PC/ABS alloy with excellent weather resistance and preparation method of PC/ABS alloy

A technology of alloy and performance, applied in the field of polymer engineering plastics and its molding processing, can solve the problems of not being able to achieve good weather resistance stably, and achieve excellent mechanical properties, easy demoulding, and easy extrusion and granulation

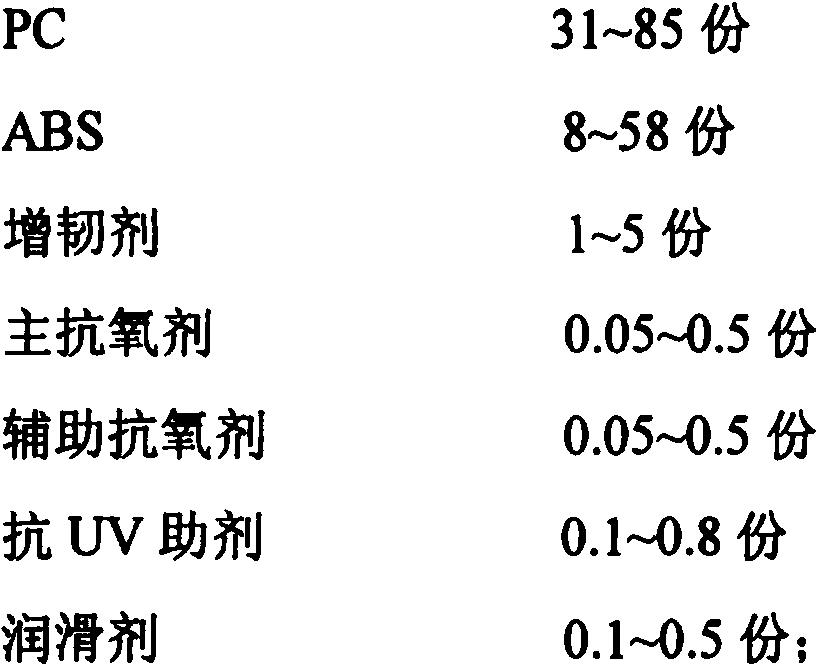

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

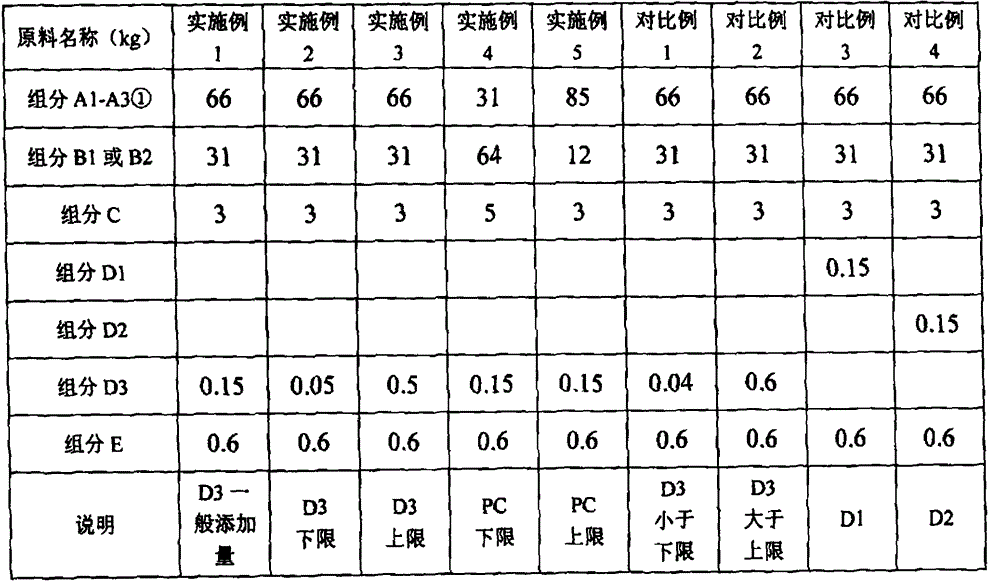

[0032] A method for preparing PC / ABS alloy with excellent weather resistance. The method includes the following steps: according to the component ratio in Table 1, after fully mixing in a high-speed mixer, it is exported, and then put into a screw machine for extrusion and granulation. The rotating speed of the screw machine is 300-500rpm and the temperature is 225-255°C, and the product is obtained.

