Stretch bending and straightening equipment for strips for nickel-metal hydride battery negative substrates

A technology for stretching and bending straightening and nickel-metal hydride batteries, which is applied in the field of stretching and bending and straightening equipment, can solve problems such as the inability to meet the stretching and bending correction of negative sheets and strips of extremely thin nickel-metal hydride batteries, and solves the problem of surface flatness, Solve the effect of strip curling and not easy to break the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

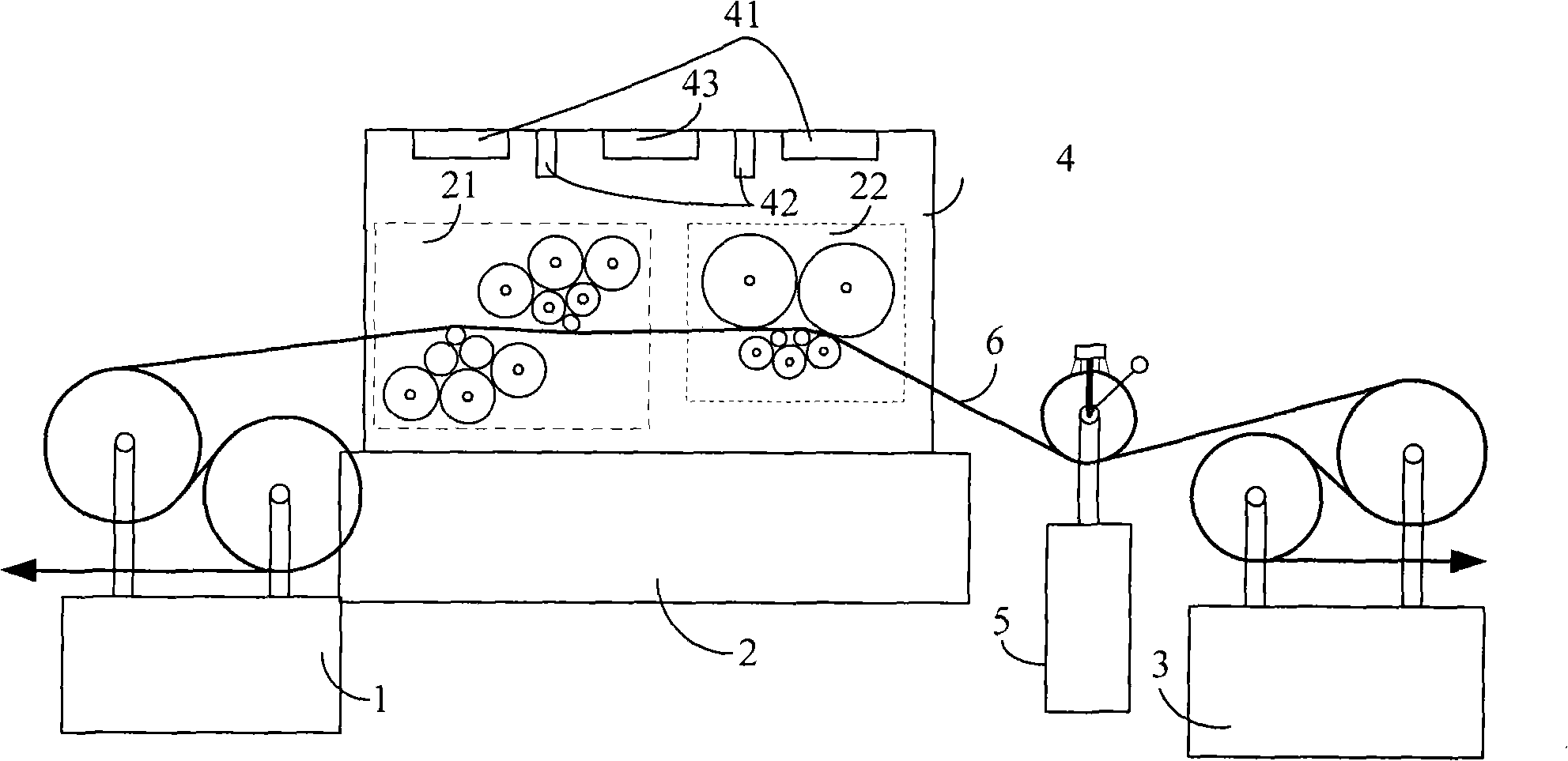

[0037] This embodiment provides a kind of stretching bending straightening equipment for the negative electrode substrate of Ni-MH battery, such as figure 1 shown, including: uncoiler, stretch bending leveler and winder;

[0038] Among them, the uncoiler and the winder are respectively arranged on both sides of the stretching and bending straightening machine. The stretching and bending straightening machine is equipped with bending rollers and leveling rollers. Bending rollers and leveling rollers of tensile bending straightening machines; such as figure 1 , the stretch bending straightening machine is composed of two sets of bending rolls 21 and one set of leveling rolls 22. The bending rolls are Y-shaped floating rolls with a roll diameter of 15mm. When the strip is bent on the rolls, its curvature radius is basically the same as the roll radius Likewise, the tensile stress of the strip can be reduced to reduce the breakage of the strip.

[0039] Moreover, a reverse bendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com