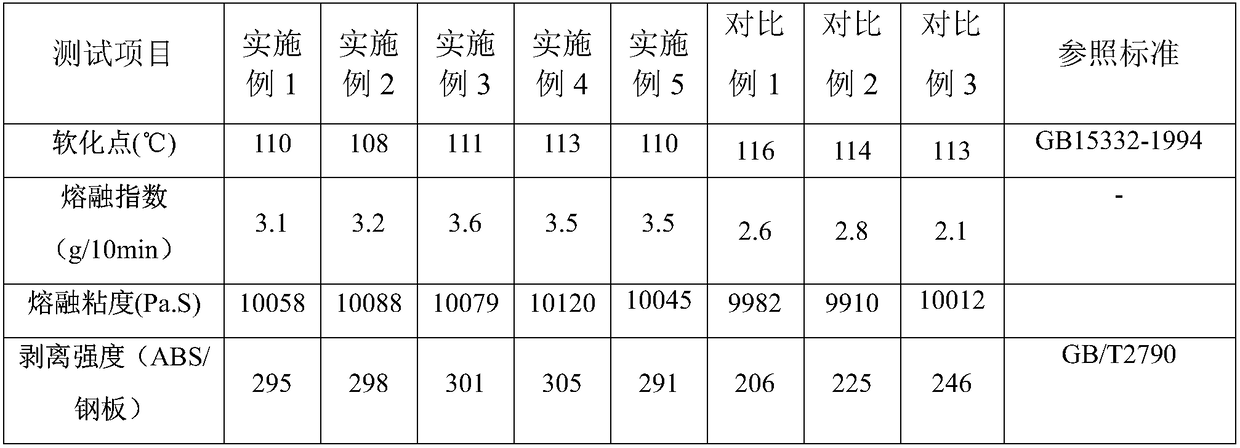

Two-layer two-sided flexibility copper clad plate and method for preparing same

ActiveCN102774077AResolve curlSolve warpingSynthetic resin layered productsLaminationThermoplasticCopper foil

The invention provides a two-layer two-sided flexibility copper clad plate and a method for preparing the same. The two-layer two-sided flexibility copper clad plate comprises two copper foil layers and a thermoplastic polyimide layer between the two copper foil layers. The thermoplastic polyimide layer is prepared by dissolving aromatic diamine and aromatic diandhydrides in a ratio of 0.9:1.1 in a polarity aprotic solvent to be reacted to generate a precursor thermoplastic polyamic acid solution and imidize the precursor thermoplastic polyamic acid solution at a high temperature. The thermoplastic polyimide layer comprises organic silicon polymer fillers which have good compatibility with organic resin, and the adding amount of the organic silicon polymer fillers is 1% to 40% of the total mass of all solid reactants of polyimide resins. The coefficient of thermal expansion of the thermoplastic polyimide can be reduced apparently to be close to the thermal expansion coefficients of copper foil and non-thermoplastic polyimide by adding the organic silicon polymer fillers, accordingly, curly and warping problems of the two-layer two-sided flexibility copper clad plate in the preparation process are solved.

Owner:GUANGDONG SHENGYI SCI TECH

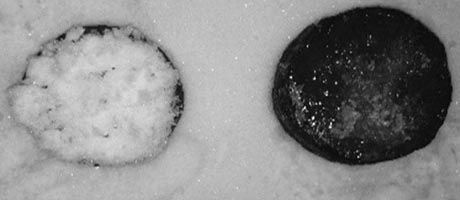

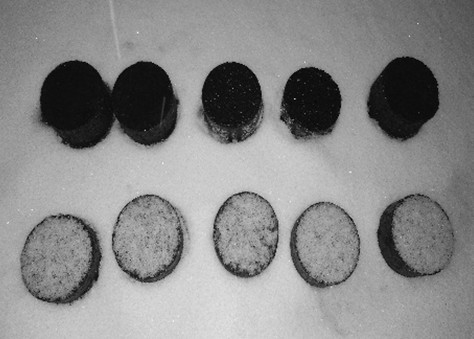

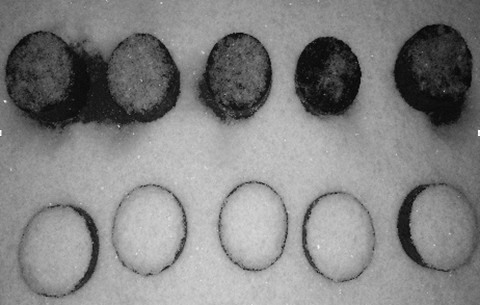

Environment-friendly efficient ice-melting coating material and preparation method and application thereof

The invention discloses an environment-friendly efficient ice-melting coating material and a preparation method and an application thereof and aims to solve the technical problem that the deicing costis high, and a deicer pollutes the environment, harms roads and the environment and cannot play roles effectively durably. The coating is prepared from the following raw materials: a deicer, a bonding material, a hydrophobic coating material, a hydrophilic coating material, a hydrophobic plasticizer, a hydrophilic plasticizer, glycerinum, an antisticking agent, talc powder, filler, a semi-fortifier, a flatting agent, a coupling reagent, a defoamer, a pore-foaming agent and hydrophobic fumed silica. The invention further provides a preparation method of the coating material. The coating material is applied to deicing traffic roads. The environment-friendly efficient ice-melting coating material is free of harmful ions, does not lead to corrosion and damage the environment during deicing durably, and has relatively good curing action to the pavement. The raw materials are wide in source, low in cost, simple in production process and easy to operate, and can be popularized and applied ona large scale. A lot of manpower and material resources are reduced, and the environment-friendly efficient ice-melting coating material has important economical value.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Phenolic resin additive, phenolic resin containing the same and preparation method thereof

InactiveCN101177505AReduce manufacturing costDoes not reduce bond strengthAldehyde/ketone condensation polymer adhesivesFeed additiveResin adhesive

The invention provides an additive for phenolic resin, a preparation method thereof and a phenolic resin adhesive containing the additive. The raw materials of the additive include dispersion medium, defatted soy protein powder, sodium carbonate and complexing agent, wherein the ratio of the raw materials is: dispersing medium 70-80, defatted soy protein powder 20-35, sodium carbonate 0.5-3, complexing agent The mixture is 0.8-2, and the complexing agent includes borax and aluminum sulfate with a weight ratio of 1.5-12:1. The additive of the present invention contains defatted soybean protein powder, and adding the additive to the phenolic resin not only reduces the manufacturing cost of the adhesive, ensures the bonding strength of the prepared plywood, but also can effectively reduce the formaldehyde emission in the prepared artificial board.

Owner:BEIJING FORESTRY UNIVERSITY

Composite formaldehyde catching agent and preparation method thereof, artificial board formaldehyde removal method and artificial board

ActiveCN111495181AAvoid being difficult to catch and removeAvoid pollutionGas treatmentNon-macromolecular adhesive additivesEpoxyAdhesive

The invention relates to the technical field of formaldehyde removal of boards, and discloses a composite formaldehyde catching agent which comprises the following components: MOFs, modified starch, fluorinated polyether, xanthan gum, ethylene urea, epoxy fatty acid methyl ester and deionized water. The invention also provides a preparation method of the composite formaldehyde catching agent. Theinvention further provides an artificial board formaldehyde removing method. The method comprises the steps: mixing an adhesive with the composite formaldehyde catching agent; hot-pressing veneering paper soaked with the mixed adhesive on the surface of a core plate; and carrying out heat treatment of the veneered artificial board. Formaldehyde and VOC released from the artificial board can be continuously adsorbed and removed, the formaldehyde-free artificial board is provided, and formaldehyde pollution and harm to a user are avoided.

Owner:成都市美康三杉木业有限公司

Phenolic resin additive, phenolic resin with the additive and its prepn process

The phenolic resin adhesive additive is prepared through mixing 3-25 % concentration sodium carbonate solution in 70-80 weight portions and fenugreek slag powder in 20-30 weight portions, heating to 70-80 deg.c to react for 3-6 hr, cooling to 30 deg.c to obtain fenugreek adhesive with viscosity 200-400 mPa.s as the additive for phenolic resin adhesive. Alkaline water soluble phenolic resin and the fenugreek adhesive in the weight ratio of 50-90 to 10-50 are mixed to obtain the phenolic resin adhesive. The phenolic resin adhesive has low production cost, high adhesion strength and low formaldehyde releasing amount.

