Patents

Literature

42results about How to "Resolve curl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

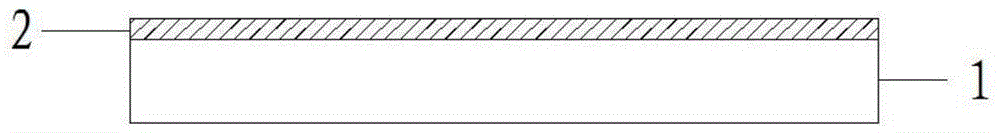

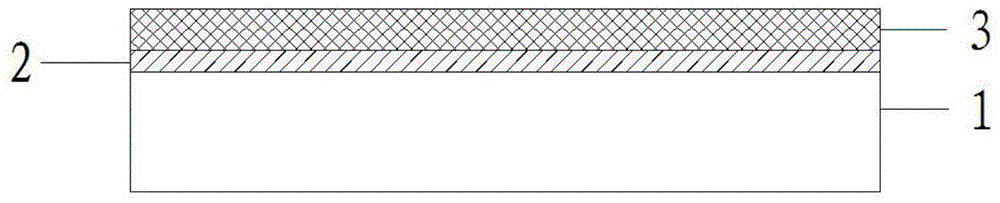

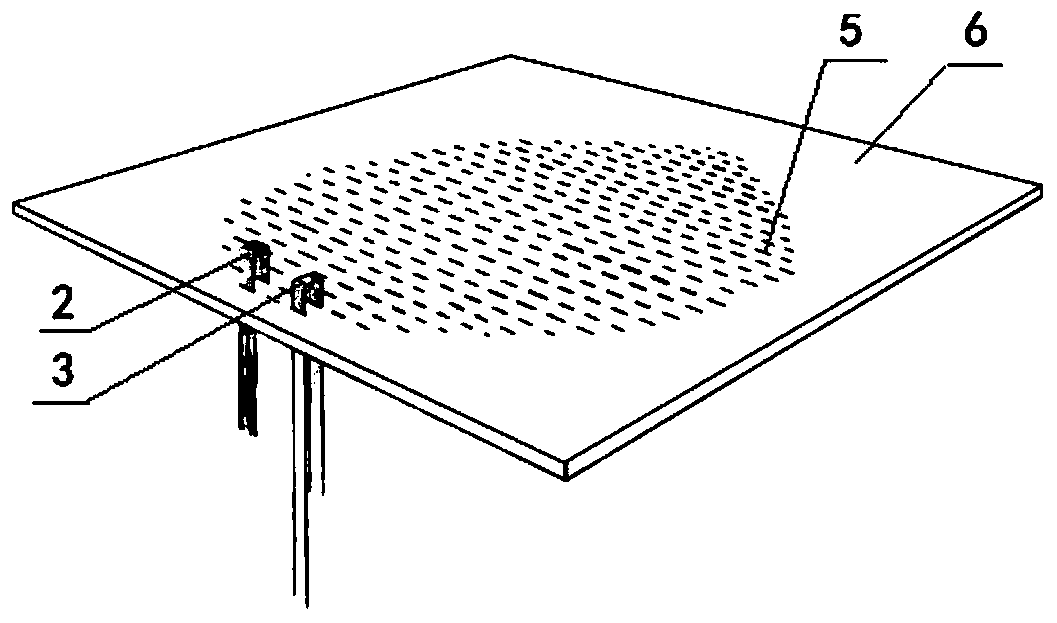

Flexible underlying substrate and manufacturing method thereof

ActiveCN104392901AResolve curlAvoid curlSemiconductor/solid-state device detailsSynthetic resin layered productsManufacturing technologyDisplay device

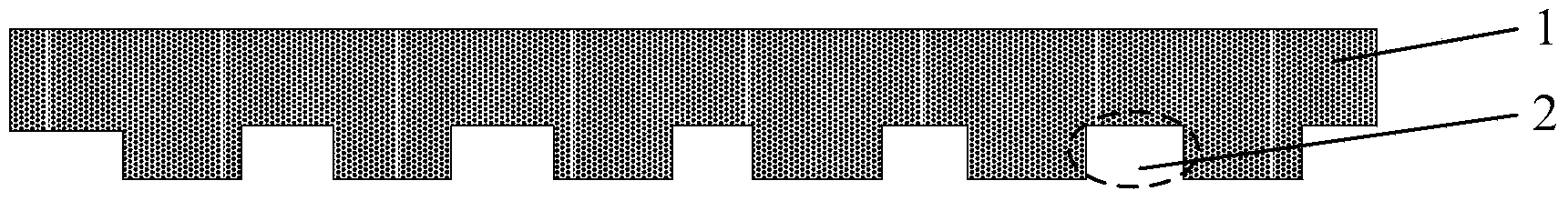

The embodiment of the invention provides a flexible underlying substrate and a manufacturing method thereof, relates to the technical field of display and solves a problem of unnecessary warping in the process of stripping the flexible underlying substrate from a bearing substrate in the manufacturing process of an existing display device so that damage to performance of the display device is avoided, display quality of the display device is enhanced and the fact that the final products become defective products is avoided. The flexible underlying substrate is formed by flexible material. The underlying substrate comprises a first flexible film layer. The lower surface of the first flexible film layer is provided with multiple grooves which are identical in thickness. The invention is applied to the manufacturing technology of the flexible underlying substrate.

Owner:BOE TECH GRP CO LTD

Manufacturing method of flexible display substrate, and manufacturing method of flexible display panel

ActiveCN104867872AImprove efficiencyImprove pass rateSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceEngineering

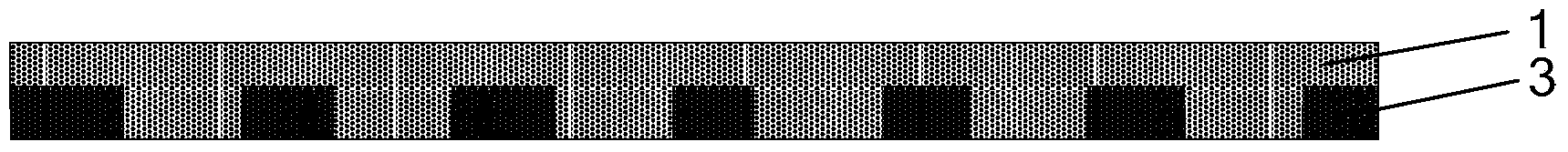

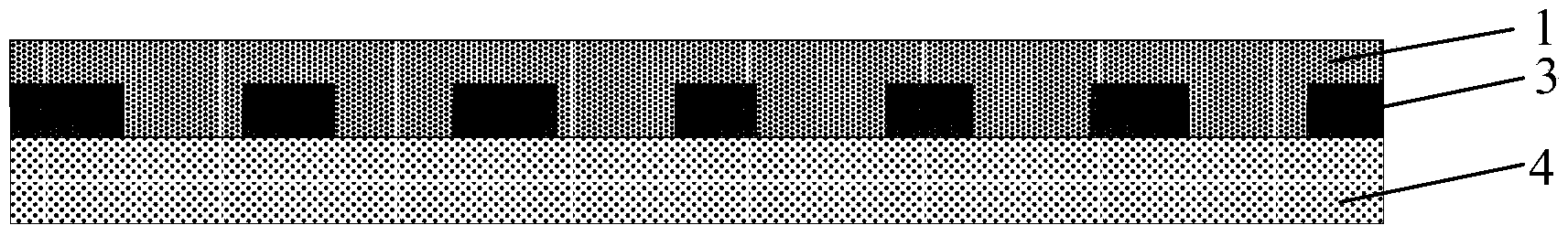

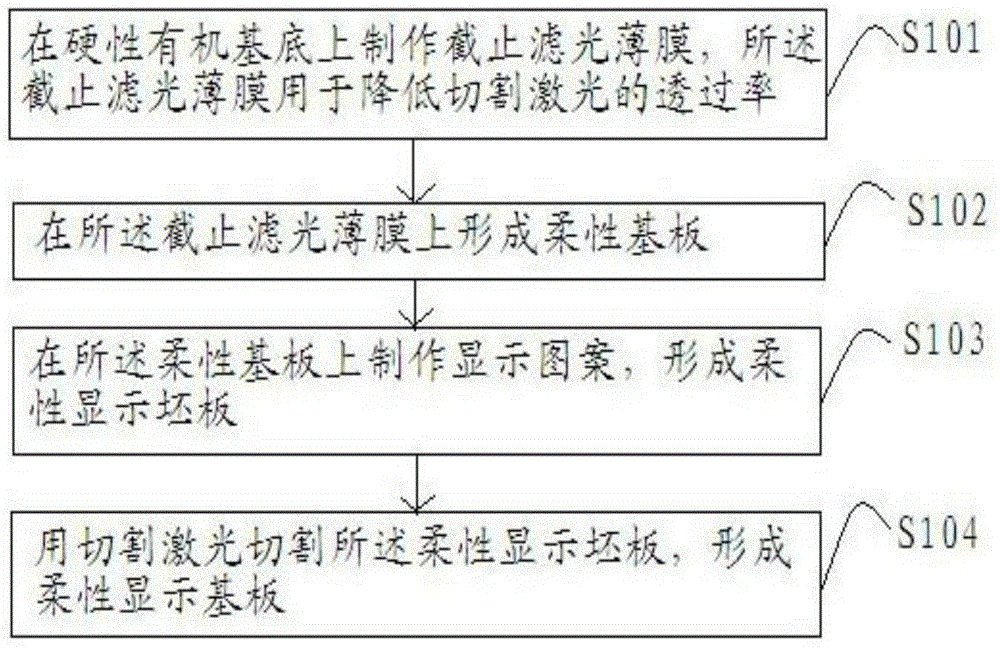

The invention relates to the field of a display technology, and especially relates to a manufacturing method of a flexible display substrate, and a manufacturing method of a flexible display panel. The manufacturing method of the flexible display substrate comprises the following steps: manufacturing a cut-off filtering film on a hard organic substrate, wherein the cut-off filtering film is used for reducing the transmittance of a cut laser; forming a flexible substrate on the cut-off filtering film; preparing display patterns on the flexible substrate to form a flexible display pallet board; and cutting the flexible display pallet board by use of the cut laser to form the flexible display substrate. According to the method, the arranged cut-off filtering film can prevent the hard organic substrate from damage caused by the cut laser, protects the hard organic substrate, enables the hard organic substrate to be repeatedly utilized for multiple times and accordingly reduces the manufacturing cost of the flexible display substrate. The manufacturing method of the flexible display substrate can be used for preparing the flexible display substrate.

Owner:BOE TECH GRP CO LTD

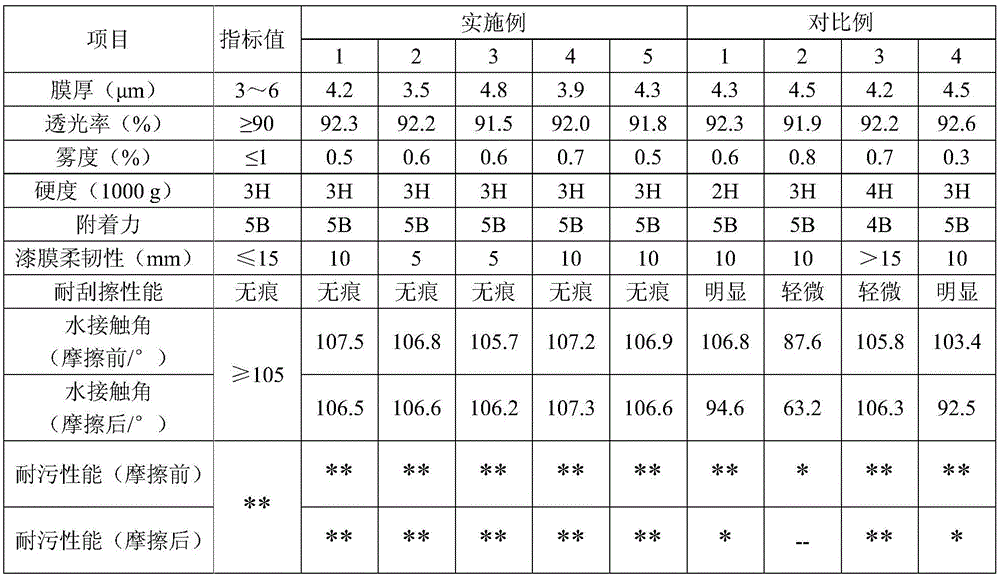

UV photocureable coating for explosion-proof membrane hardening coating of vehicle-mounted touch screen and preparation

InactiveCN106497170AIncrease crosslink densityReduce brittlenessAntifouling/underwater paintsPaints with biocidesPhotoinitiatorAcrylate

The invention belongs to the field of UV photocureable coatings, and discloses a UV photocureable coating which is extremely high in scratching resistance and hydrophobic and oleophobic anti-pollution property and is used for an explosion-proof membrane hardening coating of a vehicle-mounted touch screen, a preparation method and application of the UV photocureable coating and a hardening membrane based on the UV photocureable coating. The coating is prepared from the following components in parts by mass: 20 to 50 parts of a mulfunctional acrylate monomer, 1 to 5 parts of a sulfur alcohol monomer, 0.1 to 1 part of a fouling resistant additive, 1 to 5 parts of nano particles, 1 to 3 parts of a photoinitiator and 40 to 80 parts of an organic solvent, wherein the mulfunctional acrylate monomer is an acrylate active diluent with the mulfunctional level of 4 to 6. The invention further provides the hardening membrane obtained on the basis of the UV photocureable coating. The hardening membrane is extremely high in steel wool starching resistance (with water contact angle greater than or equal to 105 degrees) and stable in hydrophobic and oleophobic anti-pollution property and flexibility. Compared with the conventional PET hardening membrane, the hardening membrane based on the UV photocureable coating can realize comprehensive upgrading of the performance; and by the coating production mode and UV photocuring, the production efficiency is improved, and the production cost is reduced.

Owner:GUANGZHOU HUMAN ENG MATERIAL

Color printing ink for printing heat shrink film labels and preparation method of color printing ink

ActiveCN103265843ADoes not fadeDoes not fall offInksPolymer sciencePolyethylene terephthalate glycol

The invention discloses color printing ink for printing heat shrink film labels and relates to environmental-friendly ink. The color printing ink comprises the following components: acrylic resin, nitrocotton, VINISOL OH, CAB (Cellulose Acetate Butyrate) resin, EVA (Ethylene Vinyl Acetate) resin, a color pigment, additives and a diluent, wherein the additives are polyethylene wax and fumed silica. Compared with the prior art, the color printing ink for printing the heat shrink film labels, disclosed by the invention, has the advantages that the color printing ink is free of benzene and ketone, resists tetrahydrofuran and can be applied to PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), OPS (Oriented Polystyrene) heat shrink film base materials, and after the color printing ink is matched with heat shrink films for printing, the shrink films do not curl and are free of tinting. The products printed by adopting the color printing ink are in line with environment-friendly requirements, are safe and non-toxic and can be recycled; and after printing, the shrink films have very strong capability of resisting alcohol and tetrahydrofuran, thus the problem of the compatibility between the thin films and glue occurring when the thin films are subjected to skin packaging and are glued is solved very well.

Owner:CHENGDU PRESSTER NEW MATERIALS

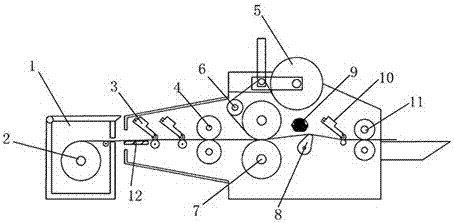

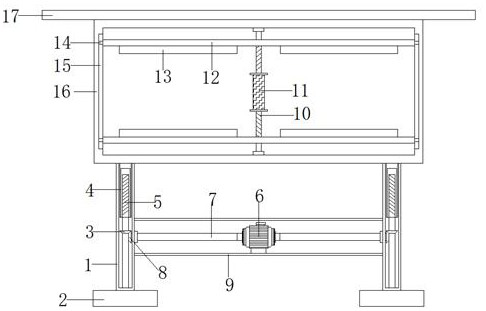

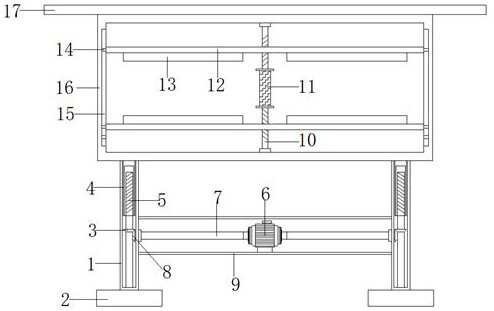

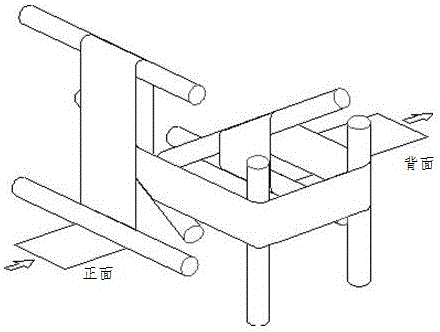

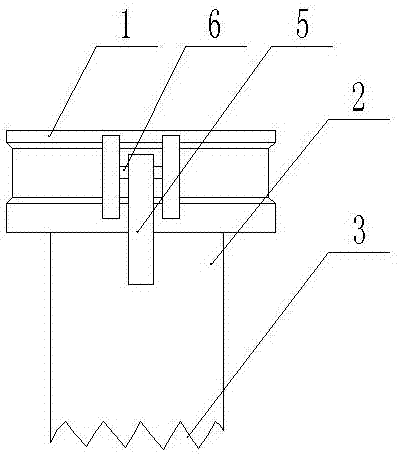

Precoating laminating machine for preventing curling

InactiveCN107538903APaper dryingPrevent lamination from curlingPrinting press partsHot pressHot pressing

The invention discloses a pre-coating film machine for preventing curling, which includes a carton, a paper roll, a transmission plate, a smoothing roll, a dehumidification pressure roll, a film roll, a guide roll, a heat press roll, a fan, a protruding shaft, a traction shaft, Cold pressure roller, this invention solves the problem of retroperitoneal paper curling caused by existing laminating machines. According to the reason of curling due to paper humidity and one-sided laminating pressure, a dehumidification pressure roller is arranged in the laminating machine. The paper is dehumidified, and on the other hand, it provides a certain pressure on the paper to be coated, so that the paper is dry and compact before the coating. A fan and a convex shaft are installed inside the laminating machine. The fan cools the paper after the coating is hot-pressed. The reciprocating rotation of the cam shaft exerts reverse pressure on the paper, and a cold pressure roller is installed at the exit of the laminating machine to shape the paper and ensure the paper is flat.

