Manufacturing method of flexible display substrate, and manufacturing method of flexible display panel

A flexible display and manufacturing method technology, which is applied in the manufacture of flexible display panels and the manufacture of flexible display substrates, can solve the problems of increasing the manufacturing cost of flexible display substrates, waste of rigid organic substrates, and the inability to reuse rigid organic substrates, thereby reducing The effect of production cost, improved efficiency, and prevention of curling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The manufacturing method of the flexible display substrate and the manufacturing method of the flexible display panel according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

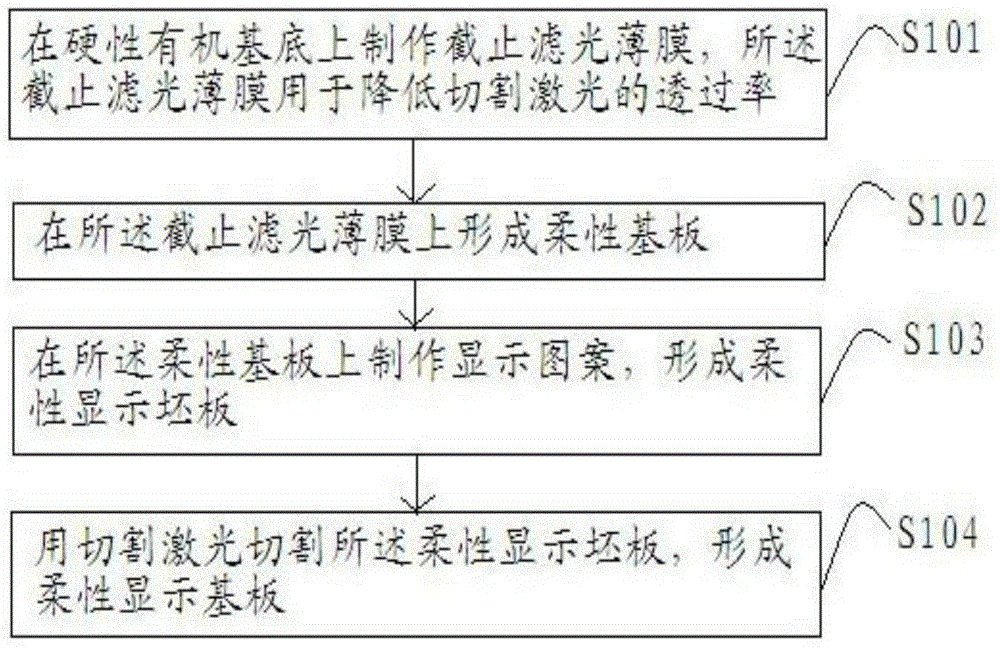

[0025] like figure 1 As shown, an embodiment of the present invention provides a method for manufacturing a flexible display substrate, including:

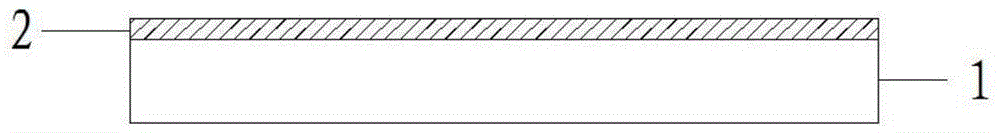

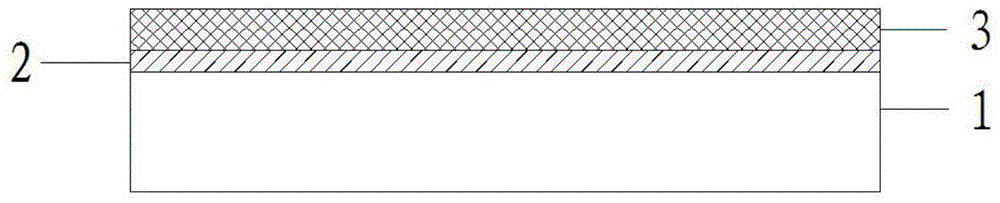

[0026] Step S101 , fabricating a cut-off filter film 2 on the rigid organic substrate 1 , the cut-off filter film 2 is used to reduce the transmittance of the cutting laser. The cross-sectional schematic diagram after forming the cut-off filter film 2 on the rigid organic substrate 1 is as follows figure 2 As shown, exemplary, the rigid organic substrate 1 is a glass substrate, because the glass substrate is transparent, easy to manufacture, and cheap. Of course, other qualified substrates can also be selected, which is not limited here.

[0027] The working principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com