Method for preparing narrow-side display device

A display device, narrow frame technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of poor sealing strength, poor reliability, liquid crystal puncture, etc., to achieve enhanced bonding strength, good display performance and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Taking PI solution (polyimide AL-00010) as an example to carry out radiation modification.

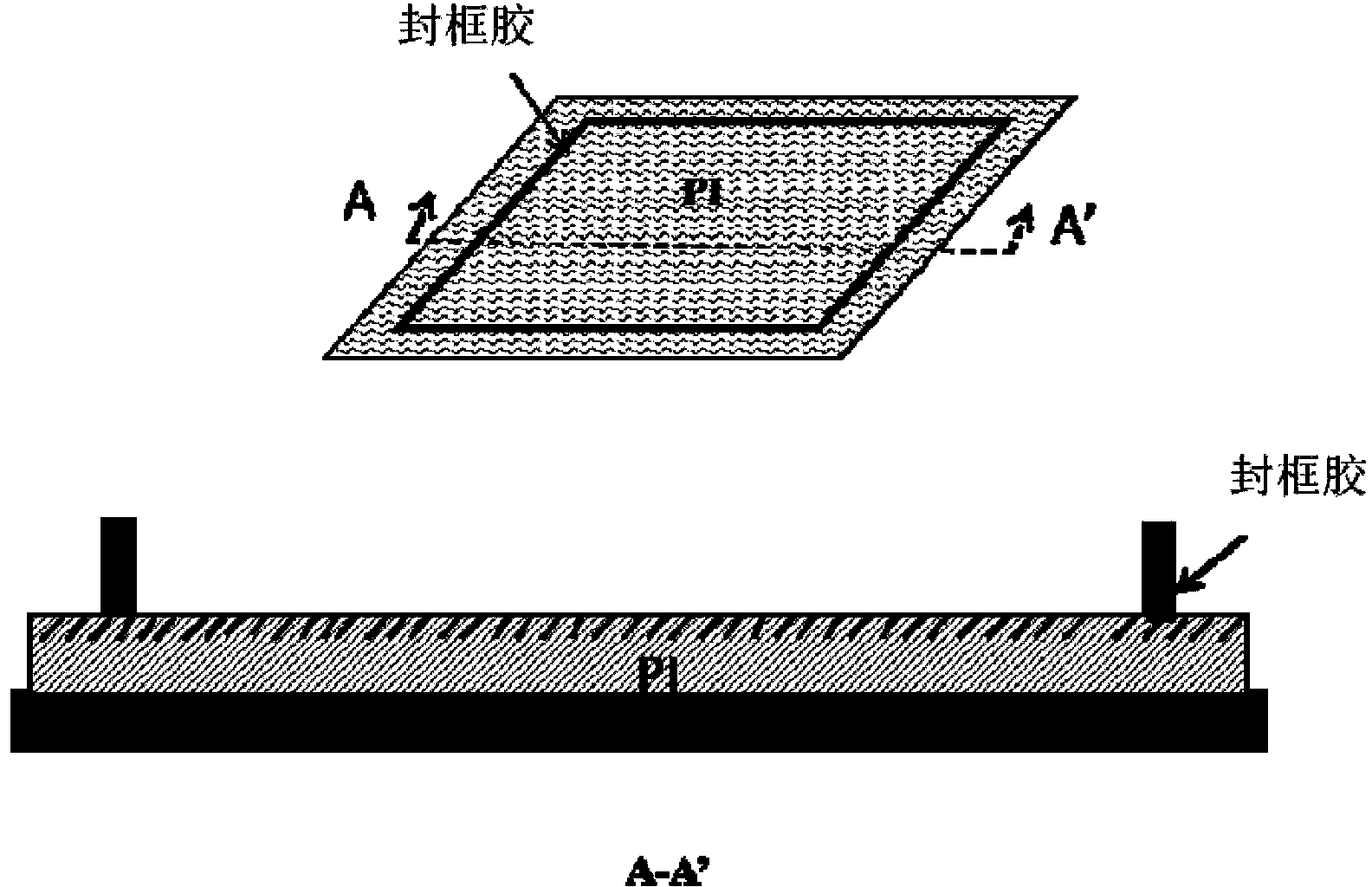

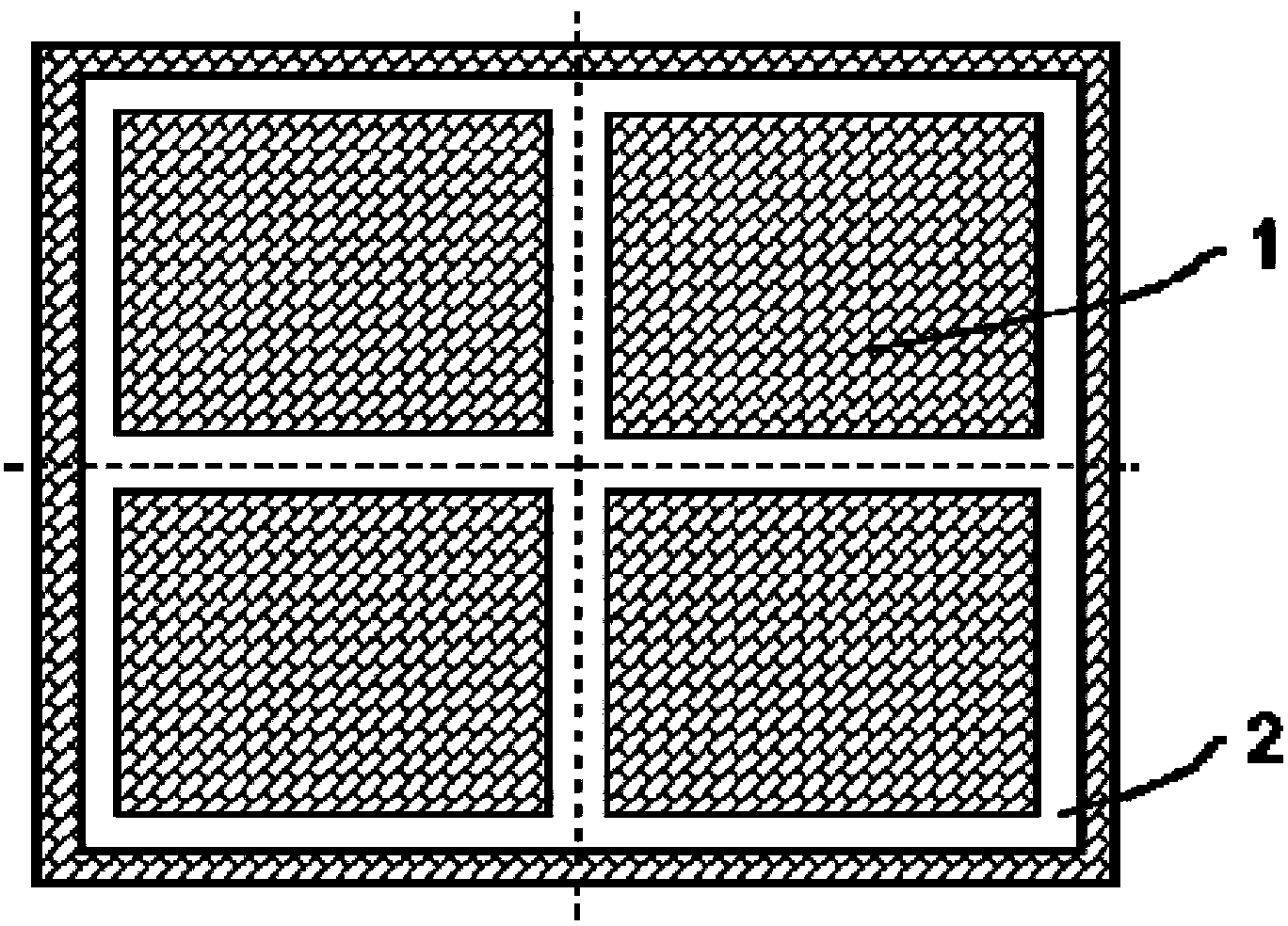

