Environmentally friendly efficient snowmelt pavement coating material

A kind of coating material and high-efficiency technology, applied in the direction of coating, etc., can solve the problems that snow melting methods cannot play a long-lasting and effective role, snow removal technology is harmful to roads and the environment, and snow melting agents pollute the environment. It achieves strong anti-ultraviolet performance, strong Effect of weather resistance and strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

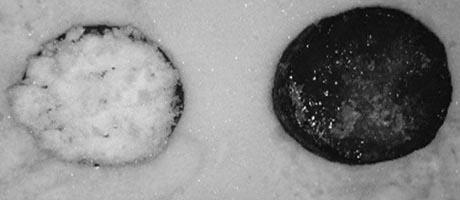

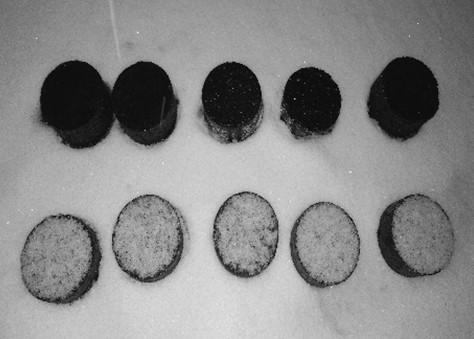

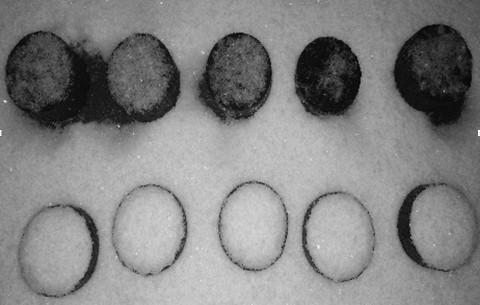

Image

Examples

Embodiment 1

[0039] Embodiment 1: An environmentally friendly and efficient snow melting pavement coating material

[0040] The coating material is made from the following raw materials by weight:

[0041] 100 parts of potassium acetate, 50 parts of one-component fluorocarbon resin, 6 parts of ethyl cellulose, 0.7 parts of hydroxypropyl methylcellulose, 0.9 parts of diethyl phthalate, 0.105 parts of PEG-400, 0.03 parts of glycerin , 0.03 parts of magnesium stearate, 0.01 parts of talc, 8 parts of calcium carbonate, 2 parts of barium sulfate, 1 part of YF-001 fluorocarbon high-efficiency leveling agent (purchased from Hubei Ustar Technology Co., Ltd.), TMC-TE 0.02 part of titanate coupling agent (purchased from Tianchang Green Chemical Auxiliary Factory), 0.001 part of dimethicone, 0.2 part of PEG-6000, and 0.1 part of hydrophobic fumed silica.

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of environmental protection and efficient snow melting pavement coating material

[0043] Embodiment 1 The preparation method of environmental protection and high-efficiency snow melting pavement coating material is:

[0044] 1. Take by weighing the raw materials according to the parts by weight described in Example 1;

[0045] 2. Surface modification treatment for fillers and semi-reinforcing agents:

[0046] (1) Dilute the TMC-TE titanate coupling agent with ethanol at a volume ratio of 10:1 to obtain an ethanol dilution;

[0047] (2) Then the calcium carbonate is m / v as 1:0.025 (kg / m 3 ) is added to the obtained ethanol diluent;

[0048] (3) Stir for 0.6-1.0h under the conditions of 40℃~60℃ and 500~600r / min;

[0049] Let stand for 2 hours until all solids are precipitated, remove the supernatant ethanol solution, and place it in a drying oven to dry to remove residual ethanol to obtain modified filler E;

[0050] (4) Th...

Embodiment 3

[0065] Embodiment 3: An environmentally friendly and efficient snow melting pavement coating material

[0066] The difference from Example 1 is that it is made from the following raw materials by weight: 100 parts of potassium acetate, 60 parts of single-component fluorocarbon resin, 6.5 parts of ethyl cellulose, 0.8 parts of hydroxypropyl methyl cellulose, 1.0 part of diethyl phthalate, 0.11 part of PEG-400, 0.04 part of glycerin, 0.04 part of magnesium stearate, 0.015 part of talc, 12 parts of calcium carbonate, 3 parts of barium sulfate, YF-001 fluorocarbon high-efficiency leveling 1.5 part of TMC-TE titanate coupling agent, 0.025 part of TMC-TE titanate coupling agent, 0.002 part of dimethicone, 0.3 part of PEG-6000, and 0.2 part of hydrophobic fumed silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com