Composite formaldehyde scavenger and preparation method thereof, method for removing formaldehyde from wood-based panels, and wood-based panels

A formaldehyde scavenger and wood-based panel technology, which is applied in the field of formaldehyde removal from boards, can solve problems such as user injury, difficulty in formaldehyde capture, and removal, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

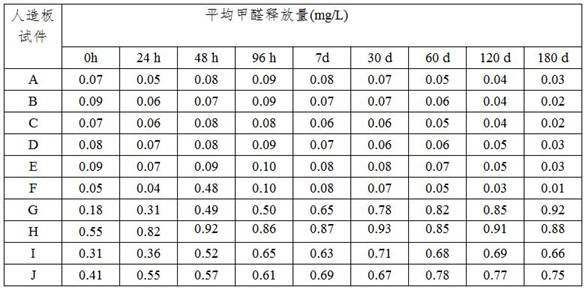

Examples

Embodiment 1

[0042] The present embodiment provides a composite formaldehyde trapping agent, comprising the following components by weight: IRMOFs material 8%, modified starch 3%, fluorinated polyether 0.5%, xanthan gum 2%, ethyleneurea 6% and epoxy fatty acid methyl ester 3%, the rest is deionized water.

[0043] The present embodiment also provides a wood-based panel aldehyde removal method, comprising the following steps: the adhesive and the composite formaldehyde trap are mixed in the proportion of a weight ratio of 5: 1 to prepare a mixed adhesive; Immerse the veneer in a mixed adhesive; The veneer paper soaked with mixed adhesive is hot pressed on the outer surface of the core board to make a veneer wood-based panel; Heat the veneer wood-based panel to 100 °C and hold it for 4h.

[0044] The above-described composite purifier comprises the following components by weight: nano zinc oxide 2%, nano titanium dioxide 1%, nano zeolite 5%, manganese dioxide 3% and polyethylene glycol 200 1%, t...

Embodiment 2

[0047] The present embodiment provides a composite formaldehyde trapping agent comprising the following components by weight: PCN material 15%, modified starch 6%, fluorinated polyether 2%, xanthan gum 5%, urea 12% and epoxy fatty acid methyl ester 8%, the rest is deionized water.

[0048] The present embodiment further provides a wood-based panel aldehyde removal method, comprising the following steps: the adhesive and the composite formaldehyde trap are mixed according to the ratio of 5: 2 by weight to prepare a mixed adhesive; The core plate and the veneer paper are impregnated with composite formaldehyde capture agent for 25min, and dried to obtain the processing core plate and the processing veneer; Impregnation of the treatment sticker in a mixed adhesive; The treatment veneer paper soaked with mixed adhesive is heat pressed on the outer surface of the treatment core board to obtain a veneered wood-based panel; Heat the veneer wood-based panel to 120 °C and keep it for 2h.

...

Embodiment 3

[0052] The present embodiment provides a composite formaldehyde trapping agent comprising the following components by weight: 10% by weight of ZIF material, 4% modified starch, 1% of fluorinated polyether, 3% of xanthan gum, 8% of urea and 5% of epoxy fatty acid methyl esters, the rest of which is deionized water.

[0053] The present embodiment further provides a wood-based panel aldehyde removal method, comprising the following steps: the adhesive and the composite formaldehyde trap are mixed according to the ratio of weight ratio 5: 3 to prepare a mixed adhesive; Immerse the veneer in a mixed adhesive; The veneer paper soaked with mixed adhesive is hot pressed on the outer surface of the core board to make a veneer wood-based panel; Heat the veneer wood-based panel to 110 ° C and keep it for 3h; The surface of the heat-treated veneer wood-based panel is uniformly sprayed with a composite purifier, and then the ultraviolet light is irradiated for 36h.

[0054] The above composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com