Hot melt adhesive for steel plastic-lined composite pipeline and preparation method of hot melt adhesive

A composite pipe and hot-melt adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of unqualified pipe ring flexibility index, affecting the quality of steel-plastic composite pipes, and the separation of steel pipes and plastic layers and other issues, to achieve the effect of improving strength and stability, low cost, and not limited by temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

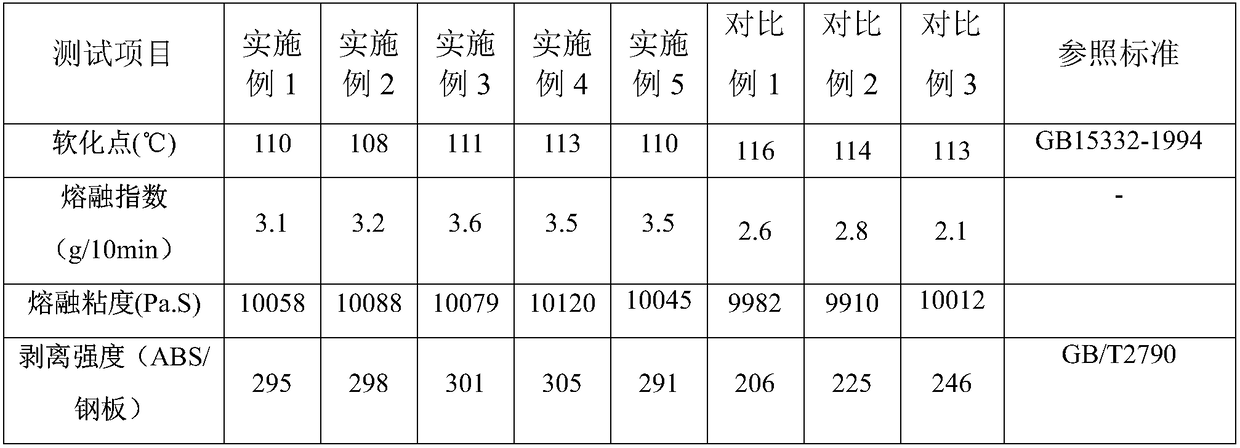

Examples

Embodiment 1

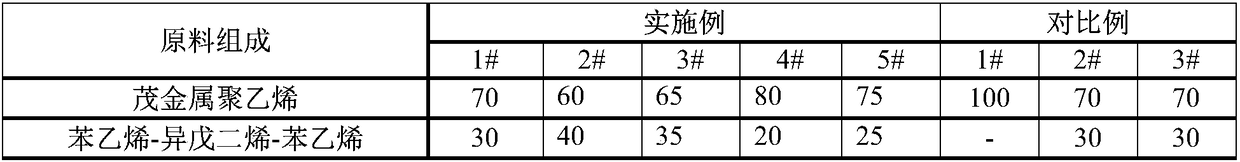

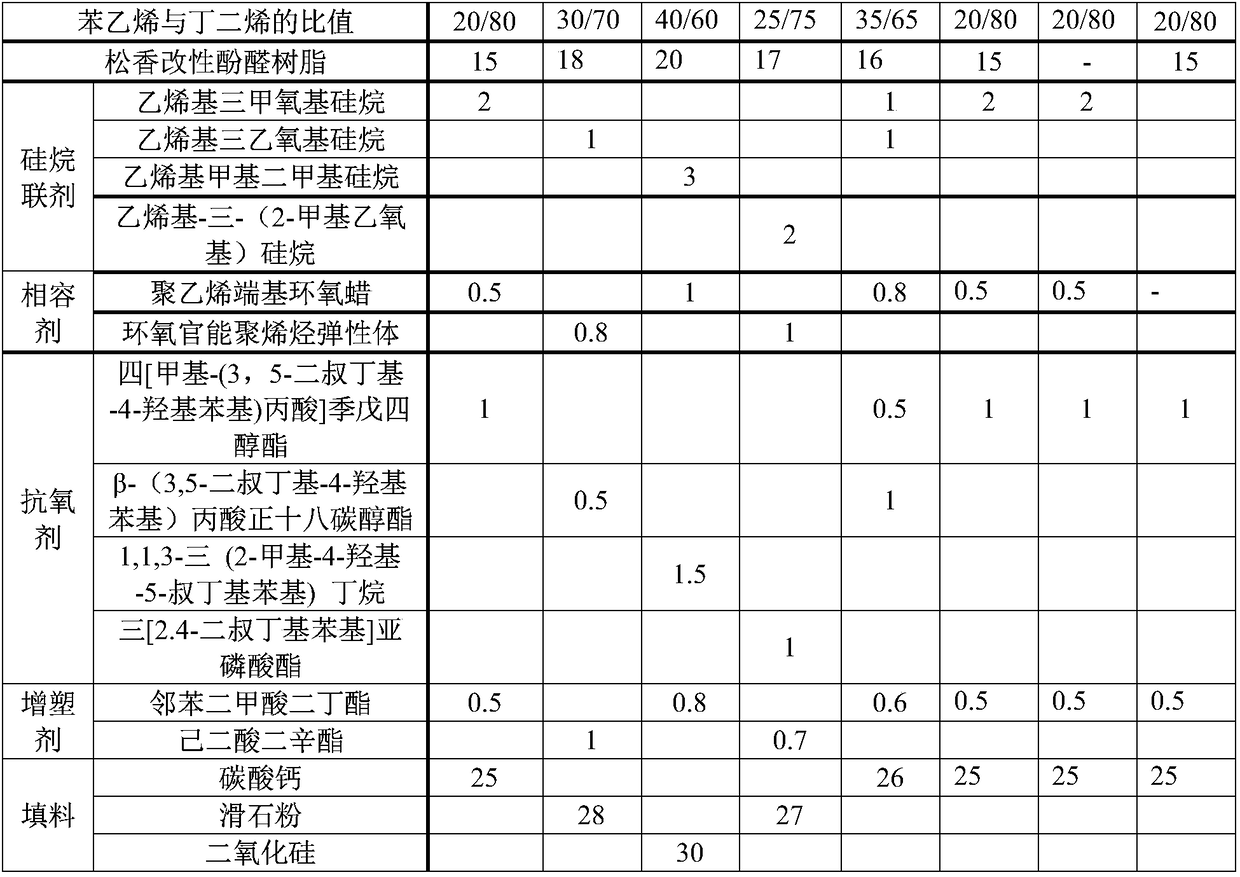

[0035] A hot melt adhesive for steel-lined plastic composite pipes is composed of the following components by weight:

[0036] Metallocene polyethylene 70 parts

[0037] Styrene-isoprene-styrene block copolymer 30 parts

[0038] Rosin-modified phenolic resin 15 parts

[0039] 2 parts of vinyltrimethoxysilane

[0040] Polyethylene terminated epoxy wax 0.5 part

[0041] 1 part of tetrakis[methyl-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol

[0042] Dibutyl phthalate 0.5 part

[0043] Calcium Carbonate 25 parts.

[0044] The metallocene polypropylene used was selected from Japan's Mitsui Chemicals, model PN0040; the styrene-isoprene-styrene block copolymer was selected from Baling Petrochemical, model: 1126; the tackifying resin rosin-modified phenolic resin was selected from Shenzhen City Yoshida Chemical Co., Ltd., model: BF06; Silane crosslinking agent vinyltrimethoxysilane, vinyltriethoxysilane, vinylmethyldimethylsilane, vinyl-tris-(2-methylethoxys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com