Owner:成都佳欣诚信科技有限公司

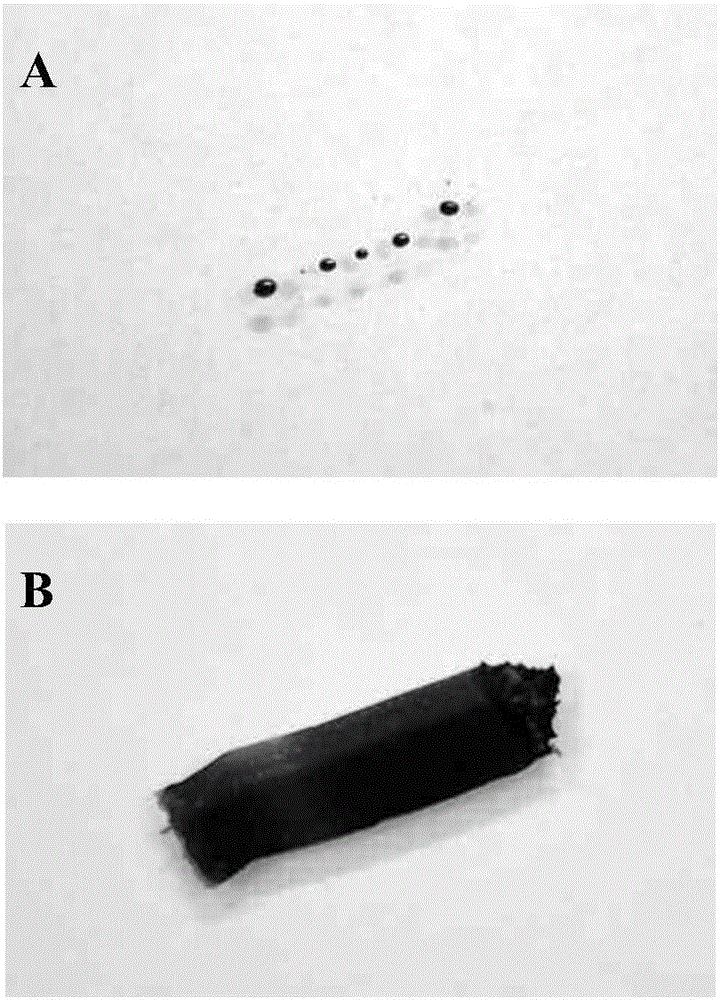

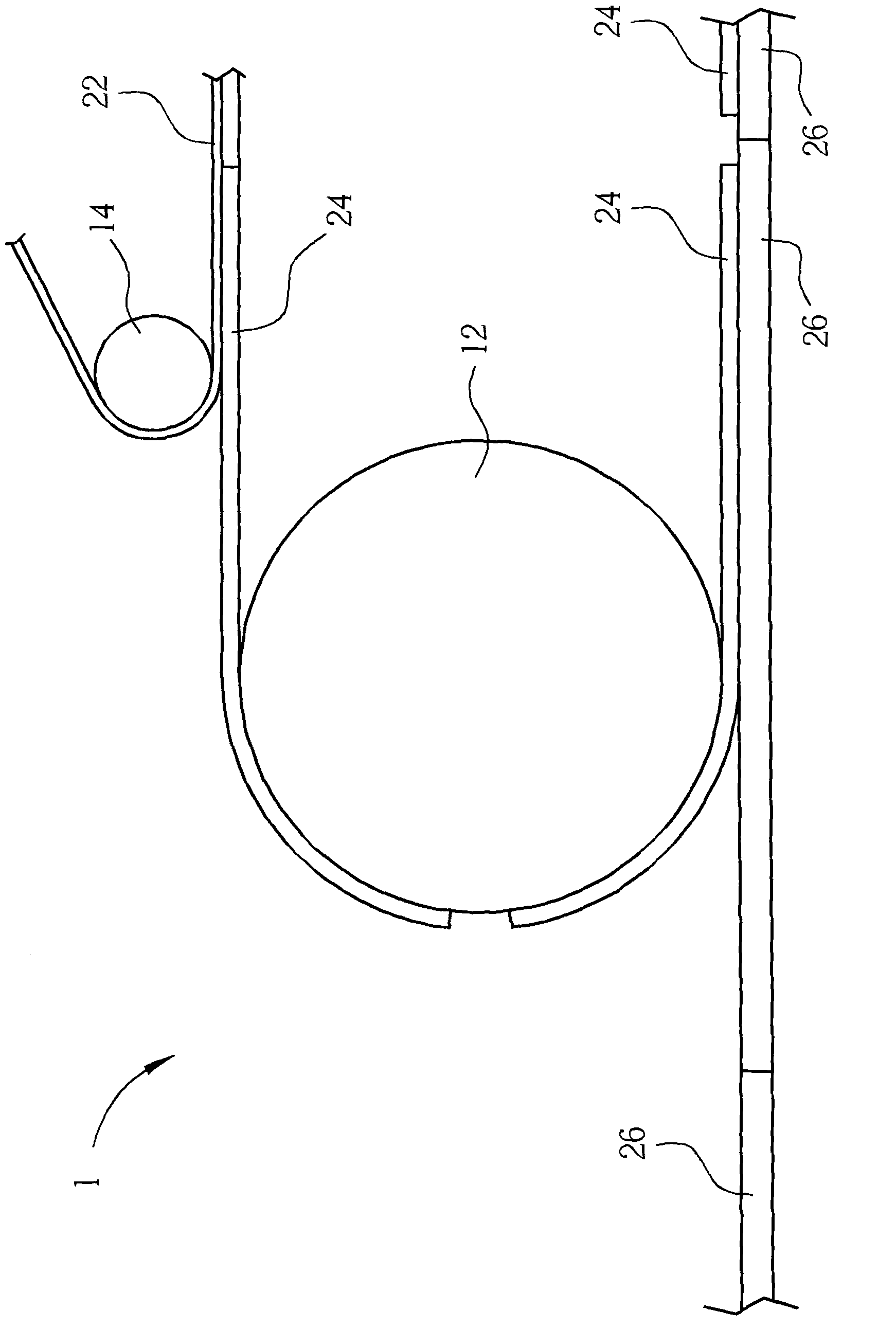

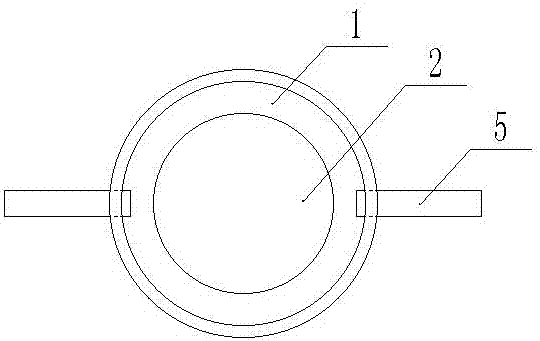

Soft thin film transferring device and soft thin film transferring method

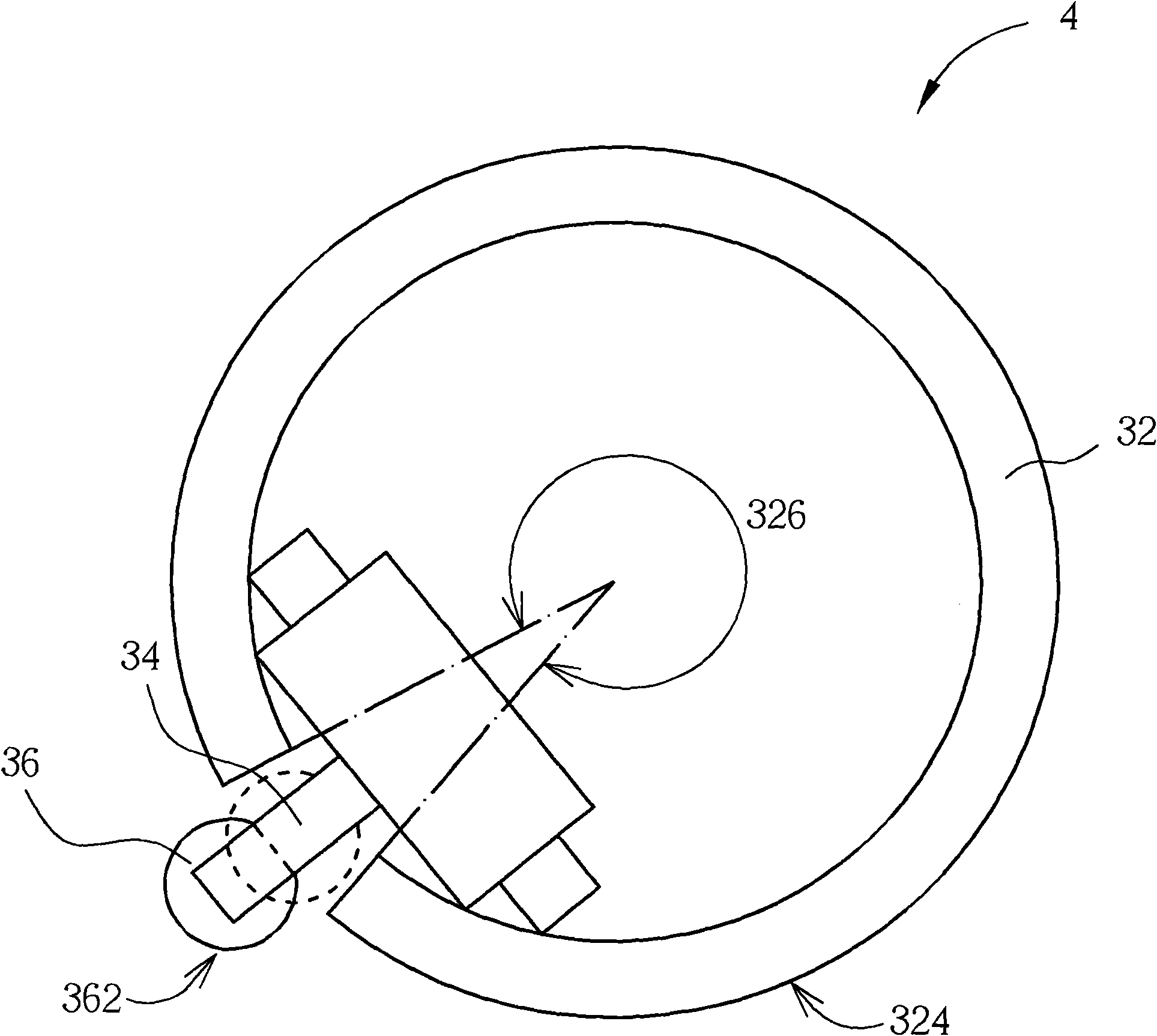

InactiveCN101958281AContribute to qualityResolve curlLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses a soft thin film transferring device and a soft thin film transferring method. The soft thin film transferring device comprises a first roller wheel, a connecting component and a second roller wheel, wherein the connecting component is pivoted to the second roller wheel and is connected to the first roller wheel telescopically so that the second roller wheel can protrude out from a first peripheral surface; and the peripheral surfaces of the first roller wheel and the second roller wheel are respectively provided with a controllable adsorption device. When in use, the soft thin film transferring method comprises the following steps of: peeling the edge part of a soft thin film which is adhered to a first support plate from the first support plate by using the second roller wheel; peeling the main part of the soft thin film from the first support plate by using the first roller wheel; adhering the edge part to a second support plate by using the second roller wheel; and adhering the main part to the second support plate by using the first roller wheel. Therefore, the device and method solve the problem of warpage when the soft thin film is transferred in the prior art.

