A tooling and a method for cleaning a CMOS image sensor circuit

An image sensor and cleaning device technology, applied in circuits, image communications, color TV components and other directions, can solve the problems of reducing the circuit performance of CMOS image sensors, chip surface damage, etc., and achieves a simple and practical cleaning method, high cleanliness, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

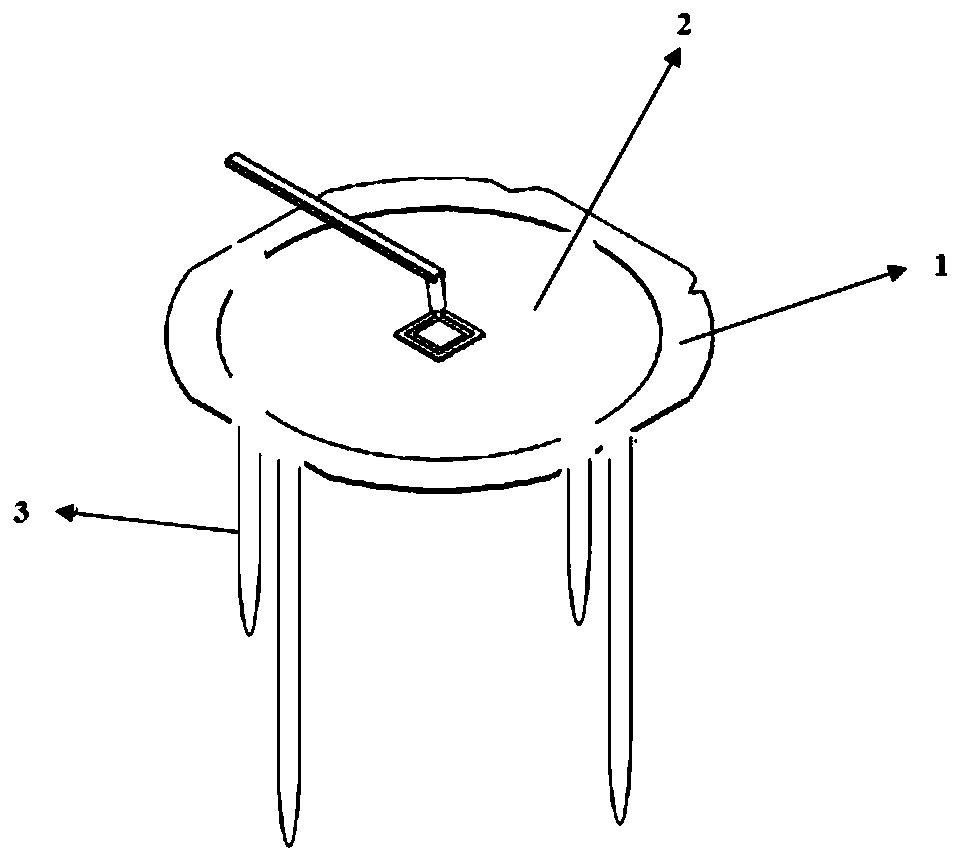

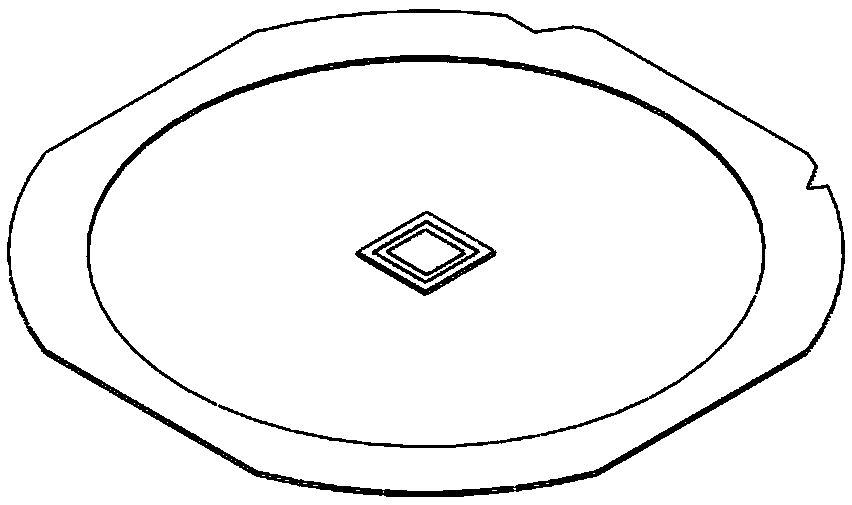

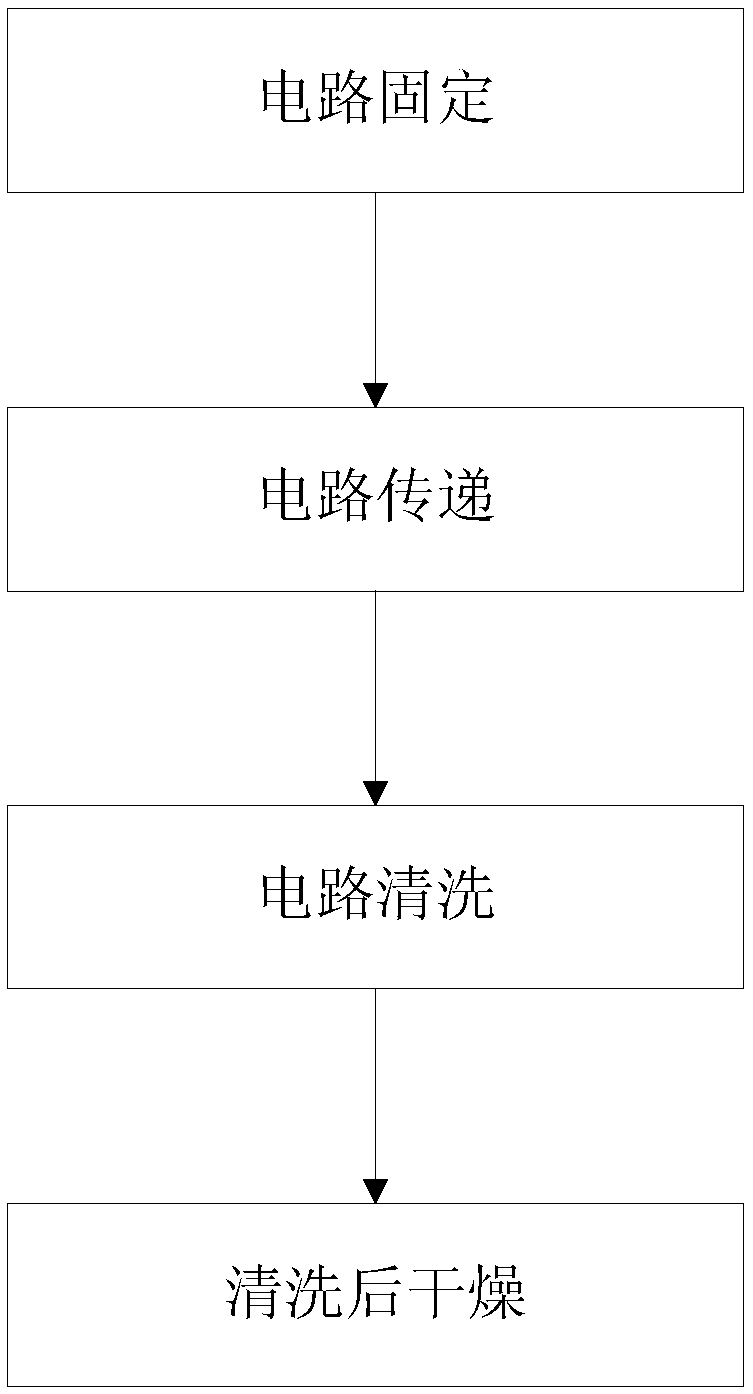

[0040] Tooling is processed according to the present invention. In an environment with a temperature of 23°C and a humidity of 40%, wear an anti-static wristband and brand-new finger cots, pinch the edge of the circuit ceramics with your fingers, and pick up the circuit steadily to prevent your fingers from slipping into the circuit cavity and the circuit from falling. One side of the bottom is the rotation axis, and the circuit is placed on the UV film supported by the dicing material ring in a rotating manner. Fix the circuit without moving, use a scraper to scrape from one end of the circuit to the other end on the lower surface of the UV film, and remove the visible air bubbles on the contact surface between the circuit and the UV film. Remove the fixed dicing material ring, UV film and the overall structure of the CMOS image sensor circuit from the bracket, and place them on the cleaning device workbench. When placed, the moisture on the surface of the CMOS image sensor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com