Method for manufacturing collar filling-in bits of shirt

A production method and inserting technology, which are applied to the field of shirt-side inserting collars, can solve the problems of walking, inserting displacement, slowing down the wearing life of the collar, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

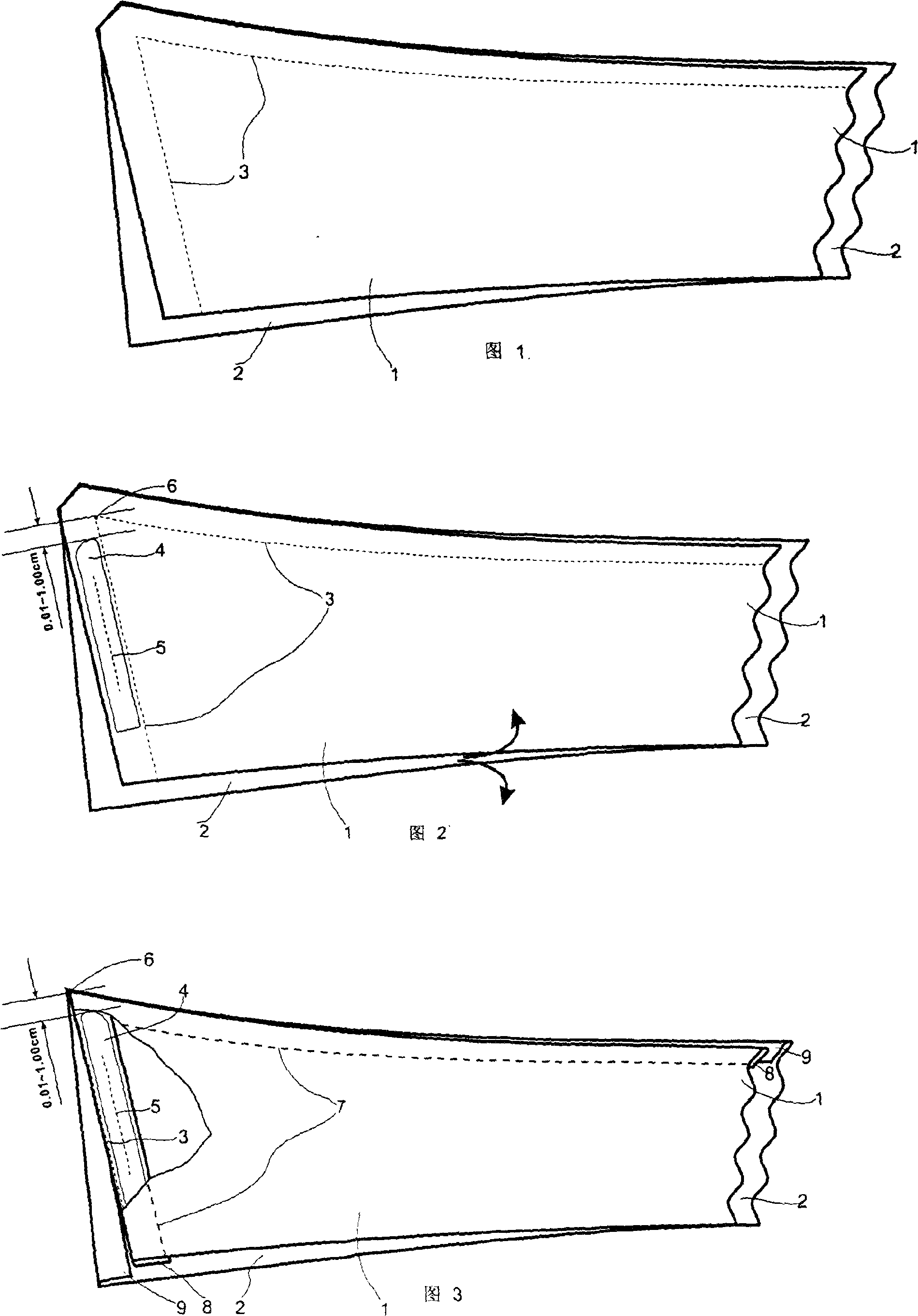

[0017] Fig. 1~3 is the processing procedure of side insert collar. Overlap the collar piece with the adhesive body 1 of the interlining and the collar piece 2, and drive in the seam 3, as shown in Figure 1; place the bamboo insert 4 on the short side or long side of the collar seam allowance and car Into the suture 5, the distance from the top of the bamboo insert 4 to the intersection point 6 of the long side and the short side of the collar 3 is 0.01-1cm, as shown in Figure 2; Turn the collar over at the bottom, insert the stitching line 7, insert the bamboo 4 between the seam allowance 8 and the collar piece 1, or place the bamboo insert 4 between the seam allowance 9 and the collar piece 2, as shown in Figure 3, and complete the upper garment collar production.