Owner:AU OPTRONICS CORP

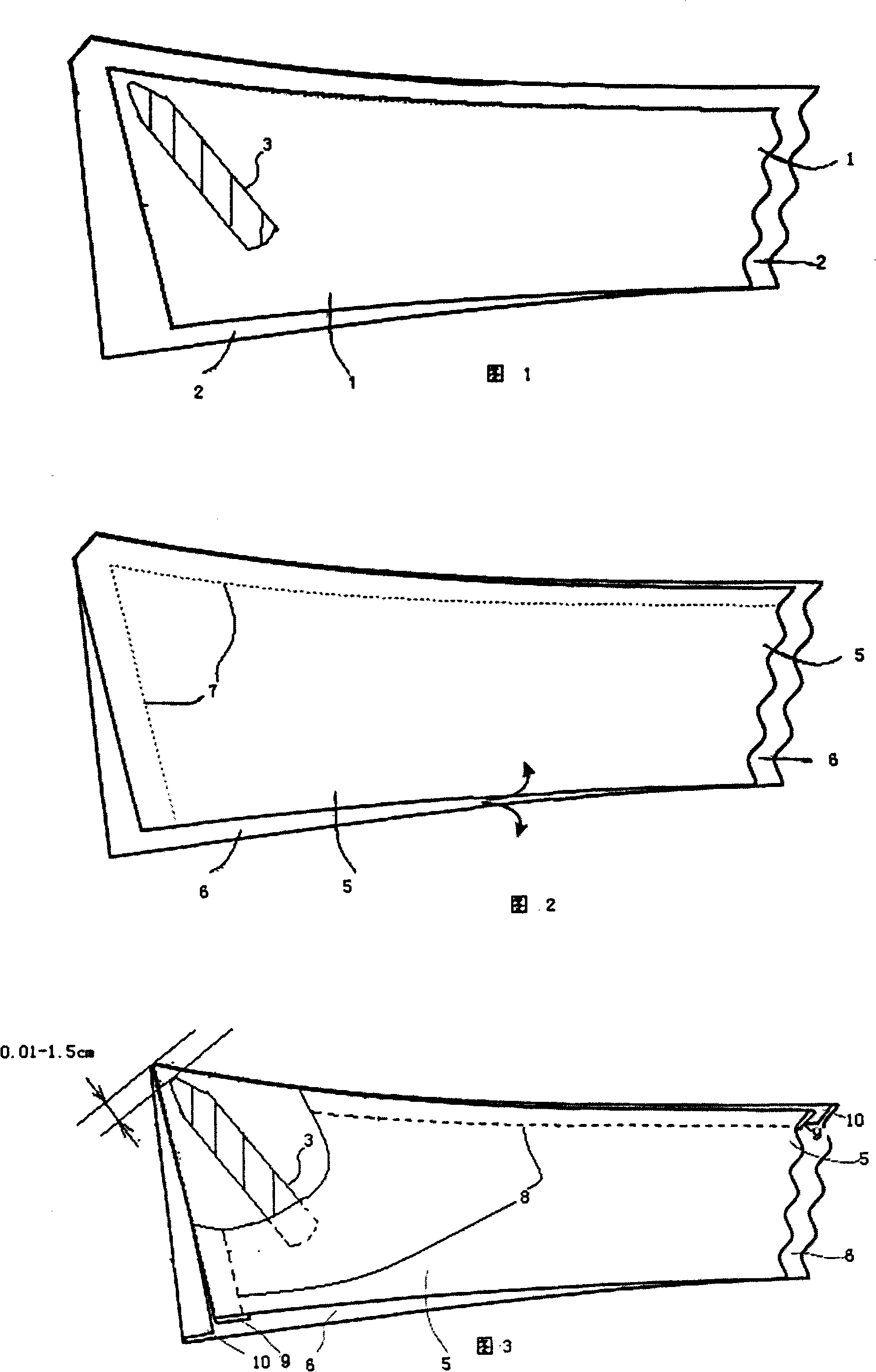

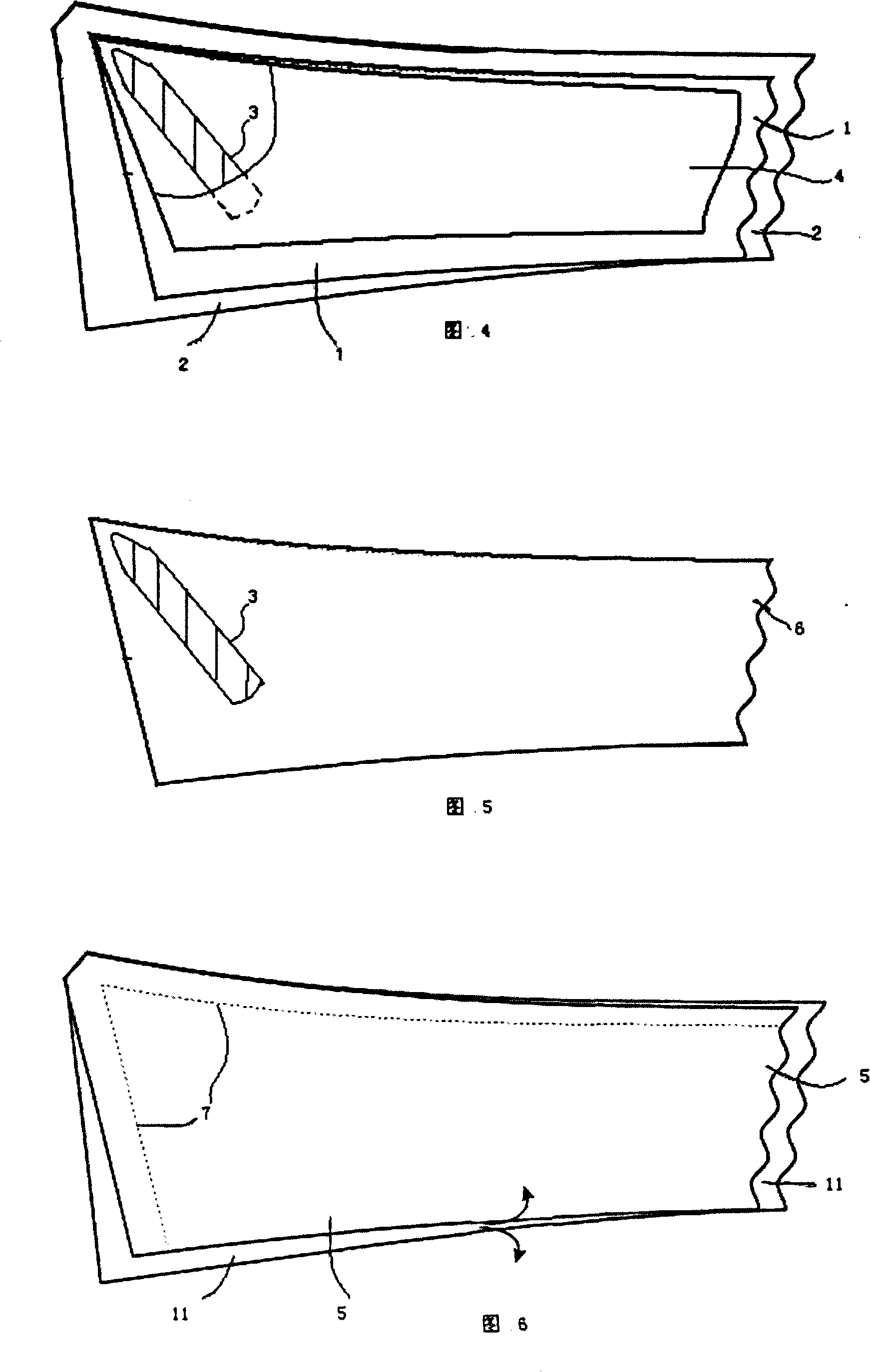

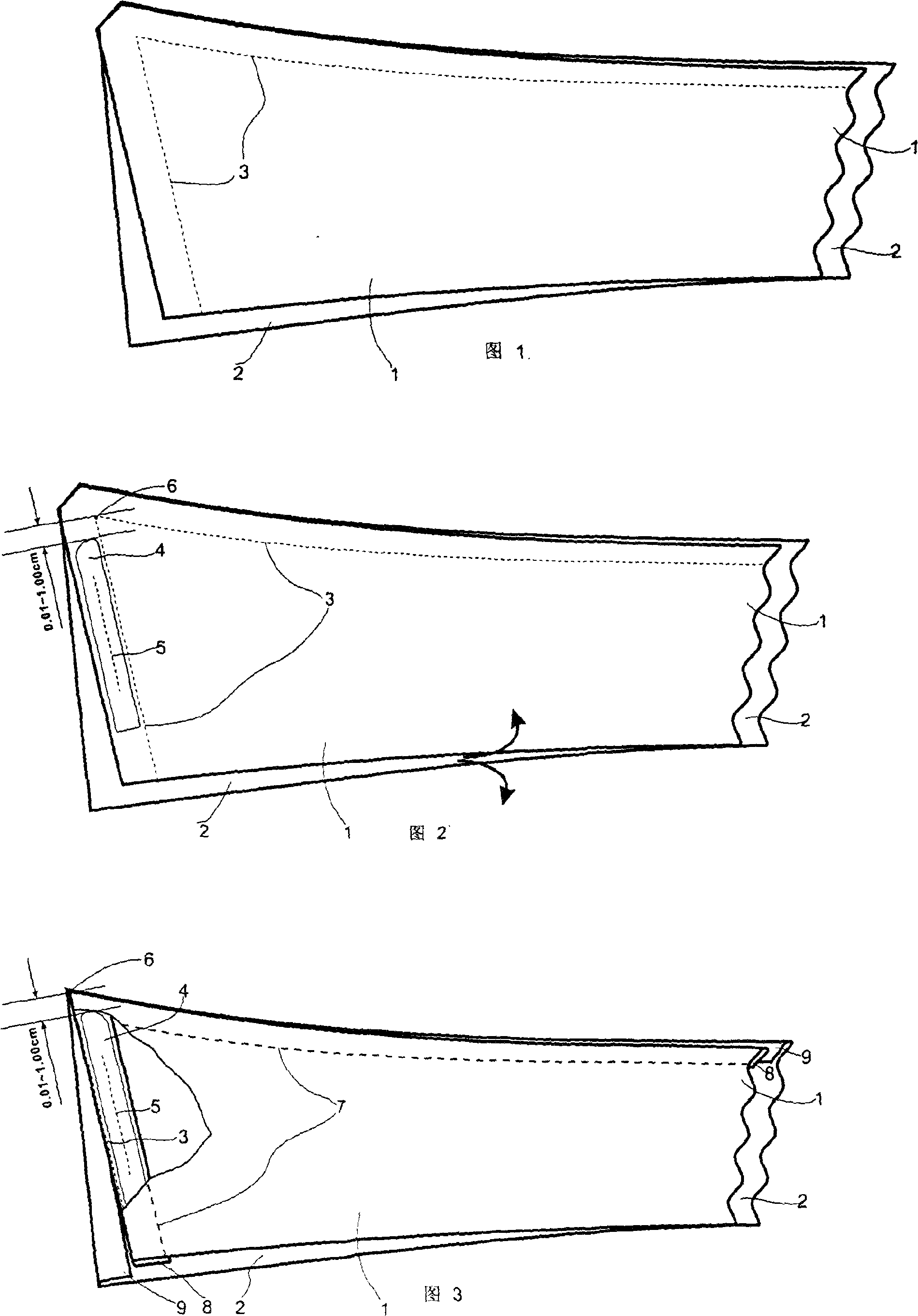

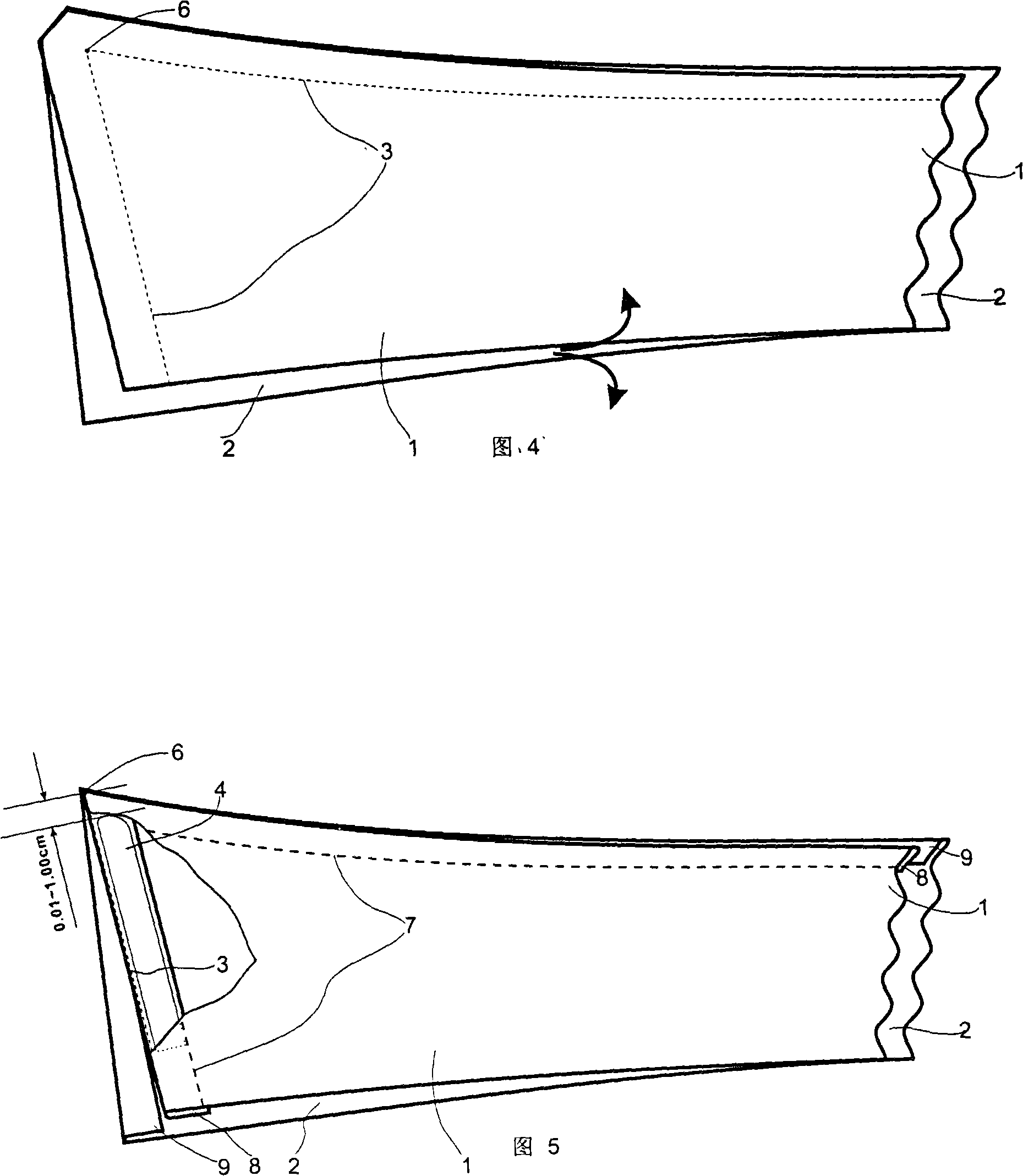

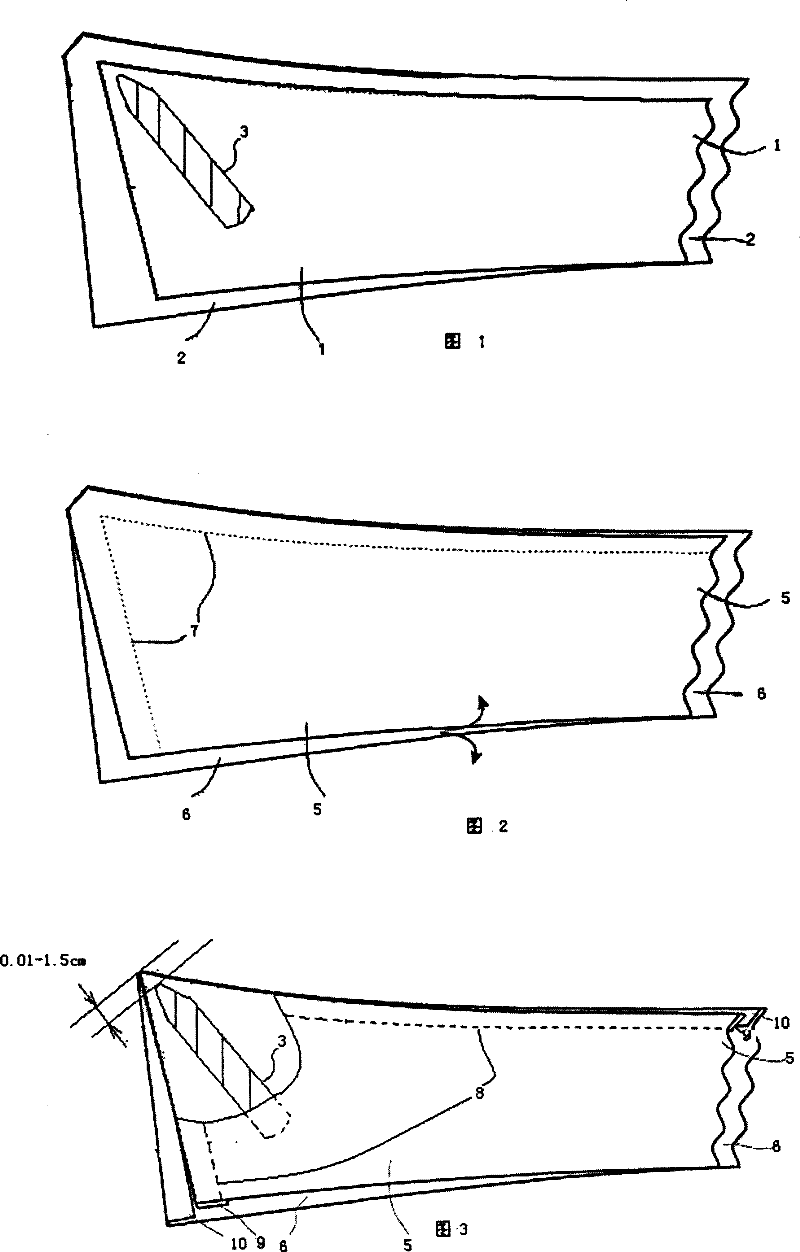

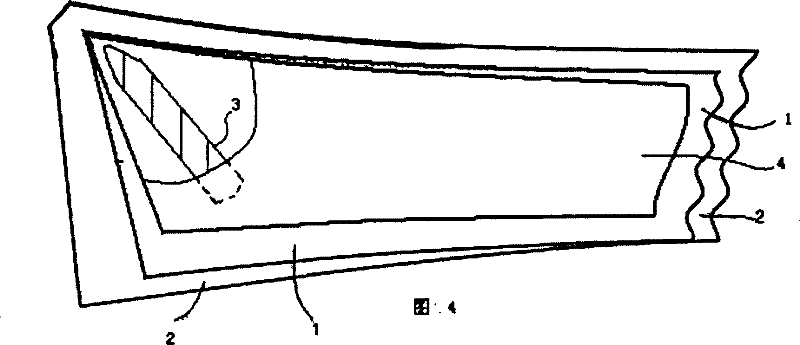

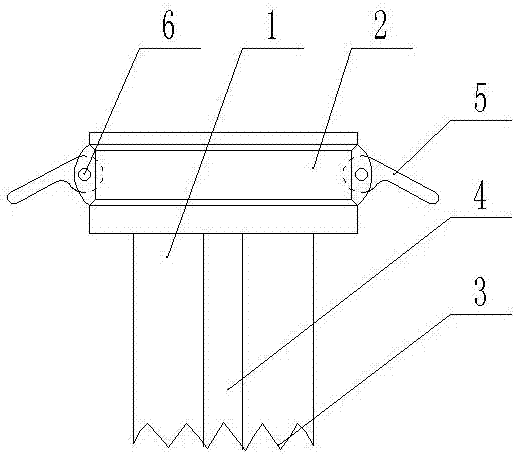

Method for producing shirt band type collar stay

Owner:GUANGDONG ESQUEL TEXTILES

Method for manufacturing collar filling-in bits of shirt

The invention relates to a stay collar on the edge of a shirt, and a machine sewing method thereof is that a collar stay is embedded in the short edge or the long edge of the collar of the shirt near a collar point, thus having the supporting effect of strengthening the collar and keeping the collar point to be crisp; after being washed for a plurality of times, the whole collar, in particular to the collar point, can still keep the exterior effect of roundness, smoothness, flatness and stiffness, and the collar point does not occur the bad phenomenon of bending towards the bottom surface of the collar or bending towards the front surface of the collar.

