Method for producing shirt band type collar stay

A technology of interlining and bamboo insertion, applied to collars, clothing, clothing, etc., can solve problems such as easy to be washed and torn, curled or bent collar tip, and limited support function of collar tip, so as to achieve the effect of ensuring aesthetics and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

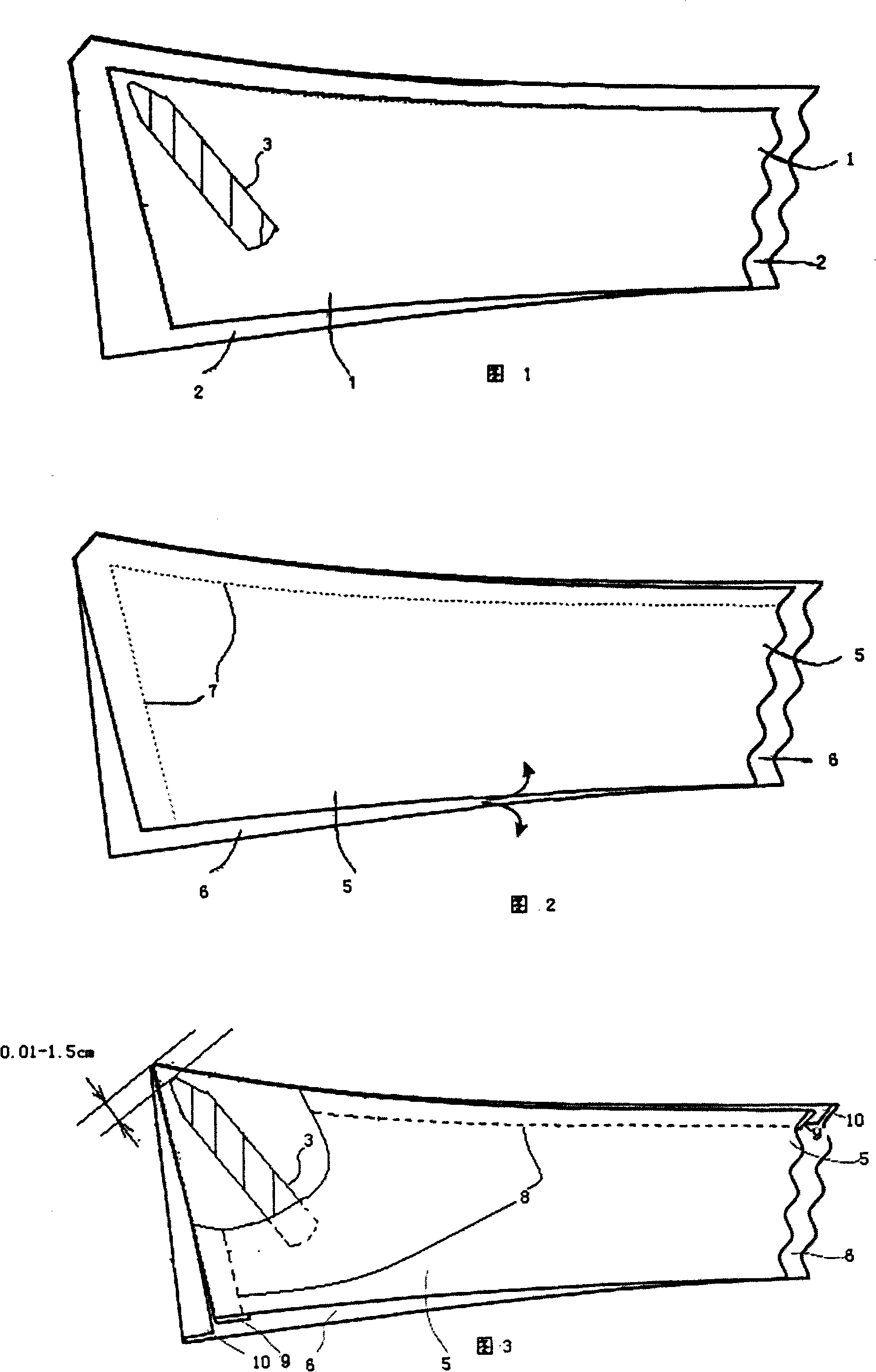

[0019] The interlining 1 with the hot-melt adhesive material, the front collar cut piece 2 of the superior collar, and the interlining type bamboo insert 3 are pressed and bonded to form a whole 5, as shown in Figure (1).

