UV photocureable coating for explosion-proof membrane hardening coating of vehicle-mounted touch screen and preparation

A light-curing coating and hardening coating technology, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of poor quality stability and performance balance of explosion-proof membranes, long after-sales service response time, Competing with imported materials and other issues, to achieve super strong and durable hydrophobic and oleophobic anti-fouling performance, super stable hydrophobic and oleophobic anti-fouling performance, and reduce volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

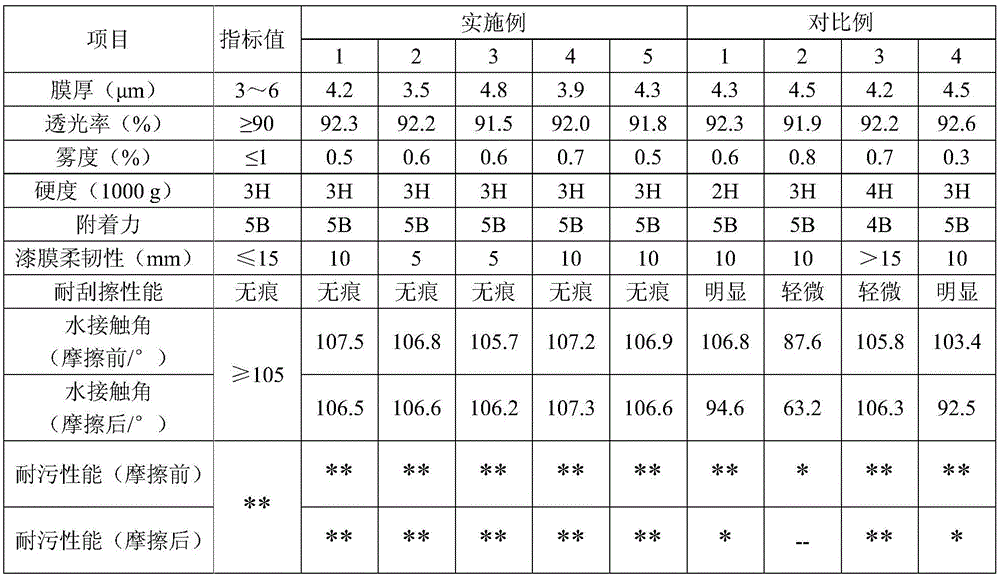

[0039] Embodiment 1: The preparation of the UV light-cured coating that is used for the explosion-proof film hard coating of vehicle-mounted touch screen

[0040] Mix 38g of multifunctional acrylate reactive diluent (Sartomer-DPHA), 0.5g of reactive fluorine-containing stain resistance additive (ShinEtsu-KY1203) and 54g of organic solvent (30g of methyl isobutyl ketone and 24g of butanone) Add 2g mercaptan monomer (SC Organic Chemistry-Lecad 804), stir and disperse evenly; add 3.5g aluminum oxide nanoparticle dispersion (NANOBYK-3602) and 2g photoinitiator (Irgacure 127), disperse evenly, filter, and obtain UV curable coatings for hardened coatings of explosion-proof films for automotive touch screens.

Embodiment 2

[0041] Embodiment 2: be used for the preparation of the UV photocurable coating that is used for the anti-explosion film hard coating of vehicle-mounted touch screen

[0042] Mix 20g of multifunctional acrylate reactive diluent (DSM-2830L), 0.1g of reactive fluorine-containing antifouling additive (DIC-RS9009) with 77g of organic solvent (30g of ethyl acetate, 30g of methyl isobutyl ketone and 17g of butyl acetate) and mix well; add 1g mercaptan monomer (SC Organic Chemistry-PEMP), stir and disperse evenly; add 1g alumina nanoparticle dispersion (NANOBYK-3602) and 1g photoinitiator (Darocur MBF), disperse evenly , and filtered to obtain a UV photocurable coating for an explosion-proof film hard coating for a vehicle-mounted touch screen.

Embodiment 3

[0043]Embodiment 3: be used for the preparation of the UV photocurable coating that is used for the anti-explosion film hard coating of vehicle-mounted touch screen

[0044] Mix 50g of multifunctional acrylate reactive diluent (Eternal-EM241), 1.0g of reactive fluorine-containing stain resistance additive (DIC-RS6007) with 40g of organic solvent (15g of ethyl acetate and 25g of methyl isobutyl ketone) Uniform; add 5g thiol monomer (SC Organic Chemistry-Lecad 803), stir and disperse evenly; add 1g silica nanoparticle dispersion (NANOBYK-3650) and 3g photoinitiator (1.5g Lucirin TPO and 1.5g Irgacure 184 ), disperse evenly, and filter to obtain the UV light-curable coating used for the explosion-proof film hard coating of the vehicle touch screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com