Owner:GUANGDONG ESQUEL TEXTILES

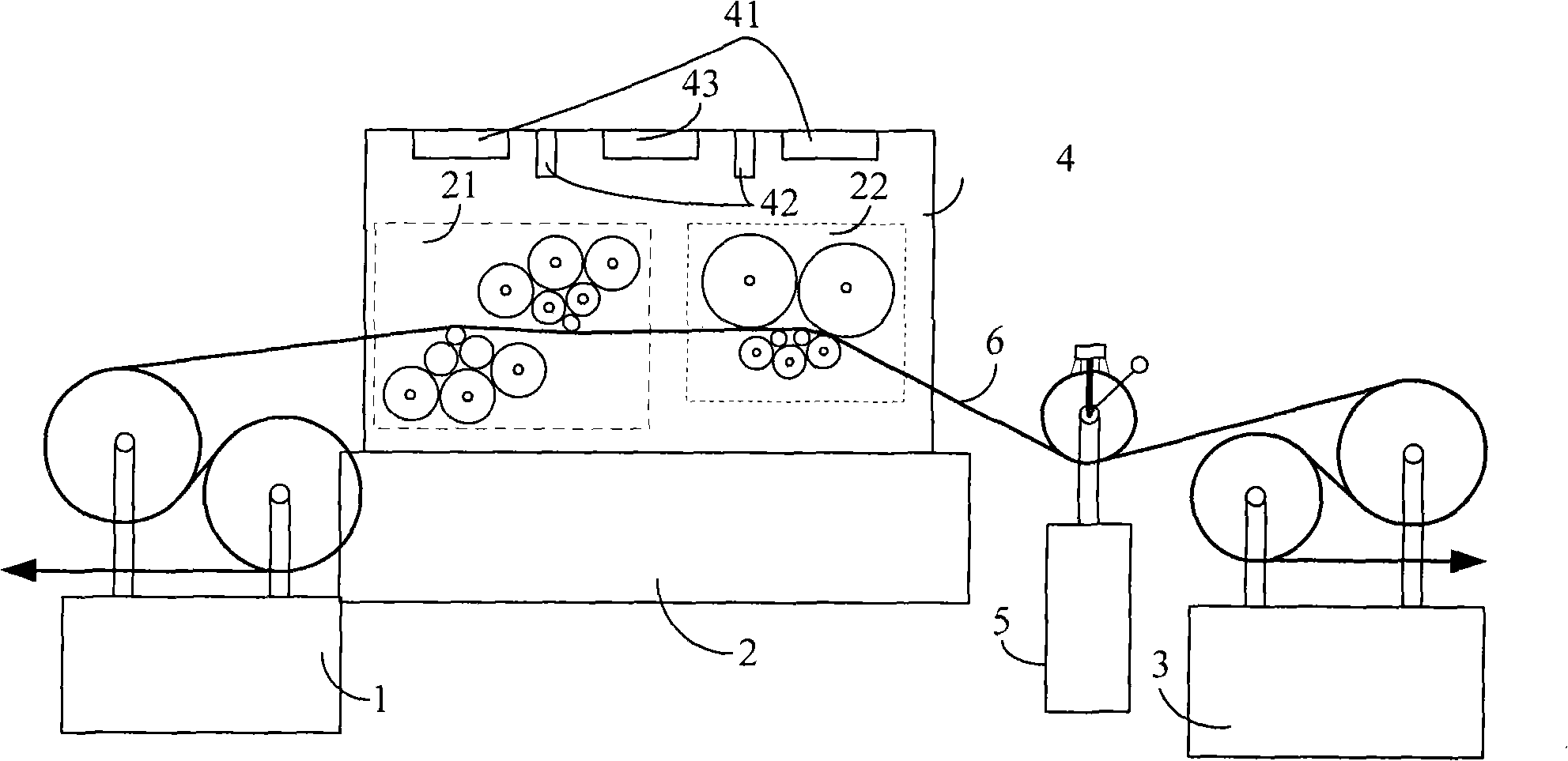

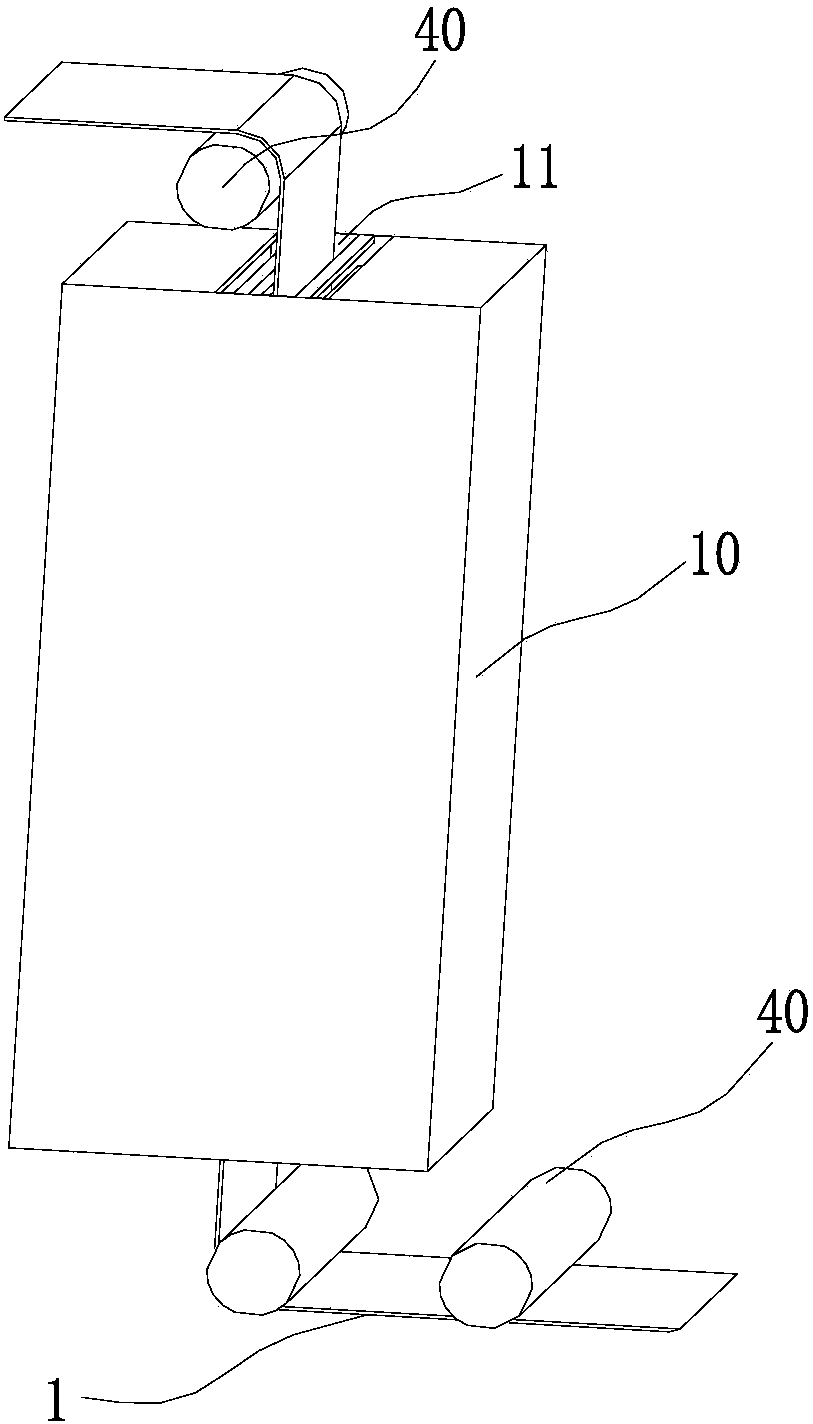

Stretch bending and straightening equipment for strips for nickel-metal hydride battery negative substrates

The invention discloses stretch bending and straightening equipment for strips for nickel-metal hydride battery negative substrates, which comprises an uncoiler, a stretch bending straightener and a coiler, wherein the uncoiler and the coiler are respectively arranged on two sides of the stretch bending straightener; a bending roll and a straightening roll are arranged on the stretch bending straightener; a thermostat is arranged outside the stretch bending straightener and covers the bending roll and the straightening roll of the stretch bending straightener; and a reverse bending device is arranged between the coiler and the straightening roll of the stretch bending straightener. The equipment has the advantages of simple structure and high efficiency, ensures the flatness of the vertical surfaces of the strips and the straightness of the strips in the horizontal direction when processing 0.035mm ultra-thin strips, and makes the straightened materials completely meet the requirement of the 0.03500 ultra-thin nickel-metal hydride battery negative substrates and reach international advanced level.

Owner:秦皇岛中达四方金属制品有限公司

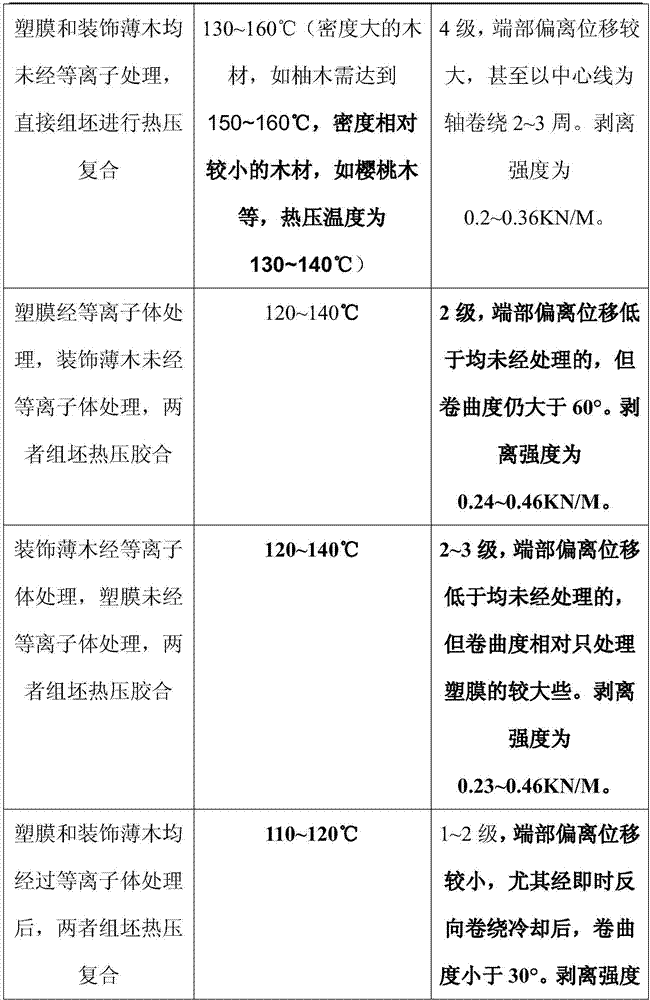

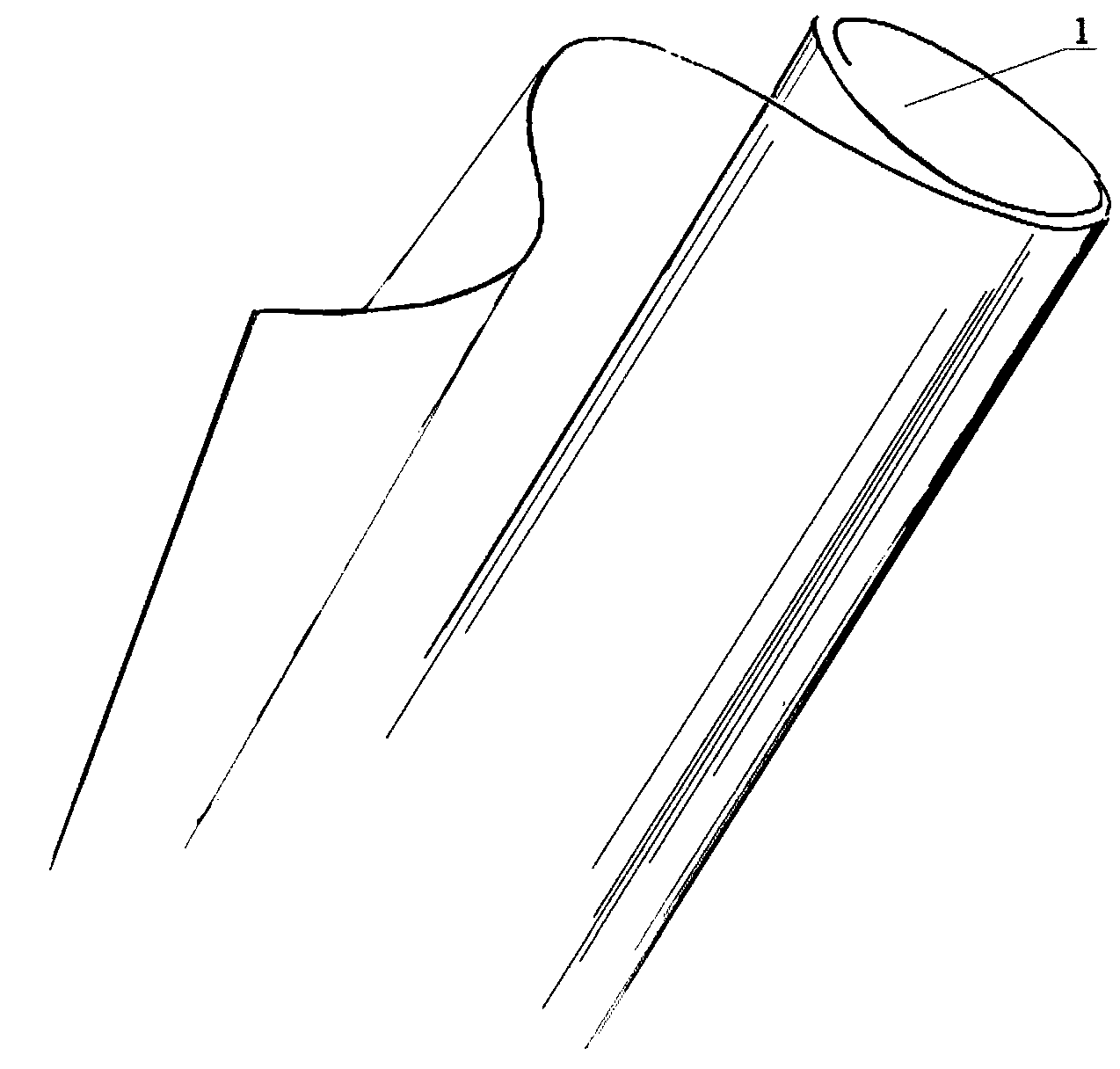

Non-formaldehyde waterproof plastic film reinforced flexible decorative veneer and preparation method thereof

ActiveCN106272804AReduce heat stressLower bonding temperatureElectric wood treatmentSynthetic resin layered productsEngineeringPlastic film

The invention discloses a non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. Composting faces of a rotary cut or sliced decorative veneer and a plastic film are subjected to low-temperature plasma modification treatment, the treated composite faces of the decorative veneer and the plastic film are stacked to form composite blanks, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer is obtained through hot-press gluing. The invention further discloses a preparation method of the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. The product prepared by adopting the method releases no formaldehyde, no adhesive or gluing procedure is omitted, the production cost is lowered, the product suppleness is good, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer has the enough transverse tensile strength, will not cause glue penetration, is good in water resistance, saves energy, and is environmentally friendly, easy and convenient to operate and high in efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

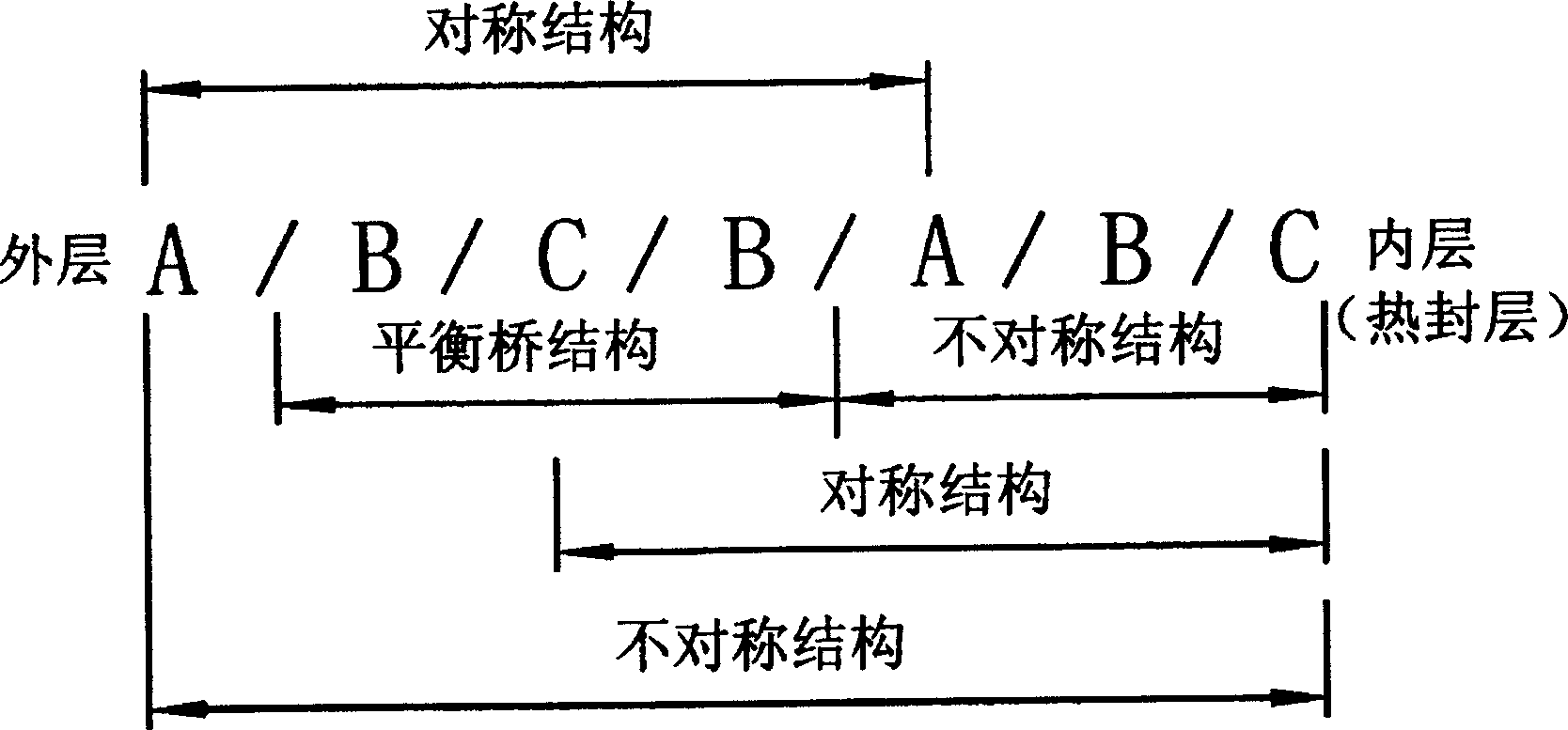

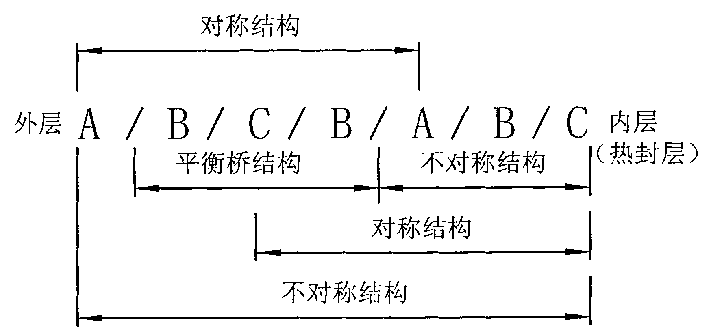

Non-symmetry structure for seven-layer laminated coiling-resistant composite film

Owner:KUSN ZHANGPU COLOR PRINTING FACTORY

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Transparent film artistic device and making method

InactiveCN104385827ASolve the problem of edge curlingResolve curlSpecial ornamental structuresSheet filmComputer science

The invention discloses a transparent film artistic device and a making method. The method comprises the steps of: 1) resolving an image into several display layers according to stereoscopic display, subjecting the images of the several display layers to layer-by-layer portraying or computer inkjet respectively onto several layers of transparent films; 2) trimming the several layers of transparent films made by step 1) into linear strip films in terms of an equal width, according to the actual interval of suspension and under the premise of ensuring no deformation of a picture, by means of retaining the linear strip films at an interval, selecting part of the used linear strip films; and 3) subjecting the retained several layers of linear strip films to layer-by-layer arrangement, hanging the upper ends of the linear strip films on a top cover, and penetrating the lower ends into corresponding pedestal hole sites, and straightening the several layers of linear strip films by the top cover and the pedestal. Through a multilayer linear transparent film lamination technology, the coloring area is increased, the work image is more prominent, and by overlapping, the artwork with a three-dimensional vision can be formed.

