Backing adhesive material for controlling evenness of paper sheets and application method of backing adhesive material

An application method and flatness technology, which is applied in the field of adhesive materials, can solve the problems of curled surface and unevenness of paper, and achieve the effect of solving curl, low cost and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

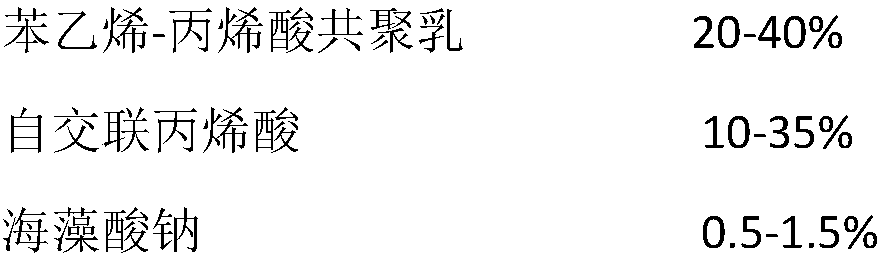

[0028] Embodiment provides a kind of adhesive material for controlling paper flatness, by mass percentage, the raw material of adhesive material comprises:

[0029]

[0030] In this embodiment, natural latex and polar functional groups are grafted; auxiliary agents include defoamers, preservatives and thickeners; the mass ratio of thickeners to auxiliary agents is 1:9; by mass percentage, except Ketone additives include: ethanolamine 60%, dimethylbiguanide 30%, propylenediamine and citric acid 10%.

[0031] According to the above-mentioned raw material proportioning, the present embodiment provides a kind of feeding process of the adhesive material of controlling the flatness of paper, comprising the following steps:

[0032] Step 1. Laminate the transfer cardboard on the laminating machine. The laminating speed is 130m / min. During the laminating process, it passes through four stages of ovens.

[0033] Step 2: After the lamination is completed, roll up the transfer cardbo...

Embodiment 2

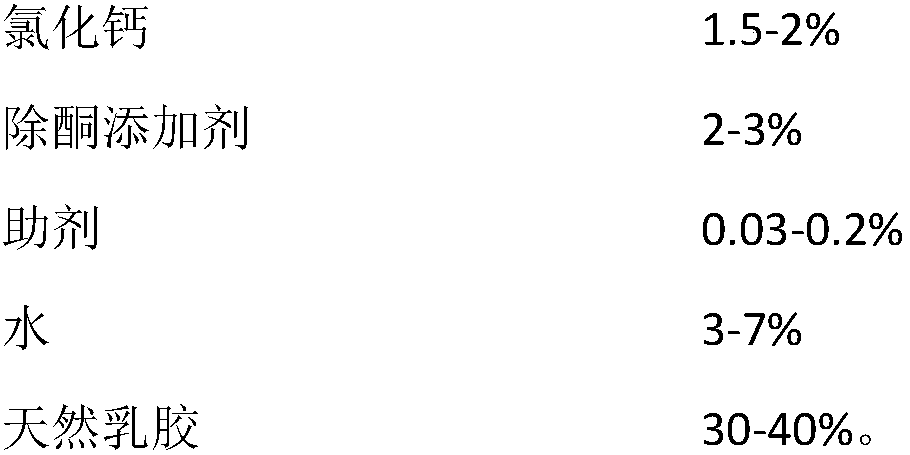

[0037] The embodiment of the present invention provides a kind of adhesive material for controlling the flatness of paper. In terms of mass percentage, the raw materials of the adhesive material include:

[0038]

[0039] In this embodiment, natural latex and polar functional groups have been grafted; auxiliary agents include defoamers, preservatives and thickeners; the mass ratio of thickeners to auxiliary agents is 3:16; Additives include: ethanolamine 50%, dimethylbiguanide 30%, propylenediamine and citric acid 20%.

[0040] According to the above-mentioned raw material proportioning, the present embodiment provides a kind of feeding process of the adhesive material of controlling the flatness of paper, comprising the following steps:

[0041] Step 1. Laminate the transfer cardboard on the laminating machine. The laminating speed is 130m / min. During the laminating process, it passes through four stages of ovens.

[0042] Step 2: After the lamination is completed, roll u...

Embodiment 3

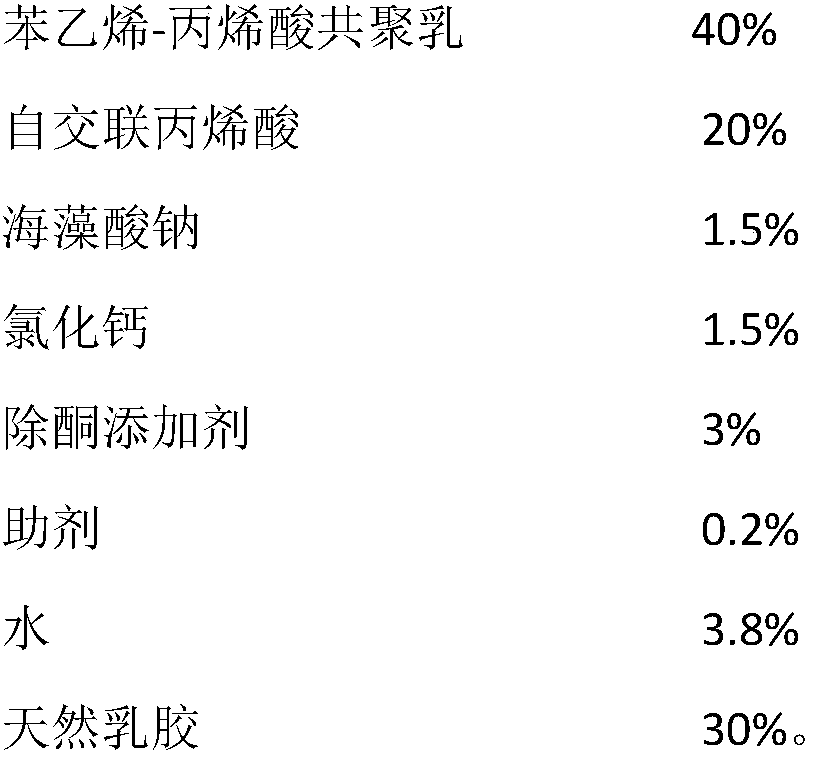

[0047] The embodiment of the present invention provides a kind of adhesive material for controlling the flatness of paper. In terms of mass percentage, the raw materials of the adhesive material include:

[0048]

[0049]

[0050] In this embodiment, natural latex and polar functional groups have been grafted; auxiliary agents include defoamers, preservatives and thickeners; the mass ratio of thickeners to auxiliary agents is 3:16; Additives include: ethanolamine 30%, dimethylbiguanide 35%, propylenediamine and citric acid 35%.

[0051] According to the above-mentioned raw material proportioning, the present embodiment provides a kind of feeding process of the adhesive material of controlling the flatness of paper, comprising the following steps:

[0052] Step 1. Laminate the transfer cardboard on the laminating machine. The laminating speed is 130m / min. During the laminating process, it passes through four stages of ovens.

[0053] Step 2: After the lamination is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com