[0033] Table 1 The content of each component by weight

[0034]

[0035] Remarks: ①It means that you can choose the combination from A1, A2, A3 according to the design requirements.

[0036] The material composition in Table 1 is as follows:

[0037] Component A1 is PC, the weight average molecular weight of polycarbonate is 32,000, produced by LG Chem;

[0038] Component A2 is PC, the weight average molecular weight of polycarbonate is 22,000, produced by Hunan Petrochemical;

[0039] Component A3 is PC, the weight average molecular weight of polycarbonate is 18,000, produced by Hunan Pe...

Embodiment 6

[0057] In this embodiment, the PC / ABS alloy with excellent weather resistance includes the following components and parts by weight: 81 parts of PC, 25 parts of ABS, 5 parts of toughening agent, 0.08 parts of primary antioxidant, 0.2 parts of auxiliary antioxidant, 0.5 parts of anti-UV additives and 0.4 parts of lubricants.

[0058] The weight-average molecular weight of PC is 17000 and the glass transition temperature is 145~150℃. The weight-average molecular weight of ABS is 140,000. Among them, the weight percentage of butadiene is 15%. Acrylonitrile The weight percentage content of styrene is 22%, and the weight percentage content of styrene is 63%.

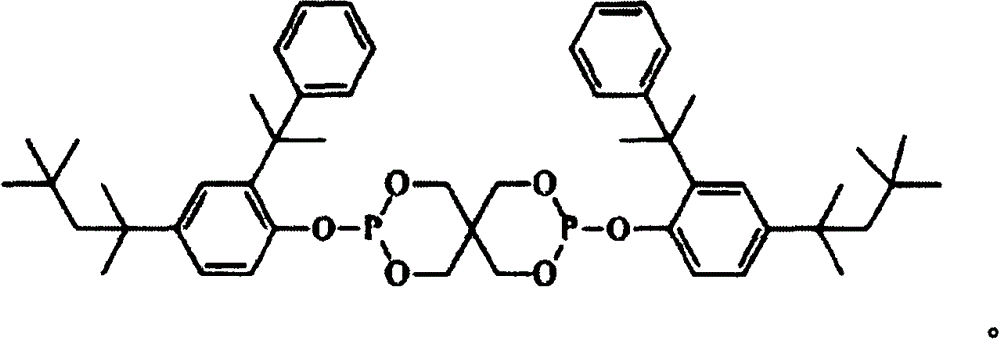

[0059] Among them, the toughening agent is an acrylic toughening agent, the main antioxidant is a hindered phenolic antioxidant, and the auxiliary antioxidant is bis(2-cumyl, 4-(1,1,3,3-tetramethyl )-Butyl) pentaerythritol diphosphite, the anti-UV assistant is a benzotriazole anti-ultraviolet light absorber, and the lubricant is ...

Embodiment 7

[0065] In this embodiment, the PC / ABS alloy with excellent weather resistance includes the following components and parts by weight: 48 parts of PC, 8 parts of ABS, 5 parts of toughening agent, 0.2 parts of main antioxidant, 0.5 parts of auxiliary antioxidant, 0.1 part of anti-UV additive, 0.5 part of lubricant.

[0066] The weight average molecular weight of PC is 35000 and the glass transition temperature is 145~150℃. The weight average molecular weight of ABS is 140,000. Among them, the weight percentage of butadiene is 24%. Acrylonitrile The weight percentage content of styrene is 26%, and the weight percentage content of styrene is 50%.

[0067] Among them, the toughening agent is a mixed toughening agent of ethylene-methyl acrylate and ethylene-butyl acrylate in a mass ratio of 2:3, the main antioxidant is a hindered phenol antioxidant, and the auxiliary antioxidant is three (2 , 4-Di-tert-butylphenyl) phosphite, anti-UV additives are benzotriazole anti-ultraviolet light abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com