A superheated steam release paper rehumidification equipment with electrostatic field and its manufacturing process

A technology of superheated steam and manufacturing process, which is applied in the field of superheated steam release paper rewetting equipment and its manufacturing process, can solve the problems of uneven curling of release paper, and achieve good flatness, high stability and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

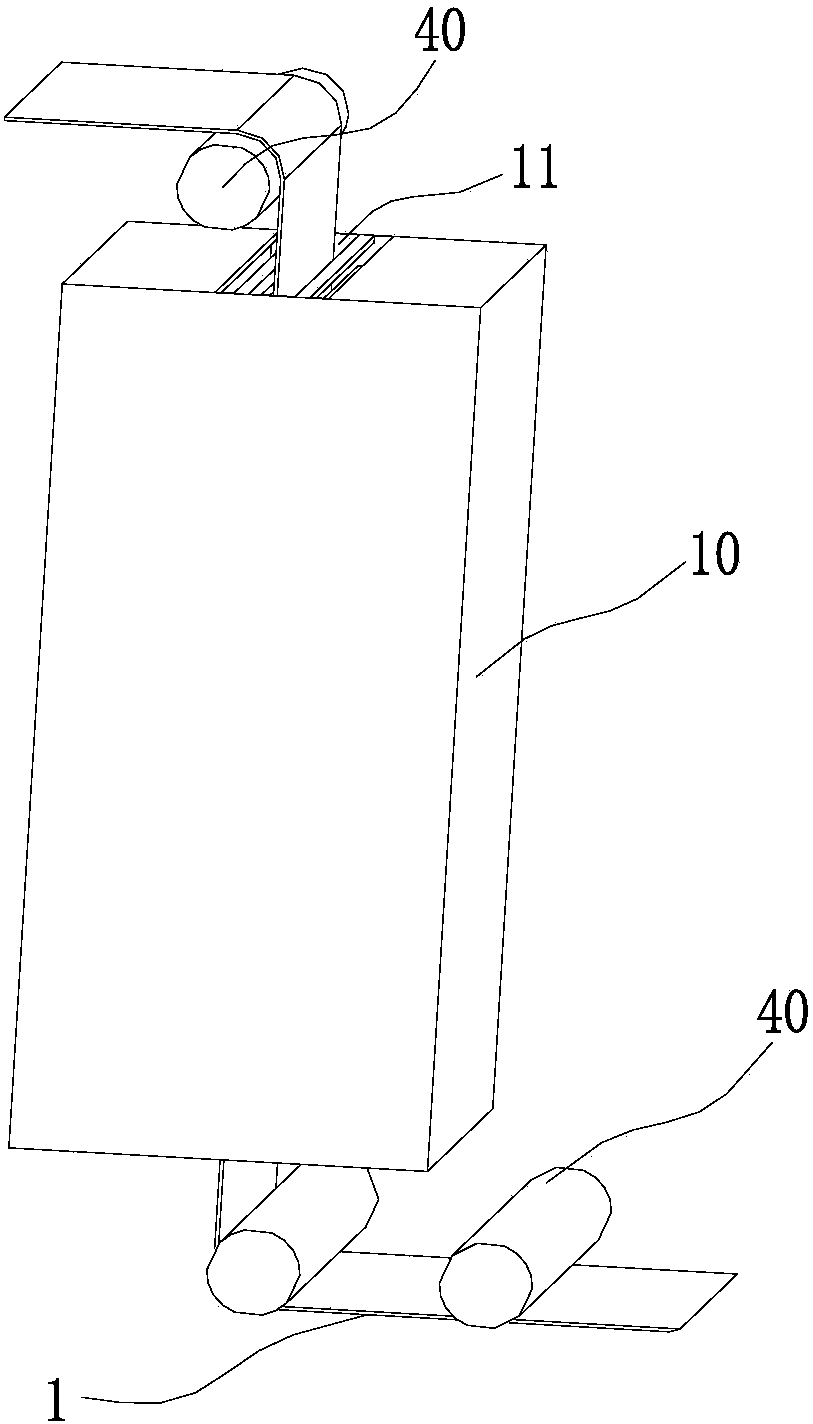

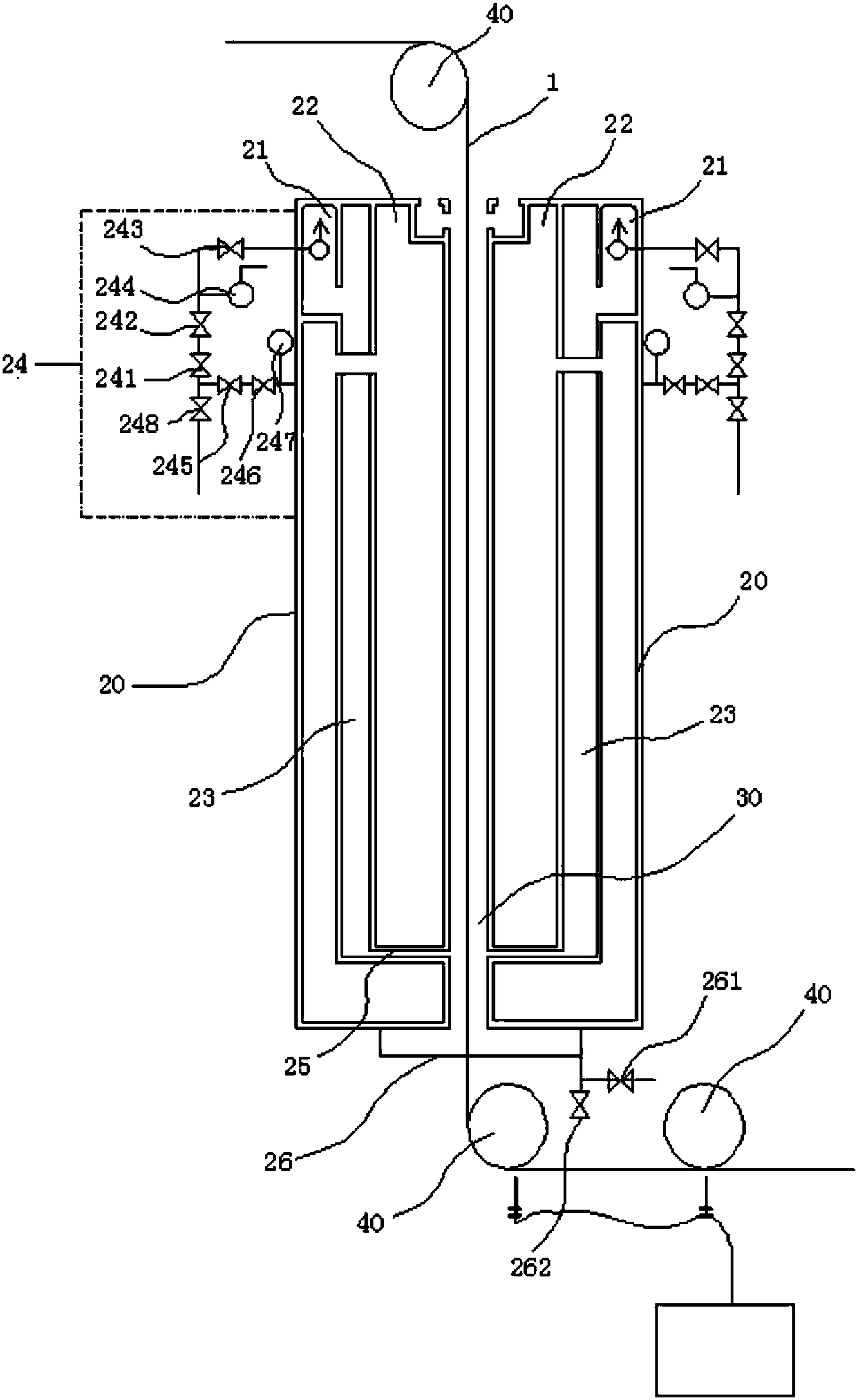

[0068] A superheated steam release paper rehumidification device with an electrostatic field, which includes a housing, the middle part of the housing is provided with a paper passage for the release paper to pass through, and the paper passage divides the housing into mutually independent There are two steam injection chambers, and there are rehumidification areas on both sides of the paper passage between the two steam injection chambers. Each steam injection chamber includes a low-pressure steam area, a high-pressure superheated steam area, a diversion area, and a steam source control mechanism. The diversion area is provided with a steam injection pipe communicated with the rehumidification area; the bottom of the housing is provided with a steam-water separator communicated with the high-pressure superheated steam area; the bottom and top of the housing are respectively provided with a The traction roller is located at the guide roller of the housing to set the high-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com