Owner:李青

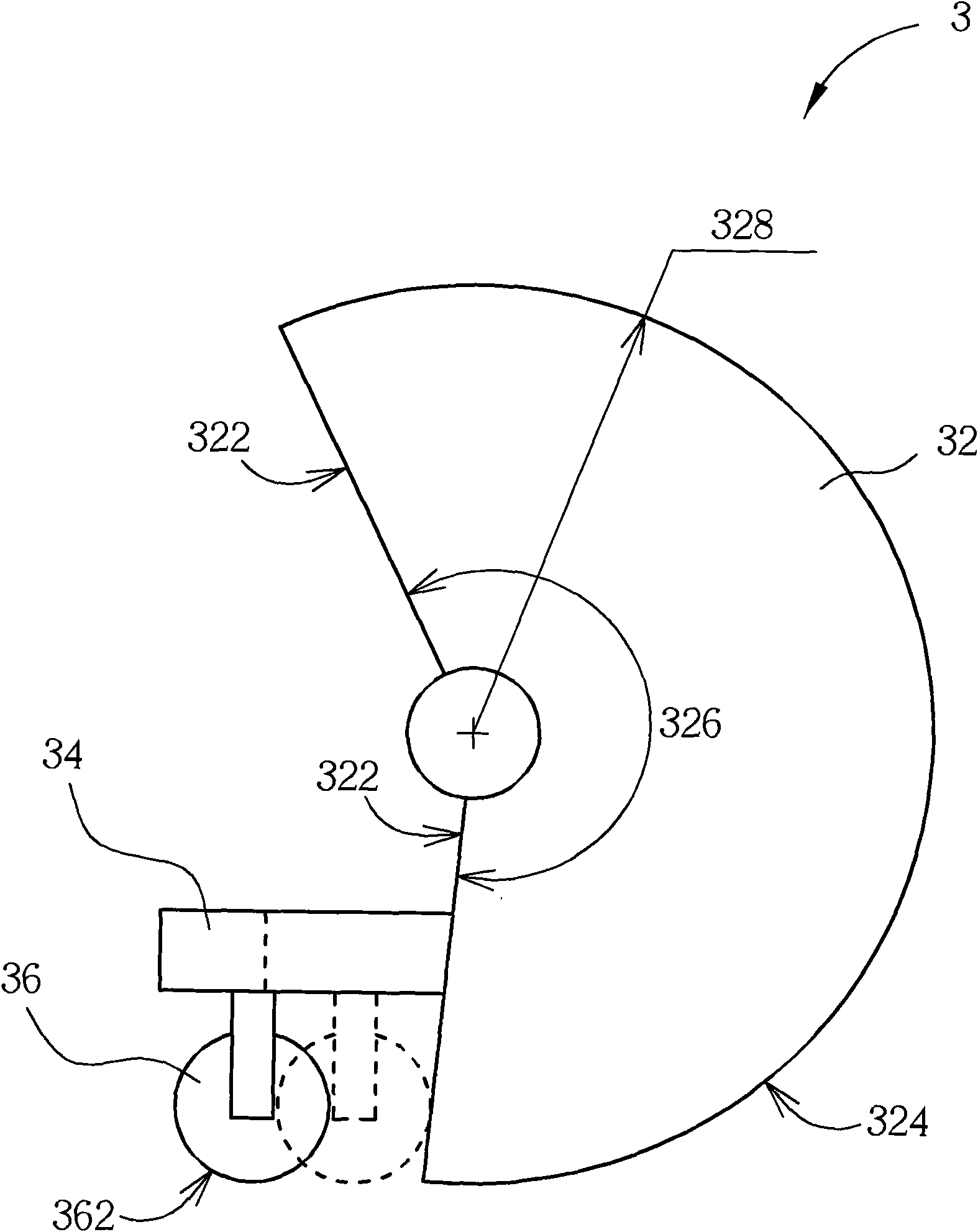

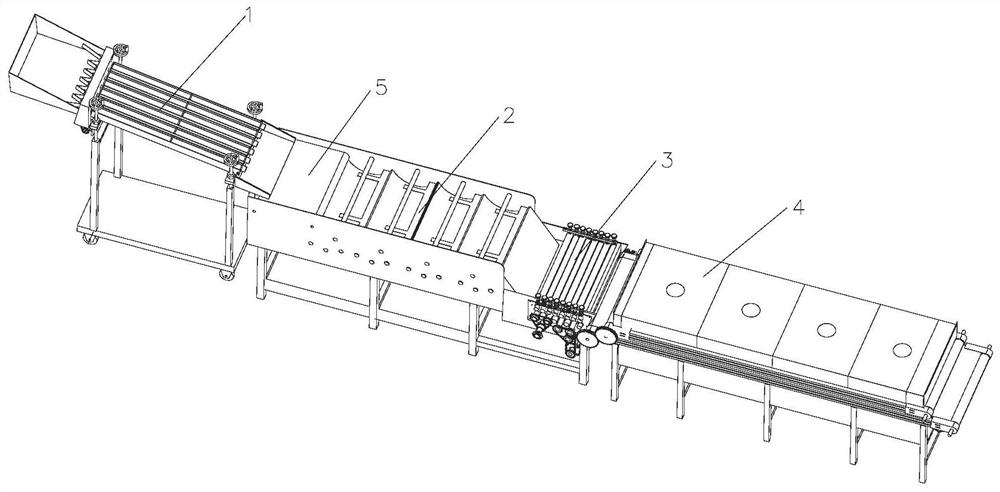

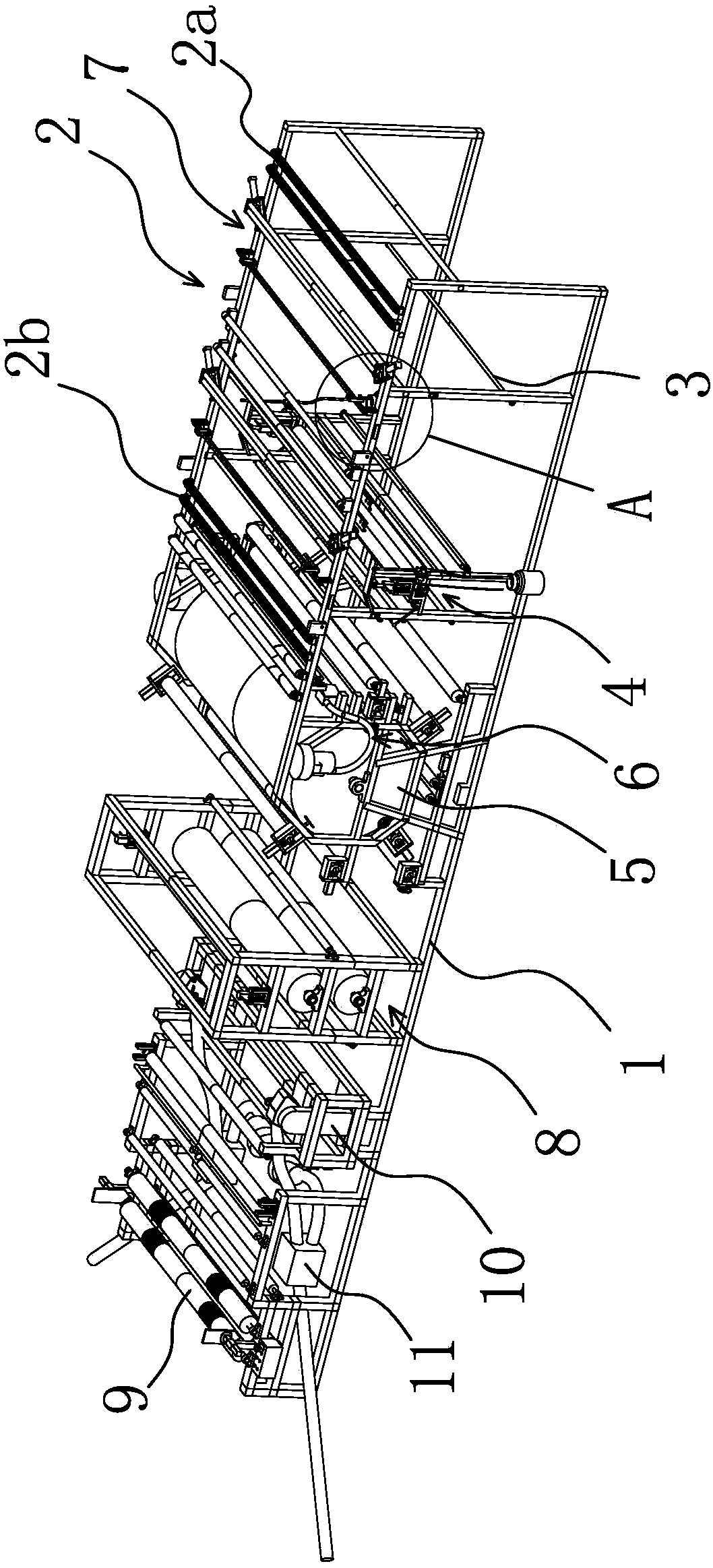

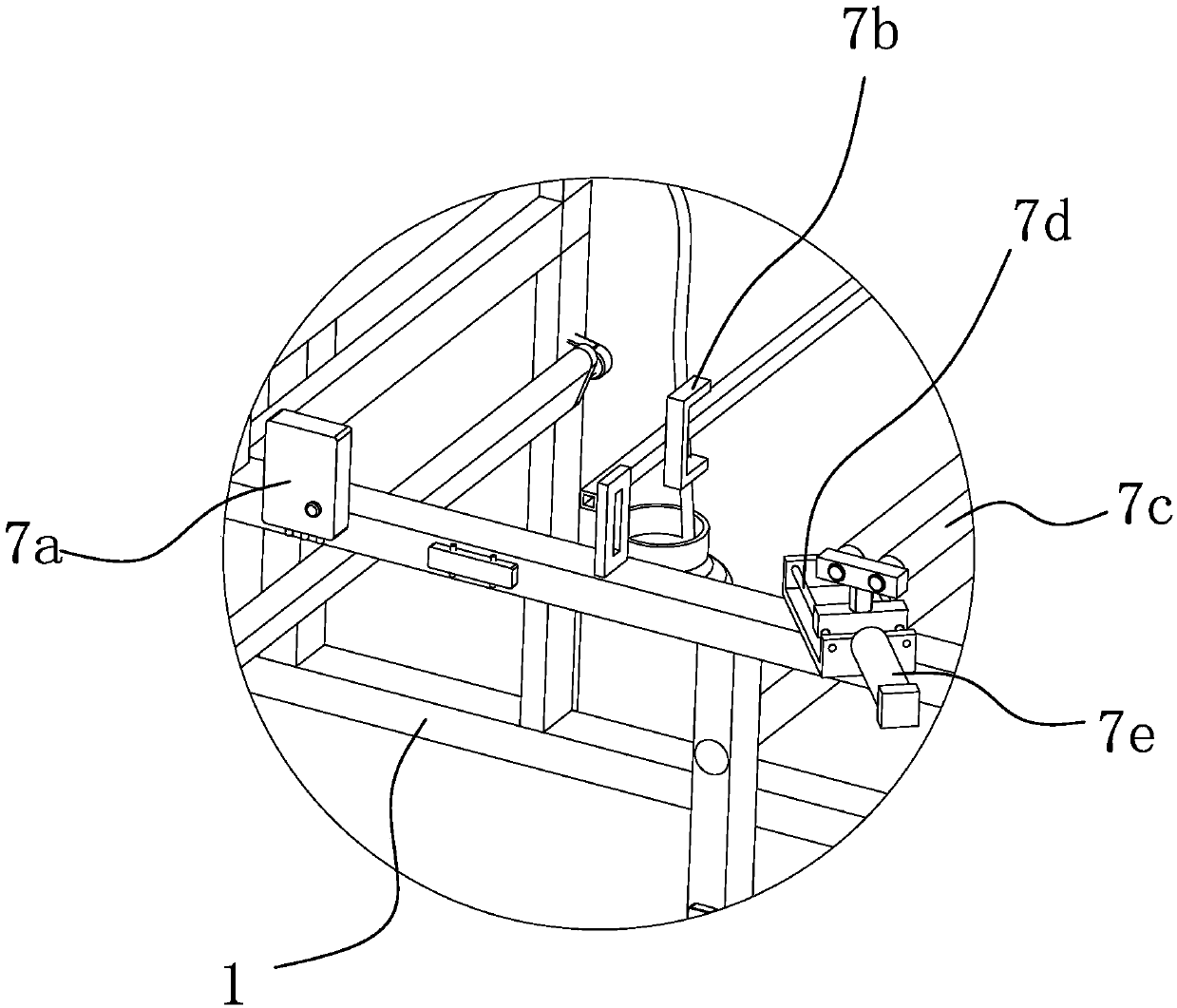

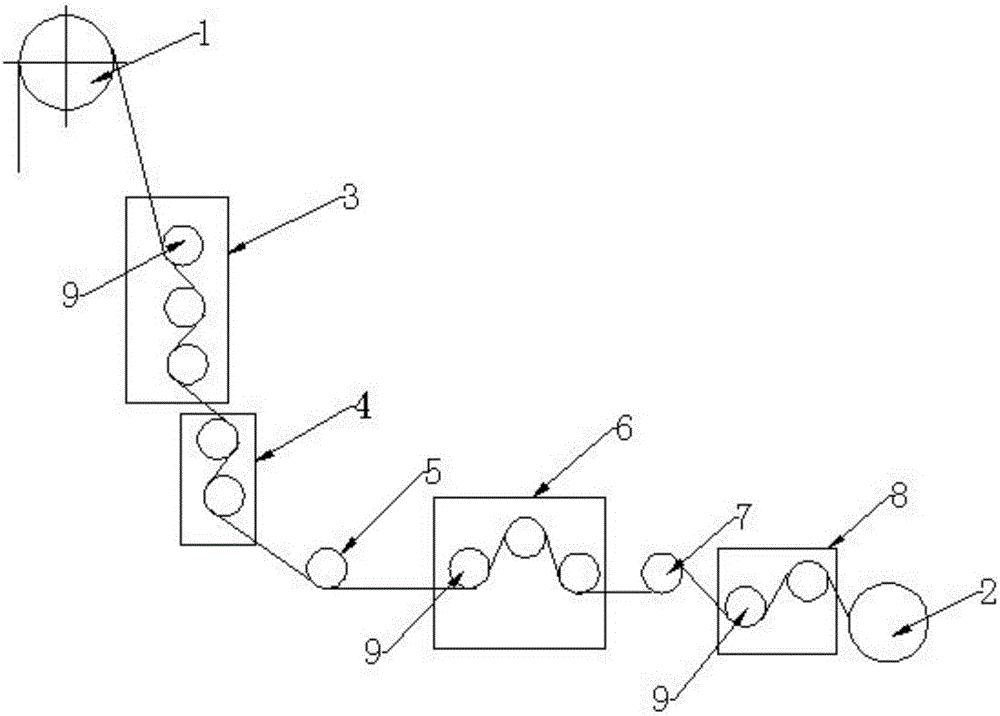

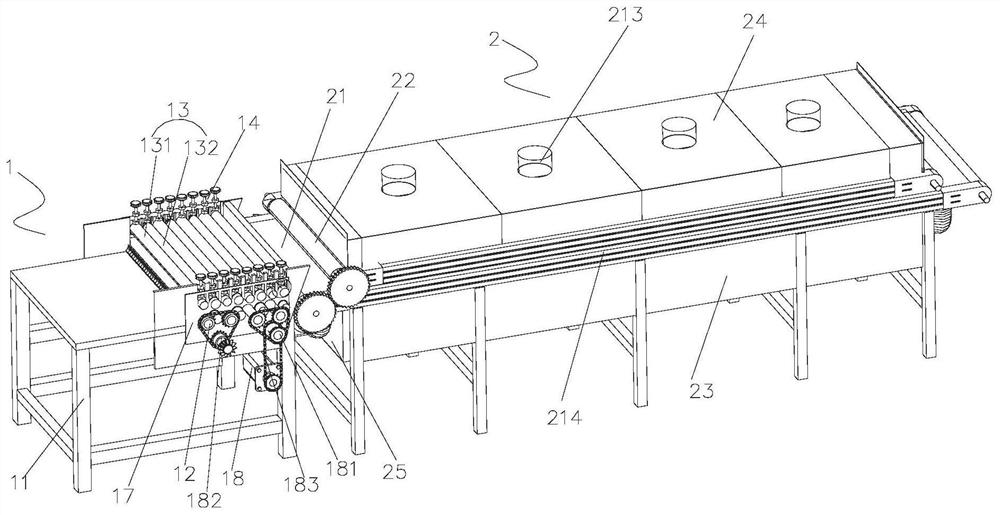

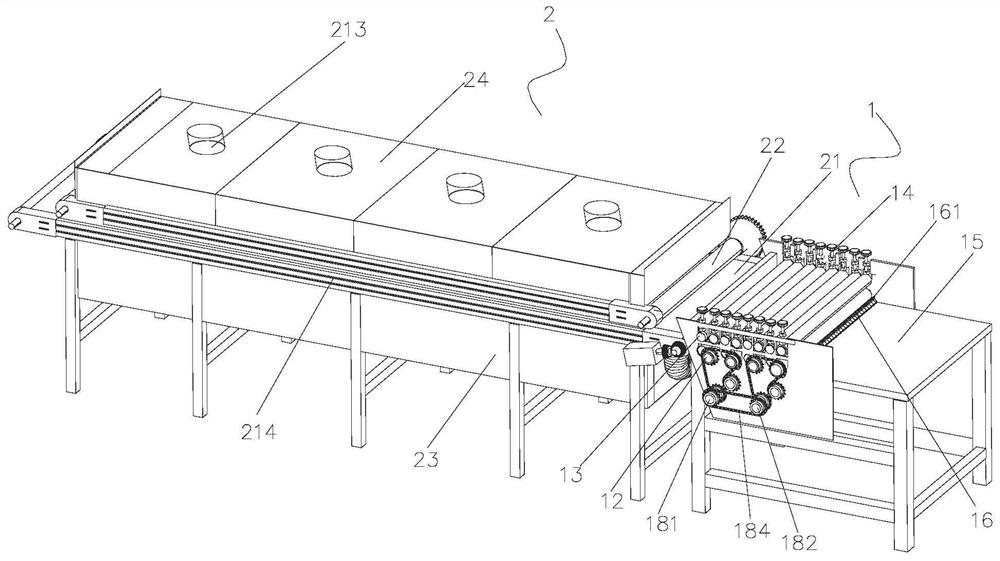

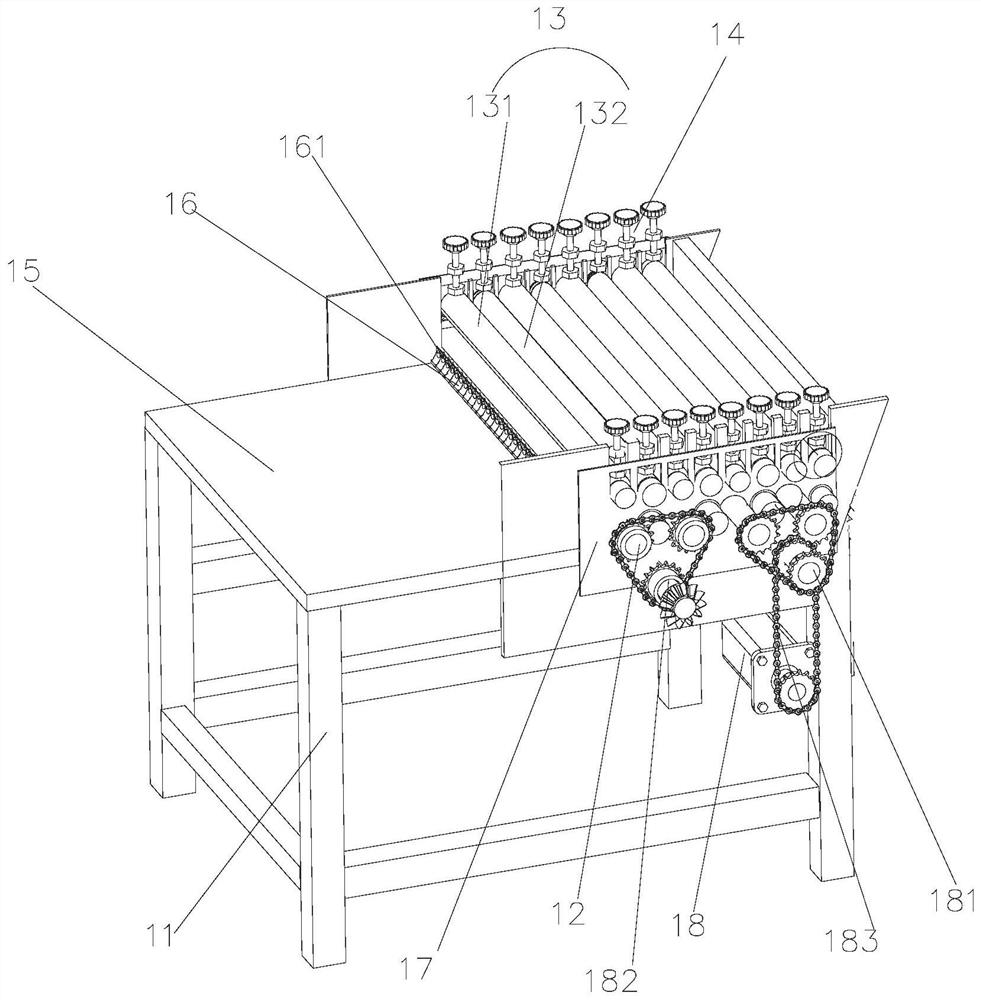

Continuous processing production line for tea leaves

ActiveCN112889947AImprove qualityGood flexibilityPre-extraction tea treatmentClimate change adaptationProcess engineeringAir blower

The invention discloses a continuous processing production line for tea leaves. The continuous processing production line comprises a fixation and carding machine, a heat preservation conveying device, a pressing forming device and a shaping and drying device which are sequentially connected, wherein the pressing forming device comprises a pressing forming rack, a group of lower pressing rollers which are rotationally mounted on the pressing forming rack and rotate in the same direction, an upper pressing roller group matched with the lower pressing rollers to press the tea leaves, and a pressure adjusting structure for controlling pressing gaps between the upper pressing roller group and the lower pressing rollers; and the shaping and drying device comprises a lower rotary conveying belt and an upper rotary conveying belt, a heat preservation box is arranged below the lower rotary conveying belt, and air blowers are arranged at two ends of the heat preservation box. Fixation, pressing and drying of the tea leaves are completed through matched connection of the fixation and carding machine, the heat preservation conveying device, the pressing forming device and the shaping and drying device, and the continuous processing production line is good in pressing forming effect, high in efficiency and capable of being widely applied to the field of tea leaf processing.

Owner:黄山市神耘节能设备制造有限公司

Transfer paper manufacture method

InactiveCN106337313AReduce surface tensionResolve curlWater-repelling agents additionSurfactants additionWaxEmulsion

Owner:谈旻轩

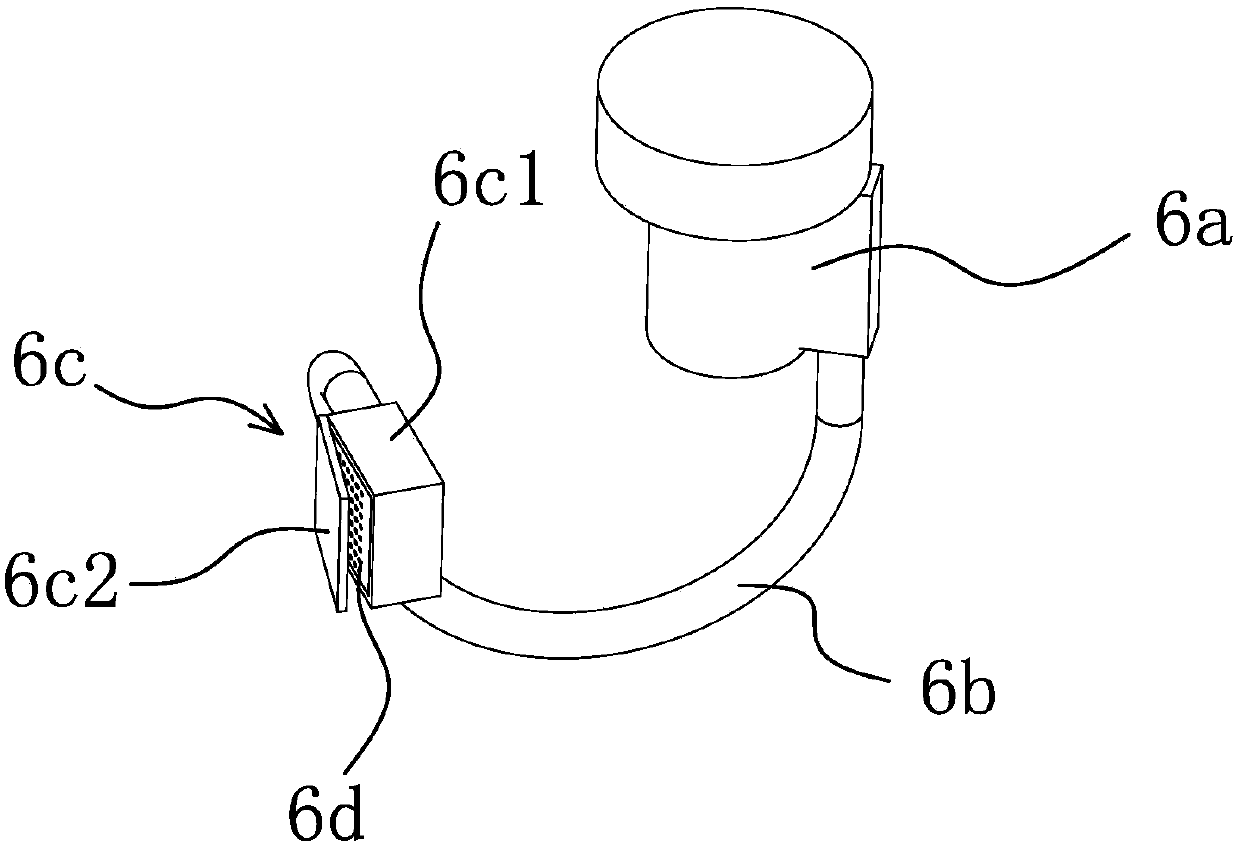

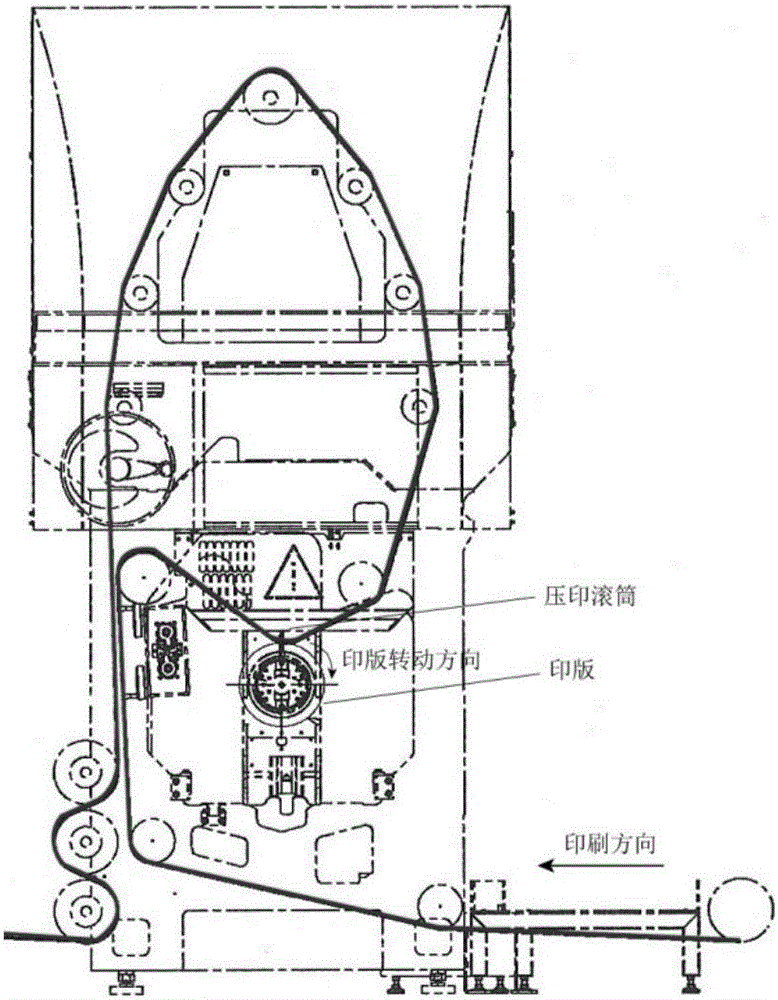

Cloth sponge compounding machine

ActiveCN107672276AAvoid crimping againImprove flatnessLamination ancillary operationsLaminationEngineeringMechanical engineering

