Dual-network zero-trans-fat-like emulsion gel capable of 3D/4D printing and preparation method of dual-network zero-trans-fat-like emulsion gel

A double network, fat emulsion technology, applied in the fields of edible oil/fat, cocoa, food science, etc., can solve the problems of high oil content, low structural strength, and not meeting the needs of consumers for a low-fat healthy diet, and achieve good Thixotropy and plasticity, the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

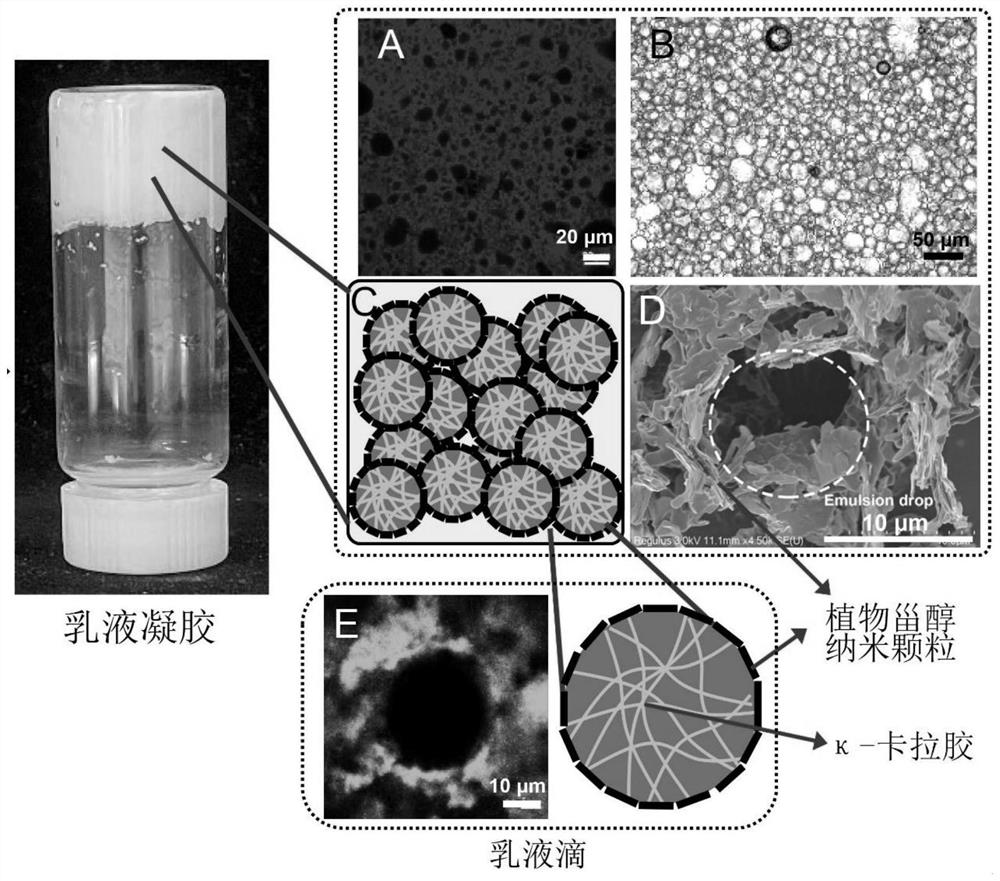

[0070] A method for preparing a 3D / 4D printable double-network zero-trans low-saturated fatty acid emulsion gel, comprising the steps of:

