Vertical bar artificial silk spinning fabric production process

A production process and rayon spinning technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of easy strain on edge and weft, inability to meet higher requirements, and easy to break wool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] [0025] The production technology of vertical rayon spinning fabric comprises the following steps:

[0042] A. Silk treatment:

[0043] a. Winding: Use a winding machine, set the winding weight to 0.83kg, the winding time to 180 minutes, and the coiling tension to 15g for winding;

[0044] b. Two-for-one twisting: use a two-for-one twister, set the spindle speed to 10000r / mim, add tension beads 0.7*2 grains, and set the wrap angle to 175° for two-for-one twisting; the reciprocating time of rewinding and moving the screw rod is controlled at 10s, and the winding The tension is controlled at 15g;

[0045] c. Segmented warping: set the speed of the large drum at 260m / min, the reversing shaft at 70m / min, and equip with No. 3 tension cap, control the warping tension at 15g, and the reversing shaft tension at 2kg, and carry out the warping according to 694 grains*16 strips through;

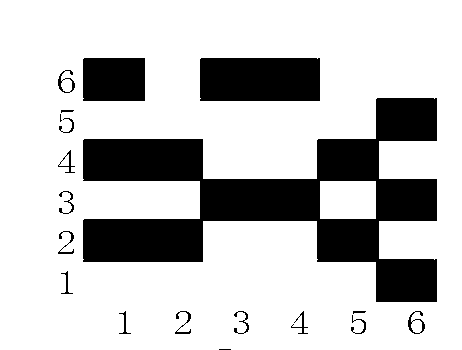

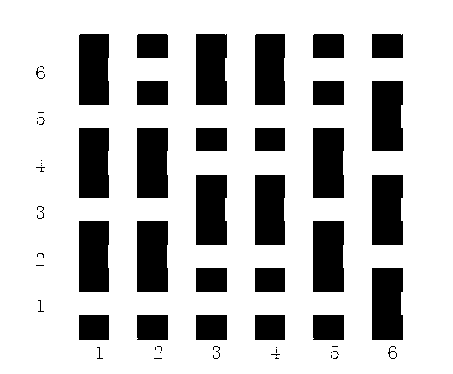

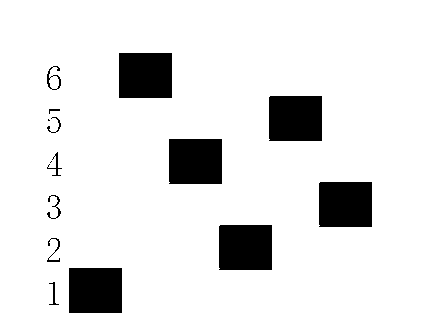

[0046] d. Heald threading: 6 pieces of healds are used, and the healds are threaded inte...

Embodiment 2

[0062] The production technology of vertical rayon spinning fabric comprises the following steps:

[0063] A. Silk treatment:

[0064] a. Winding: Use a winding machine, set the winding weight to 0.85kg, the winding time to 180 minutes, and the coiling tension to 17g for winding;

[0065] b. Two-for-one twisting: use a two-for-one twister, set the spindle speed to 12000r / mim, add tension beads 0.7*2 grains, and set the wrap angle to 185° for two-for-one twisting; the reciprocating time of rewinding and moving the screw rod is controlled at 12s, and the winding The tension is controlled at 17g;

[0066]c. Segmented warping: set the speed of the large drum at 300m / min, the reversing shaft at 90m / min, equip with No. 3 tension cap, control the warping tension at 18g, the reversing shaft tension at 4kg, and carry out the warping according to 694 grains*16 strips through;

[0067] d. Heald threading: 6 pieces of healds are used, and the healds are threaded intermittently; (such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com