Continuous processing production line for tea leaves

A production line and tea technology, applied in the field of tea continuous processing production line, can solve the problems of low degree of automation, poor forming effect, low efficiency, etc., and achieve the effect of good integrity, quality improvement and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

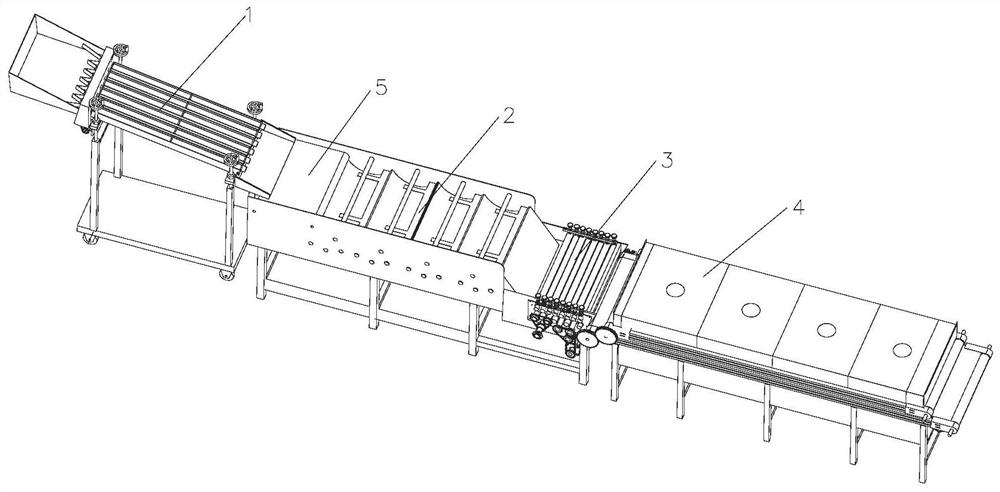

[0037] Examples such as figure 1 As shown, a tea continuous processing production line is used for continuous processing of flat tea, especially suitable for preparing Taiping Houkui tea. The production line includes a finishing machine 1, a thermal insulation conveying device 2, a pressing and forming device 3 and a shaping and drying device 4 connected in sequence. After the tea leaves are finished by the finishing machine 1, they are sent to the pressing and forming device 3 through the heat preservation conveying device 2 for pressing, and the pressed tea leaves directly enter the shaping and drying device 4 to complete drying.

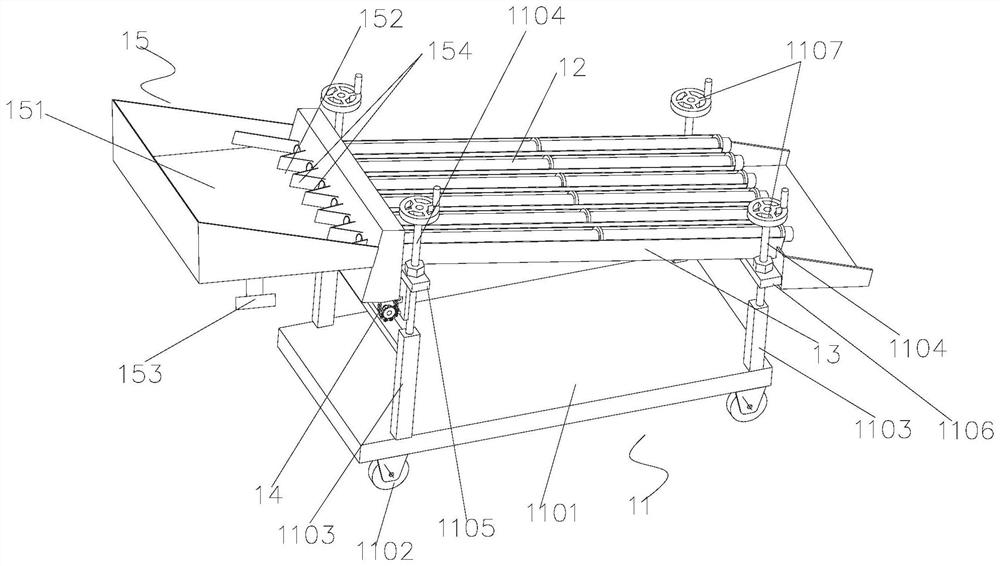

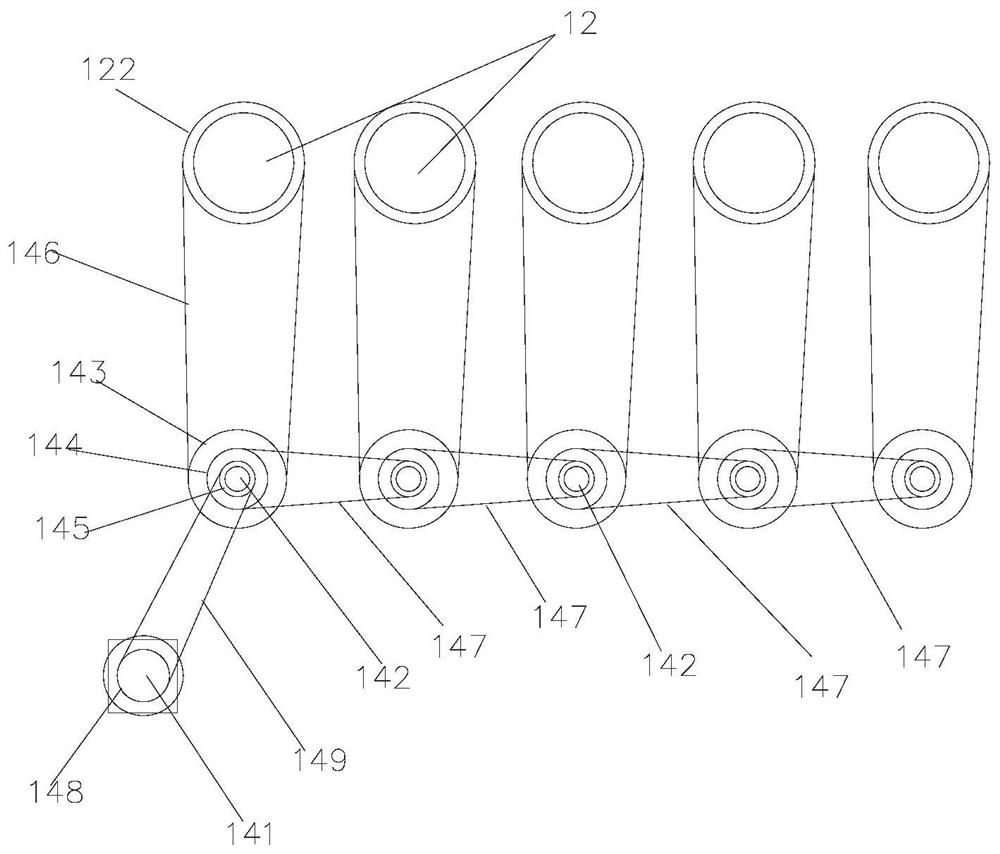

[0038] Specifically, such as Figures 2 to 5 As shown, the finishing machine 1 includes a supporting frame 11, a group of cylindrical drums 12 installed obliquely on the frame 11 and a driving mechanism 14 that drives the cylindrical drum 12 to rotate; The front top of the cylindrical drum 12 is provided with a tea feeder 15 that sends fresh lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com