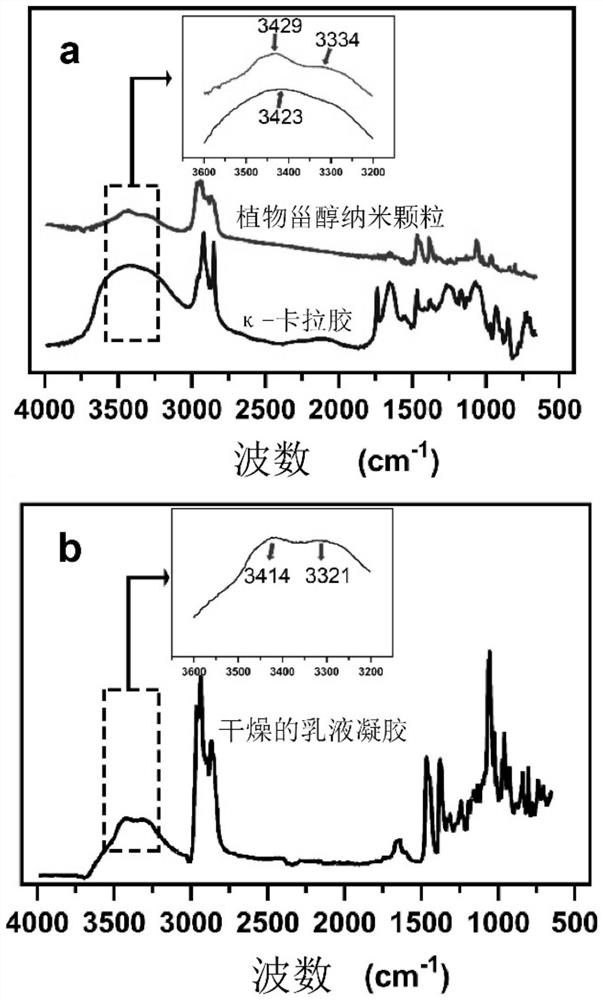

[0071] (1) Weigh 0.3g of κ-carrageenan and dissolve it in 95.7g of water at 75°C containing 4g of phytosterol nanoparticles (with a particle size of 1000nm), stir at 400rpm for 10min to dissolve κ-carrageenan, and obtain an aqueous solution;

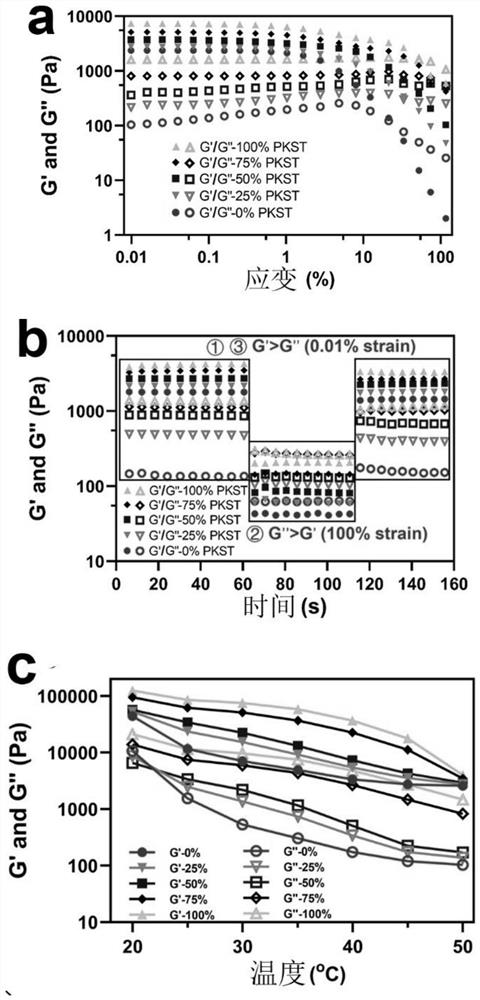

[0072] (2) Take soybean oil and palm stearin (PKST) with 1:0, 3:1, 1:1, 1:3, 0:1 mass ratio (the mass concentration of palm stearin is 0, 25, 50, 75 , 100%), mixed under the condition of heating to 70°C, stirred at 400rpm for 10min to make it fully mixed, and obtained mixed oil;

[0073] (3) Mix the aqueous solution of step (1) and the mixed oil of (2) at a volume ratio of 3:1, stir at 400rpm for 10min at 70°C to fully mix, and then perform homogeneous emulsification at a rate of 16000rpm for 4min , to obtain a 3D / 4D printable double-network zero-trans low-saturated fatty acid emulsion gel.

[0074...

Embodiment 2

[0099] The application of the double-network zero-trans low-saturated fatty acid emulsion gel obtained in Example 1 in food 3D printing comprises the following steps:

[0100] (1) The double-network zero-trans low-saturated fatty acid fat emulsion gel obtained in Example 1 is maintained at a temperature of 40° C., transferred to the storage tank of the food 3D printer, and the temperature of the storage tank is set to 45°C;

[0101] (2) Add the 3D / 4D printable double-network zero-trans low-saturated fatty acid emulsion gel to the 3D printing needle to ensure that the system in the needle is uniform and not dispersed; adjust the temperature in the printing chamber to 45°C, and select Fill the PVC plastic 3D printing gun head, adjust the X, Y, and Z axes of the 3D printer to zero through the program setting; select a 0.85mm diameter needle to set various parameters in the 3D printing process, specifically: printing layer thickness ( 0.85mm), wall thickness (0.85mm), filling den...

Embodiment 3

[0105] Example 3 Application in Preparation of Rigid Biological Porous Materials as a Template

[0106] Get the 3D / 4D printable double-network zero-trans low-saturated fatty acid emulsion gel containing palm stearin prepared in Example 1, and use a food 3D printer to print according to the method of Example 2, and the printed object is Hilbert curve. After the object to be printed is cooled and solidified at room temperature, its hardness is tested with weights. The test results are as follows: Figure 9 :

[0107] From Figure 9 It can be seen that when the content of palm stearin in the oil phase reaches 100%, the printed object can support a 500g weight, indicating that the cured printed object has a strong rigidity ( Figure 9 Middle a); When the content of palm stearin in the oil phase reaches 0, the product cannot support the weight of 500g;

[0108] Put the printed object in a -80°C refrigerator for 1 hour, and then use a freeze dryer to freeze-dry it for 24 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com