Owner:BEIJING FORESTRY UNIVERSITY

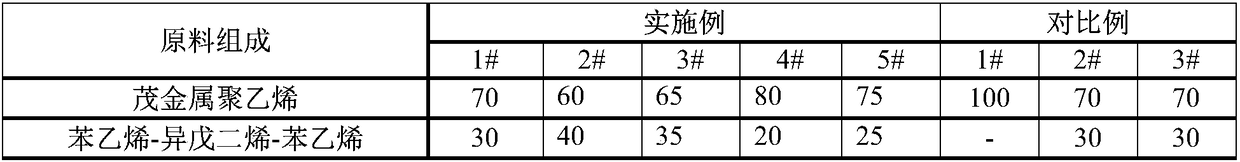

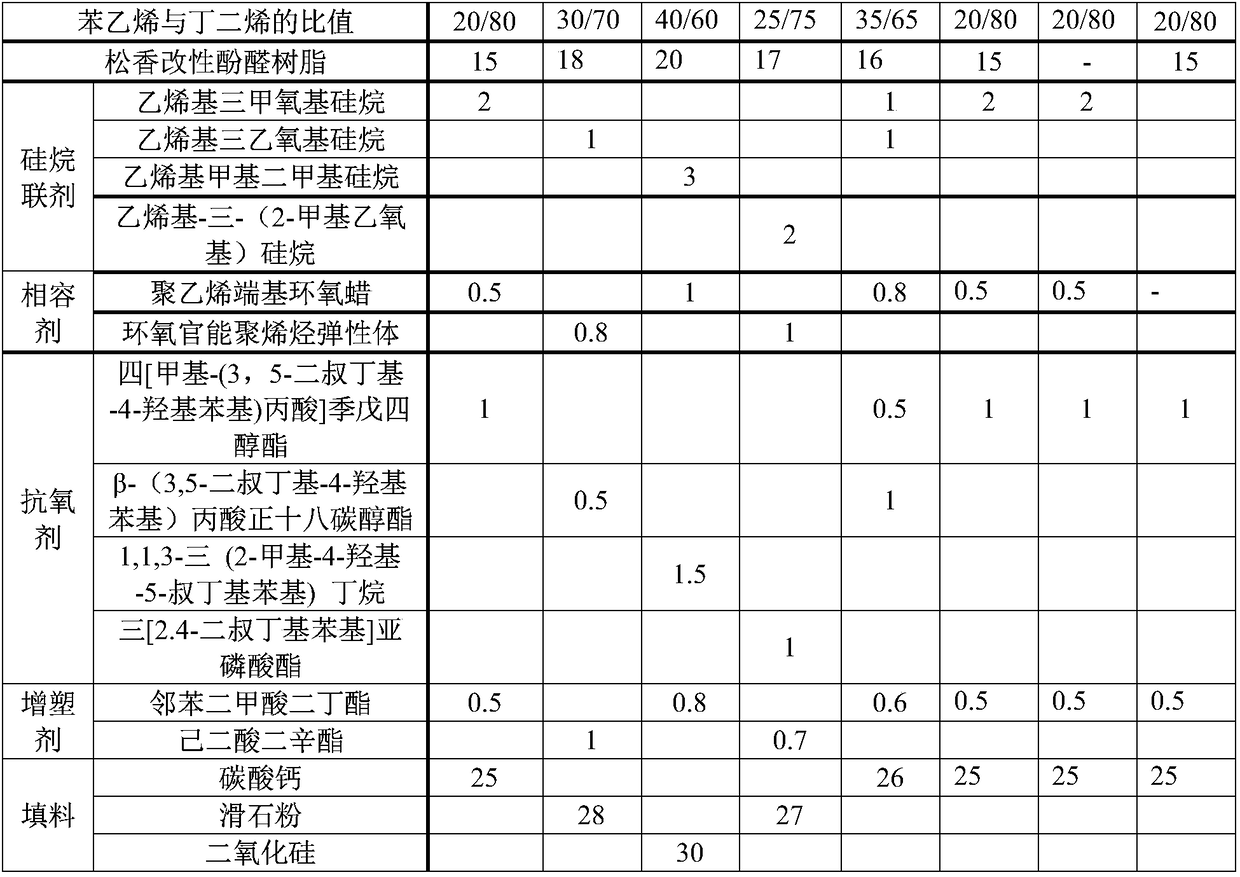

Hot melt adhesive for steel plastic-lined composite pipeline and preparation method of hot melt adhesive

InactiveCN109486445AHigh tensile strengthIncrease polarityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEnvironmental resistancePolymer adhesive

The invention belongs to the field of polymer adhesives, and particularly relates to a hot melt adhesive for a steel plastic-lined composite pipeline and a preparation method of the hot melt adhesive.The hot melt adhesive for the steel plastic-lined composite pipeline comprises, by weight, 100 parts of matrix resin, 15-20 parts of tackifying resin, 1-3 parts of silane crosslinking agents, 0.5-1 part of compatilizers, 0.5-1.5 parts of antioxidants, 0.5-1 part of plasticizers and 20-30 parts of fillers. The hot melt adhesive for the steel plastic-lined composite pipeline is high in adhesive force, good in weather resistance and heat stability, resistant to ageing, acid and alkali, green, environmentally friendly and cannot be limited by the temperature, can be normally used at low temperature and effectively adhere metal and plastics, and the preparation method is simple, easy to operate and low in cost.

Owner:丹阳市丹达防腐设备有限公司

Two-layer double-sided flexible copper clad laminate and its manufacturing method

ActiveCN102774077BGuaranteed reliabilitySmall coefficient of thermal expansionSynthetic resin layered productsLaminationThermoplasticThermal expansion

The invention provides a two-layer two-sided flexibility copper clad plate and a method for preparing the same. The two-layer two-sided flexibility copper clad plate comprises two copper foil layers and a thermoplastic polyimide layer between the two copper foil layers. The thermoplastic polyimide layer is prepared by dissolving aromatic diamine and aromatic diandhydrides in a ratio of 0.9:1.1 in a polarity aprotic solvent to be reacted to generate a precursor thermoplastic polyamic acid solution and imidize the precursor thermoplastic polyamic acid solution at a high temperature. The thermoplastic polyimide layer comprises organic silicon polymer fillers which have good compatibility with organic resin, and the adding amount of the organic silicon polymer fillers is 1% to 40% of the total mass of all solid reactants of polyimide resins. The coefficient of thermal expansion of the thermoplastic polyimide can be reduced apparently to be close to the thermal expansion coefficients of copper foil and non-thermoplastic polyimide by adding the organic silicon polymer fillers, accordingly, curly and warping problems of the two-layer two-sided flexibility copper clad plate in the preparation process are solved.

Owner:GUANGDONG SHENGYI SCI TECH

Environmentally friendly efficient snowmelt pavement coating material

The invention discloses an environmentally friendly efficient snowmelt pavement coating material and a preparation method and applications thereof, and aims to solve the technical problems that the ice removing cost in winter is high, the environment is polluted by the snow melting agents, the roads and the environment are damaged by an ice removing technology, and the snow melting means cannot last for a long time. The coating material is made of following raw materials: a snow melting agent, a binding material, a hydrophobic coating material, a hydrophilic coating material, a hydrophobic plasticizer, a hydrophilic plasticizer, glycerin, an anti-sticking agent, talcum powder, a filling material, a semi-reinforcing agent, a leveling agent, a coupling agent, an antifoaming agent, a pore forming agent, and a hydrophobic fumed silica. The invention further provides a preparation method of the coating material, and the coating material is applied to snow melting of traffic roads. The coating material is green and environmentally, and can well protect the pavement. The raw material sources are wide, the cost is low, the production technology is simple and easy to operate and is suitablefor large scale application and popularization, a great amount of human resources and materials is saved, and a great economic value is created.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

