Soft thin film transferring device and soft thin film transferring method

A film and soft technology, applied in the field of soft film transfer device, can solve the problems of ineffective application of film transfer process, rupture and damage, not too soft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

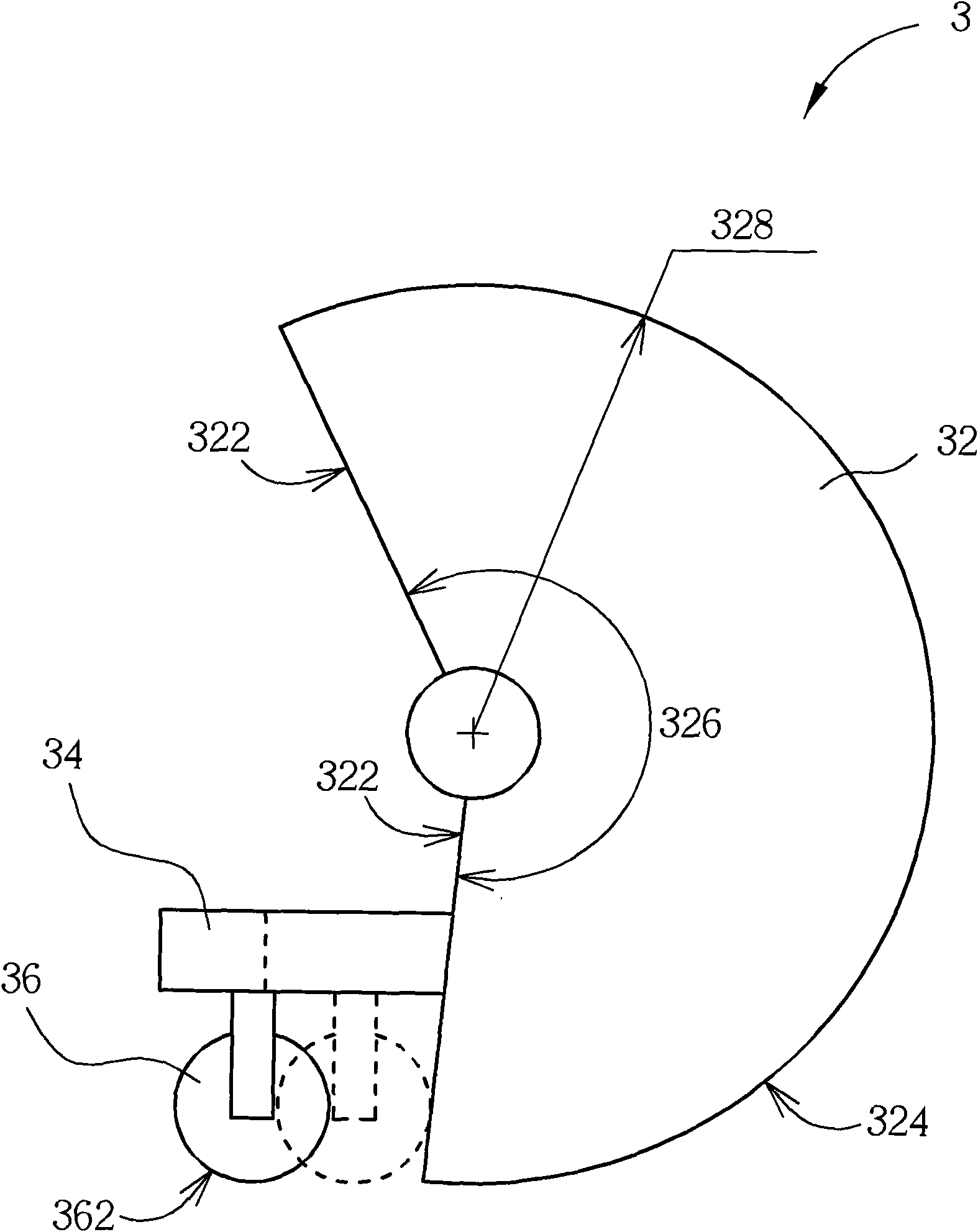

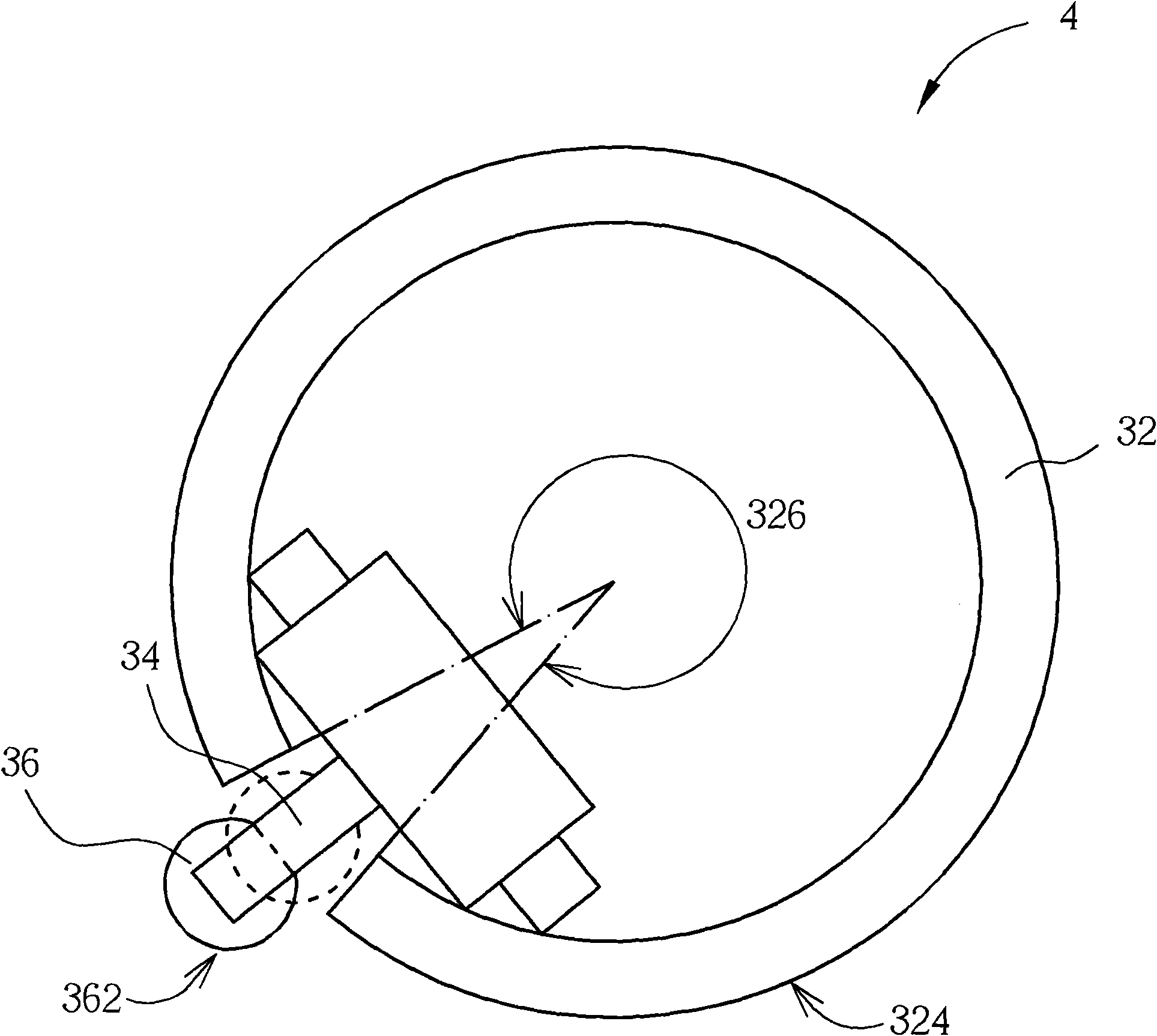

[0036] see Figure 2A , which is a schematic diagram of a flexible film transfer device 3 according to a preferred embodiment of the present invention. The flexible film transfer device 3 includes a first roller 32 , a connecting member 34 and a second roller 36 . The first roller 32 includes two radial sides 322 and a first peripheral surface 324 , and has a fan-shaped section with a central angle 326 and a radius 328 . The connecting member 34 is telescopically connected to one of the radial sides 322 . The second roller 36 is pivotally connected to the connecting member 34 and includes a second peripheral surface 362 . In FIG. 2 , the position change of the second roller 36 due to the retraction of the connecting member 34 toward the first roller 32 is shown by a dotted line.

[0037] In addition, the first peripheral surface 324 and the second peripheral surface 362 respectively have a controllable adsorption means. In this embodiment, this controllable adsorption mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com