The present invention provides a cloth sponge compounding machine, belongs to the technical field of machinery, and solves the problems that folds and turned edges are easy to produce when cloth and sponge are compounded in the prior art. The cloth sponge compounding machine comprises a frame, a cloth feeding device is arranged above the front end of the frame, a thermal compounding device is arranged at the back of the cloth feeding device, each of the two sides of the frame is provided with an anti-curling device, each anti-curling device is located between the cloth feeding device and the thermal compounding device, each anti-curling device comprises a fan I, a venting tube and an air-out component, the air-out component is in communication with the fan I through the venting tube, the air-out component is arranged at a position near the edge of a cloth feeding path on the frame, and the air-out component is provided with an air outlet facing the edge of the cloth feeding path. By use of the cloth sponge compounding machine, the edge of a compounded cloth finished product is neat and regular, and processing efficiency is high.

Owner:HIGHER TECH CO LTD

Roller type drying device

InactiveCN105937842AEliminate curlingThere will be no deviationDrying chambers/containersDrying machines with progressive movementsPulp and paper industryFlanging

The invention provides a roller type drying device. The device comprises a draw-out roller and a roller dryer, wherein a first silk distributing mechanism below which a centering device is mounted is arranged below the draw-out roller; a transferring twitch roller is arranged at one side of the centering device; a second silk distributing mechanism is arranged at one side of the draw-out roller, and a tensioning roller is arranged at one side of the second silk distributing mechanism; a third silk distributing mechanism is arranged at one side of the tensioning roller, and the roller dryer is arranged at one side of the third silk distributing mechanism. According to the roller type drying device, the silk distributing mechanisms and the centering device are used in match during the conveying process, so that a cloth can be effectively prevented from flanging, and the problem that a common conveying mechanism easily leads to flanging can be solved; the device is high in production efficiency; the cloth cannot be manually pulled before being dried and cannot be deviated, so that non-uniform drying can be avoided in the drying process, the labor can be saved, and the production efficiency can be improved.

Owner:ZHEJIANG TONGHUI TEXTILE

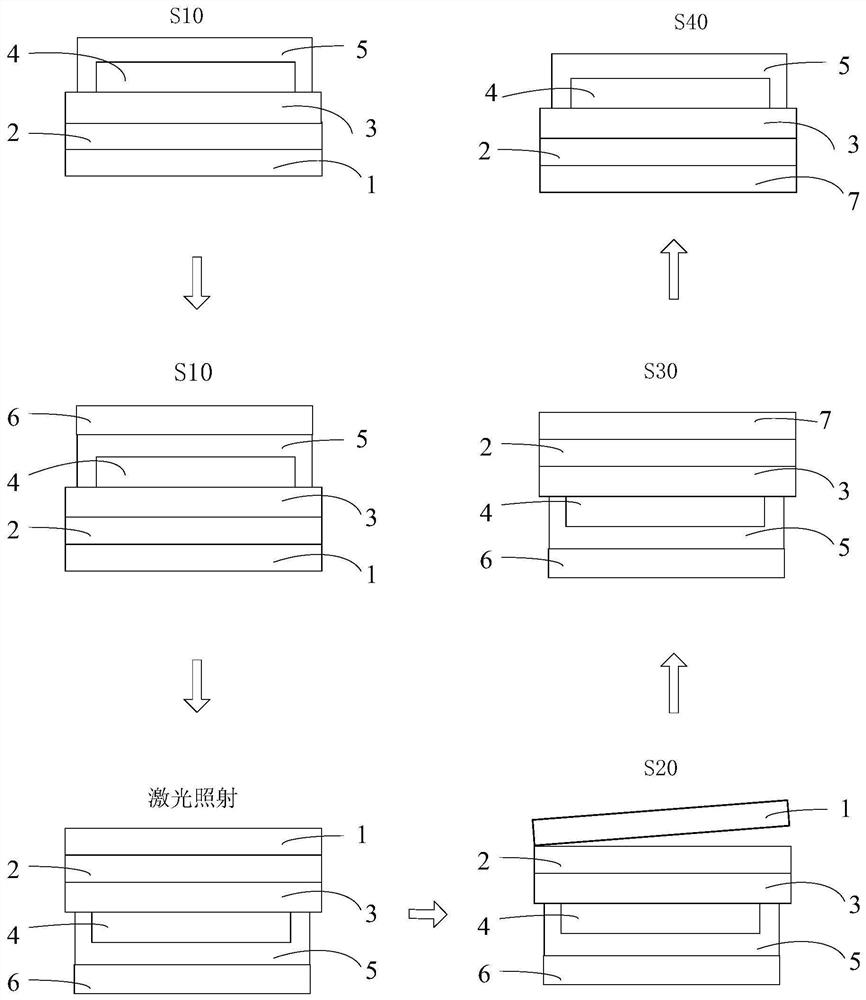

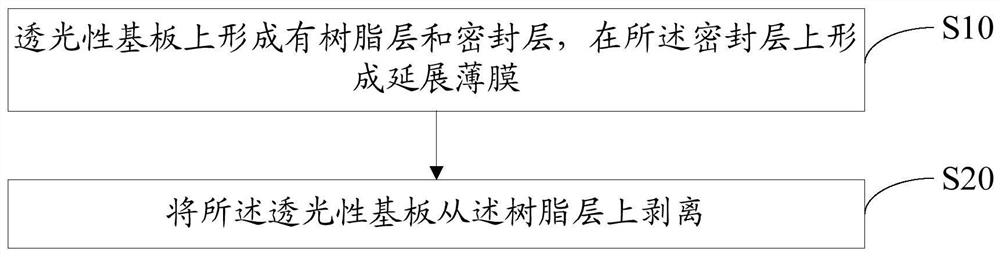

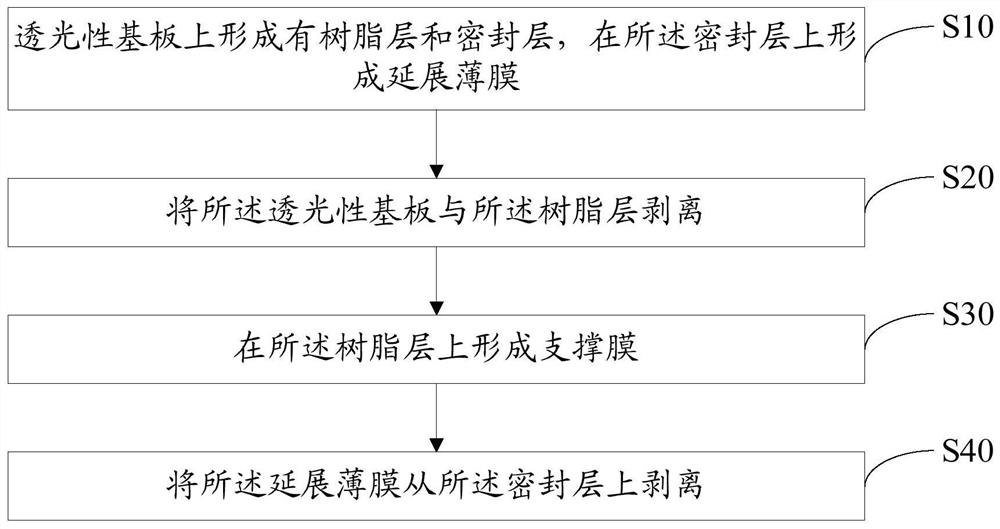

Display panel stripping method

ActiveCN111681985AResolve curlGuaranteed flatnessSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