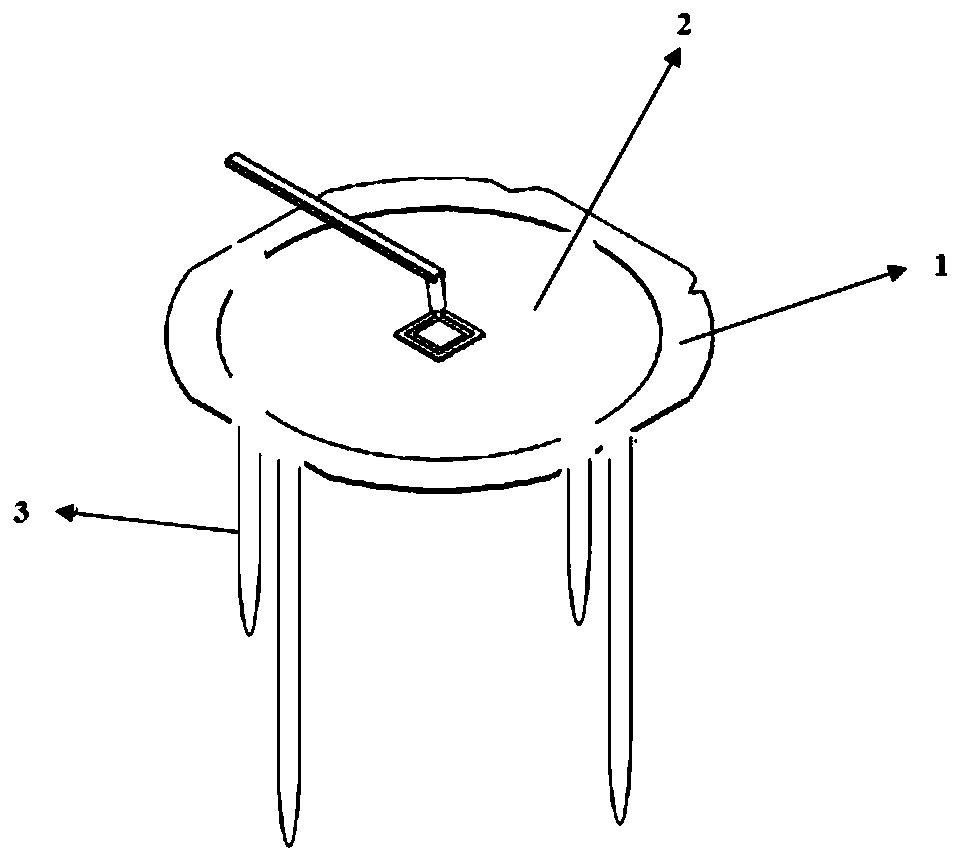

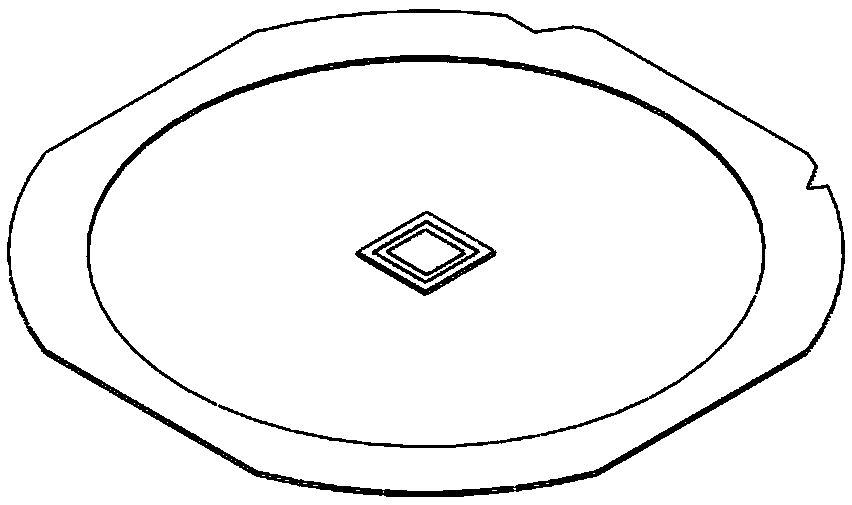

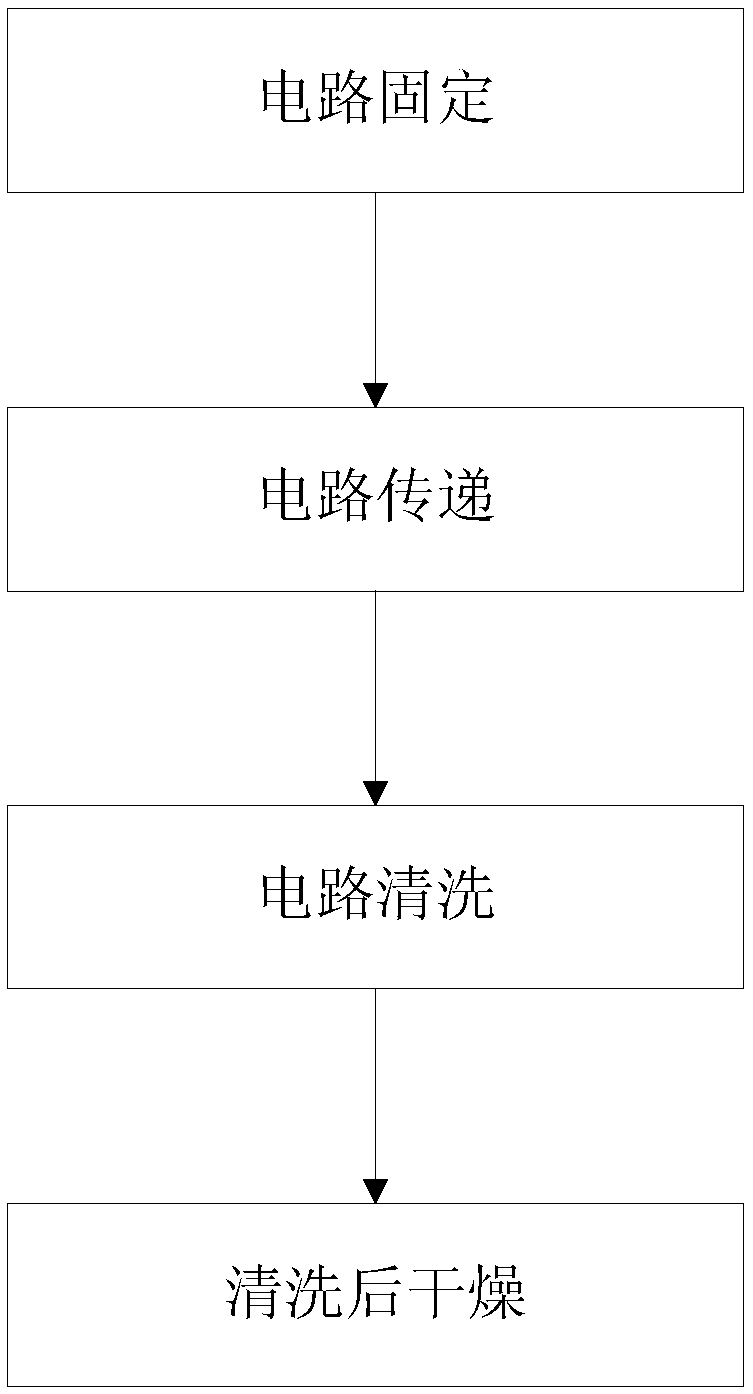

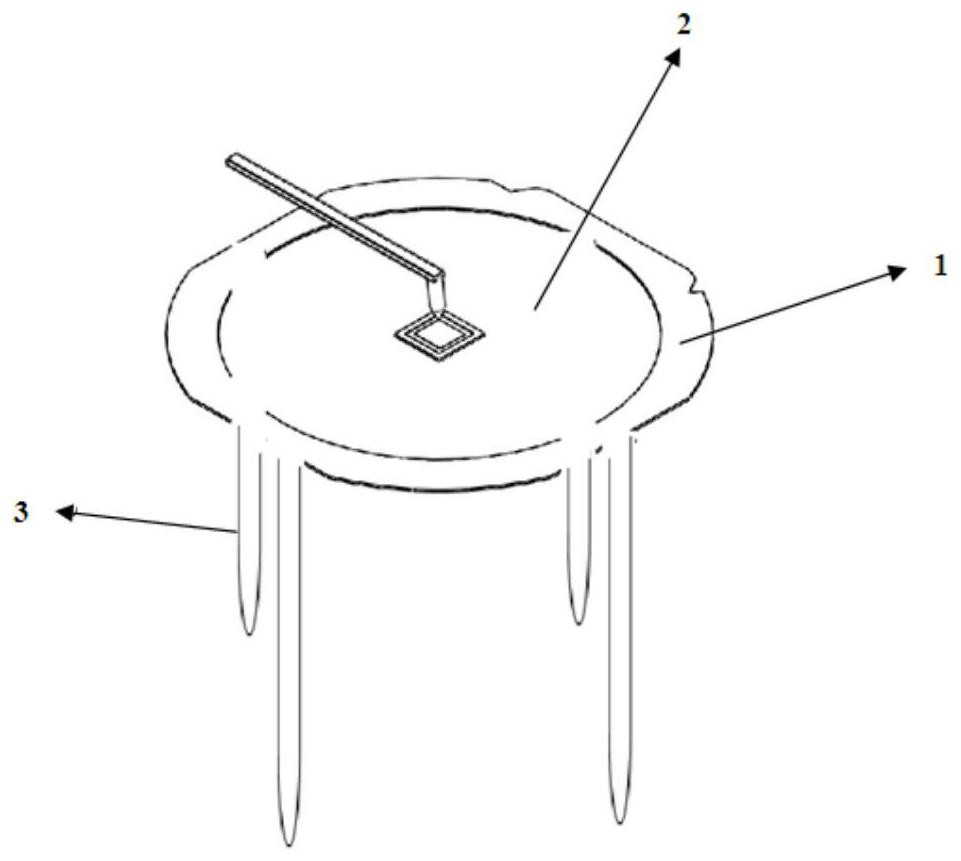

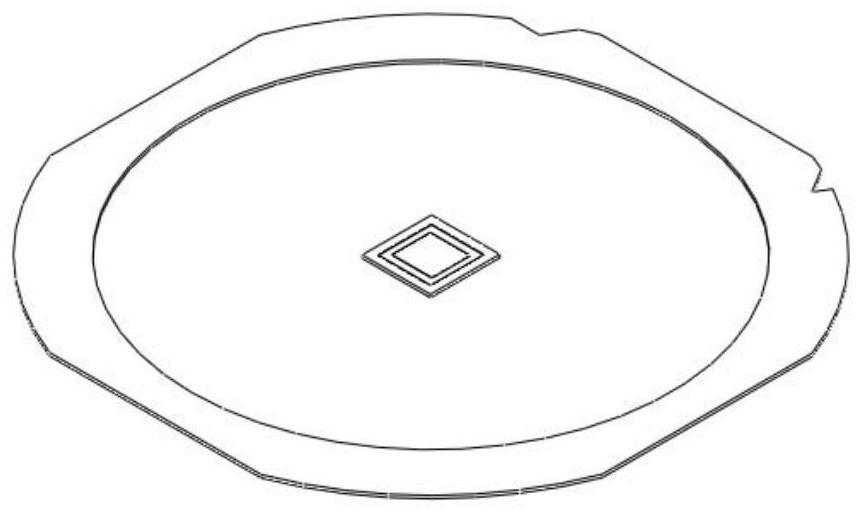

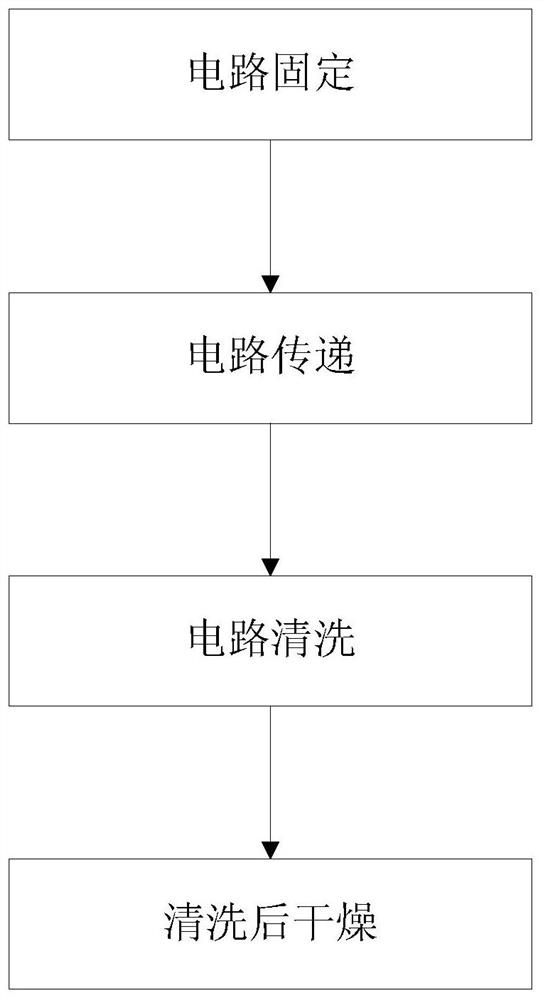

A tooling and a method for cleaning a CMOS image sensor circuit

ActiveCN109244012AImprove cleanlinessLow reliabilityTelevision system detailsSemiconductor/solid-state device manufacturingCMOSGlass cover

The invention discloses a tooling and a method for cleaning a CMOS image sensor circuit, and belongs to the CMOS image sensor circuit packaging field. Compared with conventional methods, that invention can quickly and effectively remove dirt, dust and other forms of excess attached on surfaces of a chip, a housing, and a glass cover plate, solves the problem of low reliability of the CMOS image sensor circuit due to the presence of excess in the circuit, which results in the failure of the photosensitive part, and does not affect the bonding strength of the bonding wires inside the circuit. The method of the invention can effectively remove the internal redundancy of the CMOS image sensor circuit, ensure the reliability of the CMOS image sensor circuit after packaging, effectively shortenthe production cycle, and the cleaning method is simple and practical, easy to realize and strong in maneuverability.