[0020] Sew up the bonded body 5 of the upper neck collar cut piece and the cut piece 6 of the bottom collar to obtain the transport line 7, as shown in figure (2);

[0021] On the unstitched side, reverse according to the method shown in Figure (2) to complete the reverse collar operation, get seam allowances 9 and 10, sew a suture 8 on the surface of the collar, and complete the sewing line operation between the surfaces, as shown in the figure ( 3), the distance between the bamboo tip and the collar tip is 0.01-1.5cm. Finish the sewing operation of the advanced collar.

Embodiment 2

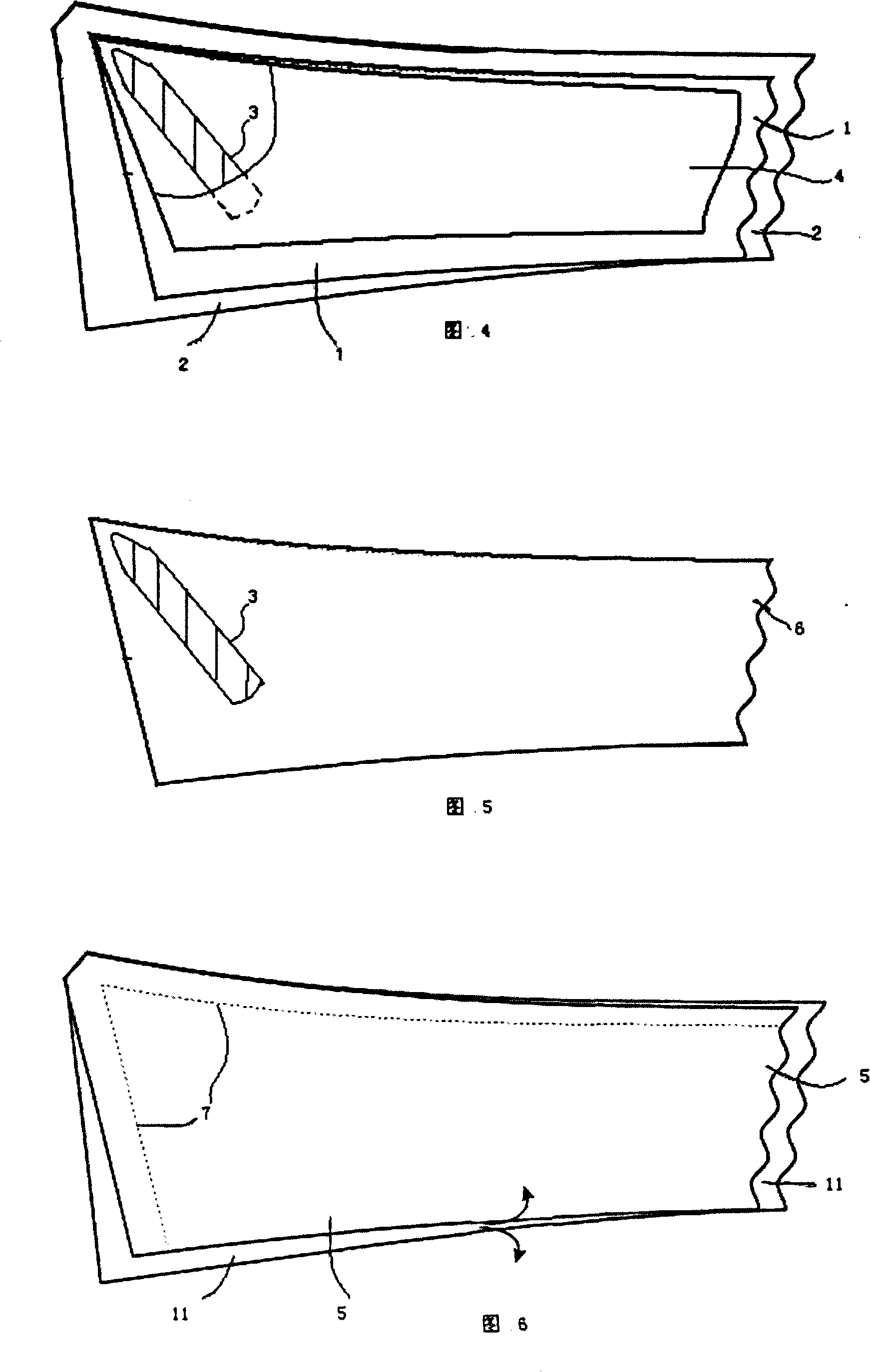

[0023] The interlinings 1 and 4 with the hot-melt adhesive material, the front collar panel 2 of the superior collar, and the interlining bamboo inserts 3 are pressed and bonded to form a whole 5, wherein 3 is located in the middle of the interlinings 1 and 4, such as Figure 4).