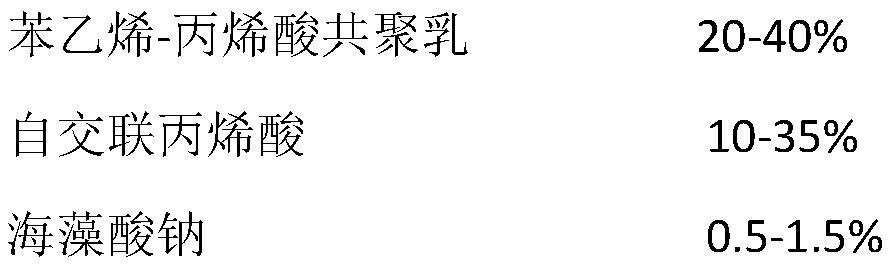

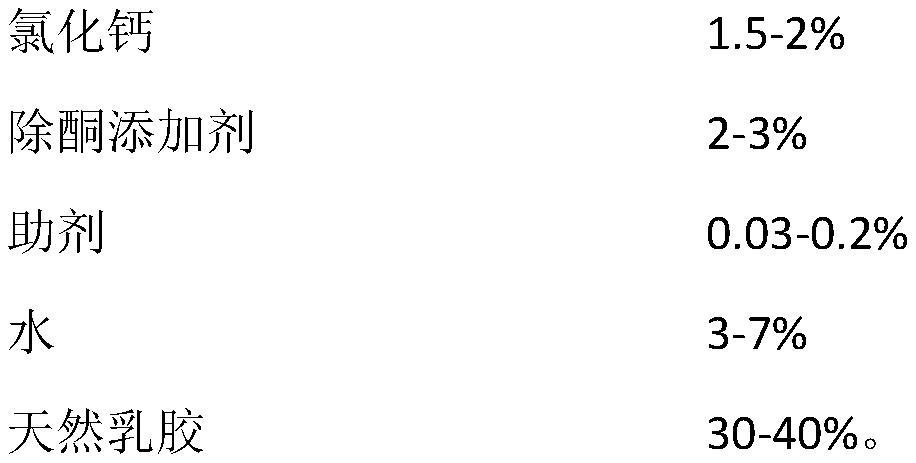

Backing adhesive material for controlling evenness of paper sheets and application method of backing adhesive material

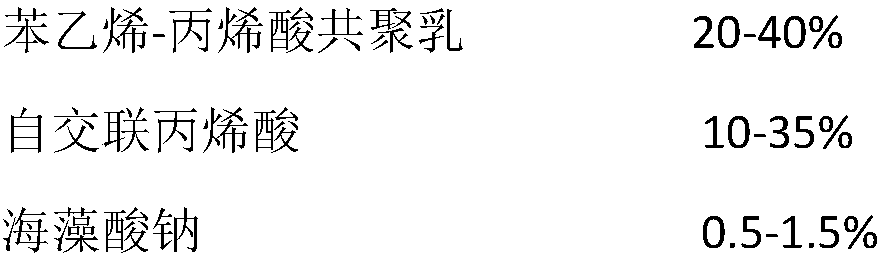

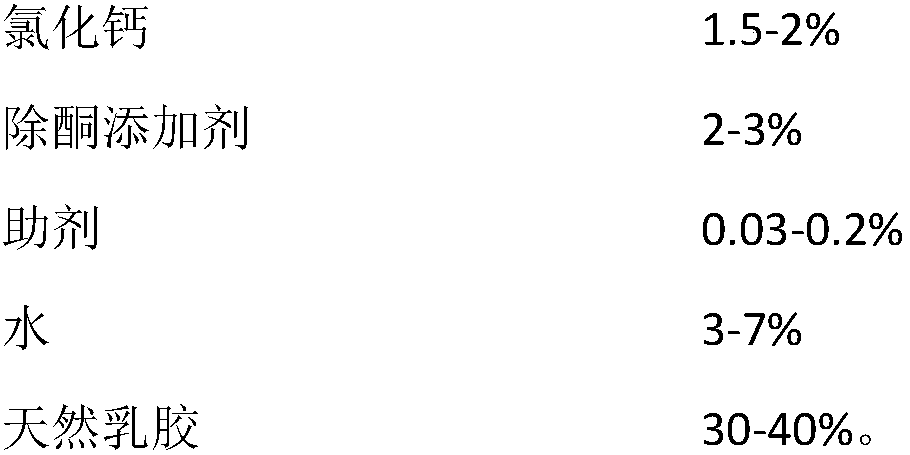

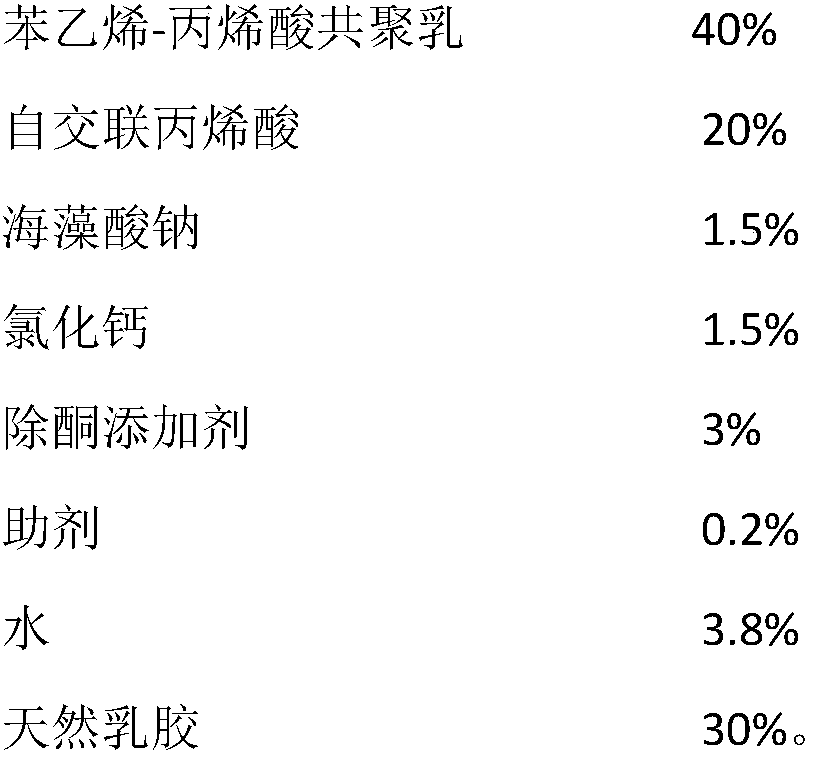

The invention provides a backing adhesive material for controlling the evenness of paper sheets and an application method of the backing adhesive material. The backing adhesive material is prepared from the following raw materials: styrene-acrylic copolymerized emulsion, self-crosslinking acrylic acid, sodium alginate, calcium chloride, a ketone removing additive, an auxiliary agent, water and natural latex, wherein the mass content of the styrene-acrylic copolymerized emulsion is 5 to 10 percent, the mass content of the self-crosslinking acrylic acid is 10 to 15 percent, the mass content of the sodium alginate is 0.5 to 1.5 percent, the mass content of the calcium chloride is 1.5 to 2 percent, the mass content of the ketone removing additive is 2 to 3 percent, the mass content of the auxiliary agent is 0.03 to 0.2 percent, the mass content of the water is 3 to 7 percent and the mass content of the natural latex is 30 to 40 percent. According to the backing adhesive material for controlling the evenness of the paper sheets and the application method of the backing adhesive material, the problems that the paper sheets are curled when an existing backing adhesive material is used andthe surfaces of the paper sheets are not even are greatly solved; the backing adhesive material has the advantages of low component cost, simple synthesis technology and relatively high applicability.

Owner:上海睿途新材料科技有限公司

Color printing ink for printing heat shrink film labels and preparation method of color printing ink

ActiveCN103265843BShrinkage does not affectReduce coefficient of frictionInksPolymer sciencePolyethylene terephthalate glycol

The invention discloses color printing ink for printing heat shrink film labels and relates to environmental-friendly ink. The color printing ink comprises the following components: acrylic resin, nitrocotton, VINISOL OH, CAB (Cellulose Acetate Butyrate) resin, EVA (Ethylene Vinyl Acetate) resin, a color pigment, additives and a diluent, wherein the additives are polyethylene wax and fumed silica. Compared with the prior art, the color printing ink for printing the heat shrink film labels, disclosed by the invention, has the advantages that the color printing ink is free of benzene and ketone, resists tetrahydrofuran and can be applied to PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), OPS (Oriented Polystyrene) heat shrink film base materials, and after the color printing ink is matched with heat shrink films for printing, the shrink films do not curl and are free of tinting. The products printed by adopting the color printing ink are in line with environment-friendly requirements, are safe and non-toxic and can be recycled; and after printing, the shrink films have very strong capability of resisting alcohol and tetrahydrofuran, thus the problem of the compatibility between the thin films and glue occurring when the thin films are subjected to skin packaging and are glued is solved very well.

Owner:CHENGDU PRESSTER NEW MATERIALS

Automatic adjustment show window based on information display

The invention discloses an automatic adjustment showcase based on information display, relates to the technical field of showcases, and provides the following scheme for solving the problems that after paper is pasted for a long time, the paper is prone to curling or falling, the height of the showcase cannot be rapidly adjusted, and people cannot conveniently watch and read the paper. Cavities are formed in the supporting columns, a storage frame is fixedly connected between the two supporting columns, a double-shaft motor is fixedly connected to the inner wall of the bottom of the storage frame, rotating shafts are fixedly connected to output shafts at the two ends of the double-shaft motor, and the outer portions of the ends, away from each other, of the two rotating shafts are fixedlysleeved with first bevel gears. The show window is novel in design and easy to operate, through the arrangement of the clamping plates, the threaded pipes and the like, the clamping plates can clamp paper, it can be guaranteed that the paper can be browsed by the masses for a long time, normal browsing of information is guaranteed, meanwhile, the height of the show window body can be rapidly adjusted, and people can watch and read conveniently the paper.

Owner:湖南正润创业服务股份有限公司

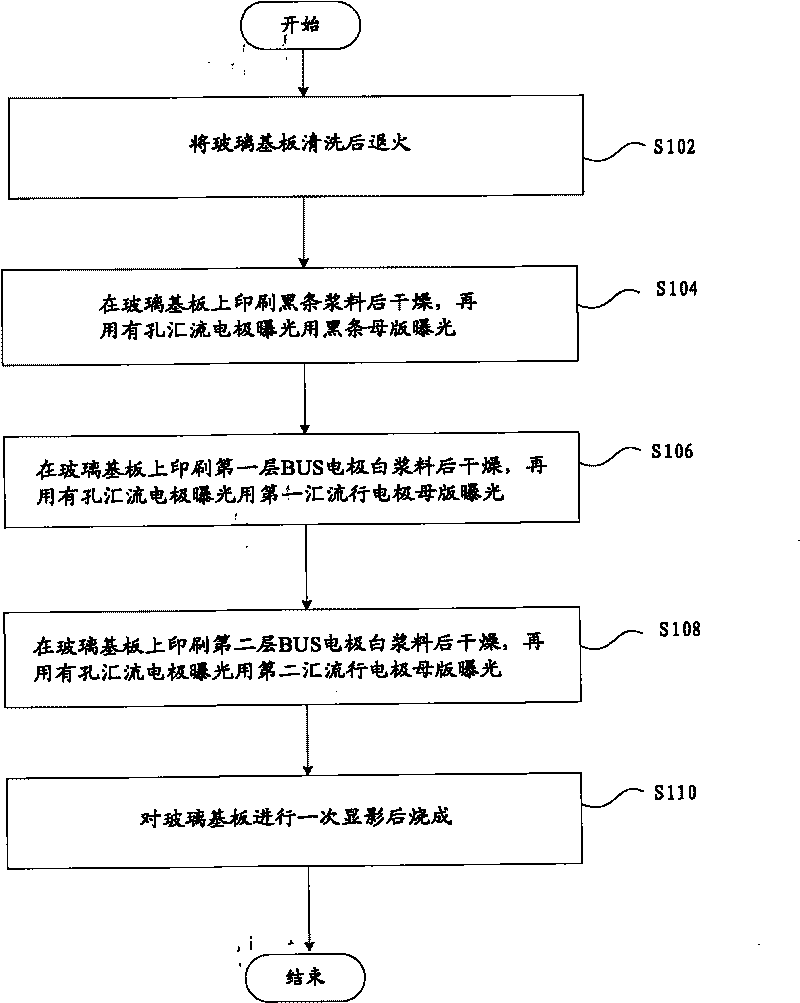

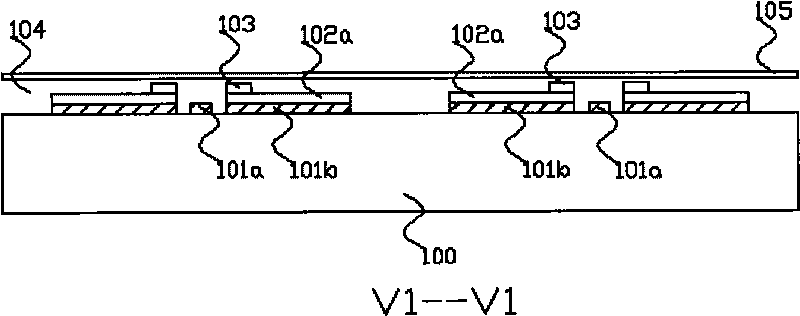

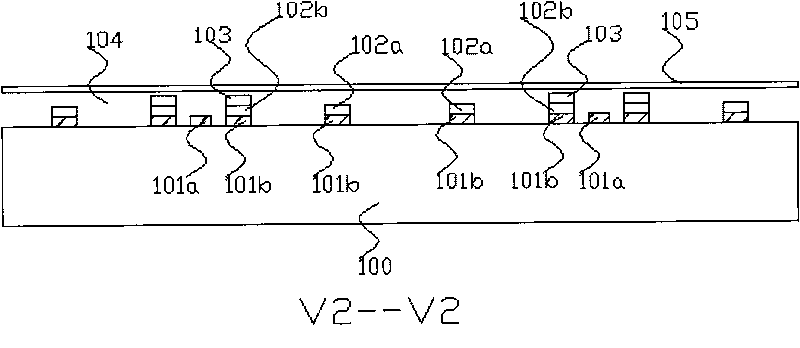

Front base plate for plasma display device and manufacturing method thereof

InactiveCN101728147AResolve curlSimple processSolid cathode detailsCold-cathode tubesState of artDisplay device

The invention discloses a front base plate manufacturing method for a plasma display device, comprising the following steps: a glass substrate is cleaned and annealed; black stripe slurry is printed on the glass substrate and is dried, and a black stripe master plate for exposure of a porous confluence electrode is used; a first BUS electrode white slurry layer is printed on the glass substrate and then is dried, and a first confluence electrode master plate for exposure of a porous confluence electrode is used; a second BUS electrode white slurry layer is printed on the glass substrate and then is dried, and a second confluence electrode master plate for exposure of the porous confluence electrode is used; and one-time development is carried out on the glass substrate and then is baked, thereby overcoming the problems that the manufacturing method in the prior art is limited by material limit, the working procedures are complex and the cost is high.

Owner:SICHUAN COC DISPLAY DEVICES

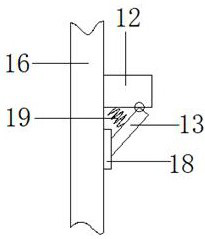

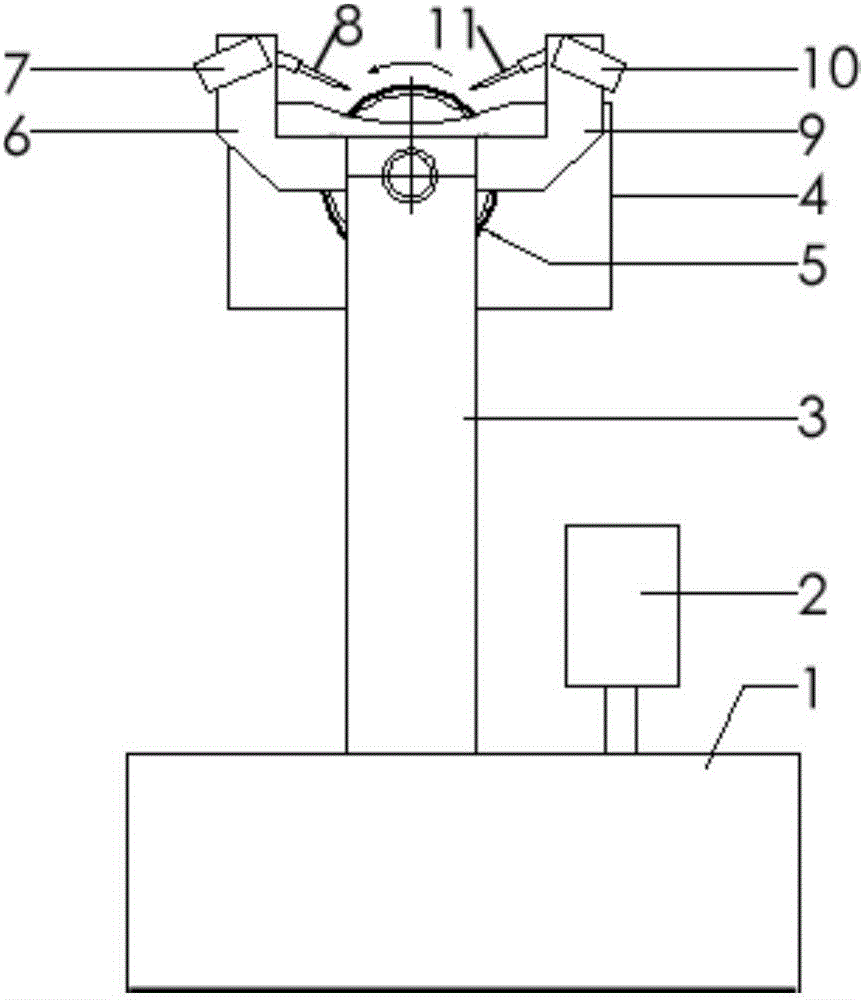

Printing device of intaglio printing press

InactiveCN106696440ARealize printing back coatingSolve the problem of upturned curlRotary intaglio printing pressEngineeringPrinting press

The invention discloses a printing device of an intaglio printing press. The printing device of the intaglio printing press is convenient to use. The printing device comprises an ink cylinder, an ink pump arranged on the ink cylinder, a support vertically installed on the ink cylinder, an ink tank installed on the upper portion of the support, and a printing plate, wherein the printing plate is installed at the upper end of the support, and the lower portion of the printing plate is located in the ink tank. The printing device further comprises a first scraper rack, a first air cylinder, a first scraper, a second scarper rack, a second air cylinder and a second scraper, wherein the first scraper rack is detachably installed on the support and located on one side of the printing plate; the first air cylinder is installed on the first scraper rack; the first scraper is installed on a piston rod of the first air cylinder; the second scraper rack is detachably installed on the support and located on the other side of the printing plate; the second air cylinder is installed on the second scraper rack; and the second scraper is installed on a piton rod of the second air cylinder. By the adoption of the printing device, the problem that a cigarette pack warps and curls towards the front printing surface can be effectively solved.

