Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

A plasma and composite flexible technology, applied in the new technology field, can solve the problems of poor surface gluing performance of plastic film and wood products, difficult to form good adhesion at the gluing interface, difficult to guarantee the quality of surface finish, etc., so as to improve the interface gluing characteristics, Improve the production environment and simplify the finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

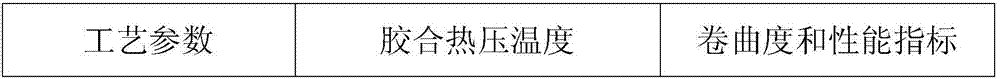

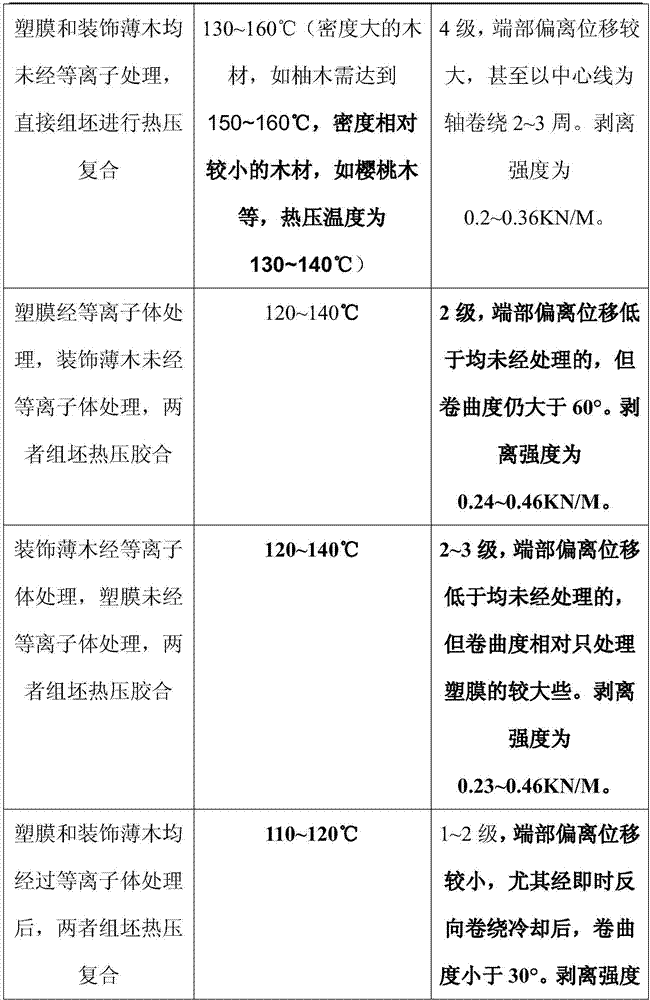

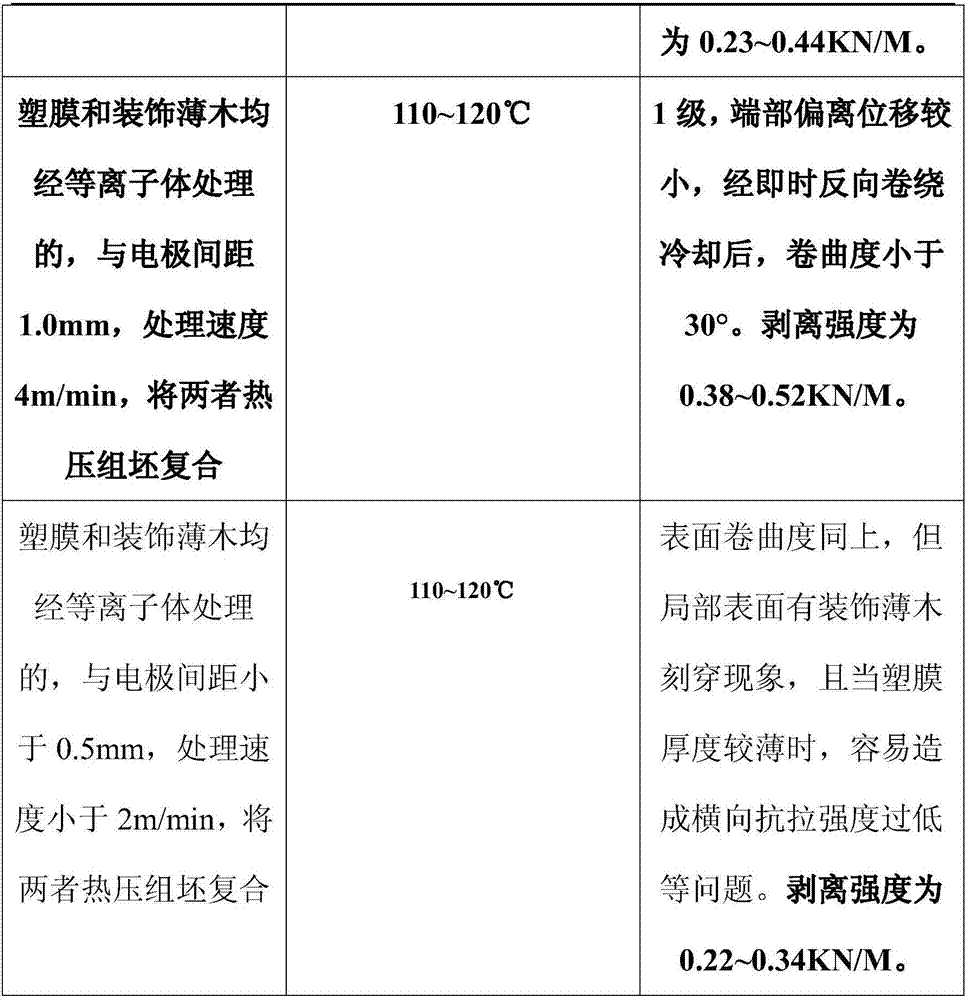

[0033] Experimental Example 1: The parameters of the present invention, such as the electrode spacing, the distance between the material and the electrodes, the plasma processing speed, and the processing power, all provide conditional guarantees for reducing the hot-pressing temperature. According to the experimental research, the hot-pressing temperature and the corresponding curling degree required for the bonding of the plastic film and the decorative veneer were compared in several cases.

[0034]

[0035]

[0036]

experiment example 2

[0037] Experimental example 2: Production energy consumption reduction experiment

[0038]

[0039]

experiment example 3

[0040]Experimental example 3: product surface bonding strength test

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com