UV curing adhesive for polarizing plate, and preparation method and application thereof

A technology for polarizing plates and adhesives, applied in adhesives, non-macromolecular organic compound adhesives, optics, etc., can solve problems such as the curing state of adhesives that are easily damaged by moisture, the deterioration of polarization efficiency of polarizing plates, and light leakage of polarizing plates. , to improve durability, increase electron cloud density, and prevent cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] According to the parts by weight of Table 1, bifunctional alicyclic epoxy compounds, polyglycidyl ethers of aromatic compounds, bifunctional (meth)acrylic compounds, vinyl ether compounds, carboxylic acid compounds containing unsaturated double bonds, Cationic photoinitiators and free radical initiators are routinely mixed to prepare UV-curable adhesives for polarizers. Wherein, in embodiment 5, the vinyl ether compound is 4-hydroxybutyl vinyl ether; in embodiment 6, the carboxylic acid compound containing unsaturated double bonds is fumaric acid; in embodiment 10, will contain The carboxylic acid compound with saturated double bond is replaced with polycaprolactone trihydric alcohol, a conventional adhesion promoter; the rest of the raw materials are as above A to G.

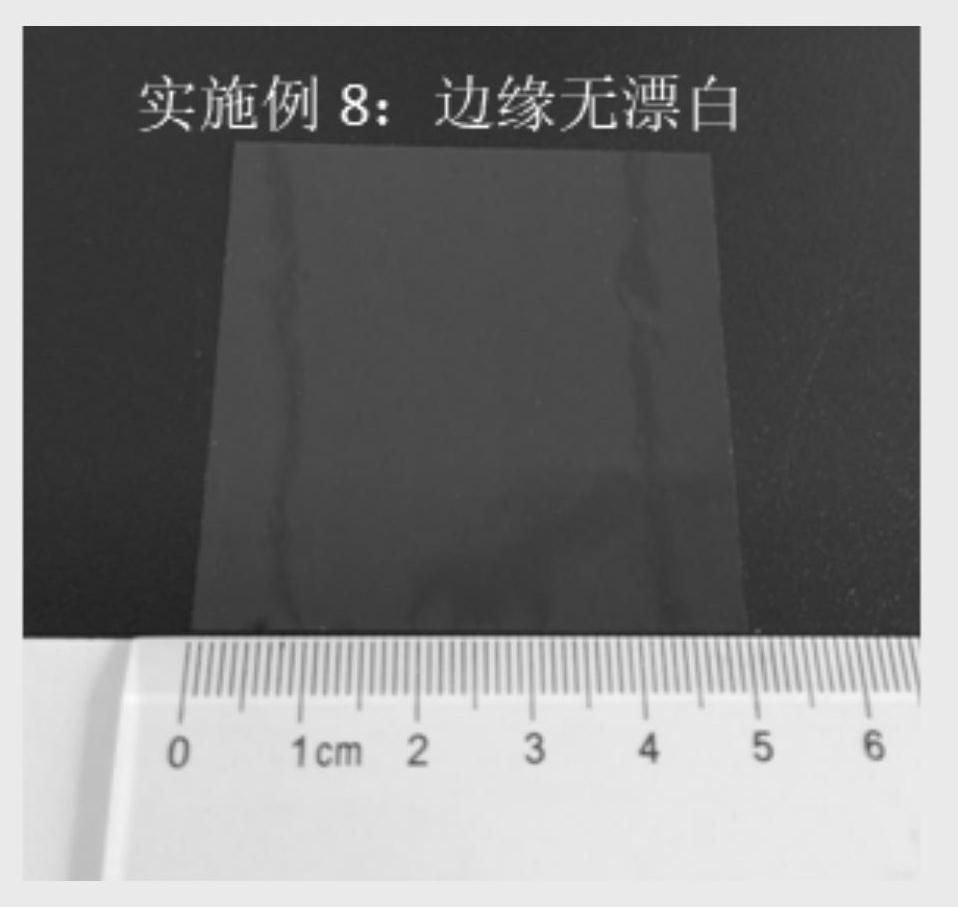

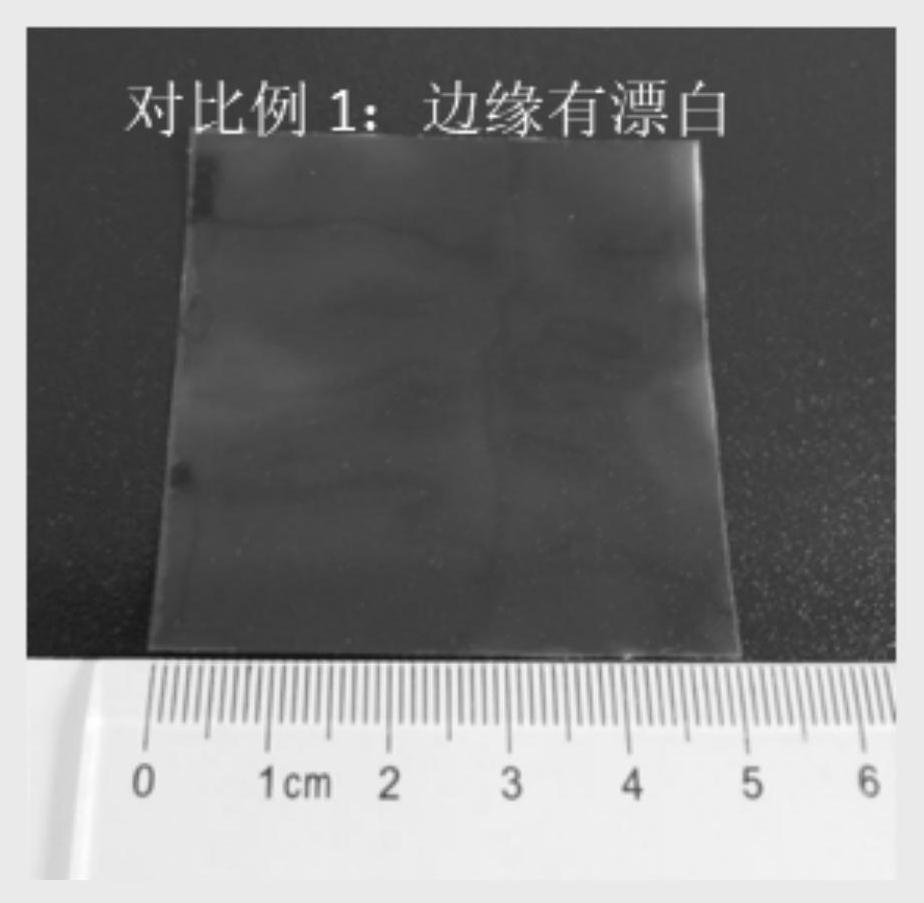

Embodiment 8

[0052] The peeling force of embodiment 8 reaches 5.6N / cm (PET film), 5.3N / cm (TAC film), 5.5N / cm (COP film); the white edge after the existing commercially available adhesive polarizing plate is very little after heat and humidity resistance, 0.1 mm, but the peel force is low and selective, 3.1N / cm (PET film), 3.3N / cm (TAC film), 1.9N / cm (COP film).

[0053] Table 2 embodiment, comparative example test result

[0054]

[0055] The UV curing adhesive for polarizing plates designed in the present invention utilizes the characteristics of delayed curing technology, interpenetrating network technology (IPN) and free radical-cationic UV curing advantages, and on this basis creatively adds vinyl ether compounds and The carboxylic acid compound with unsaturated double bonds, while ensuring the higher bonding performance of the cured adhesive, significantly improves the curing speed, heat and humidity resistance and bonding strength of the adhesive; the UV curable adhesive of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water vapor permeability | aaaaa | aaaaa |

| Water vapor permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com