Owner:云南金明源印刷有限公司

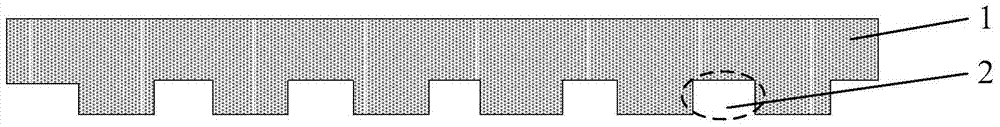

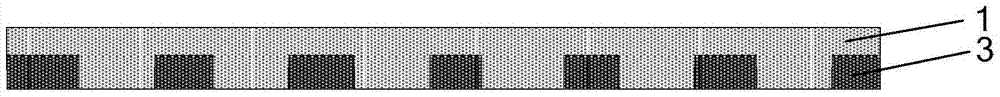

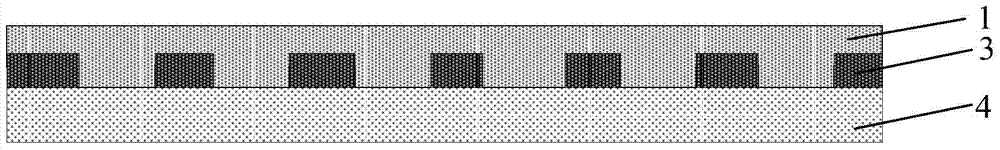

A kind of flexible substrate substrate and manufacturing method thereof

ActiveCN104392901BResolve curlAvoid curlSemiconductor/solid-state device detailsSynthetic resin layered productsBiochemical engineeringDisplay device

Embodiments of the present invention provide a flexible substrate and a manufacturing method thereof, which relate to the field of display technology and solve the problem of unnecessary curling when the flexible substrate is peeled off from the carrier substrate in the manufacturing process of the existing display device problems, avoid damage to the performance of the display device, improve the display quality of the display device, and prevent the final product from becoming a defective product. The flexible base substrate is formed of a flexible material, and the base substrate includes: a first flexible film layer, wherein: a plurality of grooves are arranged on the lower surface of the first flexible film layer; the grooves have the same thickness. The invention is applied in the manufacturing technology of the flexible base substrate.

Owner:BOE TECH GRP CO LTD

Method for producing shirt band type collar stay

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Method for preparing cross section metallographic specimen of stainless steel ultrathin precision strip steel

PendingCN113551963AReduce the difficulty of samplesRealize high-strength combinationPreparing sample for investigationSS - Stainless steelStrip steel

The invention belongs to the technical field of metallographic test devices, and particularly relates to a method for preparing a cross section metallographic specimen of stainless steel ultrathin precision strip steel. The method for preparing the cross section metallographic specimen of the stainless steel ultrathin precision strip steel. The method comprises the following steps: (1) pre-treating the stainless steel ultrathin precision strip steel; (2) pretreating an anode material; (3) preparing an electroforming solution; (4) electroforming; and (5) grinding the specimen. The method has the advantages that the blank of preparing a stainless steel ultra-thin precision strip steel cross section metallographic specimen at present is filled, the problem that the stainless steel ultra-thin precision strip steel cross section metallographic specimen cannot be prepared is solved, the stainless steel ultra-thin precision strip steel cross section metallographic specimen can be efficiently manufactured with high quality, and the metallographic structure of the stainless steel ultra-thin precision strip steel cross section metallographic specimen can be well presented.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

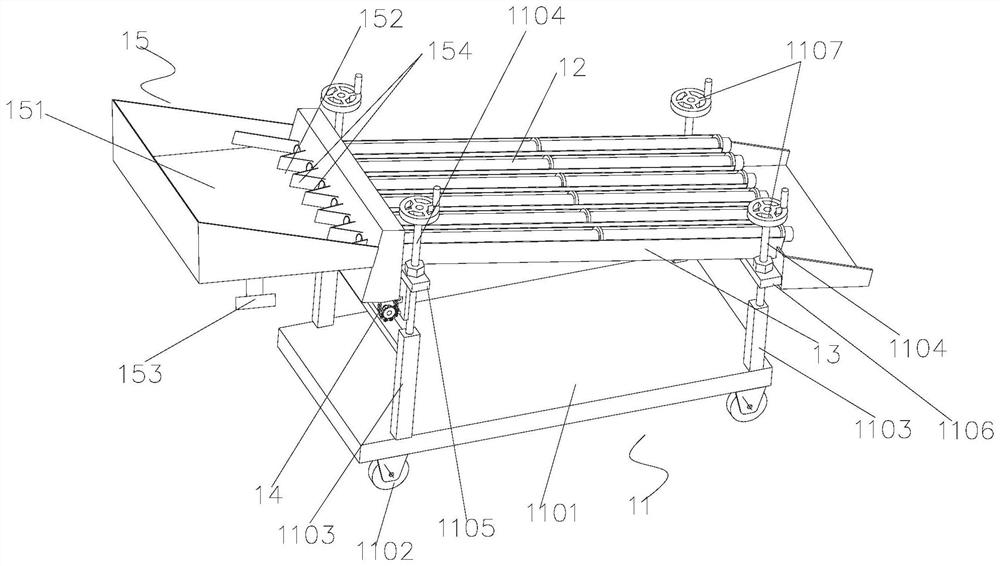

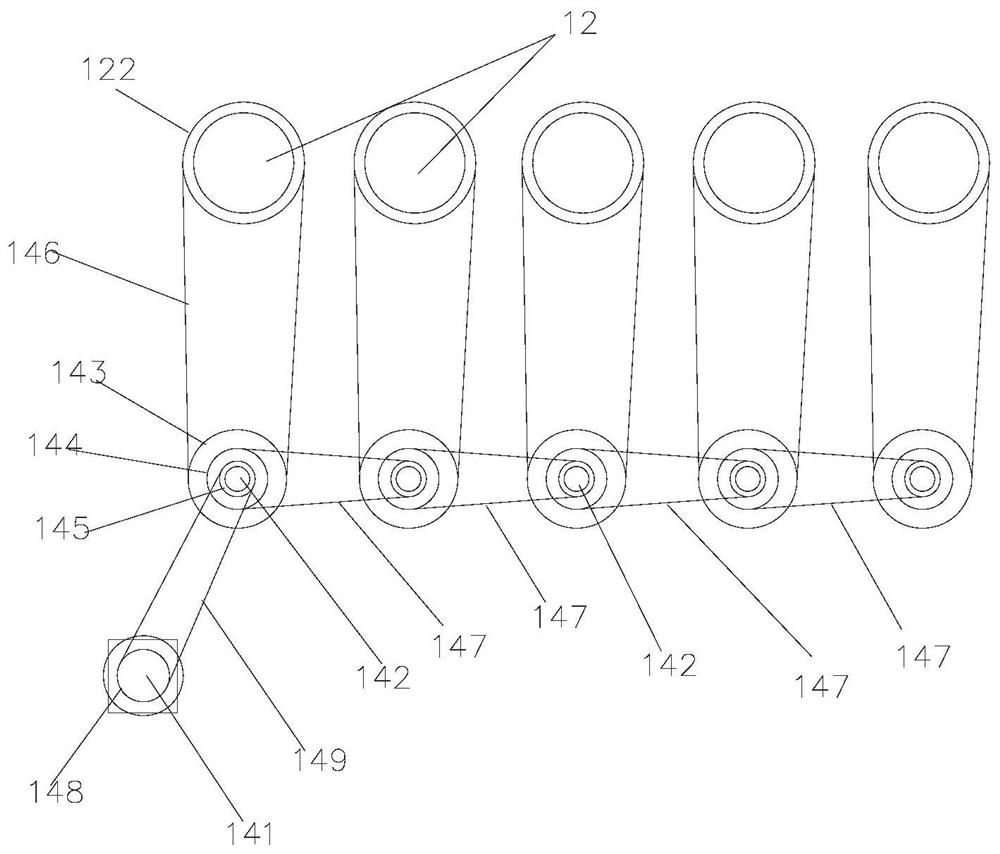

A flat tea pressing and drying equipment

ActiveCN112944808BGood shaping effectEasy to shapePre-extraction tea treatmentTea dryingThermal insulationEngineering

The invention discloses a pressing and drying equipment for flat tea, which comprises a pressing and forming device and a shaping and drying device. The pressing and forming device includes a frame, a group of lower pressing rollers rotating in the same direction installed on the frame, an upper pressing roller group cooperating with the lower pressing rollers to press the tea leaves, and a control upper pressing roller group The pressure adjustment structure of the pressing gap with the lower pressure roller; the shaping drying device includes a lower rotary conveyor belt, an upper rotary conveyor belt, an insulated box is arranged below the lower rotary conveyor belt, and an insulated box is buckled on the insulated box. A heating chamber is arranged in the heat preservation box and located at both ends of the heat preservation box respectively. A group of heating pipes are arranged in the heat preservation chamber. Air inlets are arranged outside the heat preservation chamber. A blower is provided. The invention can ensure the quality of the pressed tea leaves, reduce the breakage rate, maintain the pressed shape of the tea leaves during the drying process, and avoid the deformation of the tea leaves, thereby improving the quality of the pressed tea leaves.

Owner:四川至善茶叶有限公司

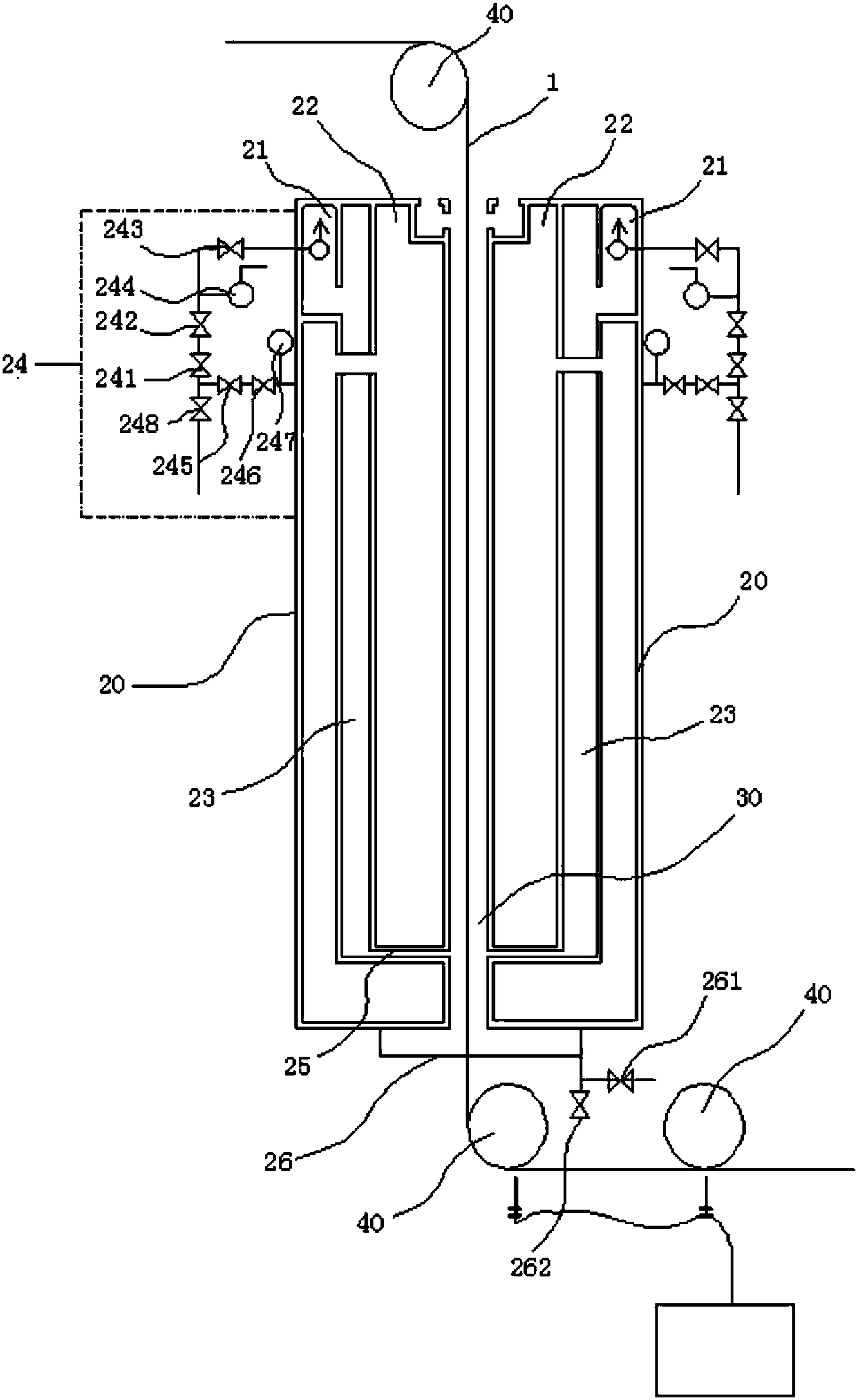

A superheated steam release paper rehumidification equipment with electrostatic field and its manufacturing process

ActiveCN106245436BImprove stabilityAvoid wrinklesSpecial paperPaper/cardboardThermodynamicsManufacturing technology

The invention discloses a superheated steam release paper rewetting apparatus with an electrostatic field, and a manufacturing technology of the apparatus. The superheated steam release paper rewetting apparatus with an electrostatic field comprises a shell, a paper traversing channel for release paper to traverse through is arranged in the middle portion of the shell, the paper traversing channel divides the shell into two mutually independent steam injection chambers, two sides of the paper traversing channel between the two steam injection chambers are provided with rewetting areas, every steam injection chamber comprises a low pressure area stem area, a high temperature area superheated steam area, a flow guiding area and a steam source control mechanism, and the flow guiding areas are provided with steam injection tubes connected with the rewetting areas; the bottom of the shell is provided with a steam-water separator connected with the high pressure superheated steam area; and the bottom and the top of the shell are respectively provided with guiding rollers used for guiding the release paper, and the guiding roller positioned in the bottom inlet of the shell is provided with a high voltage electric field generating area. The rewetting apparatus with high stability and uniform rewetting can be obtained through the manufacturing technology, avoids obstruction caused by poor water absorption property of materials, and guarantees the flat state of the materials.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

Quick-release decontamination head device of pollutant suction pipe of multi-functional combined pollutant suction car

The invention is mainly applicable to pollutant suction of various underground sewage pipelines and large factories and mines, suction and transportation of industrial waste oil and waste water, dredging and un-choking of small river ways, as well as main equipment of urban inland inundation devices. A vacuum pump is used for negative-pressure suction; the vacuum pump sucks air in a sealed container outwards; a negative pressure is formed in a tank body; and pollutants are sucked by a pollutant suction pipe into a pollutant suction tank. When a multi-functional combined pollutant suction car conducts vacuum pollutant suction, the quick-release device is installed at a pollutant suction inlet end of a pollutant suction pipe, so that balance weight at the pollutant suction inlet is increased; vibration of the pollutant suction pipe is reduced; gas flow guidance is enhanced; working efficiency is increased; the working efficiency is increased by over three multiples in comparison with efficiency of original suction with a single pollutant suction pipe; experiments are conducted for many times; dismounting is flexible and convenient; working states are sable; and residues after decontamination are obviously reduced in comparison with the situation before device installation.

Owner:SHANXI HUIFENG SPECIAL AUTOMOBILE

A kind of adhesive material for controlling the flatness of paper and its application method

ActiveCN109403135BEquilibrium moisture contentResolve curlPaper coatingCoatingsPolymer scienceKetone

The present invention is a back glue material for controlling the flatness of paper and its application method. The raw materials of the back glue material include styrene-acrylic acid copolymer emulsion, self-crosslinking acrylic acid, sodium alginate, calcium chloride, ketone-removing additive, auxiliary agent Water and natural latex, 5-10% by mass of styrene-acrylic acid copolymer, 10-15% by mass of self-crosslinking acrylic acid, 0.5-1.5% by mass of sodium alginate, chlorinated The mass component of calcium is 1.5-2%, the mass component of ketone-removing additive is 2-3%, the mass component of auxiliary agent is 0.03-0.2%, the mass component of water is 3-7%, and the mass component of natural latex The mass fraction is 30‑40%. The adhesive used to control the flatness of paper and its application method in the present invention greatly solve the problems of curling of paper and uneven surface of paper caused by the existing adhesive. The components of adhesive of the present invention are low in cost and simple in synthesis process , with high applicability.

Owner:SHANGHAI RUITU NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com