Sealing agent for electrochemical device in which nonaqueous electrolytic solution is used, and sealing agent composition for electrochemical device

A non-aqueous electrolyte and electrochemical technology, applied in the field of sealant compositions for electrochemical devices, can solve the problems of insufficient sealing performance, insufficient wettability and sufficient tightness, etc., and achieve sufficient sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

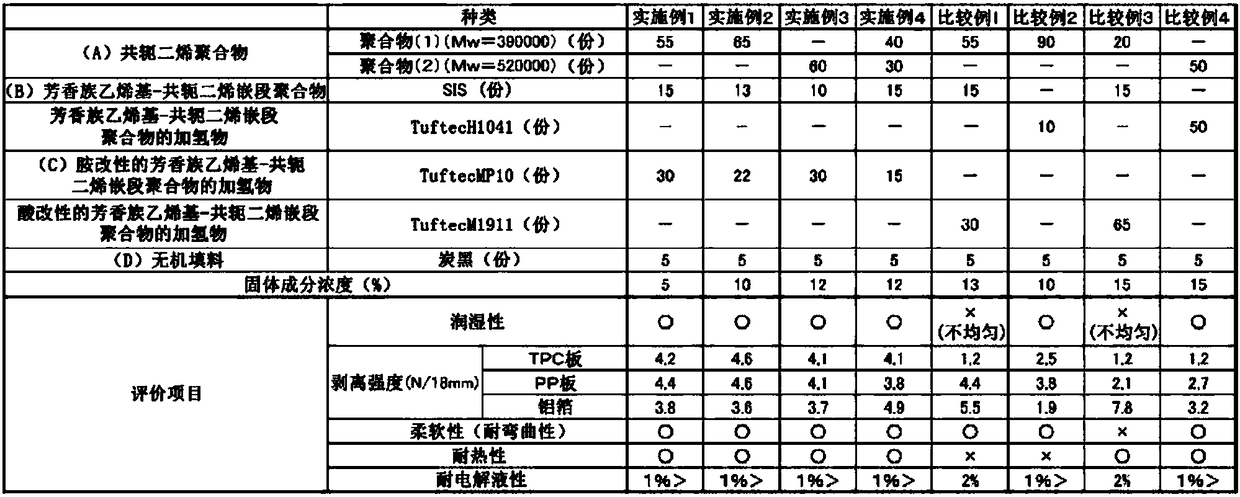

Embodiment 1

[0110] 55 parts of polymer (1) obtained in Polymerization Example 1 as (A) conjugated diene polymer, 15 parts of styrene as (B) aromatic vinyl-conjugated diene block polymer SIS content of 15%, Mw=32000, 30 parts of amine-modified styrene-ethylene-butylene as hydrogenated product of (C) amine-modified aromatic vinyl-conjugated diene block polymer Alkene-styrene block copolymer (Tuftec MP10, manufactured by Asahi Kasei Chemicals Co., Ltd.), 5 parts of carbon black (furnace black with a primary particle size of 10 nm) as (D) inorganic filler, and an organic solvent (xylene) in a belt The mixture was mixed while heating to 50° C. in a flask with a stirring blade to obtain a uniform solution (sealant composition) having a solid content concentration of 5%.

Embodiment 2

[0112] 65 parts of polymer (1) obtained in Polymerization Example 1 as (A) conjugated diene polymer, and 13 parts of polymer (1) as (B) aromatic vinyl-conjugated diene block polymer were carried out. Example 1 Same SIS, 22 parts of amine-modified styrene-ethylene-butylene-styrene block polymer as hydrogenated product of (C) amine-modified aromatic vinyl-conjugated diene block polymer Segment copolymer (Tuftec MP10, manufactured by Asahi Kasei Chemicals), 5 parts of the same carbon black as (D) inorganic filler and organic solvent (xylene) as in Example 1 were heated to 50° C. in a flask with stirring wings. While mixing, a uniform solution (sealant composition) having a solid content concentration of 10% was obtained.

Embodiment 3

[0114] 60 parts of polymer (2) obtained in Polymerization Example 2 as (A) conjugated diene polymer, and 10 parts of polymer (2) as (B) aromatic vinyl-conjugated diene block polymer were carried out. Example 1 Same SIS, 30 parts of amine-modified styrene-ethylene-butylene-styrene block polymer as hydrogenated product of (C) amine-modified aromatic vinyl-conjugated diene block polymer Segment copolymer (Tuftec MP10, manufactured by Asahi Kasei Chemicals), 5 parts of the same carbon black as (D) inorganic filler and organic solvent (xylene) as in Example 1 were heated to 50° C. in a flask with stirring wings. While mixing, a uniform solution (sealant composition) having a solid content concentration of 12% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com