Owner:BEIJING MXTRONICS CORP +1

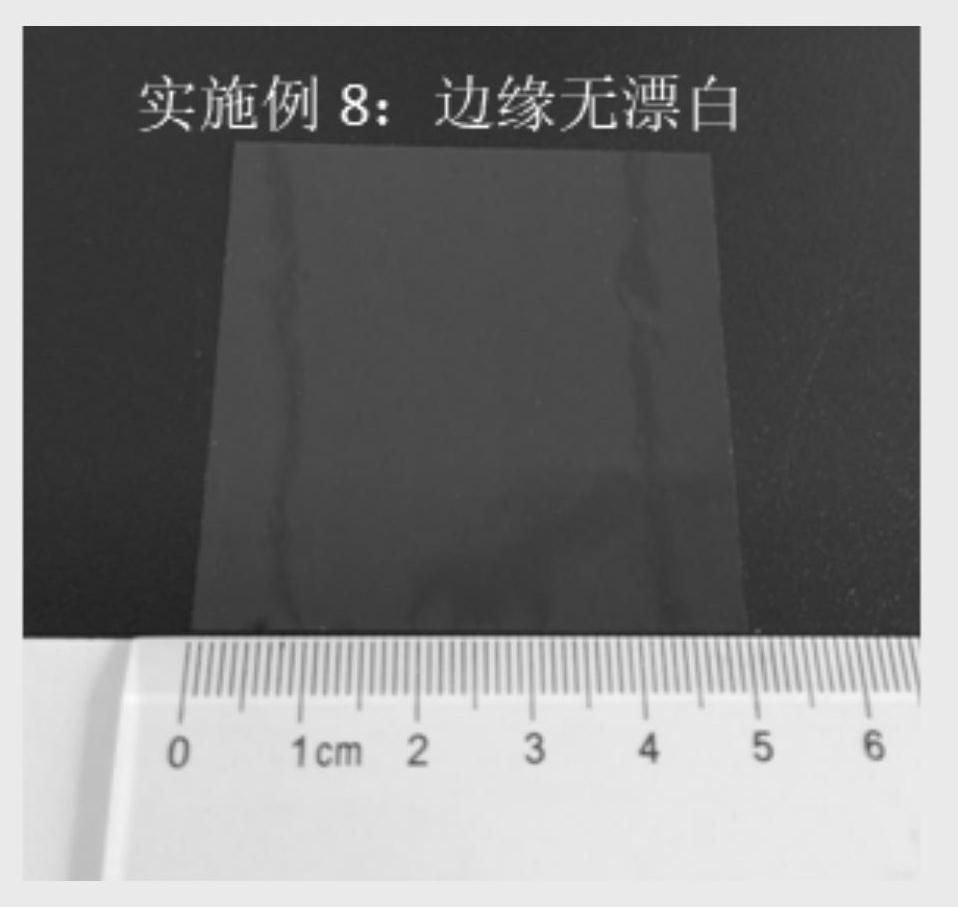

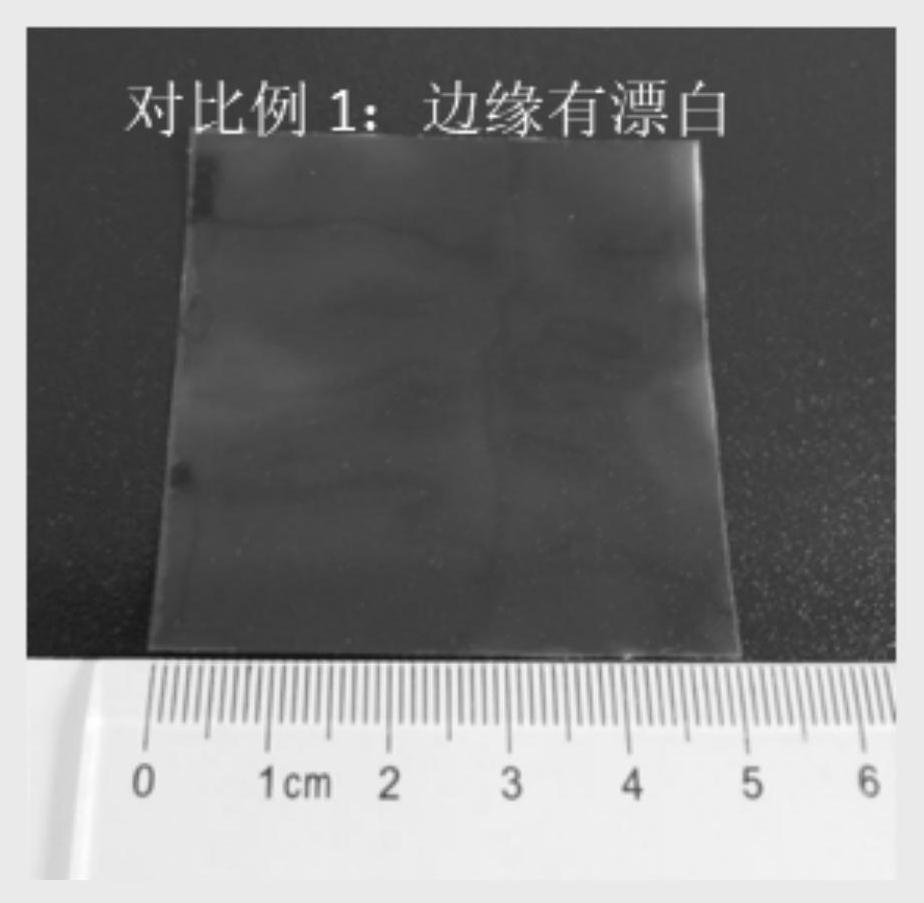

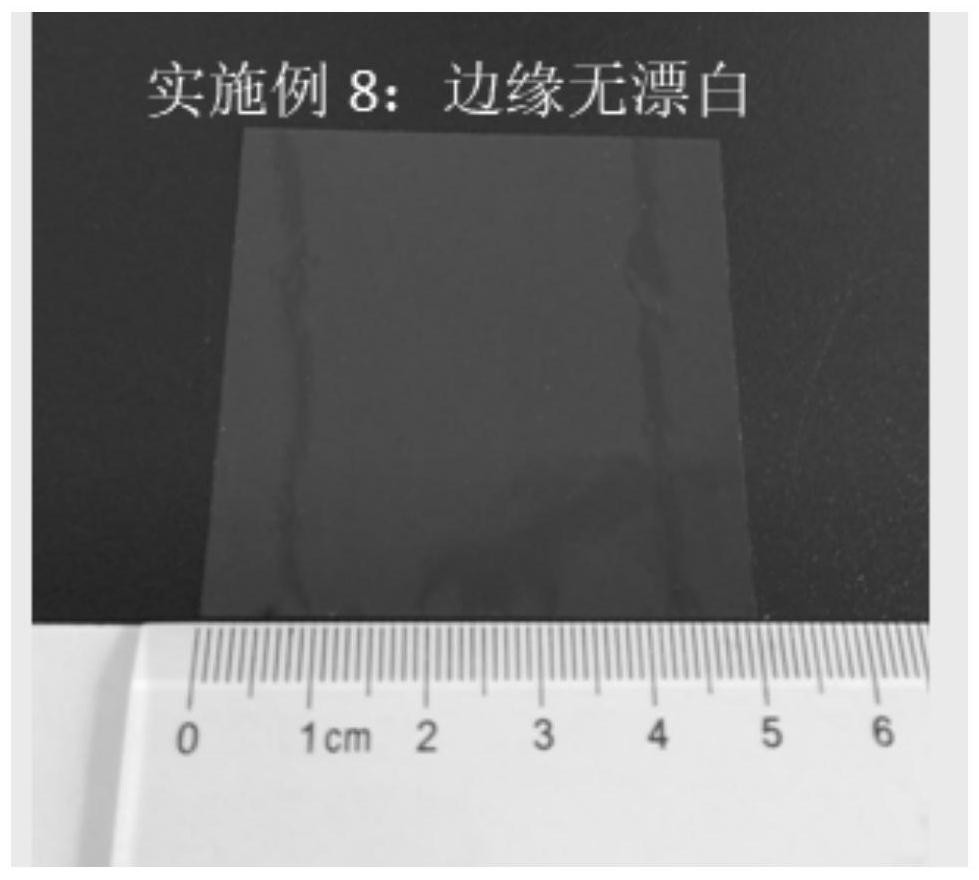

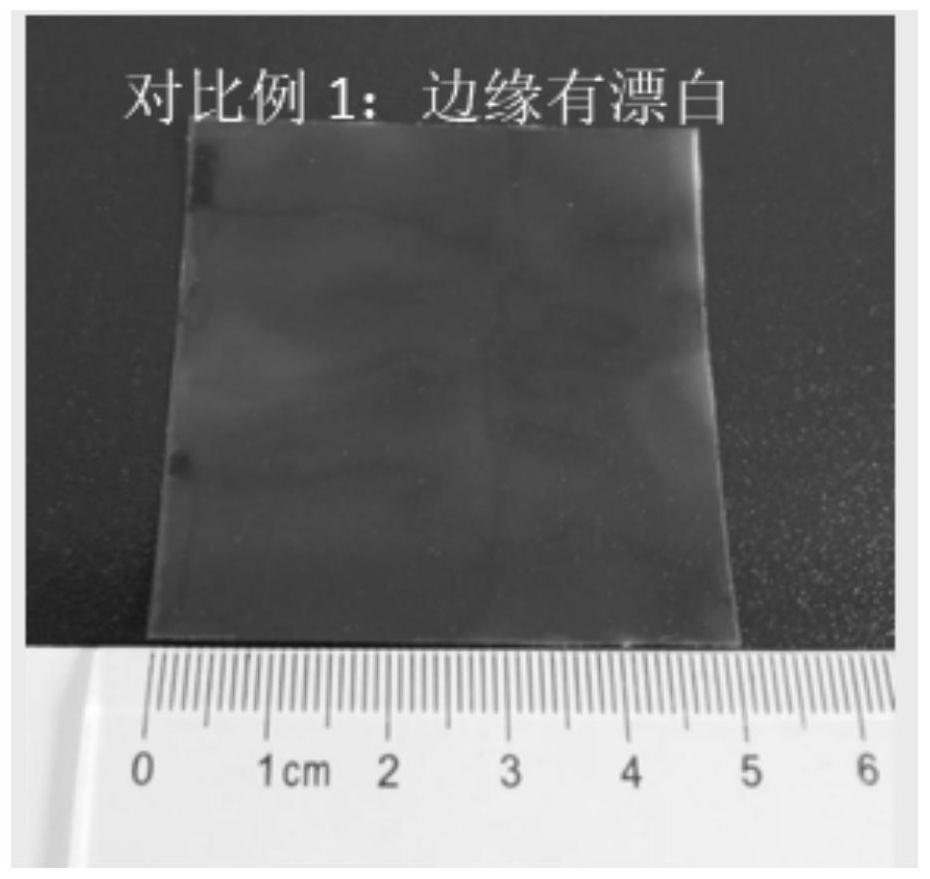

UV curing adhesive for polarizing plate, and preparation method and application thereof