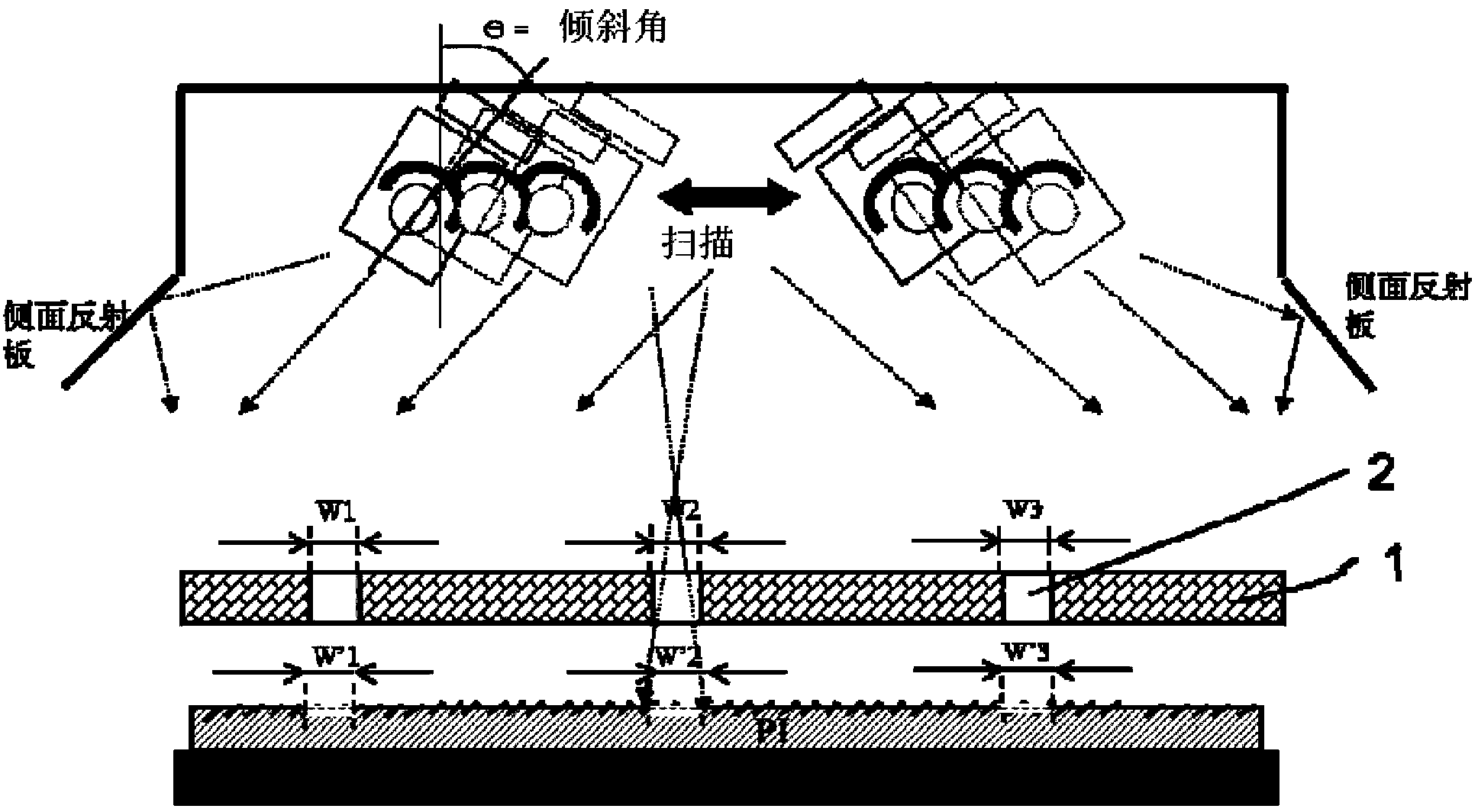

[0048] Using conventional methods in the field, the above PI liquid is coated on the array substrate to form a PI film, which is subjected to rubbing alignment treatment. The array substrate that has undergone orientation treatment is placed on the stage in the radiation precursor. Rotate the stage and adjust the position of the radiation shield so that the part of the array substrate to be treated with radiation (sealing position) is aligned with the light-transmitting part of the radiation shield.

[0049] Among them, the radiation source is an ultraviolet lamp, the wavelength of the linear ultraviolet light emitted is 254nm, and the radiation intensity is 1.0J / cm 2 .

[0050] The radiation modification process of the above PI film is shown in the following schematic diagram:

[0051]

[0052] a. The cleavage reaction of the ester group on the branched chain of the PI fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com