Embodiment 2

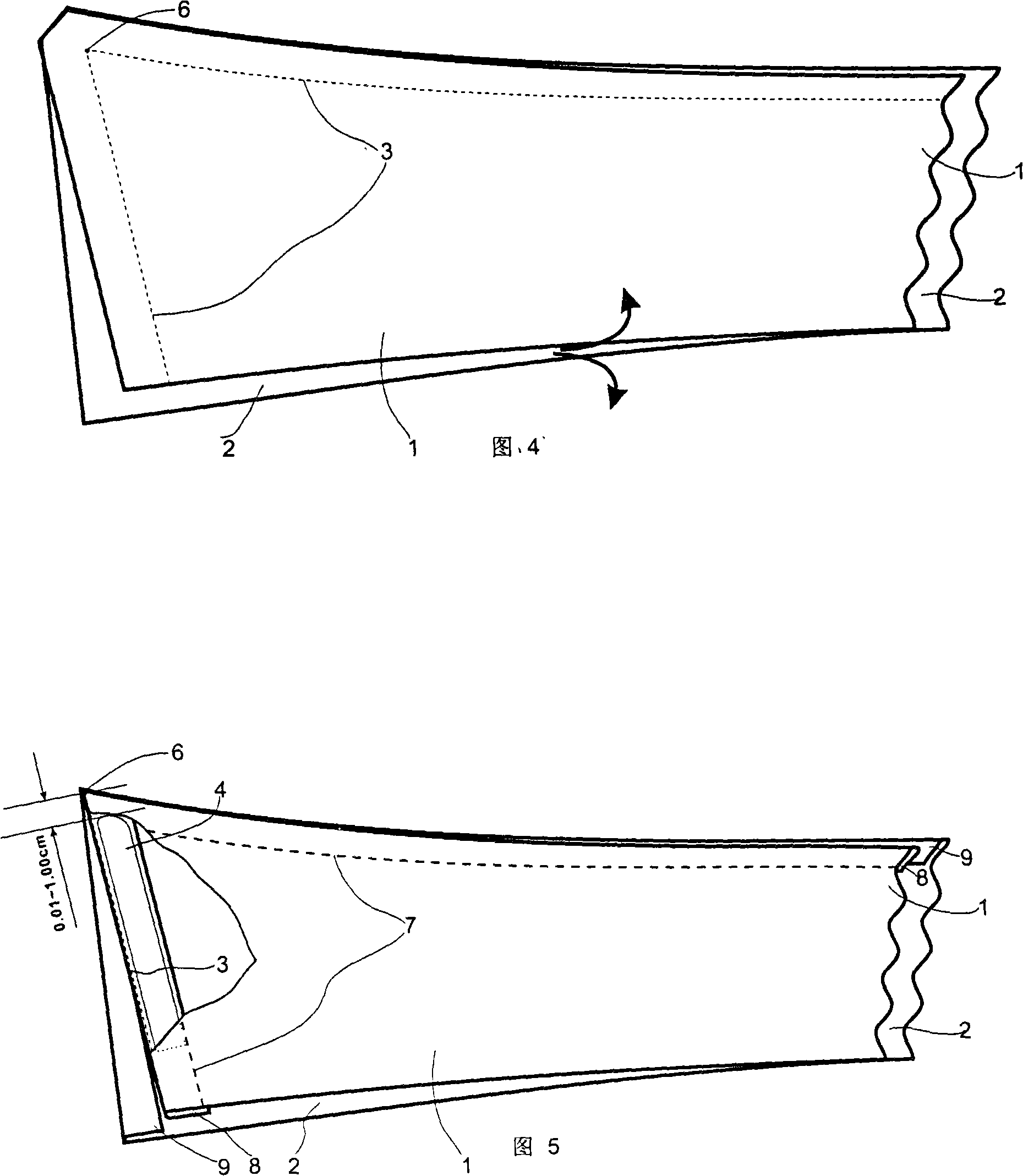

[0019] Fig. 4, Fig. 5 are the processing process of edge inserting bamboo collar. Overlap the superior collar piece with the adhesive body 1 of the interlining and the collar piece 2, and drive in the seam 3, as shown in Figure 4; as shown in Figure 4, turn over the collar from the bottom of the collar without seam and drive in Stitch 7, insert bamboo inserts into the short side of the collar along stitches 3 and 7, insert bamboo 4 between seam allowance 8 and collar piece 1, or insert bamboo 4 between seam allowance 9 and collar piece 2 The distance between the top of the bamboo insert 4 and the collar tip is 0.01-1cm, as shown in Figure 5. Finish making the superior collar as shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com