ActiveCN112029420AHigh viscosityImprove reaction speedPolarising elementsOrganic non-macromolecular adhesiveVinyl etherMethacrylate

The invention discloses a UV curing adhesive for a polarizing plate, and a preparation method and application thereof. The UV curing adhesive for the polarizing plate is obtained by mixing an epoxy compound, a (meth)acrylate compound, a vinyl ether compound, a carboxylic acid compound containing unsaturated double bonds, a cationic photoinitiator and a free radical photoinitiator. The UV curing adhesive can prevent degradation of adhesiveness of the radical curable adhesive composition by maintaining a hydrogen bond between a polyvinyl alcohol (PVA) film and a hydroxyl group of the radical curable adhesive composition, thereby improving moisture resistance of the adhesive.

Owner:JIANGSU TETRA NEW MATERIAL TECH

Environment-friendly and high-efficiency ice-melting coating material and its preparation method and application

The invention discloses an environmentally friendly and efficient ice-melting coating material and its preparation method and application, aiming to solve the problems of high cost of deicing, environmental pollution caused by deicing agents, harm to roads and the environment, and the technology that cannot function effectively for a long time question. The coating material is made of the following raw materials: deicing agent, bonding material, hydrophobic coating material, hydrophilic coating material, hydrophobic plasticizer, hydrophilic plasticizer, glycerin, anti-sticking agent, Talc powder, filler, semi-reinforcing agent, leveling agent, coupling agent, defoamer, porogen, hydrophobic fumed silica. And further provide a preparation method of the coating material, and apply it to ice melting of traffic roads. The invention does not contain harmful ions, does not cause corrosion and does not damage the environment when deicing for a long time, and has a better maintenance effect on the road surface; the raw material has a wide range of sources, the cost is low, the production process is simple and easy to operate, and can be popularized and applied in a wide range; It reduces a lot of manpower and material resources and has important economic value.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Phenolic resin additive, phenolic resin containing the same and preparation method thereof

InactiveCN101177505BReduce manufacturing costDoes not reduce bond strengthAldehyde/ketone condensation polymer adhesivesDispersed mediaResin adhesive

The invention discloses an additive of phenolic resin, the preparation method and a phenolic resin adhesive for the additive. Raw materials of the additive comprise disperse medium, protein powder ofdefatted soybean, sodium carbonate and complexing agent; wherein, for the parts by weight of the raw materials is that: 70 to 80 of disperse medium, 20 to 35 of protein powder of defatted soybean, 0.5to 3 of sodium carbonate, 0.8 to 2 of complexing agent which comprises borax and aluminum sulfate with 1.5 to 12:1 of parts by weight. The additive of the invention comprises protein powder of defatted soybean. The invention has the advantages of not only lowering the manufacturing cost of the adhesive, guaranteeing bonding strength of prepared plywood, but also effectively lowering formaldehydeemission of prepared artificial board when the additive is added into the phenolic resin.

Owner:BEIJING FORESTRY UNIVERSITY

Tool and method for cleaning circuit of cmos image sensor

ActiveCN109244012BImprove cleanlinessLow reliabilityTelevision system detailsSemiconductor/solid-state device manufacturingComputer hardwareCMOS

The invention discloses a tooling and a method for cleaning a CMOS image sensor circuit, belonging to the field of CMOS image sensor circuit packaging. Compared with the traditional method, the present invention can quickly and effectively remove the contamination, dust and other forms of redundant matter attached to the surface of the chip, the casing and the glass cover, and solve the problem that the photosensitive part of the CMOS image sensor circuit is damaged due to the redundant matter inside. The problem of low reliability caused by the formation of bad spots due to shading will not affect the bonding strength of the bonding wire inside the circuit. The method of the present invention can effectively remove redundant substances inside the CMOS image sensor circuit, ensure the reliability of the CMOS image sensor circuit after packaging, effectively shorten the production cycle, and the cleaning method is simple, practical, easy to realize and strong in operability.

Owner:BEIJING MXTRONICS CORP +1

A kind of rare earth permanent magnet and its preparation method

ActiveCN102610355BImprove uniformityResidue reductionPermanent magnetsInductances/transformers/magnets manufactureRemanenceNitrate

A rare earth permanent magnet that can increase the coercive force of the magnet without reducing the remanence and energy product of the magnet, and at the same time can not reduce the bonding strength between the substrate and the coating or coating after plating or coating, and prepare the magnet The method is as follows: first, dissolve the powder containing R2 fluoride, R3 nitrate and R4 phosphate in water or alcohol to prepare a solution; arrange the above solution evenly on the surface of the magnet to be treated; then dehydrate the magnet to be treated or alcohol treatment; finally, the treated magnet is subjected to diffusion heat treatment to obtain the treated magnet. The method used in the present invention can improve the uniformity of the powder on the surface of the magnet, reduce the powder residue on the surface of the magnet after thermal diffusion, improve the coercive force of the magnet, and not reduce the bonding between the substrate and the coating or coating after plating or coating strength.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Method for preparing narrow frame display device

A method for manufacturing a display apparatus comprises: performing radiation processing on a polyimide film at a sealed position of a substrate, so as to make the polyimide film at the sealed position of the substrate generate a free radical; and coating frame sealing glue at the sealed position, and performing consolidation. By performing radiation processing on a polyimide film, a cracking reaction of a surface group of the polyimide film occurs to generate a free radical; mutual reactions can occur between the free radical and an active group of the frame sealing glue, so that the bonding strength is increased, and the problems such as liquid crystal puncture, liquid crystal pollution and poor reliability are avoided.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