[0024] Sew up the bonding body 5 of the upper collar face collar cut piece and the cut piece 6 of the bottom collar to obtain a running line 7, as shown in figure (2);

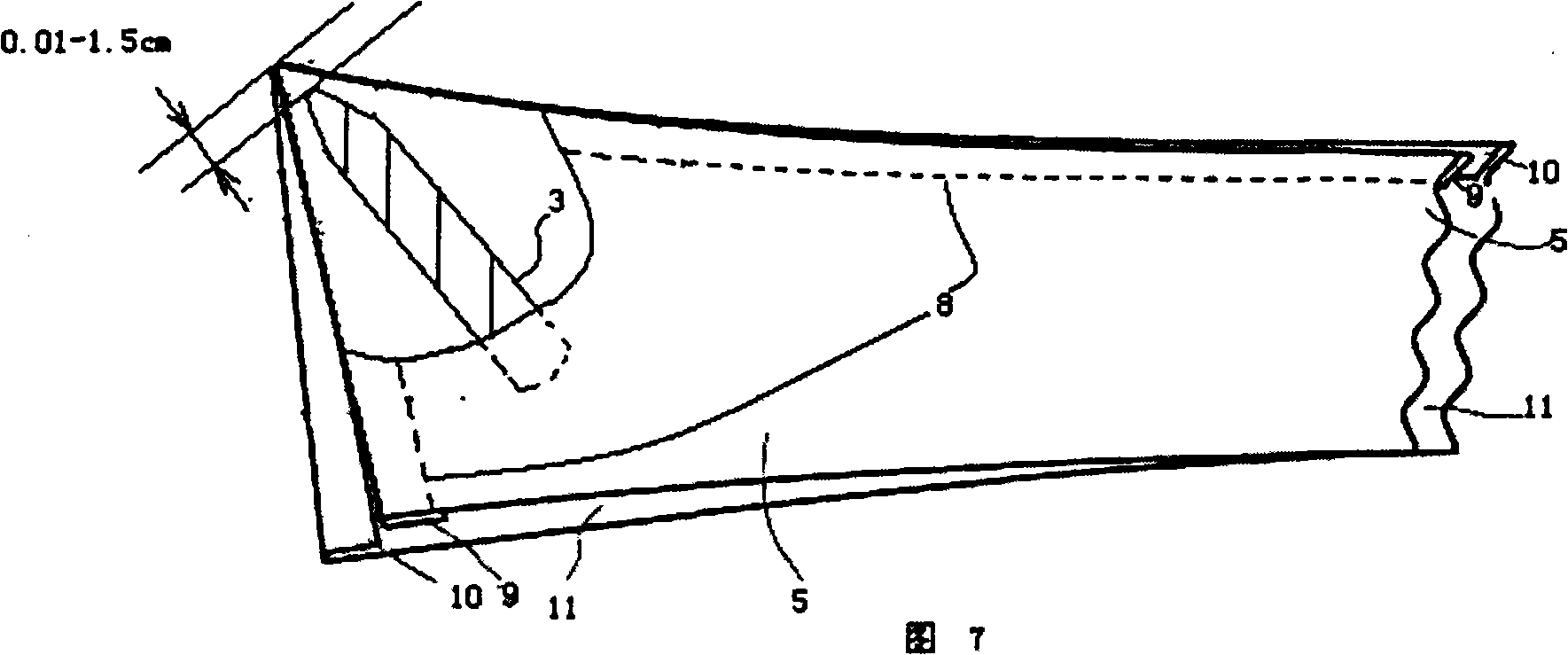

[0025] Invert the unsewn side according to the method shown in Figure (2) to complete the reverse collar operation, and get seam allowances 9 and 10; sew a suture line 8 on the surface of the collar to complete the sewing line operation between the surfaces, as shown in the figure ( 3), the distance between the bamboo tip and the collar tip is 0.01-1.5cm. Finish the sewing operation of the advanced collar.

Embodiment 3

[0027] Lining cloth type inserting bamboo 3 is bonded and bonded to form a whole 11 with the upper collar bottom surface collar cutting piece 6, as shown in figure (5).

[0028] The bonded body 5 of the face collar and interlining, the bonded body 11 of the bottom collar and bamboo inserts are sewed together to obtain the transport line 7, as shown in Figure (6).

[0029] On the unstitched side, reverse according to the method shown in Figure (6) to complete the reverse collar operation, get seam allowances 9 and 10, sew a suture 8 on the surface of the collar, and complete the sewing line operation between the surfaces, as shown in the figure ( 7), complete the operation of the entire collar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com