A flat tea pressing and drying equipment

A drying equipment and flat technology, which is applied in the field of flat tea pressing and drying equipment, can solve problems such as poor shaping effect, and achieve the effects of fast speed, good integrity and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

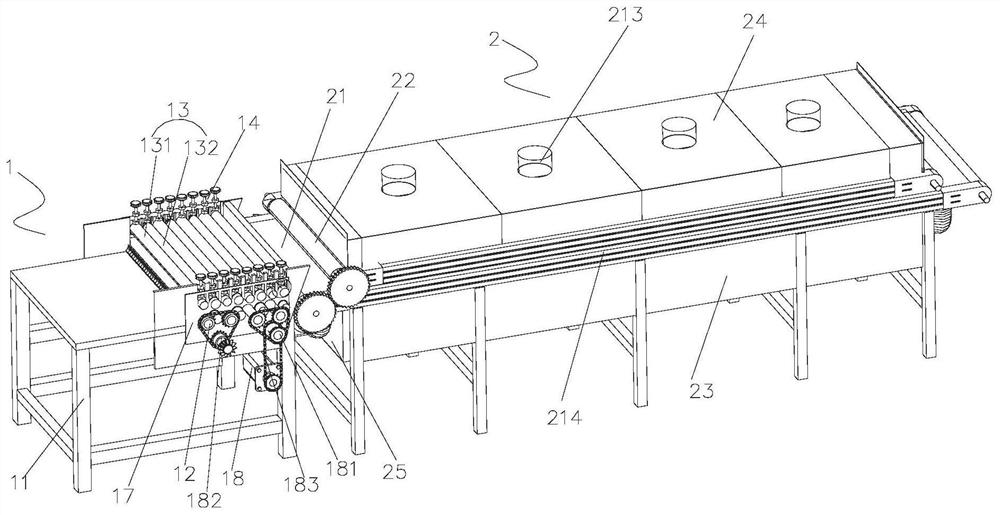

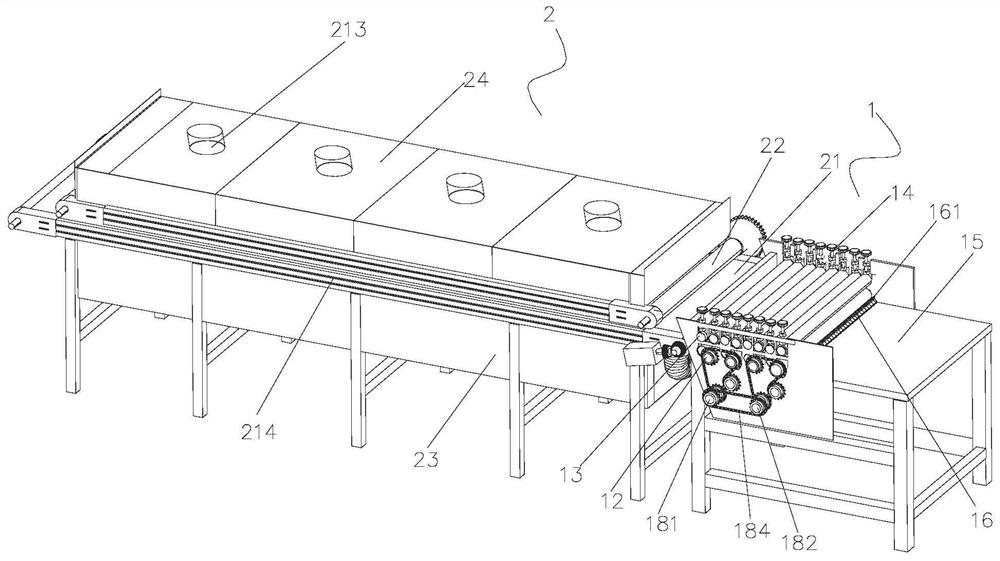

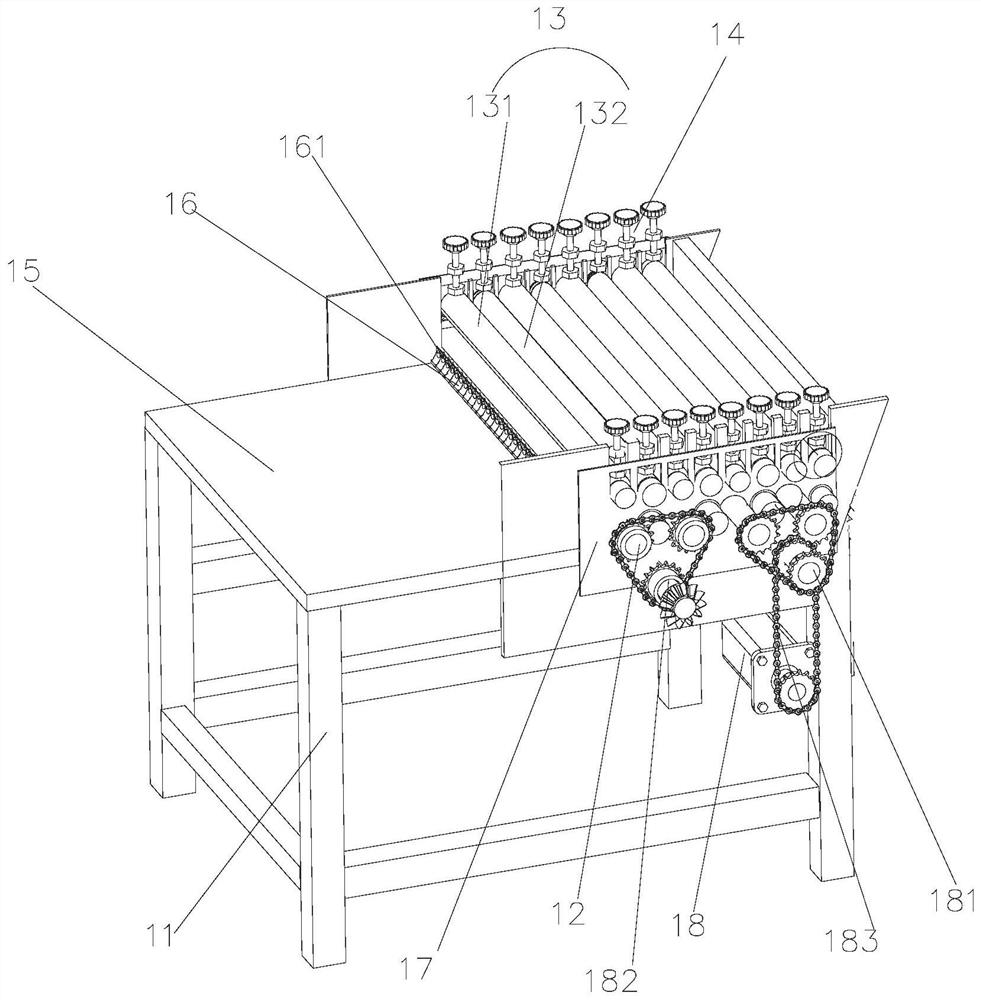

[0027] Examples such as Figures 1 to 8 As shown, a flat tea pressing and drying equipment includes a pressing and forming device 1 for flattening and shaping the roasted tea leaves and a shaping and drying device 2 for shaping and drying the shaped tea leaves. After the tea leaves are roasted, they are sent to the compression molding device 1 to complete the shaping to obtain a flat tea shape, and then sent to the shaping drying device 2 to complete the drying of the shaped tea leaves. During the drying process, the tea leaves can be Maintain the state after shaping, thereby improving the quality of tea processing.

[0028] Described press-forming device 1 comprises frame 11, a group of lower pressing rollers 12 that is rotatably mounted on the frame 11 and rotates in the same direction, and upper pressing roller group 13 that cooperates with lower pressing rollers 12 to press tealeaves, is also provided with There is a pressure adjustment structure 14 for controlling the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com