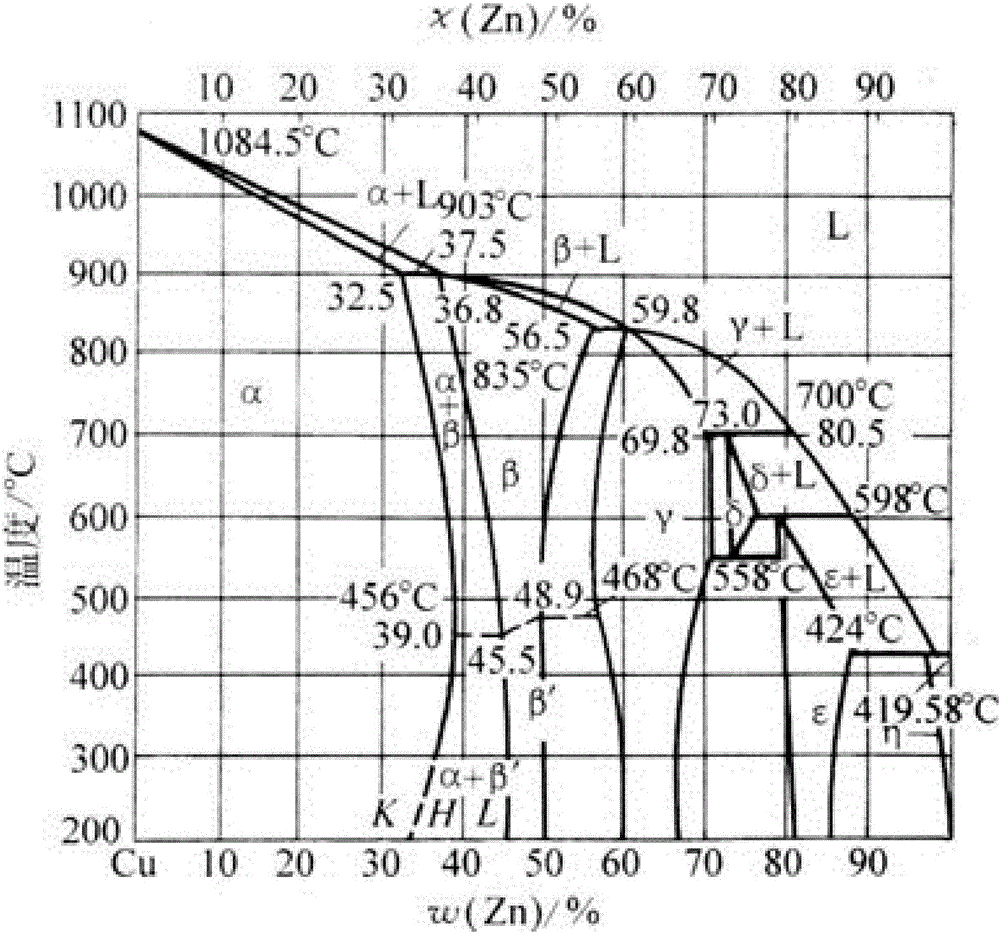

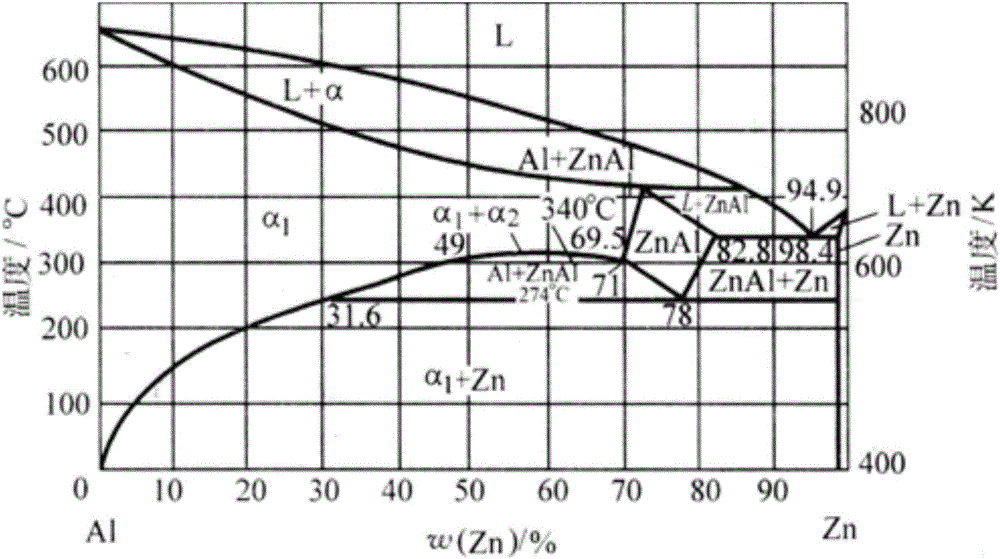

Preparation process of a copper-zinc-aluminum three-layer composite conductive wire row

ActiveCN105938741BImprove plasticityDoes not reduce bond strengthSingle bars/rods/wires/strips conductorsCable/conductor manufactureTube drawingZinc

The invention discloses a preparation technology of a copper-zinc-aluminum three-layer composite conductive wire bank. The technology comprises the following steps of: (1) cleaning a copper tube; (2) galvanizing the copper tube; (3) carrying out rolling by a three-roll planetary rolling mill after an aluminum tube is inserted to obtain a copper-zinc-aluminum three-layer composite tube blank; (4) inserting an aluminum bar and drawing the copper-zinc-aluminum three-layer composite tube blank and the aluminum bar by a tube drawing machine until the copper-zinc-aluminum three-layer composite tube blank and the aluminum bar are laminated to obtain a composite rough blank; and (5) carrying out online heating on the composite rough blank through an induction coil, and directly rolling the rectangular copper-zinc-aluminum three-layer composite conductive wire bank through a two-direction rolling mill. According to the prepared composite conductive wire bank, the surface quality is good; no brittle phase is generated among three metals; the strength of the joint surface is high; the stratification phenomenon is avoided after rolling; and the used production equipment is simple, high in flexibility and low in cost.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

