Environment-friendly and high-efficiency snow-melting pavement coating material and its preparation method and application

A coating material and high-efficiency technology, applied in coatings and other directions, can solve the problems of high cost of snow removal, hazards of snow removal technology to roads and the environment, and the inability of snow melting methods to function effectively for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

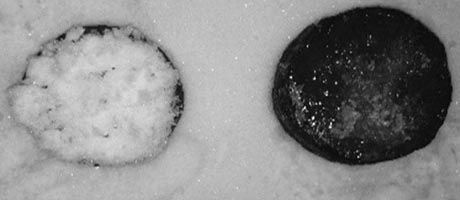

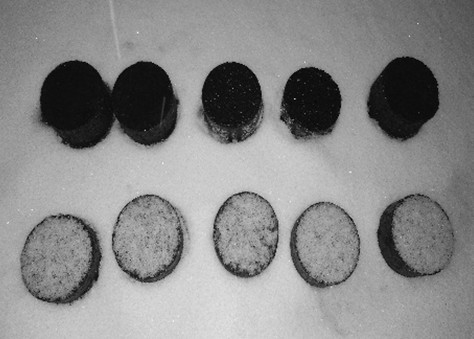

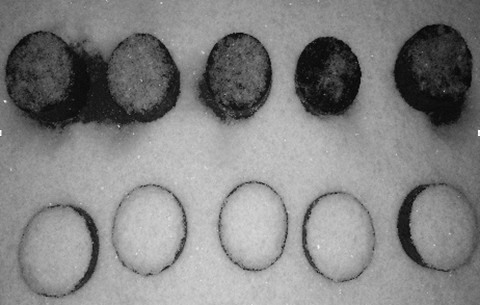

Image

Examples

Embodiment 1

[0039] Example 1: An environmentally friendly and efficient snow-melting pavement coating material

[0040] The coating material is made of the following raw materials in parts by weight:

[0041] Potassium acetate 100 parts, single-component fluorocarbon resin 50 parts, ethyl cellulose 6 parts, hydroxypropyl methylcellulose 0.7 parts, diethyl phthalate 0.9 parts, PEG-400 0.105 parts, glycerin 0.03 parts , 0.03 parts of magnesium stearate, 0.01 parts of talc powder, 8 parts of calcium carbonate, 2 parts of barium sulfate, 1 part of YF-001 fluorocarbon high-efficiency leveling agent (purchased from Hubei Youshida Technology Co., Ltd.), TMC-TE Titanate coupling agent (purchased from Tianchang Green Chemical Auxiliary Factory) 0.02 part, simethicone 0.001 part, PEG-60000.2 part, hydrophobic fumed silica 0.1 part.

Embodiment 2

[0042] Example 2: A preparation method of an environmentally friendly and efficient snow-melting pavement coating material

[0043] Embodiment 1 The preparation method of an environmentally friendly and efficient snow-melting pavement coating material is as follows:

[0044] 1. Take raw materials according to the parts by weight described in Example 1;

[0045] 2. Surface modification of fillers and semi-reinforcing agents:

[0046] (1) Dilute the TMC-TE titanate coupling agent with ethanol at a volume ratio of 10:1 to obtain an ethanol dilution;

[0047] (2) Add calcium carbonate to m / v as 1:0.025 (kg / m 3 ) ratio into the obtained ethanol dilution;

[0048] (3) Stir for 0.6-1.0 hours under the conditions of 40°C-60°C and 500-600r / min;

[0049] Stand still for 2 hours until all the solids are precipitated, remove the supernatant ethanol solution, dry in a drying oven to remove residual ethanol, and obtain modified filler E;

Embodiment 3

[0065] Example 3: An environmentally friendly and efficient snow-melting pavement coating material

[0066] The difference from Example 1 is that it is made of the following raw materials in parts by weight: 100 parts of potassium acetate, 60 parts of single-component fluorocarbon resin, 6.5 parts of ethyl cellulose, 0.8 parts of hydroxypropyl methylcellulose, 1.0 parts of diethyl phthalate, 0.11 parts of PEG-4000, 0.04 parts of glycerin, 0.04 parts of magnesium stearate, 0.015 parts of talcum powder, 12 parts of calcium carbonate, 3 parts of barium sulfate, YF-001 fluorocarbon high-efficiency leveling agent 1.5 parts, TMC-TE titanate coupling agent 0.025 parts, simethicone 0.002 parts, PEG-6000 0.3 parts, hydrophobic fumed silica 0.2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com