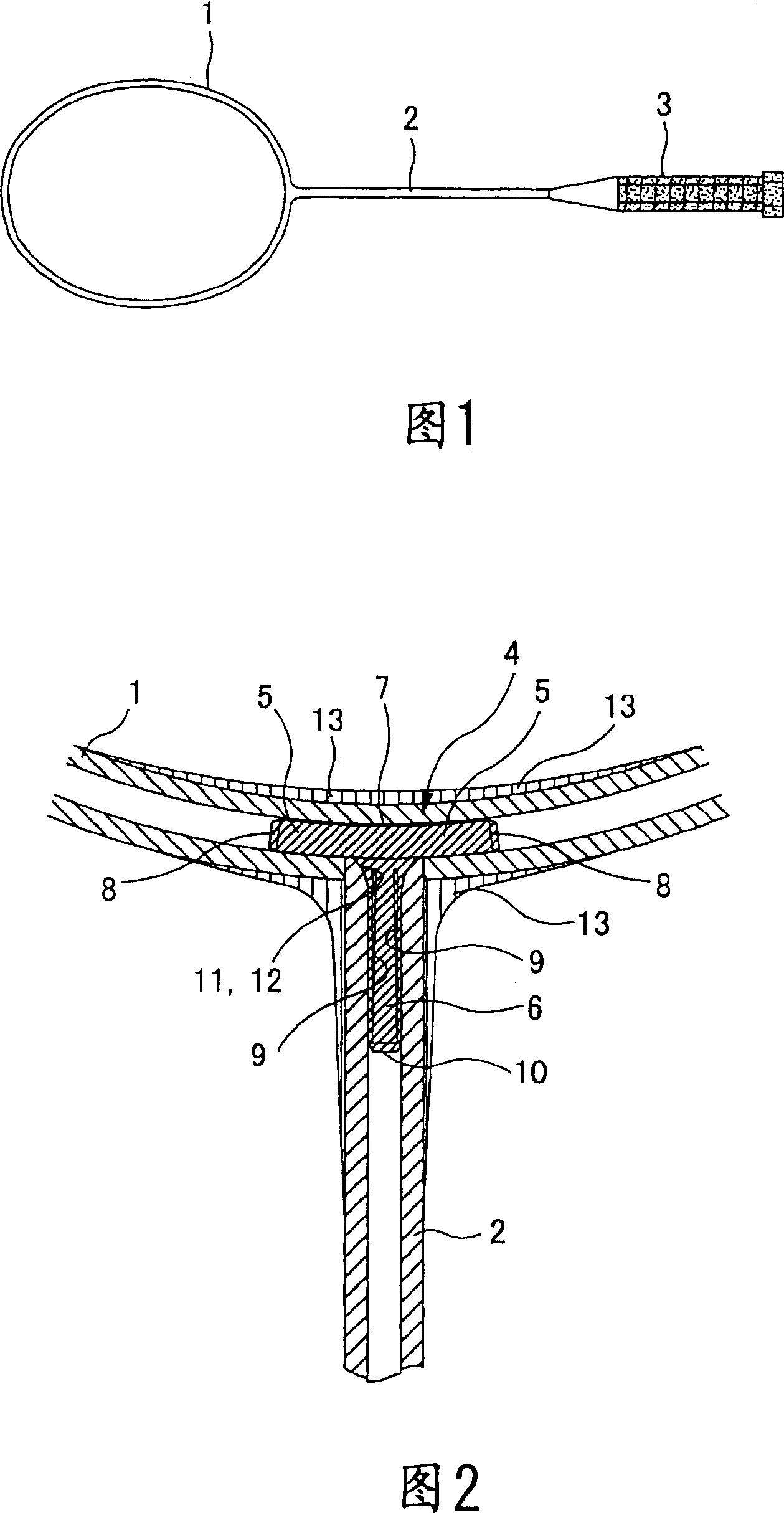

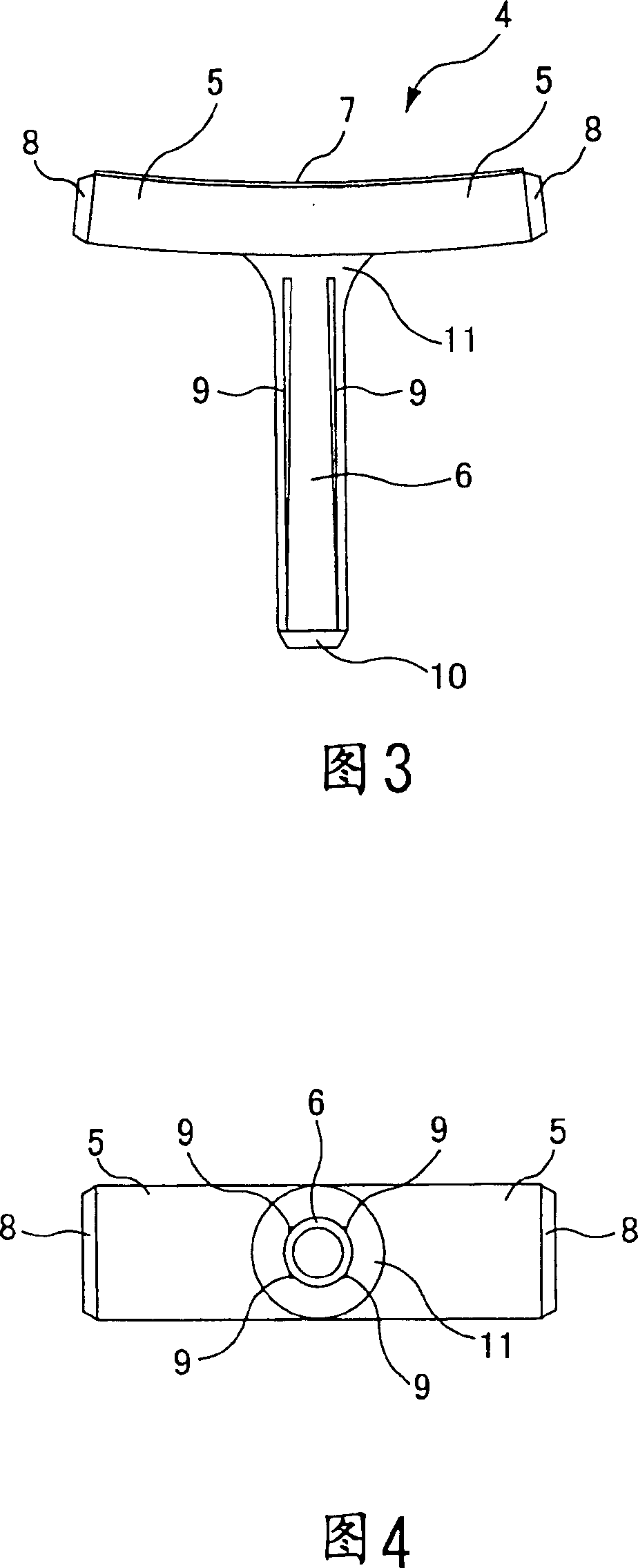

Badminton racket

ActiveCN1329095CSpread evenlyDoes not reduce bond strengthBall sportsStringed racketsEngineeringAdhesive

A badminton racket comprises an oval-shaped frame and a hollow shaft joined together by a T-joint coated with adhesive. A vertical stem of the T-joint is provided with a plurality of ribs extending axially on the external surface thereof. The ribs are formed such that, when the T-joint is inserted into an upper open end of the shaft, top edges of the ribs are brought into close contact with inner surface of the shaft.

Owner:YONEX CO LTD

Environment-friendly and high-efficiency snow-melting pavement coating material and its preparation method and application

The invention discloses an environmentally friendly efficient snowmelt pavement coating material and a preparation method and applications thereof, and aims to solve the technical problems that the ice removing cost in winter is high, the environment is polluted by the snow melting agents, the roads and the environment are damaged by an ice removing technology, and the snow melting means cannot last for a long time. The coating material is made of following raw materials: a snow melting agent, a binding material, a hydrophobic coating material, a hydrophilic coating material, a hydrophobic plasticizer, a hydrophilic plasticizer, glycerin, an anti-sticking agent, talcum powder, a filling material, a semi-reinforcing agent, a leveling agent, a coupling agent, an antifoaming agent, a pore forming agent, and a hydrophobic fumed silica. The invention further provides a preparation method of the coating material, and the coating material is applied to snow melting of traffic roads. The coating material is green and environmentally, and can well protect the pavement. The raw material sources are wide, the cost is low, the production technology is simple and easy to operate and is suitablefor large scale application and popularization, a great amount of human resources and materials is saved, and a great economic value is created.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

UV-curing adhesive based polarizing plate and preparation method thereof

ActiveCN112011276AImprove moisture resistanceNo loss of transparencyPolarising elementsOrganic non-macromolecular adhesiveMethacrylateAdhesive cement

The invention discloses a UV-curing adhesive based polarizing plate and a preparation method thereof. The preparation method comprises the following steps: coating one surface of an optical film witha UV-curing adhesive, and then covering a polarizer on the optical film; and carrying out ultraviolet curing to obtain the polarizing plate. The adhesive used in the invention enables an epoxy compound and a (methyl)acrylate compound to be fully cured without reduction in bonding strength, the transparency of an adhesive layer can be prevented from being reduced, and overflowing of an initiator isalso reduced; a compound formed after the adhesive provided by the invention is mixed and cured contains carboxyl groups and can be combined with water in a high-humidity environment at first, so theproblem that the adhesiveness of a free radical curable adhesive composition is reduced since hydroxyl groups existing on the surface of a polyvinyl alcohol (PVA) film will be preferentially combinedwith hydrogen bonds in moisture instead of being combined with hydrogen bonds in the free radical curable adhesive composition in a high-humidity environment in the prior art is overcome.

Owner:山东泰特尔新材料科技有限公司

Additive of phenolic resin, phenolic resin therewith and production thereof

InactiveCN100352879CTake advantage ofReduce manufacturing costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhenol formaldehyde resinSodium carbonate

Owner:BEIJING FORESTRY UNIVERSITY

Urea-formaldehyde resin additive, urea-formaldehyde resin containing the same and preparation method thereof

ActiveCN101205348BSolve Exhaust ProblemsSave resource usageAldehyde/ketone condensation polymer adhesivesAluminium sulfateResin adhesive

The invention provides an additive with urea formaldehyde, a preparation method and a urea formaldehyde resin adhesive. The additive is provided by the invention. The raw material of the additive is comprised of the dispersion medium, the dried egg white of the degreased bean and the complexing agent, the weight ratio of the raw material is: 70-80 of dispersion medium, 20-35 of dried egg white ofthe degreased bean, 1-3 of complexing agent, the complexing agent is consisted of the aluminium sulphate and the zirconium carbonate with the weight ratio of 0.4-2.4:1. The additive provided by the invention contains dried egg white of the degreased bean, and then both the bond strength of the prepared veneer is increased and the formaldehyde emission of the preparing artificial slabs is effective decreased when adding the additive into the urea formaldehyde.

Owner:CHANGZHOU JOEL PLASTIC

Production method of copper foil for fine line use

InactiveCN1194587CReduce surface roughnessDoes not reduce bond strengthInsulating substrate metal adhesion improvementPrinted circuit aspectsFine lineCopper foil

Owner:NIPPON DENKAI

Composite formaldehyde scavenger and preparation method thereof, method for removing formaldehyde from wood-based panels, and wood-based panels

ActiveCN111495181BAvoid pollutionDoes not reduce bond strengthGas treatmentNon-macromolecular adhesive additivesEpoxyPolymer science

The invention relates to the technical field of removing formaldehyde from boards, and discloses a composite formaldehyde scavenger comprising the following components: MOFs, modified starch, fluorinated polyether, xanthan gum, ethylene urea, epoxy fatty acid methyl ester and deionized water . The invention also provides a preparation method of the composite formaldehyde scavenger. The invention also provides a method for removing aldehydes from wood-based panels: mixing a compound formaldehyde scavenger in the adhesive; hot-pressing the veneer paper soaked in the mixed adhesive on the surface of the core board; and heat-treating the veneer wood-based panel. The invention can continuously absorb and remove the formaldehyde and VOC released from the wood-based panel, provides a formaldehyde-free wood-based panel, and avoids formaldehyde pollution and harm to users.

Owner:成都市美康三杉木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com